What is a Confined Space?

Confined Space Safety

Presented by: Allan DeLange, CL Coatings, LLC

Introduction

• This webinar is being presented to issue guidance addressing the hazards and controls for surface preparation and coating application in confined spaces.

Learning Outcomes

• At the end of this webinar, you will be able to:

– Identify confined space industry standards

– Define a confined space

– Recognize hazards in a Permit

Required Confined Space (PRCS)

– Define methods for control and elimination of hazards in a Permit

Required Confined Space (PRCS)

– Become familiar with the elements of a

Permit-Required Confined Space

Program

Introduction

• Note: This webinar is not a substitute for:

A confined space safety plan

A confined space training course

A OSHA regulation on confined space

Confined Space Industry

Standards

• During the webinar reference will be made to the following industry standards:

– OSHA’s General Industry Standard 29 CFR

1910.146 Permit Required Confined Spaces

– OSHA’s Safety and Health Regulations for

Construction 29 CFR 1926

• OSHA is working on a proposed rule on confined spaces more specific to construction as part of its upcoming revision

What is a Confined Space?

• An area being large enough and so configured that an employee can enter and perform assigned work; having limited or restricted means for entry; and not designed for continuous occupancy

Examples of PRCSs

• Some examples of PRCSs commonly encountered in industrial and marine coating operation include:

– Interiors of storage tanks

– Silos

– Ship holds

– Boilers

– Penstocks

Examples of PRCSs

Examples of PRCSs

Examples of PRCSs

Hazards of Confined Spaces

• Confined Spaces can be Deadly

• Some Confined Spaces are more Hazardous than others

• Confined Space Conditions can change rapidly

• Hazards can often be eliminated or controlled before entry

• Surface Preparation and Coating Application

Hazards usually require a written Permit

System for Entry

Main Hazards

• Oxygen Deficiency

• Hazardous Atmospheres

• Abrasive Blasting & Waterjetting

• Toxic Materials (Coatings)

• Moving Parts

• Electricity

• Physical Hazards (Heights)

Hazardous Atmospheres

• A “hazardous atmosphere” in a confined space has one or more of the following:

– Flammable gas, mist or vapor

– Flammable Dust

– Oxygen content below 19.5% or above 23.5%

– Air contaminant concentrations that would cause death, incapacitation or permanent health problems

– IDLH atmosphere

Fire and Explosion Hazard

• Flammable gases, vapors or dusts will ignite from a spark or flame if above the

“Lower flammable limit” (LFL)

• Gas or vapor levels higher than 10% of the

LFL are considered hazardous and the confined space cannot be entered until levels are reduced

Engulfment / Entrapment

• Engulfing materials include liquids or loose solids such as grain, sand or other granular material.

• Entrapment can occur in a space configured in a way that can trap a worker, for example, sides sloping towards the center.

Toxic Materials

•

The most common toxic chemicals in confined space fatalities are hydrogen sulfide and carbon monoxide.

• Other toxic chemicals can include welding fumes, vapors from chemical residues or chemical products used in the confined space.

• Chemicals can quickly reach toxic levels in the air of a confined space, especially gases, solvent vapors or sprayed products.

Other Recognized Hazards

• Electrical lines, steam lines, or hydraulic lines

• Mechanical hazards (moving parts)

• Hazards caused by work operations

– Welding

– Abrasive Blasting

– Waterjetting

– Spray Painting

Entry Permits are Required:

• When there is an actual or potential

Hazardous Atmosphere, or

• When the space contains loose material that can engulf a person, or

• When the space is configured in a way that can trap a person, or

• When there is any other recognized serious safety and health hazard

Permit Required Confined

Space

• Whenever a hazard is present in the confined space, it should be considered a permit-required confined space (PRCS)

Confined Space Entry

Program

• Establish and implement a written confined space entry program that is reviewed annually.

• Ensure all field personnel are trained in every aspect of each project-specific confined space safety plan, including the rescue plan and each person’s role in the event that the plan has to be implemented.

