Supplier Partnering

advertisement

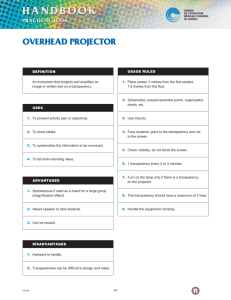

Chapter 9 Managing Supplier Quality in the Supply Chain S. Thomas Foster, Jr. Boise State University Slides Prepared by Bruce R. Barringer University of Central Florida ©2001 Prentice-Hall Chapter Overview • The Value Chain • Supplier Partnering • Applying the Contingency Perspective to Supplier Partnering • A Supplier Development Program: QS 9000 • Acceptance Sampling and Statistical Sampling Techniques © 2001 Prentice-Hall Transparency 9-2 Introduction • HP is known for its commitment to its customers and for understanding that quality performance is closely related to supply chain activities. • Remember that the performance of your suppliers directly affects your reliability and your ability to satisfy the customer. • As a result, the supplier is key in satisfying the customer. © 2001 Prentice-Hall Transparency 9-3 The Value Chain Slide 1 of 4 • The Value Chain – The value chain is a tool that disaggregates a firm into its core activities to help reduce costs and identify sources of competitiveness. – It is part of the value system that consists of a network of value chains. – The value chain and core activities that are performed by any company include inbound logistics, operations, outbound logistics, marketing and sales and service. – Figure 9.1 shows Porter’s value chain. © 2001 Prentice-Hall Transparency 9-4 Porter’s Value Chain Slide 2 of 4 ( Figure 9.1) Firm infrastructure Human resource management Technology development Procurement Support Activities (Hidden Factory) Inbound logistics Operations Outbound Marketing logistics and sales Service Core Activities © 2001 Prentice-Hall Transparency 9-5 Porter’s Value Chain • In Figure 9.1, notice that this is a chain for a single firm; however, the firm’s suppliers have value chains also. • The core activities shown in the figure are termed value chain activities because they are the tasks that add value for the customer. • Non-value chain activities typically have costs but no effect on the customer and are referred to as the “hidden factory.” • The hidden factory contains all of the bureaucratic processes that are not part of the core activities in Figure 9.1. © 2001 Prentice-Hall Transparency 9-6 The Value Chain Slide 3 of 4 • The Chain of Customers – From a quality perspective, an interesting variation of the value chain is the concept of the “ chain of customers.” – Looking at the activities along the value chain sequentially, we see that the links in the value chain are really people performing different functions. – The chain of customers is revealed when you view the next step in the chain after you as your own customer. © 2001 Prentice-Hall Transparency 9-7 The Value Chain Slide 4 of 4 • The Chain of Customers (continued) – This means that if you work at workstation 4 in a process at the core of the value chain, you will make sure that the work you do is absolutely impeccable before you release it to your “customer” in workstation 5. – The notion is that if each of us along a chain works to satisfy our own customer, the final customer will be very satisfied, and our products and services will be free of defects and mistakes. © 2001 Prentice-Hall Transparency 9-8 The Value Chain • Managing the supply chain -- The concept of supply chain management extends the economic concept of the value chain. -- Figure 9.2 shows a realistic rendering of a supply chain that includes several suppliers, plants, distribution centers, and customer groups. -- The value chain focuses on activities such as inbound and outbound logistics. -- One of the most significant aspects of the value chain is the linkage between a series of suppliers and consumers. © 2001 Prentice-Hall Transparency 9-9 The Value Chain • Figure 9.2 A Supply Chain © 2001 Prentice-Hall Transparency 9-10 Supplier Partnering Slide 1 of 7 • Supplier Partnering Concept – There has a trend toward developing closer working relationships with fewer suppliers. – Given this new approach to suppliers, a big part of quality improvement requires developing and assisting suppliers so that they can provide needed products with low levels of defects, in a reliable manner, while conforming to requirements. – Several approaches to improving suppliers result in what is called supplier partnering. © 2001 Prentice-Hall Transparency 9-11 Supplier Partnering • Supplier Partnering Concept – Inspired by JIT purchasing approaches learned from Japanese industry, supplierpartner