Greenstreet Emily Greenstreet Harlynn Ramsey Writing 340 April 29

advertisement

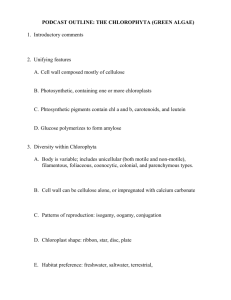

Greenstreet 1 Emily Greenstreet Harlynn Ramsey Writing 340 April 29, 2013 Nanocellulose Abstract In a world desperate for renewable material resources and reduced carbon emissions, nanocellulose is increasingly being viewed as a wonder material. Lightweight, strong, and plant-based, it can be incorporated in a huge variety of products, ranging from food to automobiles. It shows particular promise in the medical field where its natural composition allows it to be used to support bone, cartilage, and vascular re-growth, in addition to being suitable for the construction of artificial body parts. New manufacturing techniques have reduced costs and increased production to the point where nanocellulose will replace metals and oil-based plastics in many products within the next ten years. Tags: nanocellulose, algae, renewable materials, biochemical engineering, biomedical engineering, health & medicine About the Author: Emily Greenstreet is a fourth year Bachelor of Architecture Student. She is an active member of the Undergraduate Architecture Student Council at USC as well as a mathematics tutor for local high school students. She currently works for D.P. Environment, a Los Angeles based landscape architecture firm. Cellulose Cellulose is the most abundant natural substance on earth. It is a material that has been used by mankind since the dawn of civilization [1]. Wood; hay; papyrus; cotton; all are natural manifestations of cellulose. It’s the fiber in oatmeal, and in modified form provides the thickening agent for fast food milkshakes. Now, scientists working with a cellulose derivative, nanocellulose, are calling it the next wonder material. Nanocellulose is produced when cellulose is reduced down to nanosized (5-20nm diameter) cellulose Greenstreet 2 fibrils. This material has great potential because it is abundant, renewable, and biodegradable [1]. Properties of Nanocellulose Nanocellulose is incredibly versatile, offering a wide range of properties. This material is lightweight, but can simultaneously be stiffer than Kevlar, making it perfect for innovative armor. It’s non-toxic, offering possibilities for implantation in food products [2]. It has eight times the tensile strength of steel, yet also offers the possibility to replace traditional paper as a more sustainable material due to its lightweight and flexibility. A one-pound boat made of this substance would be able to carry up to 1000 pounds of cargo, proving the buoyancy of the material to be quite incredible [2]. Unexpectedly this strong material in its crystalline form is transparent, a gel made of microfibrils, as shown in Figure 1. Figure 1: Nanocellulose as a thick paste (http://www.extremetech.com) Greenstreet 3 Nanocellulose with its low weight, high strength and potential transparency is of great interest for many applications in a wide variety of areas. Production methods The extraordinary properties and potential benefits of nanocellulose are clear, so why has the material not taken off yet? When it was first studied in the 1980s, nanocellulose was not commercially viable due to the high cost in manufacturing and the large amount of energy required to delaminate the fibers [3]. In the current production process, cellulose is milled, and then hydrolyzed to remove amorphous regions [4]. The resulting nanocrystalline cellulose (NCC) is then separated and concentrated before being customized for various uses. Homogenizers are used to remove non-cellulose impurities from the wood pulp. The mixture then undergoes a gentle beating which separates the cellulose fibers, creating a thick paste [5]. This paste can be shaped and readily used. One company has created fiber pre-treatment methods, by which energy consumption can be reduced up to 98% [6]. In an alternative approach just being introduced, biogenetically altered algae can naturally create the nanocellulose while simultaneously helping to address our energy issues by producing biofuel. Genetically modified algae Scientists have genetically engineered blue-green algae with genes from Acetobacter xylinum, a vinegar bacterium that naturally secretes nanocellulose in a culture medium Greenstreet 4 [5]. Figure 2 shows algae being cultured in a science beaker. Figure 2: Cyanobacteria cultured in specific media (http://commons.wikimedia.org) R. Malcolm Brown, Jr., Ph.D. is the lead scientist on this project. Brown, along with his colleagues, has sequenced the first nanocellulose-producing genes from A. xylinum. He was also able to pinpoint the genes that are involved in polymerizing nanocellulose [5]. Despite this discovery, there have been a variety of drawbacks making this bacterium unsuccessful at producing a successful yield needed to produce commercial amounts of nanocellulose. Instead, Brown and his team turned to blue-green algae, which when engineered with the A. xylinum genes are able to produce a long-chain or polymer form of the nanocellulose material [5]. This incredibly sustainable approach is based upon fermentation tanks that require only water, sunlight, and algae. This new approach offers the potential to create organic