Materials from nanocellulose

advertisement

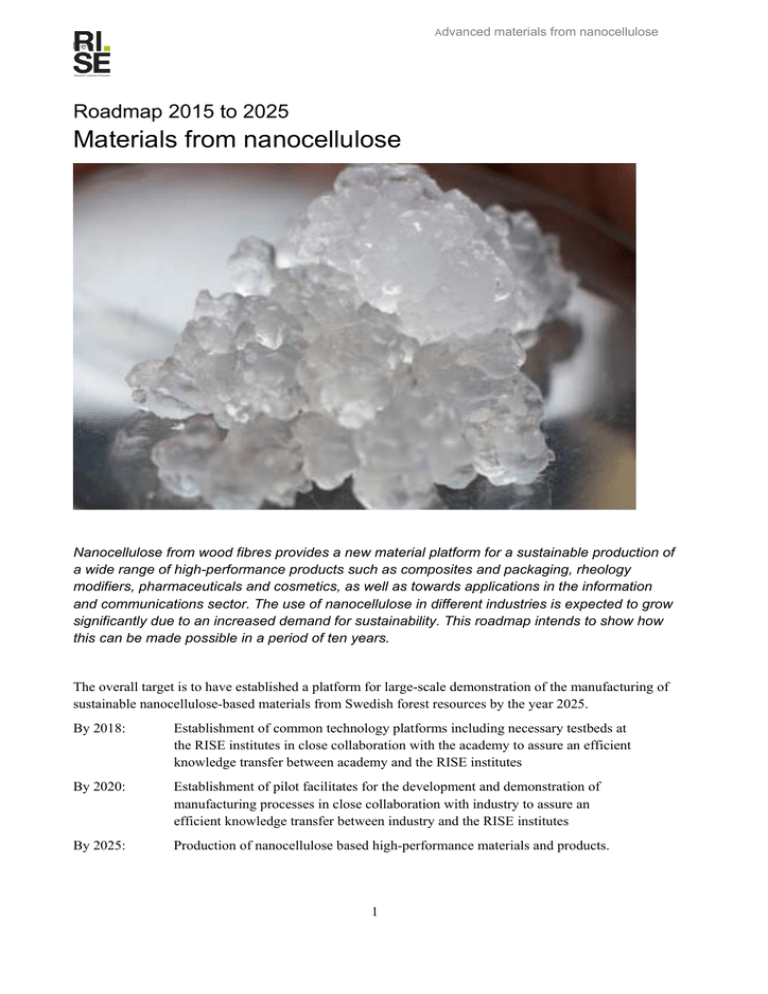

Advanced materials from nanocellulose New Roadmap 2015 to 2025 Materials from nanocellulose Nanocellulose from wood fibres provides a new material platform for a sustainable production of a wide range of high-performance products such as composites and packaging, rheology modifiers, pharmaceuticals and cosmetics, as well as towards applications in the information and communications sector. The use of nanocellulose in different industries is expected to grow significantly due to an increased demand for sustainability. This roadmap intends to show how this can be made possible in a period of ten years. The overall target is to have established a platform for large-scale demonstration of the manufacturing of sustainable nanocellulose-based materials from Swedish forest resources by the year 2025. By 2018: Establishment of common technology platforms including necessary testbeds at the RISE institutes in close collaboration with the academy to assure an efficient knowledge transfer between academy and the RISE institutes By 2020: Establishment of pilot facilitates for the development and demonstration of manufacturing processes in close collaboration with industry to assure an efficient knowledge transfer between industry and the RISE institutes By 2025: Production of nanocellulose based high-performance materials and products. 1 Advanced materials from nanocellulose New Background Nanocellulose is the structural building block of plants and is a result of a natural synthesis process that is not entirely understood. The properties of nanocellulose, as a material component, not only depend on its origin but also the production process. This roadmap focuses on nanocellulose originating from trees, specifically cellulose nanofibrils (CNF) and cellulose nanocrystals (CNC) since the pilot and commercial production facilities are planned or already in place in Sweden. The concept of the bio-based economy is today established, and large investments for supporting the development of the bio-based economy are included in Horizon 2020 as well as in the national strategic innovation program BioInnovation. Due to declining demand for printing paper products and an increasing global competition the Swedish forest industry faces significant challenges. There is an urgent need for new value-added products as a means to stay competitive. Nanocellulose is seen as a means to develop the Swedish forest-based industry and nanocellulose have potential applications related to a wide range of societal and industrial needs. Within the packaging industry, there is a trend towards sustainable lightweight packaging combined with a demand for biodegradable materials, particularly for food packaging applications. These demands are partly driven by legislation, e.g. to even ban non-biodegradable plastic materials. Within the information and communication industry, there is constant need for enhanced and new functionalities through new materials. Within the automotive industry, there is a constant need to develop new materials that contribute to the reduction of greenhouse gas emissions as a result of the reduced weight of the vehicles, as well as new materials that can be recycled. Within the building industry, there is a need to reduce greenhouse gas emissions, either by an increased use of bio-based, recyclable and lightweight building materials or by decreasing the energy consumption during the lifetime of a building by the use of novel materials with improved insulation properties. Within industries relying on formulations, such as the chemical, pharmaceutical, cosmetics, pulp & paper and food industries, there is a large incentive for bio-based, recyclable and safe products. Today´s commercial situation for Nanocellulose Cellulose nanofibrils can be produced by disintegration of wood fibres by the application of mechanical shear and/or pressure before and/or after a chemical or enzymatic treatment. Today cellulose nanofibrils are produced on an industrial scale for commercial applications by for example StoraEnso and UPM. A recent announcement of an investment in an industrial scale facility for commercial applications has been made by Borregaard. 