week5_mag

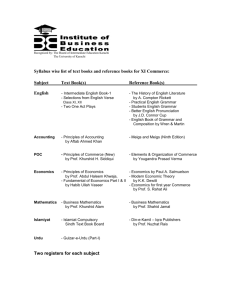

advertisement

Spring, 2007

ISE 102

Capacity Decisions

Mahmut Ali GÖKÇE

Industrial Systems Engineering Dept.

İzmir University of Economics

Week 1

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

www.izmirekonomi.edu.tr

1

Spring, 2007

Review of Past Four Weeks

Overview of Manufacturing (Service) Systems

Problems and Methods

Our job is (generally speaking) making the best

decision

i.e., optimization;

Parameters of the model - acquire data

Constraints – rules to be satisfied

Objective function – define the best

Solution Techniques – methodology to be used

Forecasting – Generate data (it is a problem as well!)

LP – A Simple solution technique

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

2 of 52

www.izmirekonomi.edu.tr

Spring, 2007

This Week

Capacity decisions

Developing Alternatives - Considerations

Using Cost-Volume Analysis to make decisions

Make or buy decisions

Decision Trees as a methodology to help making

decision under uncertainty

Location decisions

Things to be considered

Using Cost-Volume Analysis to make decisions

Transportation Model

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

3 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Hierarchy of Decision Problems

Strategic Decisions

Location, capacity, new product, layout design,

etc.

Horizon: years

Tactical Decisions

Allocation, production planning, inventory, etc.

Horizon: months-year

Operational Decisions

Scheduling, vehicle routing, assignment, etc.

Minutes-hours-days

Note that the “design” decisions will be an input for

“operational” problems

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

4 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Capacity Planning

Capacity can be defined as is the productive capability of a

facility, usually measured as a quantity of output per unit of

time

Strategic capacity planning is an approach for determining the

overall capacity level of capital intensive resources, including

facilities, equipment, and overall labor force size.

The basic questions in capacity handling are:

What kind of capacity is needed?

How much is needed?

When is it needed?

Management must review product and service choices

periodically

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

5 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Three Levels of Capacity Planning

Long-term

Physical

Medium-term

Workforce planning

Short-term

detailed planning &

control

Our focus now is longterm

.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

6 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Capacity Decisions are Important

•

•

•

•

•

•

Impacts ability to meet future demand – under capacity

Affects operating costs – excess number of workers

Major determinant of initial costs – fixed cost

Involves long-term commitment – design decision

Affects competitiveness – delivery speed

Affects ease of management – over capacity

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

7 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Performance Measures

Think of Your Typical Daily Schedule!

• Design capacity

– maximum obtainable output

• Effective capacity

– maximum capacity given product mix, scheduling

difficulties, and other doses of reality.

• Actual output

– rate of output actually achieved--cannot exceed

effective capacity

Efficiency = Actual Output

Effective capacity

Utilization = Actual Output

Design capacity

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

8 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Efficiency/Utilization Example

Design capacity = 50 trucks/day

Effective capacity = 40 trucks/day

Actual output = 36 units/day

Efficiency = Actual output

= 36 units/day

Effective capacity = 40 units/ day

= 90%

Utilization = Actual output

= 36 units/day

Design capacity = 500 units/ day

= 72%

Note that higher utilization is not always desired! Why?

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

9 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Capacity – Developing Alternatives

• Before making strategic capacity decisions managers must

consider;

• Design flexibility into systems

• Provisions for future expansions – adjacent land

• Take a “big picture” approach to capacity changes

• Extra rooms for the hotel requires extra parking lots

• Prepare to deal with capacity “chunks”

• Can’t buy buses with 35 seats; must be 48!

• Attempt to smooth out capacity requirements

• Complementary products – heating and AC.

• Identify the optimal operating level

• Economies of Scale and Diseconomies of Scale

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

10 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Economies & Diseconomies of Scale

Average cost per unit

Production units have an optimal rate of output for minimal cost.

