Safety Training

advertisement

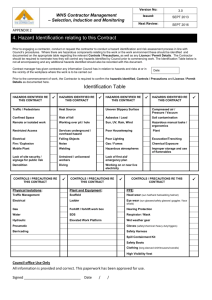

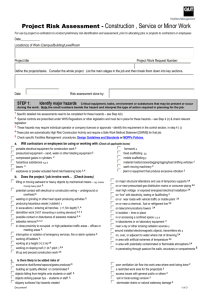

Safety Training Laurel Sand & Gravel Inc. & Affiliates TRAINING PLAN By Classification QUARRY- NEW MINER Savage Stone 2 1 . INTRODUCTION TO THE WORK ENVIRONMENT Note: Must be done before miner begins work. Do this on day 1 2 2 . Recognition and avoidance of HAZARDs Note: Must be done before miner begins work. Do this on day 1 .5 Emergency medical procedures, Escape and emergency evacuation plans and instruction on the fire warning signals and fire fighting procedures Note: Must be done before miner begins work. Do this on day 1 . 5 STATUTORY RIGHTS OF MINERS AND REPRESENTATIVES 3 . 4 . Note: Must be done before miner begins work. Do this on day 1. [LS1] Part 46 Page 2 of 8 Employee will recognize potential hazards in drilling, blasting, hauling, crushing, conveying, and stockpiling. Employee will demonstrate knowledge of[LS1] plant layout, traffic patterns, PPE requirements, and important safety and health issues in all active work areas. May include lecture and discussion, visual aids plus walk around May include audiovisuals, handouts, safety manual, work rules.[LS2] Oral response Employee will identify potential hazards in the quarry environment including electrical hazards, machinery hazards, fall hazards, engulfment hazards, hazardous energy, confined spaces, materials handling, water hazards, ground control hazards. [LS3] May include lecture and discussion, visual aids plus walk around. May include: Overheads Slides Handouts Hazard training cards Videos Lockout devices Oral response citing various hazards and preventive measures. Demonstration of knowledge of hazards. Employee will explain/identify emergency evacuation procedures and alarms. Demonstrate how to select, use and maintain fire-fighting equipment. Identify fire and explosion hazards. Demonstrate steps to prevent fire and explosion. Demonstrate what to do in an emergency. Demonstrate knowledge of alarms and signals. May include lecture and discussion, visual aids plus demonstration May include: Audio visuals Fire extinguishers Safe practice procedures. Site specific emergency plans Oral response Demonstration Observation Employees will identify[LS2] their rights under Mine Safety & Health Act of 1977 and 30 CFR Training will address typical accidents and best practices. and will teach hazard recognition specific to tasks to be assigned. Lecture and discussion May include handout material. Oral review and discussion. QUARRY TRAINING PLAN - NEW MINER SAVAGE STONE Est. Hrs 5 . 6 . .5 Subject Part 46 Objectives Page 3 of 8 Teaching Methods Course Material Evaluation Method line of authority and responsibilities of supervisors and miners and their representatives. Note: Must be done before miner begins work. Do this on day 1 Employee will be able to explain MSHA's role and responsibility, personal responsibility of every employee including supervisors, and who has responsibility and authority to correct hazards. Lecture and discussion. May include: Handouts Visuals Oral review and discussion Rules and procedures for reporting hazards Note: Must be done before miner begins work. Do this on day 1 Employee will be able to explain steps to get issues addressed and what to do if corrective action is not taken Lecture and discussion May include handouts and visual aids Oral response USE, CARE AND MAINTENANCE OF RESPIRATORY DEVICES Note: Must be completed within 60 days, but do this on day 1 Employee will demonstrate how to select, use, care, and maintain respirators. Employee will explain limitations of respirators. Employee will identify [LS1]respiratory hazards and precautions. Lecture and discussion Demonstration using respiratory devices Visuals and handouts Respiratory devices Oral response Demonstration FIRST AID METHODS Note: Must be completed within 60 days, but do this on day 1 Employee will explain basic life saving methods, steps to protect from bloodborne pathogens, emergency response plan, where equipment is located, how to control the situation. Lecture and demonstration Discussion Visual aids Handouts Audio visuals Oral response Demonstration Observation HAZARD RECOGNITION TRAINING SPECIFIC TO THE TASKS TO BE ASSIGNED note: This must be done before conducting the instruction and practice under the close observation of a competent person. Supervised practice IN HEALTH AND SAFETY ASPECTS OF THE TASKS ASSIGNED Note: Start on day 2, finish on day 3 so all of the 24 hours training will be finished. Employee will be able to explain the safety and health hazards of assigned tasks and how to avoid them before actually performing the tasks. May include lecture, discussion, practical demonstration, or show and tell at work sites J.S. A. 