2 Advanced materials from nanocellulose New In terms of pilot-scale facilities, there are today more than a dozen pilots, primarily in USA/Canada, Europe and Japan, all erected after Innventia inaugurated their pilot facility for the production of cellulose nanofibrils 2011. Cellulose nanocrystals (CNC) are different from cellulose nanofibrils, as an example it can form liquid crystalline dispersions. Cellulose nanocrystals are typically produced by acidic hydrolysis of cellulose fibrils and gives high transparency. The chemical production process gives a lower yield and has a demanding chemical recovery cycle. Today Cellulose nanocrystals are produced in industrial scale for pre-commercial development by Celluforce Inc. in Quebec, a Canadian company linked to Domtar and FPInnovations and at American Process Inc. in the US. SEM image of CNC, Majoinen, Kontturi, Ikkala and Gray, Cellulose (2012) 19:1599-1605. Image of a CNF gel. Possible commercial applications using nanocellulose have been developed to very different degrees and several are in a pre-commercial stage. Within the papermaking industry cellulose nanofibrils are today used to make lighter and stronger paper and paperboard products. Potential future applications There are several potential markets for nanocellulose based materials, where envisaged applications include low-end large-scale commodity applications in the pulp and paper sector (strength additives and barrier/coating applications), mid-range applications (food additives and structural materials) and highend applications (substrates for printed electronics and batteries). These applications have different demands on the nanocellulose and, hence, require different process designs. Barriers for food packaging The packaging industry faces an increasing demand for cost-effective biodegradable materials for packaging applications, particularly for food packaging. Nanocellulose can be used to make films or to coat packaging materials to provide biodegradable barriers with adequate oxygen permeability and protection against grease penetration. 3 Advanced materials from nanocellulose New Flexible electronics The information and communication industry faces an increasing demand for printed electronics, solar cells, OLEDS, transistors and other electronic components requires new types of thin polymer films which can be used in roll-to-roll production. Nanocellulose can provide films that have high strength, nano-scale smoothness, optical transparency, low coefficient of thermal expansion but the films are sensitive to moisture. Image of a CNF film. Moulded composites The automotive industry has a never-ending need to develop stronger lightweight vehicles and an important part of this is to develop injection moulded components that are lighter than today and preferably recyclable. Nanocellulose has the potential to be used to manufacture reinforced injectionmoulded composites having significantly improved mechanical properties. Transparent composites The information and communication industry, the building industry and the automotive industry all have a demand for lightweight transparent materials with good thermal stability. Nanocellulose can be used as reinforcement in transparent composites due to the size of the fibrils and crystals. The nanocellulose can also be surface modified by e.g. grafting to provide a wide range of additional functionalities. Insulation materials The building industry is facing an imminent need to mitigate from expanded polystyrene foams for insulation applications due to environmental concerns. In the form of aerogels or reinforced foams nanocellulose has the potential to provide a biobased and biodegradable alternative by providing excellent mechanical structural integrity as well as excellent thermal and sound insulation properties. Structural materials in buildings The building industry has a need to develop new concepts for improving the building process as well as to reduce the transportation need of material. Nanocellulose in the form of cellulose nanocrystals can be used as a so called superplasticizer in cement allowing it to be produced, transported and pumped at higher solids content and with more uniform particle distribution, which also leads to a stronger material. 4 Advanced materials from nanocellulose New Technical fibres The automotive industry needs to develop high performance structural materials at the lowest possible weight, which today is achieved using composites reinforced with woven fabrics. Today it is possible to spin continuous strong and stiff fibres directly from nanocellulose suspensions, which could be used as a biodegradable alternative to today’s woven reinforcement fabrics. Rheology modifiers and hydrogels The industries relying on formulations have a need for bio-based alternatives as well as to develop products with improved or new properties. Nanocellulose offers unique properties in hydrogels, thickeners and various other formulation applications. Specific product examples could be food additives, wound dressing and lotions. Compared to cellulosic