Minimum

cost

0

Figure 5-3

Rate of output

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

11 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Economies & Diseconomies of Scale

Average cost per unit

Figure 5-4

Minimum cost & optimal operating rate are

functions of size of production unit.

0

Small

plant

Medium

plant

Output rate

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

Large

plant

Q* (What about Demand?)

12 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Capacity – Evaluating Alternatives

• One must examine different alternatives from different

perspectives. Most obvious ones are economical

consideration. Will it be feasible? Also one must consider

public opinion.

• A number of techniques are going to be discussed from an

economical stand point

• Cost-Volume analysis

• Decision analysis

• Financial analysis

• Waiting line analysis.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

13 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Cost-Volume Analysis

• Focuses on relationships between cost, revenue and the

volume of the output.

• The idea is to estimate the income of the company under

different operating conditions and select the most

appropriate one.

• First step is identifying the all costs

• Fixed costs (FC) : Tend to remain constant regardless of

the volume of output; cost of land, heating, property tax,

etc.

• Variable cost (VC) : Vary directly with volume of output;

raw materials, labor, etc. {VC=Q*v – where v is variable

cost per unit)

• Total Cost (TC) =FC+VC

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

14 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Cost-Volume Analysis

• Revenue per unit(R) is the price of the product.

• Total Revenue (TR) = R*Q

• Profit (P) = TR – TC = R*Q – (FC + Q*v)

• Rearranging the terms:

P = Q(R-v) – FC

• Q where we have no loss or no profit is known as

breakeven point.

• A figure worth hundred words…

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

15 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Cost-Volume Relationships

Amount ($)

Figure 5-5a

Fixed cost (FC)

0

Q (volume in units)

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

16 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Cost-Volume Relationships

Amount ($)

Figure 5-5b

0

Q (volume in units)

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

17 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Cost-Volume Relationships

Amount ($)

Figure 5-5c

0

BEP units

Q (volume in units)

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

18 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Cost-Volume Analysis

• Capacity alternatives may involve step costs, e.g., a firm may

have the options of purchasing one, two or three machines, with

each machine fixed costs increases, perhaps not linearly.

• Potential volume would depend on the number of machines

purchased: implication is multiple break-even quantities.

• Example:

• A manager has the option of purchasing one, two or three

machines. Fixed costs and potential volumes are as follows:

MC#

1

2

FC

Capaci

$9600 ty

$1500 301

0 to 0

600

300

Asst. Prof. Dr.

Izmir University

of Economics

3Mahmut Ali GÖKÇE,

$2000

601

Week 1

0

900

Variable cost is $10

Revenue is $ 40

19 of 52

www.izmirekonomi.edu.tr

Break-Even Problem with Step Fixed

Costs

Spring, 2007

Figure 5-6a

3 machines

2 machines

1 machine

Quantity

Step fixed costs and variable costs.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

20 of 52

www.izmirekonomi.edu.tr

Break-Even Problem with Step Fixed

Costs

Spring, 2007

Figure 5-6b

Number of

Machines

to be

bought

should be

decided

based on

sales

forecast.

BEP

$

BEP

TC

TC

TC

3

2

1

Quantity

Step fixed costs and variable costs.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

21 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Make or Buy?

Sometimes a company requires “temporary” increase in the

capacity.

Such situations are handled with over time working, hiring

more workers, etc. if the extra capacity needed (or constrained

resource – or bottleneck resource) is labor force.

Another possibility is outsourcing the production to external

companies. This might be helpful particularly if extra machining

hours is needed. Rather than investment on new machines it

might be better to “rent” it.

Cost volume analysis is helpful for these decisions.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

22 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Cost-Volume-Profit Analysis Example

Alto, Inc. is planning to introduce a new model of

student saxophone which will be sold for $500

each. If they produce it themselves, they will incur

annual fixed costs of $1,000,000 and the variable

cost of production will be $300 per unit. Another

option is to subcontract production to Tenor, Inc. If

they subcontract, then Tenor, Inc. will charge them

$400 per unit.

a. If Alto, Inc. decides to produce the saxophones

themselves, what quantity is required for them to

break even for the year?

