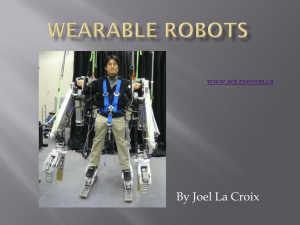

FORTIS Presentation DoD Technology Showcase

advertisement

Relief for the Daily Grind Keith Maxwell Lockheed Martin Keith.Maxwell@lmco.com O: 407-356-2831 C: 407-620-2289 What is the FORTIS® Exoskeleton? − The FORTIS® Exoskeleton is an anthropomorphic structure that provides an alternate load path to the ground for a suspended load • Enhancing human strength, endurance and productivity − The FORTIS® Exoskeleton is an passive exoskeleton that relies on mechanical advantage to transfer load to the ground • Passive means the system is actuated by the human in the system and has no batteries − The FORTIS® Exoskeleton relieves musculoskeletal stress on the human body • Reducing the operator’s fatigue, increasing productivity and decreasing risk of injuries − The FORTIS® Exoskeleton is safe and easy to operate • The user cannot move in an unintended or unnatural manner The FORTIS® Exoskeleton System Design − Structure: • Weighs less than 27 lbs. (12.3 kg) • Supports tools up to 36 lbs. (16.3 kg) • Aluminum Frame Torso Frame Counterweights − Features: • Fits users from 5’4” to 6’3” tall (1.64 to 1.95 m) • Transfers load at the feet when standing or the knees for when kneeling • Quick, tool-free adjustability • Anthropomorphic joints • No pinch points • Designed for single operator use and adjustment • Designed to be comfortable for men and women • Designed for 24-hour operation in salt spray with daily wash down and regular maintenance • Easy to operate, minimal training required • Affordable Torso Harness Counterweight Arm Arm Mount Hip Frame Hip Joint Waist Strap Leg Frame Knee Support Knee Joint Calf Strap Ankle Joint Foot Strap Foot Support The FORTIS® Arm System Design − Structure: • Weighs less than 10 lbs. (4.5 kg) • Supports tools up to 50 lbs. (22.7 kg) • Aluminum/Stainless Frame − Features: • • • • • Adjustable for light to heavy tools Quick, tool-free adjustability Locking joints for hands-free stability No pinch points Can be mounted to the FORTIS® Exoskeleton, stand or fixed workstation • Designed for 24-hour operation in salt spray with daily wash down and regular maintenance • Greater functionality, more affordable than similar products The FORTIS® Exoskeleton Features Easily adjustable harnessing, leg height and hip width User is able to walk up and down stairs or kneel The FORTIS® Exoskeleton Applications Routing Drilling Riveting With minimal modification, integrates with current processes and tools of many maintenance, manufacturing, and support operations Grinding Sand Blasting Painting FORTIS’s Versatility Offers Endless Possibilities for Industrial Applications U.S. Navy Industrial Exoskeleton Trials − Many jobs require workers to operate heavy tools that put them at risk − Impacts to Total Ownership Cost / Productivity / Injury Rates − Trials on overhead grinding • Augmented workers performed sustained overhead grind for 25 minutes, where unaugmented users required 21 breaks per 25-minute period • Significant quality improvement were seen when augmented • Enabled a user with a muscular-skeletal disease to perform task he was previously unable to perform − Trials to remove SHT tiles on submarine hull using heat induction tools • Augmented workers demonstrated increased productivity by enabling a 2worker team to equal the production of a 3-worker team • Improves worker ergonomics and significantly reduces worker fatigue • Performed effectively in a wide array of work environments (unstable footing, loose impediments, rain, wind and cold) Exoskeleton-augmented workers reported a 66% reduction in fatigue when an using an exoskeleton vs. no augmentation Demonstrated Potential to Shorten Dry-Dock Period with Productivity Enhancements Commercial Industrial Experience • FORTIS® has found a home in the Commercial Aerospace, Heavy Construction, Automotive and Shipbuilding/Repair Industries. • Return on Investment validated through increased productivity and injury avoidance. • Environmental Safety and Health has identified FORTIS® as a technology that reduces worker fatigue. • FORTIS® expands the labor pool; potentially extending the careers of skilled workers, opening/expanding career opportunities to all skilled workers. • “FORTIS® Works.” FORTIS® Awards & Recognition The Defense Manufacturing Excellence Award 2014 The Industrial Gold Spark Award 2014 Good Green Design Green 100 Award 2015 Reddot Best of the Best Award Industrial Category 2015 Coolest Gadgets of 2014 Product Design of the Year 2014 But we aren’t done yet… Introducing FORTIS® v3.0 • FORTIS® 3.0 now includes the FORTIS Tool Arm in price and FORTIS® v 3.0 is more affordable than ever before • Tool Arm has Patented Locking Mechanism at Each Joint • Suspends up to 36 lbs on FORTIS™ and 50 lbs Bench Mounted • No Pinch Points, Easy Adjustment, Less Expensive than Comparable Alternatives • Increased Agility • Walk, Kneel, Squat, Run…. Dance… if you want to! • Simplified Operation • 30 Minute Training Time • One Person Operation • Tool Free Adjustment • Don in Under 1 Minute Unassisted • Doff in Under 15 Seconds Unassisted • Reduced Cost • Improved Manufacturing Processes • Reduced Part Count Why DoD Should Buy The FORTIS® Exoskeleton? − Proven technology – U.S. Navy (NAVSEA PSNSY/NNS/PNSY and NAVAIR Advanced Designs for Aircraft Maintenance) test reports conclude that workers augmented with Lockheed Martin exoskeleton technologies are: • More Productive – extending time on task by up to 27 times without requiring rest • Less Fatigued – workers report feeling 66% less fatigued than when doing the same job without Lockheed Martin exoskeleton augmentation • More Effective – Navy Quality Assurance reported that augmented workers delivered better quality work with fewer defects, requiring less rework than unaugmented workers − Reduced risk of musculoskeletal injury • Reduced load on muscles • Reduced vibration from tools − Greater job satisfaction • Augmented workers feel valued for craftsmanship rather than brute strength • Less expensive to own and operate than powered exoskeletons Questions and Answers