Manufacturing Processes - Su

advertisement

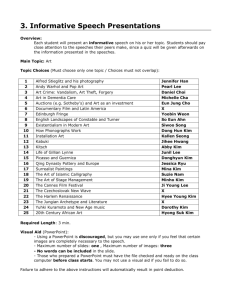

Manufacturing Processes Bulk Deforming (부피 성형가공) Bulk Deforming © www.afdex.com Manufacturing Processes © 2012 Su-Jin Kim GNU Su-Jin Kim Mechanical Engineering Gyeongsiang National University Korea Contents • • • • • Forging Rolling Extrusion Drawing Tube deforming Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Forging (단조) • • • • • Forging is the shaping of metal using plastic deformation takes place by compressive forces. It can be carried out at room (cold forging 냉간단조) or above recrystallization temperature (hot forging 열간단조). Stronger than an equivalent cast or machined part. Expensive die, press and furnace facilities. Post machining is required. Ductile metal. Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Open-die forging(자유단조) • • Open-die forging is usually done by hammering a part between two flat faces. It is used to make parts that are too big to be formed in a closed die or in cases where only a few parts are to be made without die. ©steelindustriesinc.com Bulk Deforming Manufacturing Processes http://www.youtube.com/watch?v=tLRkOupbARM&p=9B6D9EAE75875D9D © 2012 Su-Jin Kim GNU SME 1min Open-die forging • • • Berreling is caused by friction force at die-workpiece interface. Friction and the aspect ratio effects forging force. Forging force: F≈σyA(1+μr/h) F h Die r Barreling μ, friction Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Impression-die forging (형단조) • Workpiece acquires the shape of the die cavity while deformed between the closing dies. • Forging force : F k p y A kp: pressure-multiplying factors (3~12) • also called Closed-die forging (패쇠단조) Die Parting line Flash Land Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Forging Die (단조 금형) • Require multi-stage forging to ensure proper distribution of the material in the die cavities. • Parting line is designed based on shape, metal flow, force. • Flash clearance is 3% of max thickness. • Draft angle > 5~7° for steel. • Corner fillets radii for smooth flow. Die Fillet • low and wide Ribs Parting line Flash • Metal fiber flow lines. Flow lines Rib Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Forging die & flash • Source geometry and die and flash size. Forging die Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU O X flash Impression-die hot forging 1STAGE 2STAGE 3STAGE Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU http://ma.gnu.ac.kr/vod/Forming/Hot_Forging.wmv Hot forging Bucket Tooth ©gsf.co.kr Continuous Cross Section • Rolling • Extrusion • Drawing Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Rolling (압연) • Metal stock is passed through a pair of rolls to reduce thickness. • Hot rolling(열간압연) > recrystallization temperature > Cold rolling(냉간압연) • • • • • (Roll bending) (Roll forming) Flat rolling Ring rolling Structural shape rolling Bulk Deforming Manufacturing Processes http://www.youtube.com/watch?v=6xnKmt_gsLs&p=9B6D9EAE75875D9D © 2012 Su-Jin Kim GNU Rolling 3m Flat Rolling (평판 압연) • Rectangular cross-section (sheet, plate) • Force: F ≈ σylw • Draft: t0 - tf < μ2R w t0 F tf l R Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Ex) Flat Rolling Force Power Ductile plate (width: 0.1 m, thickness: 10 mm, strength: 400 MPa) is rolled by flat rollers (radius: 0.1 m). The friction coefficient of roller and plate is 0.2 and production rate is 1 m/s. How many times should the plate pass the roller to get 5 mm thickness plate? Please predict approximate rolling Force (kN) and Power (kW). Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Ring rolling (링압연) • Driven and idle roll presses the ring to decrease thickness and increase diameter. Driven roll Idler roll Side roll Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU http://www.youtube.com/watch?v=GDyWyDP3cvs Ring rolling Structural shape rolling (형압연) • Structural shape rolling uses profile rolling techniques where the workpiece is passed through a series of rollers that match the workpieces' cross-section. Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Thread rolling (나사 전조) • Threads are formed by pressing a blank with the former(shaped die). Thread Rolling Die Blank www.horstengineering.com Bulk Deforming Manufacturing Processes Bolt: http://www.youtube.com/watch?v=7ORomNNCSUQ&p=9B6D9EAE75875D9D Bolt Nut 5m © 2012 Su-Jin Kim GNU Extrusion (압출) • A round billet is placed in a chamber and forced through a die opening by a ram. • It creates complex fixed cross-sectionals. • Pressure: p≈σy(0.8+1.4ln(Ao/Af)) Container Die Ram Billet F Ao Af Hot extrusion profiles of steel Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU http://www.youtube.com/watch?v=7qiDJ5U4uRc Extrusion 1m Drawing (인발) • • Reduce the cross-section of a road, wire or tube by pulling it through a drawing die Lubrication is essential for good surface finish and long die life Die A0 Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Af F Spring forming machine • Spring forming machine controlled by mechanical cam and link. Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU http://ma.gnu.ac.kr/vod/Forming/Spring_Former.wmv Spring former Rotary Swaging • Split dies separate and close to reduce the diameter and produce a taper of tube. Die Tube Mandrel Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Tube (Pipe) Bending • • Straight tube is bended into the desired form. Be careful to buckle inward during bending. Former Tube bending Clamp Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU http://ma.gnu.ac.kr/vod/forming/Pipe_Bending.wmv Tube Hydroforming • Hydraulic pump injects high pressure fluid inside a hollow tube to expand until it matches a negative mold. • Strong and light structures for vehicles Dies Hydraulic pressure Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Tube Seals SME: http://www.youtube.com/watch?v=nylIvins3XE Com: http://www.youtube.com/watch?v=i2ac6A3FJ6E&hl=ko Characteristics (특징) Advantages Disadvantages Fast & mass production Expensive equipment and dies Improved strength Ductile materials Surface finish and tolerance are better than casting Shape is limited by strain/flow Size is limited by force/equipment Strength is improved because of work hardening, grain refining, fevering, defect closure Surface finish and tolerance are better than casting, worse than machining Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU Economics (경제성) Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU 4 5 6 7 8 9 Cost per pieces • Tool and die cost middle or high but spread over the number of parts For large quantities forging is more economical than sand casting Investment casting Forging Sand casting 1 2 3 • 100 Die casting 101 102 103 104 Number of pieces 105 106 Bulk Deforming Simulation • http://www.afdex.com Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU References • http://www.afdex.com • http://www.kforge.or.kr • http://www.posco.co.kr Bulk Deforming Manufacturing Processes © 2012 Su-Jin Kim GNU