relationships have emerged that treat suppliers as de facto subsidiaries of the customer organization. – The relationship begins to resemble a parent/subsidiary in stead of separate firms. – As is shown in Table 9.1, a variety of systems are used to help develop suppliers. © 2001 Prentice-Hall Transparency 9-12 Supplier Partnering Slide 2 of 7 Table 9.1 Supplier Development Approaches 1. Sole sourcing 2. Dual sourcing 3. Supplier evaluation 4. Souring filters (ISO 9000, MBNQA) 5. Supplier certification or qualification programs 6. Supplier development programs 7. Supplier audits © 2001 Prentice-Hall 8. Partnering Transparency 9-13 Supplier Partnering Slide 4 of 7 • Supplier Partnering Approaches – Sole sourcing • Refers to narrowing down the list of approved supplier for a single component to just one supplier. – Dual Sourcing • Companies that are uncomfortable with using a single supplier may use dual sourcing where the number of approved suppliers is reduced to just a few. © 2001 Prentice-Hall Transparency 9-14 Supplier Partnering Slide 5 of 7 • Supplier Evaluation – Is a tool used by many firms to differentiate and discriminate between suppliers. – Supplier evaluations are often recorded on report cards in which potential supplier are rated based on criteria such as quality, technical capability, or ability to meet schedule demands. © 2001 Prentice-Hall Transparency 9-15 Supplier Partnering Slide 6 of 7 • Sole-Source Filters – That are used in many companies rely on external validation of quality programs. – Two of the most common filters are the Baldrige criteria and ISO 9000. The ISO is commonly used in the international community © 2001 Prentice-Hall Transparency 9-16 Supplier Partnering Slide 7 of 7 • Supplier Certification – Many companies perform lengthy inspections of their suppliers. These programs are often called supplier certification or qualification programs if the focus is entirely on evaluation. • Supplier Development Program – If the focus is on helping the supplier improve, then the programs are called supplier development programs. © 2001 Prentice-Hall Transparency 9-17 Supplier Partnering • Supplier Audit -- This is similar to supplier certification except that a team of auditors visits the supplier and then provides results of the audit to the customer. -- The audits are performed to ensure that product quality and procedural objectives are being met. © 2001 Prentice-Hall Transparency 9-18 Supplier Partnering • We should mention that there are drawbacks to sole sourcing. • When there are few suppliers, there is more exposure to interruption of supply. • If labor relations are not solid, sole sourcing can have the effect of shifting negotiating power to unions in supplier plants. • Other problems include possible interruptions because of transportation problems, quality problems, or disagreements concerning pricing. © 2001 Prentice-Hall Transparency 9-19 Supplier Partnering 1. In the 1980s, a defective rate of 5% for a supplier was acceptable. 2. In this new century, parts-per-million levels of quality are expected from suppliers. 3. In addition, many companies such as Mercedes are moving to sole source suppliers. ( see Quality Highlight 9.1) © 2001 Prentice-Hall Transparency 9-20 Supplier Partnering 4. Other change have occurred as well. 5. The strategy of purchasing group are different now. 6. The way to develop a supplier is to have adequate communications, linear production schedules, and time to make necessary changes. © 2001 Prentice-Hall Transparency 9-21 Supplier Partnering 7. Supplier contacts are one way to ensure adequate communication. 8. Assigning one person or team to each supplier can reduce the potential for miscommunication. 9. Another way to communication is through supplier programs where the product or service producer ensures suppliers access to information. 