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

23 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Cost-Volume-Profit Analysis Example

b. What is the “indifference point” for these two

options? Over what range of volumes would each

option be preferred?

c. If Alto, Inc. decides to produce the saxophones

themselves, by how much would they have to

reduce annual fixed costs in order to reduce their

break-even volume to 3,000 units? Assume that

revenues and variable costs remain the same.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

24 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Decision Making Under Uncertainty

Sometimes the decision maker may not be certain

about the future.

The decision must be done under uncertainty

For our purposes suppose that the uncertainty is

in future demand and represented with certain

probabilities associated with different possible

scenarios.

An example is as follows;

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

25 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Example of a Decision Tree Problem

A glass factory specializing in crystal is experiencing a

substantial backlog, and the firm's management is

considering three courses of action:

A) Arrange for subcontracting,

B) Construct new facilities.

C) Do nothing (no change)

The correct choice depends largely upon demand, which

may be low, medium, or high. By consensus,

management estimates the respective demand

probabilities as .10, .50, and .40.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

26 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Decision Trees

Decision trees are methodologies that help us to

handle these type of problems.

One must first identify alternatives (course of

actions), secondly possible sources of

uncertainties (state of natures) and finally the

payoffs (outcomes).

Note that for each possible course of action and

state of nature there will be a certain outcome.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

27 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Decision Trees

In this problem we have three possible alternatives

Arrange for subcontracting,

Construct new facilities.

Do nothing (no change)

We have three possible states of nature

Medium Demand

Low Demand

High Demand

Suppose that each demand scenario (low, medium, high) is

quantified with a number. Based on these demand values,

fixed cost of new facilities, variable costs with new facilities,

variable cost of subcontracting, and all other necessary data,

we have already calculated a profit for each possible scenario.

These profits are presented in the following “payoff table”.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

28 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Example of a Decision Tree Problem:

Step 1. The Payoff Table

The management estimates the profits when choosing

from the three alternatives (A, B, and C) under the

differing probable levels of demand. These costs, in

thousands of dollars are presented in the table below:

A

B

C

0.1

Low

10

-120

20

0.5

Medium

50

25

40

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

0.4

High

90

200

60

29 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Decision Trees

Next step is constructing the decision trees;

Each decision is represented with a rectangle.

Each alternative is an arc originated from this

rectangle to the right side.

Each chance event is represented with a circle.

Each state of nature is an arc originated from

this circle to the right side.

All relevant data, probabilities, outcomes, etc.

should be presented accordingly.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

30 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Step 2. Draw The Decision Tree

High demand (.4)

Medium demand (.5)

Low demand (.1)

A

High demand (.4)

B

Medium demand (.5)

Low demand (.1)

$90k

$50k

$10k

$200k

$25k

-$120k

C

High demand (.4)

Medium demand (.5)

Low demand (.1)

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

$60k

$40k

$20k

31 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Step 3. Calculate the Exp. Monetary

Values

Third step is known as rolling back the tree.

For each chance event one must determine the

expected monetary values that the chance event

will yield

For each decision node one must select the

decision that yields the highest expected

monetary return.

In our simple example there are three chance

events and after calculating expected return of

these chance events there is only one decision to

be made.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

32 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Step 2. Draw The Decision Tree

High demand (.4)

Medium demand (.5)

$62k

A

B

$80.5k

Low demand (.1)

High demand (.4)

Medium demand (.5)

Low demand (.1)

$90k

$50k

$10k

$200k

$25k

-$120k

C

High demand (.4)

$46k

Medium demand (.5)

Low demand (.1)

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

$60k

$40k

$20k

33 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Step 4. Make decision

High demand (.4)

Medium demand (.5)

$62k

A

B

$80.5k

Low demand (.1)

High demand (.4)

Medium demand (.5)

Low demand (.1)

$90k

$50k

$10k

$200k

$25k

-$120k

C

High demand (.4)

$46k

Medium demand (.5)

Low demand (.1)

$60k

$40k

$20k

Alternative B generates the greatest expected profit, so our

choice is B or to construct a new facility.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

34 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Location Decisions

Week 1

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

www.izmirekonomi.edu.tr

35

Spring, 2007

Location Problem

As the capacity decision, another important design parameter

used as an input in operational decisions (transportationallocation, vehicle routing, inventory, etc.) is the location

decisions.

