Site visit checklist (DOCX, 87.3 KB, pages)

advertisement

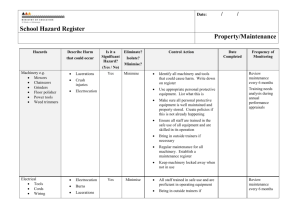

Mentor Program Site Visit Inspection Checklist Workplace Site Visit Business Name: Date: Mentor conducting inspection: This checklist has both a workplace & systems focus. It should be used as a guide for Mentors and Mentees to identify issues for discussion & to assist in the development of the mentee action plan. Consultation Yes / No / Not Applicable Comments Consultation arrangements HSRs elected to represent workgroup/s Yes No N/A WHS Committee formed Yes No N/A Other WHS Consultation arrangements in place Yes No N/A Consultation records kept Yes No N/A What are they? Managing Risk Yes / No / Not Applicable Comments Managing Risk Safety risks are identified Yes No N/A How? Safety risks are assessed & controlled Yes No N/A How? Safe work procedures are developed & implemented Yes No N/A Workers involved in developing safe work procedures Yes No N/A Hierarchy of control is used to eliminate, or minimise risk Yes No N/A Schedule in place to review effectiveness of controls Yes No N/A Working Environment Yes / No / Not Applicable Air Quality Plant & equipment maintained to minimise emissions Yes No N/A Airborne contaminants released during a work process Yes No N/A If yes, local exhaust ventilation is used to control these contaminants Yes No N/A Ventilation & air conditioning systems serviced & maintained in a safe condition Yes No N/A Electrical equipment tested & tagged in hostile working environments Yes No N/A If yes, register of tagging current Yes No N/A Electrical Comments Electrical equipment maintained in safe operating condition Yes No N/A Electrical equipment regularly inspected & maintained Yes No N/A First aid kit provided Yes No N/A Kit stocks refreshed Yes No N/A All workers have access to first aid equipment Yes No N/A First Aid Officer available Yes No N/A Facilities available to administer first aid Yes No N/A Emergency procedures in place Yes No N/A Emergency contacts displayed Yes No N/A Fire extinguisher / equipment available & suitable for the types of risk at the workplace Yes No N/A Fire extinguisher / equipment regularly inspected Yes No N/A Used when required Yes No N/A Correctly used by workers Yes No N/A Preventative maintenance in place Yes No N/A Maintenance records provided Yes No N/A Operator ticketed / competency verified Yes No N/A Procedures developed & followed Yes No N/A First Aid / Emergency / Injury Personal Protective Equipment Plant & Equipment Training All workers have: General industry (safety awareness) training Yes No N/A Site specific induction training Yes No N/A Task specific training Yes No N/A High Risk Areas Yes / No / Not Applicable Hazardous Chemicals / Dangerous Goods All hazardous chemicals / dangerous goods identified Yes No N/A Register current Yes No N/A Safety Data Sheets available Yes No N/A All hazardous chemicals / dangerous goods correctly labelled Yes No N/A Ignition sources are controlled Yes No N/A Workers are provided with adequate information, training, instruction and supervision Yes No N/A All hazardous manual tasks are identified Yes No N/A All HMT are eliminated or controlled effectively Yes No N/A Procedures are implemented & followed Yes No N/A Hierarchy of control is used to eliminate, or minimise risk Yes No N/A Hazardous Manual Tasks (Manual Handling) Comments Noise Noisy works are identified Yes No N/A At risk workers are identified Yes No N/A Noise control measures are identified for implementation &/or existing control measures checked Yes No N/A Hearing protection frequently used as a control measure Yes No N/A If yes to hearing PPE, audiometric testing is conducted Yes No N/A Hierarchy of control is used to eliminate, or minimise risk Yes No N/A Work area, walkways & stairs well lit Yes No N/A Walkway / stairs / work area clear Yes No N/A Floor surfaces are free of water, ice or other fluids Yes No N/A Floor surfaces are even Yes No N/A Handrails on stairs are adequate Yes No N/A Access paths defined (signage tape, other) Yes No N/A Prohibited areas display warning signs and barricaded Yes No N/A Workers are at risk of falling from one level to another Yes No N/A Fall hazards are identified Yes No N/A Fall hazards are eliminated or controlled effectively Yes No N/A Hierarchy of control is used to eliminate or minimise risk Yes No N/A Slips Trips & Falls Workers Compensation & Return to Work Yes / No / Not Applicable Comments Workers Compensation & Return to Work Procedures in place to report safety issues & incidents Yes No N/A Injuries are reported to Insurer within 48 hours Yes No N/A Workers Compensation policy current & accurate Yes No N/A Suitable duties are provided to injured workers if they have capacity to work Yes No N/A Useful reference: The following is a link to Codes of Practice on Safe Work Australia’s website. Codes of practice are practical guides to achieving the standards of health, safety and welfare required under the Work Health and Safety (WHS) Act and the WHS Regulation. http://www.safeworkaustralia.gov.au/sites/swa/legislation/model-cop/pages/model-cop.aspx