10. Another issue of communication between suppliers and customers is that production schedules must match. © 2001 Prentice-Hall Transparency 9-22 Supplier Partnering • Electronic Data Interchange – Is a system that aids customer and supplier communication by linking together supplier and customer information systems. – Customer now are helping suppliers to isolate bottlenecks in operations, balance production systems, and reduce setup times in an effort to reduce lead times. © 2001 Prentice-Hall Transparency 9-23 Supplier Partnering • Sole sourcing example – Sole sourcing has changed the landscape of purchasing. – Suppliers were chosen for their current quality practices and their willingness to work with Xerox to implement a quality improvement program. – The Dell computer Company’s goal was to work with suppliers to figure out how to minimize the supplier chain and hold the least amount of inventory. © 2001 Prentice-Hall Transparency 9-24 Supplier Partnering • Sole sourcing example – If suppliers do not understand your business, you end up creating buffers that translate into inventory. – Lockheed0Martin was a defense contractor that worked closely with its suppliers. – Lockheed-Martin developed criteria that each supplier had to meet. Quality was a top requirement. Each supplier was required to use statistical process control, have a 0% rejection rate at the point of inspection for six months, and achieve zero nonconformance. A supplier had to maintain a 98% concurrency to contract delivery schedules. © 2001 Prentice-Hall Transparency 9-25 Applying the Contingency perspective to Supplier Partnering • Different firms take different approaches to supplier development. • One variable that affect what customers want from their suppliers is the customer’s position in the supplier chain. • A study of the auto industry supply chain found that the auto manufacturers, direct suppliers, and indirect suppliers had somewhat different expectations from their suppliers. • Table 9.2 shows these priorities and their ranking. © 2001 Prentice-Hall Transparency 9-26 Applying the Contingency perspective to Supplier Partnering • Table 9.2 Supply Chain Priorities © 2001 Prentice-Hall Transparency 9-27 HISTORY OF QS-9000 • Chrysler, Ford and General Motors Harmonize Their Supplier Quality System Standards • Late in 1992, Purchasing and Quality executives of the Big Three automakers met in Detroit and agreed to help themselves and their suppliers by replacing their individual quality system standards with a single set of Quality System Requirements, later named QS-9000. © 2001 Prentice-Hall Transparency 9-28 HISTORY OF QS-9000 • After two years of development involving the Big Three, and their suppliers and representatives of third-party certification organizations, the automotive industry's needs and expectations of its parts suppliers were developed. © 2001 Prentice-Hall Transparency 9-29 QS-9000: Third-Party Registration • A key point was that compliance to the new contractually-mandated quality system requirements could be confirmed by independent third parties -- specially-qualified ISO 9000 registrars capable of applying an internationally recognized, automotivefocused registration system. © 2001 Prentice-Hall Transparency 9-30 QS 9000 • QS 9000 is an automotive QMS standard, based on ISO 9000:1994, that contains additional requirements from Chrysler, Ford, General Motors, truck manufacturers and other subscribing companies for internal and external suppliers of production and service parts and materials. © 2001 Prentice-Hall Transparency 9-31 What Are the Components of QS-9000? • QS-9000 is composed of two sections: ISO 9001based requirements and customer-specific requirements. • ISO 9000-based requirements are founded on Section 4 of the 1994 version of ISO 9001. The 20 elements of ISO 9001 are included in QS-9000, together with supplemental requirements. Customer-specific requirements are additional standards that Chrysler, Ford, General Motors and truck manufacturers have imposed. © 2001 Prentice-Hall Transparency 9-32 What Are the Components of QS9000? • In addition, a QS-9000 supplements have been published for producers of semiconductor devices, and for tooling and equipment suppliers. © 2001 Prentice-Hall Transparency 9-33 What Are the Components of QS9000? -- There are also six customer reference manuals that provide additional guidance for various functions. They are: 1. Production Part Approval Process (PPAP) 2. Advanced Product Quality Planning and Control Plan (APQP) 3. Failure Mode and Effects Analysis (FMEA) 4. Measurement Systems Analysis (MSA) 5. Fundamental Statistical Process Control (SPC) 6. Quality System Assessment (QSA). © 2001 Prentice-Hall Transparency 9-34 A Supplier Development Program: QS 9000 • QS 9000 – A supplier development program developed by a Chrysler/Ford/GM supplier requirement task force. – The purpose of QS 9000 is to provide a common standard and a set of procedures for the suppliers of the three companies. © 2001 Prentice-Hall Transparency 9-35 QS 9000 Requirements( Table 9.3) Slide 1 of 14 ( Based on ISO 9001:1994) Requirement