Permit Required

Confined Space Program

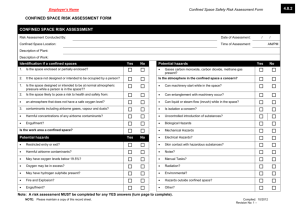

• Identify the space

• Identify the hazards

• Eliminate or control the hazards

• Isolate & control the space

• Pre-entry verification

Permit Required

Confined Space Program

• Permit preparation, authorization & cancellation

• Safe work practices

• Emergency Response / Rescue Services

• Training

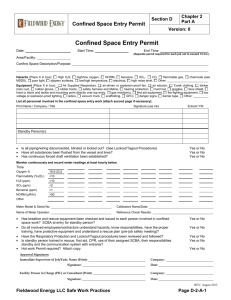

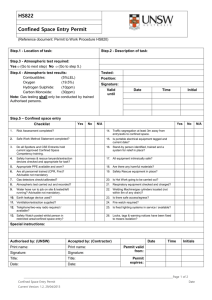

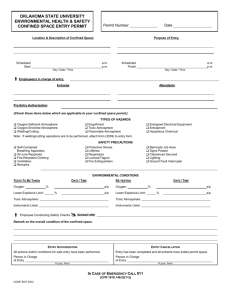

Confined Space Permit

Elements

• Identity of Space

• Purpose of Entry

• Date and Duration

• Supervisor, Entrants & Attendants

• Hazards of the space

• Means to isolate & control space

• Acceptable entry conditions

Confined Space Permit

Elements cont.

• Rescue & emergency services

• Communication methods

• Safety, communication, rescue & PPE equipment required

• Atmospheric test results

• Authorization, release for entry, suspension and cancellation

Planning for Confined Space

Entry

• Before beginning work, a job safety analysis (JSA) should be performed taking into consideration the equipment and materials to be used

Job Safety Analysis (JSA)

• Proper completion of a JSA, listing planned activities, identifying all potential hazards of a confined space entry and establishing the means to control the hazards and eliminate accidents is an excellent way to prepare for confined space entry and completion of an entry permit.

Hazard Control

• Hazardous Atmospheres

– Drain or pump out liquid contents

– Blank off, double block & bleed all in-feeding lines

– Air test and ventilate

– Continue ventilation during entry

– Exit space if conditions deteriorate

– Use non-sparking tools where feasible

Hazard Control

• Lock Out / Tag Out

– Identify all potential energy sources

– Comply with client operating procedures

– Lock out / tag out energy isolating devices

– Walk down all isolation points prior to each shift

– Verify “Lock Out” of operating equipment

(witness bump test)

Entry Control

• Post Warning Signs

• Limit access by using entry barriers or locks

• Prevent entry by unauthorized workers

• Holes and openings must be closed or guarded when not attended

Pre-Entry

• Complete pre-entry briefing for all planned entrants and attendants

• Complete pre-entry testing for air quality

• Verify isolation of the confined space

• Confirm required pre-entry requirements and availability of all permit required materials and equipment

Ventilation

• Engineered Supply & Exhaust

• Cross ventilation – circulation

• Breathing zone issues

• Source of ventilation

• Point of exhaust

Monitoring Confined Spaces

• Confined spaces should always be monitored for hazardous atmospheres both prior to entry and continuously in areas where work is being performed

Air Monitoring

• Required prior to and during confined space entry

• Monitor for O2, LEL, CO, H2S, SO2

• Monitors must have current calibrations

• Results must be documented

Personal Protective

Equipment (PPE)

• All required PPE per entry permit

• Respiratory protection

• Eye protection, hearing protection

• Protective clothing, gloves & footwear

• Fire retardant clothing - Chemical suits

• Fall protection

• Harness (& lifeline) to facilitate rescue

Lifelines

• Examine the workspace for snags and equipment and tool placement that could make retrieval difficult

