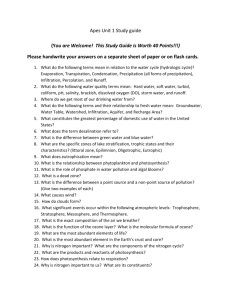

Basics of Crop Production I

advertisement

Basics of Crop Production Soil and Plant Fertility Soil Quality • This is the most important factor in farm crop production. • Soils will determine which plant species yields the most, the time of harvest, and ultimately the investment a landowner must make to yield an acceptable economic return from management. Soil Profile The soil profile shows the layers, known as horizons that represent the soil. Horizons formed over the centuries due mostly form weathering. A lettering system is used to name the different horizons. Where can you find info on a farm’s soil? • In the County Soil Survey Map. • There are Tables on several land options such as Woodland Management and Productivity which provides a lot of valuable information on the potential for soil erosion, seedling mortality, species preference, and tree growth. County Soils Map There is even a table in the Soil Survey Map that evaluates sites for wildlife habitat. Factors Controlling Plant Growth • Light • Mechanical Support • Heat • Air • Water • Nutrients • All except for light, involves soil Major Components of Soil Air Water Organ. Matter Mineral 50% Soil Terminology • Soil texture - concerns the size of mineral particles, specifically the relative proportion of various size groups in a given soil • Soil structure - the arrangement of soil particles into groups of aggregates Soil Texture • Soil texture is separated into three soil separates based on particle size. 1 Sand 2 Silt 3 Clay Soil Texture • Silt, clay - imparts a fine texture and slow water and air movement, also high water holding capacity • Sandy to gravelly - are referred to as lighter soils with lower water holding capacity Soil Texture • Sandy soils are normally very well drained and often lack nutrients due to constant leaching loss. • Mostly clay soils are at the opposite end of the soil spectrum. They tend to allow water to move through more slowly and will stay wetter longer. They will hold nutrients. Soil Terminology • Pore space - is that portion of the soil occupied by air and water - sandy soils have low soil porosity, while silt and clay soils have high soil porosity • Soil compaction - fine textured, wet soils are more easily compacted - compaction reduces pore spaces Soil Terminology • Soil depth - defined as that depth of soil material favorable for plant root penetration - deep, well drained soils are the best Soil Terminology • Slope - land topography largely determines the amount of drainage, runoff, and erosion - the steeper the land, the more management is required Soil Terminology • Organic matter - it consists of plant and animal residues in various stages of decay - adequate levels benefit soil by: 1) improving physical condition 2) increasing water infiltration 3) improving soil tilth 4) decreasing erosion losses 5) supplying plant nutrients 6) holding cation nutrients Soil Terminology • pH - expression of both acidity and alkalinity on a scale whose values run from 0 to 14 with 7 representing neutrality, <7 represents acidity, and >7 represents alkalinity • pH has a significant impact on the availability of soil nutrients • pH 6.5 - pH objective for most ag crops pH Scale The figure shows the break down of where acidity to alkalinity is on the pH scale. PH 7 is neutral. pH Effect on Nutrient Availability This graphic shows how the major plant nutrients change in availability with the increase and decrease of pH. The wider the black band in this graphic, the more available the nutrient. This has a direct impact on plant health. For most agricultural crop recommendations, the goal is to have a 6.5 pH. At this pH most of the essential plant nutrients are available. pH Preferences by Plants This graphic shows the range in pH preferred by plants. This shows that it is important for producers to know the fertility and pH requirements of the plants they plan to grow. As can be seen from the black bands, most plants prefer a pH between 5.5 and 7.0. A pH below 5.5 is considered to be very acid and above 7.0 is alkaline. . Limiting Factors Root • A layer which restricts the downward penetration of a plant’s root system will reduce growth in direct relation to the depth of the layer. • On rare occasions, a limiting layer may increase site productivity, such as on sandy soils where the layer may retard leaching of nutrients and increase available moisture. Subsoiling Subsoilers have long shanks that physically dig down to break open the hard soil to form channels where plant roots can penetrate. There are farm implements available that can breakup soil hard pans and improve the crop production in otherwise limited soils. 