Section Number Management responsibility 4.1 Quality system 4.2 Contract review 4.3 Design control 4.4 Document and data control 4.5 Purchasing 4.6 Control of customer-supplier product 4.7 Product identification and trace-ability 4.8 © 2001 Prentice-Hall Process control 4.9 Transparency 9-36 QS 9000 Requirements ( Based on ISO 9001:1994) (continued) Slide 2 of 14 Requirement Section Number Inspection and testing 4.10 Control of inspection, measuring, and test inspection 4.11 Inspection and testing 4.12 Control of nonconforming product 4.13 Corrective and preventive action 4.14 Handling, storage, packaging, preservation, and delivery 4.15 Control of quality records 4.16 Internal quality audits 4.17 Training 4.18 © 2001 Prentice-Hall Transparency 9-37 QS 9000 Requirements ( Based on ISO 9001:1994) (continued) Slide 3 of 14 Requirement Section Number Servicing 4.19 Statistical techniques 4.20 © 2001 Prentice-Hall Transparency 9-38 QS 9000 Requirements Slide 4 of 14 • Management Responsibility( see Table 9.4) – The first element of the QS 9000 standard is management responsibility. Supplier management is responsible for documenting its policies for quality along with its objectives and its level of commitment. © 2001 Prentice-Hall Transparency 9-39 QS 9000 Requirements Table 9.4 Management Responsibility in QS 9000 -- Quality policy -- Organization -- Resources -- Management representative -- Organizational interface -- Management and review -- Business plan -- Analysis and use of company-level data -- Customer satisfaction © 2001 Prentice-Hall Transparency 9-40 QS 9000 Requirements • Quality System ( see Table 9.5) – The supplier firm is required to establish, document, and maintain a quality system so that the product conforms to requirements. © 2001 Prentice-Hall Transparency 9-41 QS 9000 Requirements Table 9.5 Quality system requirements in QS 9000 -- General -- Quality system procedures -- Quality planning - Special characteristics - Use of cross-functional teams - Feasibility reviews - Process FMEA - The control plan © 2001 Prentice-Hall Transparency 9-42 QS 9000 Requirements Slide 5 of 14 • Contract Review – During contract review the supplier examines the steps associated with contracting with its own suppliers. • Design Control ( see Table 9.6) – The design control standard focuses on designing processes. To meet requirements, suppliers establish and maintain procedures for controlling the design of the product. © 2001 Prentice-Hall Transparency 9-43 QS 9000 Requirements Table 9.6 Design control requirements in QS 9000 -- General information -- Design and development planning - Required skills -- Organizational and technical interfaces -- Design input -- Design output -- Design review -- Design verification -- Design validation -- ©Design changes 2001 Prentice-Hall Transparency 9-44 QS 9000 Requirements Slide 6 of 14 • Document and Data Control – Document and data control include the procedures or approvals used in issuing documents and data and making changes to such data. • Purchasing – To satisfy requirements for purchasing, the supplier must establish and maintain documents of procedures to ensure that purchased products conform to specified standards. © 2001 Prentice-Hall Transparency 9-45 QS 9000 Requirements Slide 7 of 14 • Control of Customer-Supplied Product – The standard for this part of the QS 9000 standard is worded as follows, “Suppliers must establish and maintain documented procedures for the control of verification, storage, and maintenance of customersupplied product provided for incorporation into supplies or for related activities.” © 2001 Prentice-Hall Transparency 9-46 QS 9000 Requirements Slide 8 of 14 • Product Identification and Trace-ability – QS 9000 requires documented procedures for product trace-ability during all stages of the production process. • Process Control – The element relating to process control establishes that suppliers identify and plan the production, installation, and servicing processes that result in quality products. © 2001 Prentice-Hall Transparency 9-47 QS 9000 Requirements Slide 9 of 14 • Inspection and Testing – Inspection and testing activities must put in place to ensure that specified requirements for products are met must be documented. • Control of Inspection, Measuring, and Test Equipment – Suppliers must establish and document procedures to control, calibrate, and maintain testing equipment. © 2001 Prentice-Hall Transparency 9-48 QS 9000 Requirements Slide 10 of 