• If obstructions render lifelines unusable, require entrants to wear the harnesses regardless to facilitate rescue

Communication

• A means of communication must be provided between the attendant and entrants

– 2 way radio systems

– Air Horns

– Audible and/or visual direct contact

– Signaling protocols

– Lifelines

– Alarm systems

Hazardous Materials

• Try to substitute less hazardous materials

• Use paints and solvents with flash points above 100F

• Minimize the total amount of hazardous materials within a confined space at any time

Electrical Systems

• GFCIs and Assured Grounding Program

• Ground and bond containers when transferring liquids

• Electrically ground coating spray systems

• Electrically ground blowers and duct work

• Explosion proof electrical and lighting systems are required when flammable atmospheres may be present.

Entry Supervisor

• The person (such as a foreman), trained, competent, and responsible for determining if acceptable entry conditions are present at a permit space where entry is planned, for authorizing entry and overseeing entry operations, and for terminating entry.

REVIEW THE JSA!

Entry Supervisor Duties

• The Entry Supervisor has TOTAL Responsibility for the Confined Space and must:

‾ Pre-entry briefing on the confined space

‾ Know the hazards in the confined space

‾ Verify testing and confirm equipment availability before endorsing permits

‾ Terminate entry and cancel permits as needed

‾ Verify that a rescue team is available

‾ Remove unauthorized personnel

‾ Determine that operations are consistent with the terms of the permit and JSA

Confined Space Attendant

• An individual stationed outside one or more permit required confined spaces who monitors the authorized entrants and who is trained to perform all attendants duties assigned per the

Confined Space Entry Program.

• Mandatory for PRCS.

Duties of the Attendant

• The Attendant must:

‾ Know the hazards in the confined space

‾ Be aware of the behavioral effects of exposure

‾ Maintain an accurate count of entrants

‾ Remain outside until relieved by another attendant

‾ Monitor activities in confined space and order an evacuation if necessary

Duties of the Attendant

• The Attendant must:

‾ Monitor activities in confined space and order an evacuation if necessary

‾ Summon rescue team when necessary

‾ Prohibit unauthorized entry

‾ Perform non-entry rescue if necessary

‾ Perform no other duties

Authorized Entrant

• An employee who is authorized and trained by the Company or an approved third party, to enter a permit space.

Duties of the Entrant

• The entrant is authorized by the entry permit to enter the confined space.

The entrant must:

• Know the hazards faced during entry

• Properly use the required equipment

• Communicate with the attendant

• Alert attendant of possible exposure or changes in conditions

• Exit the space quickly when conditions warrant

Confined Space Rescue

• A means must be provided for both safe normal entry or exit , and emergency extrication. Tripods with hoist, lifeline, and full body harness are often used for emergency extrication. Ladders may be used for ordinary entry and exit.

Confined Space Rescue Team

• Rescue and emergency services must be available for Permit Required Confined Spaces

• The personnel designated to rescue employees from permit spaces, may be employees specifically trained for confined space rescue, client site services, local paid or volunteer fire department, or other trained services

Confined Space Rescue

• Require that confined space rescue team be readily available for call out within 5 minutes at the permit spaces

Outside Rescue Service

• Visit the closest fire station and provide the Chief with a briefing about the job, including all entries.

• Give the Chief a copy of all

MSDSs.

• Have a site visit with the fire

Chief to review the entry permit and work site.

Training

• Employers are required to certify that all employees, including attendants, entrants and entry supervisors, have been properly trained for permit space operations.

• Rescue and emergency service providers must receive special training and practice permit space rescues annually

Summary

• Accepted industry practices and regulatory requirements should be implemented prior to and during all surface preparation and coating application operations in confined space which may create a hazardous atmosphere

Conclusion

• This concludes our webinar for today.

Please join us for our next webinar, April

13 th at 11am EST on Common Legal

Problems in Coating Work and How to

Stay Out of Court