derivatives now commonly used in the area of thickeners, nanocellulose can be more cost efficient and introduce new properties. Challenges There is a set of challenges that needs to be addressed as a part of the development of nanocellulosic materials. The moisture sensitivity of nanocellulosic materials must be alleviated if nanocellulose should have a significant role in packaging materials as well as in many high-end applications. Furthermore, the high aspect ratio of the fibrils makes nanocellulose a gel already at low concentrations. The capacity to remove water while manufacturing different material components will be a challenge in many applications as well as the dispersion, which will be a challenge, particularly when used in composite applications. Basic research is imperative to identify solutions and new research and development infrastructure will be needed. The technology platforms for the economically efficient production of films, aerogels and filaments are today lacking. Current and future technology development at the RISE-institutes Production of CNF in pilot scale TRL 6 Production of CNC in pilot scale TRL 4 Technologies for development of films TRL 3 Technologies for spinning of nanofibrillated cellulose TRL 2 Technologies for development of nanocellulose-based composites TRL 4 Technologies for development of nanocellulose based aerogels TRL 2 Technologies for formulations TRL4 TRL stands for Technology Readiness Level which is an indication of the technology matureness, low number indicates a low matureness. 5 Advanced materials from nanocellulose New Production of cellulose nanofibrils (CNF) In recent years Innventia has received considerable attention for its activities in the field of nanocellulosebased materials. For example, Innventia was first to operate a pilot plant for production of cellulose nanofibrils (CNF). Today it possesses several base patents for production and utilization of nanocellulose materials in different industrial applications. Innventia has the capability of producing cellulose nanofibrils from a wide range of sources, and also the know-how of functionalizing the nanocellulose. Innventia are developing and tailoring new qualities suitable for different applications. Production of cellulose nanocrystals (CNC) SP presently invests in a pilot facility for the production of cellulose nanocrystals together with an industrial consortium. The facility will be located close to SP’s facilities in Örnsköldsvik, Sweden. The overall aim of his facility is to provide tailor-made cellulose nanocrystals for projects at a wide range of Technology Readiness Levels in such quantities and given specified qualities to allow relevant prototyping and testing in various fields of application. The facility will be flexible enough to allow development of both process and application oriented projects. The commissioning of the facility is planned to take place first half of 2016. Transparent films for barriers and flexible electronics There are several different routes for the manufacturing of nanocellulose based films. The choice of production process will influence the final properties of the film. Innventia are currently working together with several industrial companies to identify and implement technologies for pre-pilot production of nanocellulose based films. The development of a test bed that allows a flexible manufacturing and evaluation of different types of nanocellulose-based films would be a crucial step towards commercialisation. Spinning of nanofibrillated cellulose The technical possibility to spin fibres directly from nanofibrillated cellulose has been shown at several locations around the world. One process that stands out in terms of achieving high mechanical performance is hydrodynamic alignment by flow focusing concept. A consortium of RISE-institutes, industry and a university (KTH) is currently working together in a project with the aim to scale-up the technology. A crucial step that significantly would facilitate scale-up and enable a critical evaluation is an open test bed for production of filaments from nanofibrillated cellulose within the RISE group. Processes for nanocellulose‐based composites The field of biobased composites is a focus area at Swerea. Swereas main role is to evaluate and improve processing capabilities as well as to evaluate and improve composite properties of these materials in order to lower the barriers for market entry of these materials. One area of special importance for the biobased materials is durability and the long-term properties. Special methods have been developed in order to be able to evaluate and predict these properties. In