14 • Inspection and Test Status – The QS 9000 standard requires that inspection test status be maintained throughout the production process, installation process, and service processes of the product. • Control of of Nonconforming Product – When nonconforming products are produced, they can be (1) reworked to meet requirements, (2) accepted as is, (3) re-graded for alternative applications, or (4) rejected and scrapped. © 2001 Prentice-Hall Transparency 9-49 QS 9000 Requirements Slide 11 of 14 • Corrective and Preventive Action – When problems result in defective products, a standard process for addressing them is needed so that corrective and preventive action can take place in a disciplined way. • Handling, Storage, Packaging, Preservation, and Delivery – Among the areas to be documents are inventory control methods and the way inventory turnovers are optimized. © 2001 Prentice-Hall Transparency 9-50 QS 9000 Requirements Slide 12 of 14 • Control of Quality Records – The records control standard states that the supplier must establish and follow documented procedures for identifying, collecting, indexing, accessing, filing, storing, maintaining, and disposing of quality-related records. • Internal Quality Audits – Suppliers are required to perform internal quality audits to ensure compliance with QS 9000 requirements. © 2001 Prentice-Hall Transparency 9-51 QS 9000 Requirements Slide 13 of 14 • Training – A supplier firm must have documented procedures for assessing training needs and for training all personnel who might impact a company’s quality. • Servicing – The servicing requirement states that a supplier’s servicing efforts should meet the customer’s specified requirements. © 2001 Prentice-Hall Transparency 9-52 QS 9000 Requirements Slide 14 of 14 • Statistical Techniques – The QS 9000 standard states that SPC and process capability measures must be maintained. Appropriate statistical techniques are chosen during advanced quality planning and must be maintained in the control plan. © 2001 Prentice-Hall Transparency 9-53 Reflecting on QS 9000 • QS 9000 is specifically designed to help suppliers to automakers prove that they have standardized processes for dealing with their customers. • The success of QS 9000 is reflected in various corners of the auto industry ( see Quality Highlight 9.2). © 2001 Prentice-Hall Transparency 9-54 Acceptance Sampling and Statistical Sampling Techniques Slide 1 of 3 • Acceptance Sampling – It is a technique used to verify that incoming goods from a supplier adhere to quality standards. – Acceptance sampling inspection can range from 100% of the delivery to a relatively few items from which the receiving firm draws inferences about the whole shipment. © 2001 Prentice-Hall Transparency 9-55 Is Acceptance Sampling Needed? Slide 2 of 3 Examples of when acceptance sampling might be needed 1. When dealing with new or unproven suppliers. 2. During start-ups and when building new products. 3. When products can be damaged in shipment. 4. When dealing with extremely sensitive products that can be damaged easily. 5. When products can spoil during shipment. 6. When products with a certain supplier have been noticed in the production process that bring the supplier’s performance into question. © 2001 Prentice-Hall Transparency 9-56 Acceptance Sampling Slide 3 of 3 • Acceptance Sampling Fundamentals – We define acceptance sampling as a statistical quality control technique used in deciding to accept or reject a shipment of input or output. – Acceptance sampling inspection can occur at the beginning of the process when receiving components, parts, or raw materials from a supplier or at the end of production as in the case of final inspection. – We focus here on inspection of incoming materials. © 2001 Prentice-Hall Transparency 9-57 Acceptance Sampling • One interesting application of acceptance sampling occurs with seed producers. • Because of the biological nature of seed, a supplier can place the seed on the truck in perfect condition and the seed can arrive in an unsuitable state. • There are different methods for developing sampling plans. • We discuss how to develop sampling plans using both Dodge and Romig tables and OC curves. © 2001 Prentice-Hall Transparency 9-58 Acceptance Sampling • Producer’s and Consumer’s Risk – Producer’s risk is the risk associated with rejecting a lot of materials that has good quality. – In this case, you have been judged inaccurately. – Consumers risk is the exact