16 Essential Elements (part 1) • Primary Nitrogen (N) Phosphorus (P) Potassium (K) • Secondary Sulfur (S) Magnesium (Mg) Calcium (Ca) The primary elements are plant nutrients that are needed and most used by plants for growth. The primary nutrients can be found in commercial complete fertilizers as the fertilizer number reflects these three elements, i.e. 10-6-4. Secondary elements are the next most needed plant nutrients. Magnesium and calcium are obtained from liming materials. During the Industrial revolution, most of our sulfur came from air pollution (sulfur dioxide). In recent years, producers have had to routinely include supplemental sulfur to their crop fertility programs as the air around us becomes less contaminated with sulfur. 16 Essential Elements (part 2) • Micro-nutrients Iron (Fe) Manganese (Mn) Boron (B) Chlorine (Cl) Zinc (Zn) Copper (Cu) Molybdenum (Mo) 16 Essential Elements (part 3) • The final three (3) essential elements to plant growth come mostly from air and water. • They are: Carbon (C) Hydrogen (H) Oxygen (O) The Primary Elements • Nitrogen: It gives plants their green color, promotes above ground growth, and regulates utilization of other elements. • Phosphorus: It has favorable affect on - cell division - stem strength - crop maturation - root development - flowering/fruiting - disease resistance The Primary Elements (con’t) • Potassium (K) - It is essential for starch formation and translocation of sugars. It is also essential to the development of chlorophyll. K helps plants to over-winter. What is the nutrient content of commercial fertilizers? • Expressed as a percent called the “guaranteed analysis” or fertilizer grade. • Nutrient content always appears in this order: % total nitrogen % available phosphate (P2O5), or phosphoric acid % soluble potash (K2O) The Fertilizer Number The fertilizer number refers to a ratio of N-PK 5-10-5 (1-2-1 ratio) has: 5% N 10% P205 5% K20 = 20% The other 80% of the material is called the carrier. This is typically some inert material. 10 - 6 - 4 (2-1-1 ratio) 10 -10 -10 (1-1-1 ratio) What does a fertilizer guarantee mean? Ag-Gro-Pro 5-10-15 50 lbs. This bag contains: 5% nitrogen--10% phosphate--15% potash or 2.5 lbs. nitrogen 5 lbs. phosphate 7.5 lbs. potash Common Fertilizers • • • • • • • Urea Ammonium nitrate UAN Ammonium sulfate Diammonium phosphate Triple superphosphate Muriate of potash 46 - 0 - 0 34 - 0 - 0 30 - 0 - 0 21 - 0 - 0 18 - 46 - 0 0 - 46 - 0 0 - 0 - 60 Determining Fertilizer Need Production Goal: Total lb/A N - P - K soil reserve N –P - K crop residue N manure N-P-K ______________ Commercial fertilizer + lb/A N - P - K Example: Calculating the Quantity of Commercial Fertilizer Required to meet a Nutrient Recommendation Jasper Little Farm: • needs 60 lbs./A of potash (K2O) on his soybean crop • broadcasts muriate of potash (0-0-60) pre-plant • see Example 4-1, p.18 in training guide Calculating Quantity of Commercial Fertilizer 1) RECORD recommended quantity of nutrient (see nutrient management plan). 60 lbs./A 2) RECORD the percentage of nutrient in the preferred product, muriate of potash. 60% 3) CONVERT the percentage of nutrient to a decimal fraction by multiplying the % by .01 60 x 0.01 = .60 Calculating the Quantity of Commercial Fertilizer CALCULATE the quantity of muriate of potash required in lbs./A: divide the recommended quantity of nutrient by the nutrient content expressed as a decimal fraction. 