factories capable of making nanocellulose on an industrial scale. Greenstreet 5 Genetically altered cyanobacteria are entirely self-sustaining. Like any other plant, they consume carbon dioxide as they grow, producing their own food from sunlight while absorbing carbon dioxide emissions from the atmosphere. In fact, these algae have been shown to thrive on smokestack emissions [7], and for highest productivity actually require access to significantly increased concentrations of CO2 [8]. The required CO2 can be supplied through the establishment of binary facilities, where the algae growth utilizes combustion gasses bubbled into their growth tanks from the smokestacks of a factory or power plant, instantly sequestering the associated greenhouse gas. A further benefit of using genetically modified algae to produce nanocellulose is that a major byproduct is biofuel oil [5]. In the past, production of nanocellulose consumed large amounts of energy. Now, because one of the major byproducts of nanocellulose production through algae is biofuel, the results are a net increase in available energy. Projected biodiesel production rates, given by Pike Research in a report for AEEI, are claimed to be as high as 6500 gallons of fuel per acre per year, in comparison to ethanol plants, which produce only 450 gallons per acre per year. Clearly this is an advancement in production and should allow nanocellulose use to rapidly advance beyond current applications in the food, biomedical, and cosmetics industries into more high-tech composite materials. Future of nanocellulose Nanocellulose has only recently become a viable commercial material – this year (2013) in fact following the refinement of the blue-green algae production process. However there is already a huge range of potential applications of this material, and there are more applications coming forward almost daily. It is a solution looking for more problems to Greenstreet 6 solve. As a construction material it can be used in place of fiberglass to make 10% lighter auto components, thus creating a proportional reduction in vehicle fuel consumption [10]. In the medical field the potential is enormous, both for the construction of new body parts, and also as a scaffolding for the re-growth of cartilage, bone, and vascular components. It can also be used for arthritis joint relief, and in making nanochitosan for the instant clotting and sealing of traumatic wounds on the battlefield and in emergency response [9]. And its potential is not constrained solely to the scientific field. It has potential in the commerce. One of the most profitable applications may be in the food industry, where the incorporation of nanocellulose into products offers the potential for a wide range of new low-calorie alternatives such as fluffier, fiber-enhanced, ice cream. The cosmetics industry will also benefit from new wrinkle-reducing products using nanocellulose [9]. Even further into the future, NCC offers the potential for the creation of a whole new class of transparent nanomaterials. Wonder Material It seems that every few years an eager group of engineers announces a new “wonder material” which then fades into obscurity. This is unlikely to happen with nanocellulose. With its flexibility, strength, and transparency, nanocellulose is poised to have longreaching effects upon many industries. With the introduction of genetically modified algae, the production of nanocellulose can now not only address commercial needs, but also help the current issue of greenhouse gas emission, providing benefits in carbon sequestration and biofuel production that will ultimately help to reduce global warming. With further publication and funding nanocellulose appears destined to gain widespread support and enter large-scale production. Greenstreet 7 References [1] "Applications of Nanocellulose" StudyMode.com. 01 2012. 01 2012 <http://www.studymode.com/essays/Applications-Of-Nanocellulose899911.html>. [2] Anthony, Sebastian. "Nanocellulose: A Cheap, Conductive, Stronger-than-Kevlar Wonder Material Made from Wood Pulp." ExtremeTech. N.p., 23 Aug. 2012. Web. 10 Apr. 2013. [3] Turbak, A. F. Naylornetwork.com. Rep. N.p., n.d. Web. 10 Apr. 2013. [4] Simončič, Barbara. Biodegradation of Cellulose Fibers. New York.: Nova Science, 2010. Print. [5] American Chemical Society (ACS) (2013, April 7). Engineering algae to make the 'wonder material' nanocellulose for biofuels and more. [6] "Nanocellulose." Innventia. N.p., n.d. Web. 10 Apr. 2013. <http://www.innventia.com/en/Our-Expertise/New-materials/Nanocellulose/>. [7] Toor, Amar. "Can We Grow a Stronger-than-steel 'wonder Material' to save the World?" The Verge. Vox Media, 8 Apr. 2013. Web. 10 Apr. 2013. [8] All About Algae. Rep. no. DE-EE0003118. Algae Biomass Organization, n.d. Web. 13 Apr. 2013. [9] "Applications." CelluForce. N.p., n.d. Web. 10 Apr. 2013. <http://celluforce.com/en/product_applications.php>. [10] Turbak, A.F.; F.W. Snyder, and K.R. Sandberg (1983). "Microfibrillated Cellulose, a New Cellulose Product: Properties, Uses, and Commercial Potential." In A. Sarko Greenstreet 8 (ed.) Proceedings of the Ninth Cellulose Conference, Applied Polymer Symposia, 37, New York, N.Y., USA: Wiley. pp. 815–827. ISBN 0-471-88132-5.