opposite. – As a consumer, you receive a shipment of poor quality product and believe that it has good quality. Therefore, you pay for the product, use it in you production process, and suffer the consequences. © 2001 Prentice-Hall Transparency 9-59 Acceptance Sampling • Producers risk is denoted by alpha and is called a Type Ⅰ error. • Consumers risk is denoted by beta and is referred to as a Type Ⅱ error. • Table 9.7 contrast alpha and beta risk. • The goal of acceptance sampling is to reduce producer’s risk to low levels while maintaining consumer’s risk at acceptance levels. © 2001 Prentice-Hall Transparency 9-60 Acceptance Sampling Table 9.7 Alpha and Beta Risk State of Nature Product Is Good Outcome Product Is Defective Consumer Accepts Product OK Consumer’s risk Consumer Rejects Product Producer’s risk OK © 2001 Prentice-Hall Transparency 9-61 Statistical Sampling Techniques Slide 1 of 8 • Acceptable Quality Level (AQL) – The maximum percentage or proportion of nonconformities in a lot or batch that can be considered satisfactory as a process average. – The AQL concept has been troublesome to many who consider it to condone an acceptance of less-than-perfect quality. © 2001 Prentice-Hall Transparency 9-62 Statistical Sampling Techniques • Lot Tolerance Percent Defective (LTPD) – The level of poor quality that is included in a lot of goods. – Lots of AQL or better should usually have an alpha ( that is, for example, a 5%) or less change of rejection. – Producer’s risk is the probability that good products will be rejected by the consumer. © 2001 Prentice-Hall Transparency 9-63 Statistical Sampling Techniques • Lots of LTPD or worse should have a beta ( that is, sat a 10%) or less change of acceptance. • Consumer risk is the chance that poor products will be acceptance by producers. • There is, theoretically, only one combination of sample size (n) and acceptance number ( c ) that meets both conditions simultaneously. • In practice, we will be unable to meet both conditions precisely and must choose a combination of n and c that approximate both conditions simultaneously. © 2001 Prentice-Hall Transparency 9-64 Statistical Sampling Techniques Slide 2 of 8 • n and c ( single sampling plan) – The bottom line in acceptance sampling is that acceptance sampling plans are designed to give us two things: n and c, where • n = the sample size of a particular sampling plan • c = the maximum number of defective pieces for a sample to be rejected – It is important to remember that you should always randomize when selecting products from a supplier to be inspected. © 2001 Prentice-Hall Transparency 9-65 Statistical Sampling Techniques Slide 3 of 8 • OC Curves – The operating characteristic (OC) curve provides an assessment of the probabilities of acceptance for a shipment, given the existing quality of the shipment. – An OC curve is constructed to show the probability of accepting individual lots when the percent defective of the various individual lots is known or assumed to be at a given level. – These curves also can be used to develop sampling plans. © 2001 Prentice-Hall Transparency 9-66 Statistical Sampling Techniques • OC Curves – Figure 9.3 shows an OC curve for an optimal sampling plan. – This ideal sampling plan shows that the probability of accepting a lot of goods with less than 2% defective is 100%. However, OC curves never appear like the ideal case. – Figure 9.4 shows OC curves for a sample size of n = 100 and c = [0, 1, 2, 3]. © 2001 Prentice-Hall Transparency 9-67 Statistical Sampling Techniques • OC Curves – Notice that as c gets smaller, the OC curve gets steeper. – Generally speaking, this means that higher values of c lead to higher probabilities of accepting bad shipments ( consumer’s risk). – Also, higher values of n affect the OC curves in such a way that have greater confidence that we have accepted a good shipment. © 2001 Prentice-Hall Transparency 9-68 Statistical Sampling Techniques Slide 4 of 8 Probability of acceptance Pa Figure 9.3 Perfect OC curve 1.00 P’ .01 .02 .03 .04 Lot fraction nonconforming © 2001 Prentice-Hall Transparency 9-69 Statistical Sampling Techniques Slide 5 of 8 Figure 9.4 Various OC Curves © 2001 Prentice-Hall Transparency 9-70 Statistical Sampling Techniques • Figure 9.5 shows an OC curve for N = 2000, n = 200, c = 2. • This shows that the probability of accepting a lot with 2% defective product is 92%. • This means that if a lot has 2% defective, and this sampling plan is used, then the producer’s