60 lbs./A ÷ 0.60 = 100 lbs./A Little needs 100 lbs. of muriate of potash to supply 60 lbs. of potash. Done! Determining Production Goal • Cropping history • Soil Survey Map/Soil Capability Chart • Investigate species/variety potential - other growers - field days - private and university trial results • FSA records • Experimentation Determining Yield Goal • Take the average yield for typical years that a crop is grown in a certain field. • Estimate yields goal by averaging the yield from the best 3 of 5 growing MASCAP seasons. • When actual yield data is not available, estimated yields for the soil type in the field can be found in “MASCAP”. MARYLAND’S AGRONOMIC SOIL CAPABILITY ASSESSMENT PROGRAM Va. A. Bandel, and E.A. Heger Agronomy Department Cooperative Extension Service September 1994 University of Maryland Soil Reserve • Soil test - university lab - private labs • Frequency of testing - depends on crop and management • Typical test looks at P, K, Ca, Mg, O.M., and pH. Minors are as needed. Fig. 1-1: Phosphate Recommendation (lbs/A) as a function of soil fertility level (FIV-P) for corn grain (yield goal-150 bu/A) 110 100 85 70 80 45 45 60 35 40 30 20 20 20 Low FIV-P Optimum Medium 90 70 50 30 0 0 10 # P205/A 65 110 120 Excessive Crop Residue • Benefits left by a previous crop or cover crop • Previous crops leave little unless it was a leguminous crop • Leguminous crops leave nitrogen • The amount of N left depends on the species of legume and the stand density and maturity. • Cover crops are not harvested and will recover nutrients otherwise lost. Manure Analysis is available from the University of Maryland’s Soil Testing Laboratory. How much of the nitrogen in manure is plant-available? It depends on: * the nitrogen content * animal species * incorporation practices Figure 2- 3b. Distribution of organic nitrogen & ammonium nitrogen in dairy manure 3 Ammonium nitrogen Organic nitrogen 9 This dairy manure contains 12 pounds of total nitrogen per ton. Available Organic Nitrogen Only part of the nitrogen in manure becomes plant-available -- through the process of mineralization -- the year it’s applied. Nitrogen “Credits” • Organic nitrogen in organic sources continues to break down or mineralize for several years after application. • The largest proportion of this organic nitrogen breaks down and becomes available in the year of application. • Organic sources include manure, biosolids (sludge), and composts. Nitrogen “Credits” • Progressively smaller amounts of the organic nitrogen break down and become available in the subsequent years. • Credit needs to be given to this available nitrogen from previously applied manure to the current year’s nitrogen recommendation. Figure 2- 4b: Distribution of Available Nitrogen from Organic and Ammonium Nitrogen Components in Dairy Manure Ammonium nitrogen 0.6 lb 2.4 lb 6 lb 3 lb Available ammonium nitrogen Available organic nitrogen Organic nitrogen This dairy manure contains 12 pounds of total nitrogen and 5.4 pounds of available nitrogen per ton A funny slide to breakup the class. This could be an Iraqi surface to air missile. Don’t Overload! Manure Mineralization Factors •Vary by animal species. The mineralization rate of manure varies between animal species. A table explaining these differences can be found in the Nutrient Applicator Guide on page 10. •See Table 2-1 in the Nutrient Applicator Guide. Available Ammonium Nitrogen • NH4 is a plant-available form of N. • When manure is left on the soil surface after application, it can be lost through the process of volatilization. Nitrogen Loss Estimated Manure Values • Dairy (fresh, spread daily) 89% moist. 7 - 3 - 6 (lb/T) • Dairy (stored outside, leachate lost) 87% moist. 3 - 2.5 - 4 (lb/T) • Poultry (layer stored in pit) 65% moist. 25 - 27 - 24 (lb/T) • Swine (storage tank beneath slotted floor) 95% moist. 2.5 - 3 - 5 (lb/T) • Beef (bedded manure pack under roof) 80% moist. 5 - 4 - 8 (lb/T) Example: Calculating Quantity of Dairy Manure to Meet Crop Nutrient Recommendation Ralph Gonzales Farm • PAN content of semi-solid dairy manure is 6 lbs./T • wants to supply the N for his corn crop • yield goal is 120 bu/A • incorporates the manure the same day as application • see Example 4-2, p.19 in training guide Calculating Quantity of Dairy Manure to Meet Recommendation Note: The nitrogen recommendation for corn grain is 1 lb./A of PAN per bushel of yield. 1) RECORD nitrogen recommendation (lbs./A) from the nutrient management plan. 120 lbs./A 2) RECORD PAN of manure (lbs./T) 6 lbs./T Calculating Quantity of Dairy Manure to Meet Recommendation CALCULATE the quantity of manure required in T/A: divide the nitrogen recommendation by the PAN of manure. 