's, MSDS's, Handouts Oral response and observation Correct job performance Employee will demonstrate correct job performance and perform tasks in accordance with the safely and health standards outlined in the training. On the job training, observation, correction, and practice May include checklists, job training books and guides, and operating manuals .5 7 . 1 8 . 1 9 16 Observation of job performance TRAINING PLAN Safety Training Plan Section I: Company and Mine Names [Section 46.3(b)(1)} Savage Stone. LLC P.O. Box 850 Laurel, Maryland 20725 Mine: Savage Stone Quarry 8420 Baltimore Washington Boulevard Jessup, Maryland 20794 MSHA ID: 18-00768 Section II: Person Responsible for the safety and health training at the mine [Section 46.3(b)(2)} Owen Stewart, Plant Manager. Terry B. Eichelberger, Director, Safety & Quality Control Plant Phone Number: 301-953-7650 Date of Plan: August 1, 2005 New Miner Training Plan – Savage Quarry Section III: Competent Persons and subject areas [46.3(b)(4)] The following persons are competent to instruct in the corresponding subject areas. See the training plan for specific content. 1 Introduction to the Work Environment 6 Rules and procedures for reporting hazards 2 Recognition and avoidance of Hazards 7 use care and maintenance of respiratory devices 3 Emergency medical procedures, escape and emergency evacuation plans and instruction on fire warning systems and firefighting procedures 8 first aid and methods 4 statutory rights of miners and representatives 9 hazard recognition training specific to tasks assigned 5 line of authority and responsibilities of supervisors, miners, and their representatives Employee Name 1 2 3 4 5 6 7 8 9 Owen Stewart X X X X X X X X X Terry Eichelberger X X X X X X X X X New Miner Training Plan – Savage Quarry Section III: Competent Persons and subject areas for Task Training [46.7] The following persons are competent to instruct Task Training in the corresponding subject areas. Mobile Equipment 1 Front End Loader 8 grader 2 Quarry Truck 9 boom truck 3 Water Truck 10 4 Hydraulic Breaker 11 5 Excavator/Backhoe 6 bucket truck 7. skid steer dozer Employee Name 1 2 3 4 5 6 7 8 9 Owen Stewart Jerry Collins X X X X X X X X X X 1 0 X 1 1 X Plant Maintenance 1 Crusher Operator 8 Maintenance-mobile equipment 2 Pug Mill Operator 9 Maintenance-dust collector 3 Utility/laborer Maintenance-pug mill 4 Maintenance-screens 5 Maintenance-conveyors 6 Maintenance-crushers 1 0 1 1 1 2 7 . Maintenance – cutting/welding Maintenance-screws/cyclones Maintenance pumps Employee Name 1 2 3 4 5 6 7 8 9 10 11 12 Owen Stewart X X X X X X X X X X X X Each new miner must receive no less than 24 hours training [Section 46.5(a)}. Miners who have not received the full 24 hours of new miner training must work under the observation of an experienced miner. Training Plan Summary And Training Guide Savage Stone LLC Safety Training Program and Employee Orientation The Safety Training Program and Employee Orientation Program is designed to provide a new employee with a comprehensive understanding of safety procedures, equipment and requirements. The trainer shall follow the guidelines listed below and ensure that the employee completes the entire program. The trainer shall provide the employee with the basic safety equipment required prior to entering the work place, except safety shoes which are the responsibility of the employee. The trainer shall ensure that all employment forms are completed before the completion of the training program. Training should be conducted in a relaxed environment. Ask the employee questions throughout the training to help ensure their understanding. Encourage the employee to ask questions. Determine if the employee requires assistance with reading the materials or taking the test. In these cases the trainer shall assist the employee and conduct an oral test. The trainer shall make a notation on the test and training material that the training was conducted orally. Materials Required Safety Training Manual Company Safety Policy NSA New Miner Video and other Videos Lockout Box (optional) General Company Policy - Rules and Procedures Employee Evaluation Policy Noise Policy (if applicable) Water Safety Policy (if applicable) Forms W4 Application I-9 Employee is required to produce: a Drivers License & Social Security Card, or other acceptable proof of citizenship. Safety Shoe Agreement Safety Training Record Safety Training Orientation (Test) Receipt for Safety Policy Receipt for Seat Belt Policy Receipt for Employee Evaluation Policy Receipt for Noise Policy (if applicable) Receipt for Water Safety Policy (if applicable) Employee Issued Equipment Record ( receipt for safety equipment) Sample Forms: Daily Equipment Checklist Daily Shop Inspection Sheet Daily Plant Inspection Sheet Daily Work Place Inspection Sheet Safety Inspection Guidelines Supervisor's Accident Investigation Form Sample of a