risk is 8%. • If the lot really has much poorer quality, say 8% defective, the chance of acceptance is quite low, about 24%. This means that there is a consumer’s risk of 24% with the poor quality lot. © 2001 Prentice-Hall Transparency 9-71 Statistical Sampling Techniques • Figure 9.5 OC curve for the sampling plan N=2000, n=200, c=2 © 2001 Prentice-Hall Transparency 9-72 Statistical Sampling Techniques • Example 9.1 -- OC curve of N = 2000, n = 50, c = 2. is shown as figure 9.5. -- The producer’s risk is 1%. -- The consumer’s risk is 42%. © 2001 Prentice-Hall Transparency 9-73 Statistical Sampling Techniques Slide 6 of 8 • Building an OC Curve – There are two ways to construct OC curves. The first uses the binomial distribution and the second, the Poisson distribution. – We rely on tables that have been developed for simplicity in computing single sampling plans. – The Dodge-Romig table in Figure 9.6 shows a table that was developed to simplify such calculations. © 2001 Prentice-Hall Transparency 9-74 Statistical Sampling Techniques • Figure 9.6 Probability curves for Poisson distribution © 2001 Prentice-Hall Transparency 9-75 Statistical Sampling Techniques • Example 9.2 -- n = 60, c = 2 -- Use Dodge - Romig table ( Figure 9.6) to take the OC curve probability ( see Table 9.8) and plot OC curve as Figure 9.7. © 2001 Prentice-Hall Transparency 9-76 Statistical Sampling Techniques • Table 9.8 OC curve probabilities © 2001 Prentice-Hall Transparency 9-77 Statistical Sampling Techniques • Figure 9.7 Resulting OC curve for n = 60, c = 2 © 2001 Prentice-Hall Transparency 9-78 Statistical Sampling Techniques • Estimating AQL and LTPD – OC curves can be used to estimate both AQLs and LTPDs. – Figure 9.8 shows an OC curve for a single sampling plan with n = 50 and c = 1. – Figure 9.8 shows that, AQL= 0.72% and Pa = 0.95, LTPD = 7.6% and Pa = 0.1. © 2001 Prentice-Hall Transparency 9-79 Statistical Sampling Techniques Slide 7 of 8 Figure 9.8 OC Curve of Single Sampling Plan n = 50 and c = 1 © 2001 Prentice-Hall Transparency 9-80 Statistical Sampling Techniques • More Complex Sampling Plans -- multiple sampling plans have advantages over single sampling plans. -- The sample size used in multiple sampling plans will be smaller, on average, with the same amount of protection as a single sampling plan. -- The decision to use multiple sampling plans will usually be made in the first phase of the sample. -- Exercise 9.3 provides an illustration of a double sampling plans. © 2001 Prentice-Hall Transparency 9-81 Statistical Sampling Techniques -- Exercise 9.3: Demonstrating a Double Sampling Plan - n1 = 40, c1 = 1, r1 = 5, and n2 = 60, c2 = 5, r2 = 6 - Please explain to management how this double sampling plan works. © 2001 Prentice-Hall Transparency 9-82 Statistical Sampling Techniques Slide 8 of 8 • Developing Double Sampling Plans – Although OC curves can be used to develop double sampling plans, the calculations to develop the OC curves are much more complex than for single sampling plans. – We will use a standard approach that is used by many practitioners. – The main limitation of this plan is that sample size must be specified, as well as AQL, LTPD, producer’s risk, and consumer’s risk. © 2001 Prentice-Hall Transparency 9-83 Developing Double Sampling Plans • Use Table 9.9 or Table 9.10 to develop Double Sampling Plan. -- AQL = 0.020, LTPD = 0.040 -- PR = 0.05, CR = 0.10, n1 = 0.5 n2 -- LTPD/AQL = 0.040/0.020 = 2 -- From Table 9.10, Take Double Sampling Plan number 15, c1= 4 , c2 = 20 and p’n1 = 4.75 ( P = 0.95) © 2001 Prentice-Hall Transparency 9-84 Developing Double Sampling Plans ( continued) • n1 = p’n1/AQL = 4.75/0.020 = 237.5 = 238 • n2 = 2 n1 = 2* 237.5 = 475. © 2001 Prentice-Hall Transparency 9-85 Developing Double Sampling Plans • Table 9.9 values for constructing a double sampling plan having a ' ' specified p1 and p2 ( n1=n2, 0.05, 0.10 ) © 2001 Prentice-Hall Transparency 9-86 Developing Double Sampling Plans • Table 9.10 values for constructing a double sampling plan having ' ' a specified p1 and p2 ( n1=2n2, 0.05, 0.10 ) © 2001 Prentice-Hall Transparency 9-87 Acceptance Sampling in Continuous Production • The MIL-STD-1235C (1988) named “ Single and Multiple – Level Continuous Sampling Procedures and Table for Inspection by Attributes” is available from the Department of Defense ( DoD). • The military standard can be ordered from the internet address of DoD http://www.dod.ssp.daps.mil/ © 2001 Prentice-Hall Transparency 9-88