Some objectives;

Maximize population coverage within an x-mile radius

Minimize or limit the maximum travel distance for a

customer (or raw materials)

Minimize average transportation cost (or customer

travel distance)

Options include, expand existing facilities, add new facilities,

move to a new location or do nothing!

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

36 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Location Decision Factors

Regional Factors

Community

Considerations

Site-related

Factors

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

37 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Regional Factors

Location of raw materials – perishability, transportation

Canning fresh fruits, paper industry near forests, etc.

Location of markets – convenience, responsiveness

Retail stores, restaurants, etc.

Labor factors – cost, availability

High tech firms near metropolitans,

Climate and taxes

Nobody goes to Siberia!

Foreign locations

Less expensive areas, time zone differences in case

of call centers!

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

38 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Community Considerations

Desirability of the community;

Quality of life

Services

Attitudes

Taxes

Environmental regulations

Developer support

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

39 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Site Related Factors

What about the construction sites?

Land

Transportation

Environmental

Legal

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

40 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Multiple Plant Strategies

If the company has several sites may use;

Product plant strategy

Market area plant strategy

Process plant strategy

Multiple Plant

Strategies

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

41 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Manufacturing vs. Service

Considerations

Manufacturing/Distribution

Service/Retail

Cost Focus

Revenue focus

Transportation modes/costs

Demographics:

age,income,etc

Energy availability, costs

Population/drawing area

Labor cost/availability/skills

Competition

Building/leasing costs

Traffic volume/patterns

Customer access/parking

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

42 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Evaluating Locations

Cost-Profit-Volume Analysis

Determine fixed and variable costs for each

alternative

Plot total costs

Determine lowest total costs

Note that the fixed and variable costs

includes all costs, land, labor, transportation, etc.

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

43 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Example 1: Cost-Volume Analysis

Fixed and variable costs for four potential

locations

L o c a tio n

A

B

C

D

F ix e d

C ost

$ 2 5 0 ,0 0

1 0 0 ,0 0

1 5 0 ,0 0

2 0 0 ,0 0

0

0

0

0

V a r ia b le

C ost

$11

30

20

35

How did you come up with these costs in the first

place?

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

44 of 52

www.izmirekonomi.edu.tr

Example 1: Solution for

Output=10,000

Spring, 2007

Fixed

Costs

A

B

C

D

$250,000

100,000

150,000

200,000

Variable

Costs

$11(10,000)

30(10,000)

20(10,000)

35(10,000)

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

Total

Costs

$360,000

400,000

350,000

550,000

45 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Example 1: Solution

$(000)

800

700

600

500

400

300

200

100

0

0

D

B

C

A

A Superior

C Superior

B Superior

2

4

6

8

10

12

14

16

Annual Output (000)

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

46 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Evaluating Locations (cont.)

Transportation Model

Decision based on movement costs of raw

materials or finished goods

Factor Rating

Decision based on quantitative and

qualitative inputs

Center of Gravity Method

Decision based on minimum distribution

costs

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

47 of 52

www.izmirekonomi.edu.tr

Spring, 2007

The Transportation Model

While evaluating the best location alternative we use

costs (fixed and variable). Particularly for multiple plant

cases these costs can be identified after an allocation

decision is made. That is to say we can’t calculate the

cost of transportation from an alternative site to demand

centers before we decide which demand centers are

going to be served by which production site.

This problem is known as allocation problem.

The allocation problem with objective of minimizing the

transportation cost is known as “transportation model”.

Also after a location decision is made transportation

problem must be solved to reduce the distribution costs!