addition, Swerea has an extruder with following injection moulding equipment that can be used for the purpose of developing CNF reinforced composites. Innventia is exploring the field of composites reinforced with cellulose nanofibrils. In order to utilize the full potential of nanocellulose as reinforcement the technology for dispersion of cellulose nanofibrils in the composite matrixes needs to be developed. Innventia has an extruder with injection moulding 6 Advanced materials from nanocellulose New equipment that together with the cellulose nanofibril material produced at the pilot production unit can be adopted for the purpose of developing CNF reinforced composites. Nanocellulose‐based aerogels Aerogels are highly porous materials that can have very low densities, high surface areas, low thermal transport and have the potential to be engineered into a wide variety of application for insulation, cushioning materials etc. A potentially large-scale application is to replace expanded polystyrene (EPS) foams with biodegradable foams. Innventia is exploring possibilities for producing biodegradable aerogels, in a cost-competitive manner, based solely on nanocellulose or with nanocellulose as a reinforcing agent. One approach that is deemed viable and that is studied in more detail is to foam a biodegradable thermoplastic that has been reinforced with nanocellulose. Formulations New technologies are needed to enable a wide-spread use of nanocellulose in the formulation area. Technologies that are of importance are wet and dry surface modification techniques such as adsorption, chemical reactions or plasma, emulsification and dispersion, particle engineering etc. Most of these technologies and corresponding state-of-the-art instrumentation is available at the RISE-institutes. Efforts needed to reach the targets Innventia was the first company in the world to establish manufacturing of nanocellulose in larger scale. This step was possible thanks to long-term research funding from industrial and public stakeholders. The access to a large volume production of nanocellulose under the same roof as a pilot paper machine made it possible to demonstrate the use of nanocellulose as a property enhancer for the manufacturing of paper and paperboard, and it is also as such it is used industrially today. For most other applications, the time to market is still considered to be long, and it should be noted that for these applications neither the necessary knowledge nor the infrastructure is in place. To promote the commercial introduction of new and exciting high-performance materials and products made from nanocellulose, a continued investment in basic research, as well as a strong industry involvement supporting scale-up activities, is needed. Significant financial resources will also be needed since new materials typically imply new processes, which in turn imply a need for testbeds and demonstration facilities. By having these facilities in place, Sweden can maintain a strong position with respect to the development of future nanocellulosic materials. Sources 1. Shatkin, J. A., et al. (2014). "Market projections of cellulose nanomaterial-enabled products-Part 1: Applications." Tappi Journal 13(5): 9-16. 2. Shatkin, J. A., et al. (2014). "Market projections of cellulose nanomaterial-enabled products-Part 2: Volume estimates." Tappi Journal 13(6): 57-69. 3. Markets and Markets. "Nanocellulose market – Regional trends & Forecast to 2019." Chemicals & materials CH3320 (2015). 7 Advanced materials from nanocellulose New Contacts Main contact Anna Wiberg Innventia anna.wiberg@innventia.com +46 768 767361 Tom Lindström Innventia tom.lindstrom@innventia.com +46 768 767370 Marielle Henriksson SP marielle.henriksson@sp.se +46 10 5166258 Agne Swerin SP agne.swerin@sp.se +46 10 5166031 Bengt Hagström Swerea bengt.hagstrom@swerea.com +46 31 7066362 Birgitha Nyström Swerea birgitha.nystrom@swerea.com +46 911 74409 Authors and contributors The RISE Research Institutes of Sweden - Innventia, SP, Swerea and Swedish ICT - are a major R&D player in the bioeconomy sector, with a combined annual turnover in the field of 800 million SEK (85 million €). During 2014-2015 the activities were reviewed in the RISE-project RISE Bioeconomy. Areas with the greatest growth potential were identified and strategies for how to move forward were published in the following eight roadmaps for the period 2015-2025: The pulp mill biorefinery Textile materials from cellulose Advanced material from nanocellulose Bio-based composites Lignin-based carbon fibres Biofuels for low-carbon steel industry Food industry and pulp mill symbiosis Sensors for increased resource efficiency