120 lbs./A ÷ 6 = 20 T/A Twenty tons of a dairy manure with this PAN are needed to provide 120 lbs./A of PAN. Done! Use of Raw Manure • Heavy applications can throw off nutrient balance • Excess available N can lead to excessive growth and nitrate buildup in plant • Plants with high nitrates do not store as well and attract insects • Nitrogen and phosphorus are pollutants • Weed seeds pass through animals Often Forgotten Sources of N • Carryover from past manure/biosolids • Cover crops ( fixed & recycled N) • N released from soil organic matter (40-80 lb/A) • Nitrates in rain & irrigation water • Weeds, plowed down have slow-release N, 85 lb/T pigweed, 80 lb/T lambsquarter • Crop residues, humus, bedding, and composts Component Input to soil Loss from soil The Nitrogen Cycle Atmospheric nitrogen Atmospheric fixation and deposition Industrial fixation (commercial fertilizers) Crop harvest Animal manures and biosolids Volatilization Plant residues Runoff and erosion Biological fixation by legume plants Plant uptake Denitrification Organic nitrogen Ammonium (NH+4) Nitrate (NO-3) Leaching Component Input to soil Loss from soil The Phosphorus Cycle Crop harvest Animal manures and biosolids Atmospheric deposition Mineral fertilizers Plant residues Organic phosphorus •Microbial •Plant residue •Humus Leaching (usually minor) Plant uptake Soil solution phosphorus •HPO4-2 •H2PO4-1 Primary minerals (apatite) Runoff and erosion Mineral surfaces (clays, Fe and Al oxides, carbonates) Secondary compounds (CaP, FeP, MnP, AlP) Component Input to soil Loss from soil The Potassium Cycle Crop harvest Plant residues Animal manures and biosolids Mineral fertilizers Runoff and erosion Plant uptake Exchangeable potassium Soil solution potassium (K+) Leaching Mineral potassium Fixed potassium Input to soil Component Loss from soil The Sulfur Cycle Atmospheric sulfur Atmospheric deposition Volatilization Crop harvest Mineral fertilizers Animal manures and biosolids Plant residues Runoff and erosion Elemental sulfur Absorbed or mineral sulfur Plant uptake Organic sulfur Reduced sulfur Sulfate Sulfur (SO-4) Leaching Fertilizer Application Terms • Broadcast - fertilizer is applied uniformly to entire field before crop emerges • Topdress - fertilizer is applied uniformly to entire field after crop emerges • Plowed down or tilled in - fertilizer is applied to field then is tilled in with a disk or a plow Fertilizer Application Terms • Banded - fertilizer is applied directly over the top of the crop row, generally before the crop emerges, omitting the area between the rows • Side-dressed - fertilizer is applied directly to growing crop, generally in a band at the base of the plant Calibrating Nutrient Application Equipment • Calibration is a way to set your application equipment to apply material uniformly at the desired rate. • It insures application of the required amount of nutrients without overfertilizing. • Two common methods are used: - weight-area method - load-area method Basics of Calibration Determining the square feet in an area is basic to the calibration of farm equipment. The size of an area can be determined by multiplying length X width. L e n g t h L e n g t h Area = Length x Width Width Width How to Calibrate Nutrient Application Equipment • Measure the actual rate of application. • Compare actual application rate to the recommended application rate. • If the application rate is substantially greater or less than the recommended rate, try: - changing equipment settings, or - changing ground speed of the tractor Load-Area Method Know: • capacity of the spreader • size of the area where manure is spread Apply nutrient supplying material, then measure area of application. Project rate of application to a per-acre basis. Weight-Area Method for Manure 1. Arrange at least 3 plastic sheets in the center of the spreader’s path. 2. Drive the spreader over the center of the sheets at a known speed with specific equipment settings. 3. Collect & weigh the manure on each sheet. 4. Average the quantity applied to the sheets and project to T/A. Weight-Area Method • Works well with calibrating fertilizer spreaders and planters. • Works well with calibrating both dry and liquid manure spreaders. - pans can be used to catch liquid manure - plastic sheets can be used to catch dry manure Basics of Calibration Using Sheets and Pans This diagram shows how pans and sheets can be arranged in a field to calibrate a spreader. 