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

48 of 52

www.izmirekonomi.edu.tr

Spring, 2007

The Transportation Model

Requirements:

List of origins and each one’s capacity

List of destinations and each one’s demand

Unit cost of shipping

Assumptions

Items to be shipped are homogeneous

Shipping cost per unit is the same

Only one route between origin and destination

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

49 of 52

www.izmirekonomi.edu.tr

Spring, 2007

The Transportation Problem: An

Example

D

(demand)

S

(supply)

D

(demand)

D

(demand)

S

(supply)

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

Week 1

50 of 52

www.izmirekonomi.edu.tr

Spring, 2007

Transportation Problem

Network Representation (m = 2, n = 3)

1

d1

2

d2

3

d3

c11

s1

c12

1

c13

c21

s2

2

c22

c23

SOURCES

DESTINATIONS

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

www.izmirekonomi.edu.tr

Spring, 2007

Example: BBC

Building Brick Company (BBC) has orders for 80

tons of bricks at three suburban locations as follows:

Northwood -- 25 tons, Westwood -- 45 tons, and

Eastwood -- 10 tons. BBC has two plants, each of

which can produce 50 tons per week.

How should end of week shipments be made to fill

the above orders given the following delivery cost

per ton:

Plant 1

Plant 2

Northwood

24

30

Westwood

30

40

Eastwood

40

42

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

www.izmirekonomi.edu.tr

Spring, 2007

Example: BBC

LP Formulation

Decision Variables Defined

xij = amount shipped from plant i to suburb j

where i = 1 (Plant 1) and 2 (Plant 2)

j = 1 (Northwood), 2 (Westwood),

and 3 (Eastwood)

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

www.izmirekonomi.edu.tr

Spring, 2007

Example: BBC

LP Formulation

Objective Function

Minimize total shipping cost per week:

Min 24x11 + 30x12 + 40x13 + 30x21 + 40x22 + 42x23

Constraints

s.t.

x11 + x12 + x13 < 50 (Plant 1 capacity)

x21 + x22 + x23 < 50 (Plant 2 capacity)

x11 + x21 = 25 (Northwood demand)

x12 + x22 = 45 (Westwood demand)

x13 + x23 = 10 (Eastwood demand)

all xij > 0

(Non-negativity)

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

www.izmirekonomi.edu.tr

Spring, 2007

Example: BBC

Partial Spreadsheet Showing Optimal Solution

A

10

11 Dec.Var.Values

12

13

14

15

16

17

18

19

B

X11

C

X12

D

X13

E

X21

F

X22

G

X23

5

45

0

20

0

10

Minimized Total Shipping Cost

2490

Constraints

LHS

P1.Cap.

P2.Cap.

N.Dem.

W.Dem.

E.Dem.

50

30

25

45

10

RHS

<=

<=

=

=

=

50

50

25

45

10

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

www.izmirekonomi.edu.tr

Spring, 2007

Example: BBC

Optimal Solution

From

Plant 1

Plant 1

Plant 2

Plant 2

To

Amount Cost

Northwood

5

120

Westwood

45

1,350

Northwood

20

600

Eastwood

10

420

Total Cost = $2,490

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

www.izmirekonomi.edu.tr

Spring, 2007

The Transportation Problem

LP Formulation

The linear programming formulation in terms of

the amounts shipped from the origins to the

destinations, xij, can be written as:

Min SScijxij

ij

s.t.

Sxij < si for each origin i

j

Sxij = dj for each destination j

i

xij > 0 for all i and j

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

www.izmirekonomi.edu.tr

Spring, 2007

The Transportation Problem

LP Formulation Special Cases

The following special-case modifications to the

linear programming formulation can be made:

Minimum shipping guarantees from i to j:

xij > Lij

Maximum route capacity from i to j:

xij < Lij

Unacceptable routes:

delete the variable

Asst. Prof. Dr. Mahmut Ali GÖKÇE, Izmir University of Economics

www.izmirekonomi.edu.tr