1 Spread 2 manure 2 1 3 4 7 5 Spread manure 8 6 3 9 10 Refer to your “Nutrient Applicator’s Training Guide “ for additional help Let’s take a quick look at some other materials we apply to our soils. Limestone • Supplies calcium and magnesium • Mined calcium carbonate is the principle liming material, typically 50% oxides • CaCO3 equivalent is the basis for liming material recommendation rates • Comes in various forms and grades Comparing Liming Materials Effective Neutralizing Value E.N.V. This is a comparative value that refers to the ability of a liming material to modify soil pH within a year. Reference Standard: Calcium carbonate (CaCO3) E.N.V.= 100 This means that liming materials are compared (greater than or less than) to the neutralizing ability of calcium carbonate. E.N.V. can be found on the labels of liming materials and fertilizer as an indicator of the products impact on soil pH. Limestone • Mesh size determines how quickly it reacts in the soil • Good quality ag lime is typically 80% 90-100 mesh and 20% 40 mesh • Ground dolomite (dolomitic lime) is over 10% magnesium; it is a good source of Mg when needed Other Liming Agents • These are typically industrial byproducts • These include stack dust, sludge lime, and river mud • Domino Sugar lime is a new source • Solubility and % oxides vary, so get an analysis • These contain mostly Ca and traces of other elements and materials Liming Recommendations • Know the analysis, especially % oxides -Application rate is based on lb/A oxides • % calcium and magnesium - may not need additional Mg • Oxide form of calcium (CaO) is readily available • Mesh size of carbonate form of Ca (CaCO3 ) reflects its availability - smaller particles work faster Liming Notes • Limestone recommendations are based on raising the pH of the plow layer (top 7-9”) to 6.5; except for special crops; i.e. alfalfa. • Limited to 1,500 lb/A oxides/year when not incorporating; i.e. pastures • Avoid applying liming products and fertilizer at, or around the same time. • Liming materials laying on the surface will neutralize pesticides. Compost Decomposed Plant & animal Matter • When correctly done: - pH is near neutral - C:N ratio is 15:1 - Majority of weed seeds & disease organisms are dead - Offers a well balanced slow release supply of nutrients - As much as 1/4 of compost weight is microbes (dead & alive) Principles of Composting • Best composts come from piles with the highest microbial activity • Temperature is easiest sign of microbial activity • Good composts heat to approximately 140 - 1600 F within the first 3 or 4 days Principles of Composting • Small particle size makes a greater surface area available to microbes - particles that are too small however can pack a pile • Adequate volume, or size of pile keeps it from cooling too quickly - piles 4 x 4 x 4 ft. do well Unfinished Composts • Can hurt crops • Chemicals formed in process are toxic to plants • N can be tied up • Good composts take 12 - 18 months • Moisture must be adequate (50 - 70%) similar to a squeezed sponge • C:N ratio in initial pile should be 30:1 Common C:N Ratios • Undisturbed top soil 10:1 • Alfalfa 13:1 • Rotted barnyard manure 20:1 • Corn stalks 60:1 • Small grain straw 80:1 • Oak 200:1 • Spruce 1000:1 Compost Problem Solving • Bad Odor - not enough air - turn the pile more frequently • Center of pile too dry - not enough water - moisten while turning Compost Problem Solving • Pile is damp & warm in center, but nowhere else - pile is too small - collect more material and mix the old ingredients into a new pile • Pile is damp and sweet smelling, but will not heat up - lack of nitrogen - mix in N-rich material like fresh grass, manure, or urea Crop Rotation and Cover Crops • Benefits crop fertility - fixed and recaptured nutrients • Benefits soil structure (tilth) - cover crops add organic matter - variability in root growth improves soil pores and water penetration • Pest management - breaks the parasite life cycle • Harvest vs. cover crop is the decision Some Parting Advice • Seek help when you are not sure about what you are doing. There are a lot of resources out there for you. • Don’t be like the old farmer who told the County Agent that he did not need any advice. He told the Agent that he has already worn out two farms and that he had his own way of doing things. THANK YOU