Monthly Safety Meeting Savage Stone LLC Safety Training Program and Employee Orientation Agenda Day 1: Review the Company Safety Policy Classroom Orientation Review Videos Process Employment Forms Receive Company Safety Policy, General Company Policy, and Employee valuation Policy. General review Safety Quiz Workplace and plant Safety Tour - Field Training NOTE: Employees must have safety shoes before they are allowed to start work. Day 2: On the job training under observation of an experienced miner. Day 3: On the job training under observation of an experienced miner. Employees will be evaluated based on their performance and their knowledge of safety procedures. Savage Stone LLC Safety Training Program and Employee Orientation Day 1 Review the agenda for the safety training program with the employee. Explain the training procedure - classroom and field. Explain that the test will be multiple choice and true or false. Follow the instruction outlined the Safety Training Manual Issue and review forms as required by the manual. Show the NSA video. Show other videos applicable to employee tasks. Administer the Safety Training Orientation (test) Orally review all questions and answers on the test with the employee. If an employee answers a question incorrectly, the trainer shall review the subject in detail to ensure that the employee understands. Trainer shall ensure that all basic safety equipment has been issued. Trainer shall ensure that all form receipts are properly completed and signed. Trainer or designee shall provide a plant/workplace walk through orientation. Provide a comprehensive tour of the pit or quarry. Identify and discuss: Berms ( height and required areas) Highway safety Traffic safety (patterns, signs, speed) Water safety Task Training Task Training for Front End Loader Operator Competent Persons performing the task training shall initial each category as the training is completed and certify that the employee is qualified to operate the equipment. The employee shall initial each category as the training is completed and certify that the training was conducted and that he or she received the training, understands the operating procedures, and believes that they can operate the equipment in a safe and efficient manner. Review and Discuss the following Training Topics and Instructions Competent Person Review the Equipment Operator Manual Perform a Pre-shift examination of equipment prior to use –Review Form Seat Belts shall be worn at all times when operating equipment Report all defects to your supervisor before operating equipment Do not operate equipment with mandatory defects – brakes, steering, flammable fluid leaks, broken windshield-obscures vision/cut hazard, lights, horn, backup alarm. Check area and sound horn warning prior to moving equipment Maintain 3-point contact when mounting or dismounting equipment. Persons are not allowed ride on equipment or work out of buckets Observe speed limits and traffic control signs Check the park and service brake at pre-shift and on grade Review, identify, explain: auxiliary systems-steering, braking ,etc. Demonstrate controls for the operation of the equipment Do not load trucks unless the operator is in the truck or designated place Do not operate within 10-Ft of power lines Do not operate within 20-Ft from the stable crest of highwall or stockpile Demonstrate and observe pre-shift inspection of equipment (check when complete) Prior to Starting – Provide a Pre-shift Inspection Form Fluid levels: oil __ transmission __ hydraulic __ coolant __ Major leaks: oil __ transmission __ hydraulic __ hoses __ Tires.. __ Windows __ Steps and ladders __ Fire extinguishers __ Gauges __ Seat Belt __ Starting Equipment: Mount-3-point __ Fasten Seat Belt __ Brakes-Service __ Brakes-Park __ Back-up Alarm __ Steering Control __ Wipers __ Lights __ Horn __ Operation of Equipment Check Area __ Release Brake __ Sound Horn __ Operate Equipment…… __ Check Work Area: Berms, Highwalls, Roads, etc __ Check Brakes on Grade __ Shut down Park __ Set Brake __ Turn Wheels in if on grade __ Dismount 3-Point __ Competent Person Comments: Exam and Certification Section on Reverse Side Initials Employee Task Training for Front End Loader Operator - Task Training Examination – Circle Correct Answer True or False The operator is the person responsible for the safety and operation of the equipment It is OK to operate the equipment if the park brakes does not work only if you park the unit on level ground. You must maintain a three-point contact when mounting and dismounting the unit What is the minimum distance from an electric line that you can operate the unit? 8Ft15Ft Seat Belts must be worn at all times when operating the equipment You are not required to report an unsafe condition if it is not in your work area Berms shall be at least mid-axle height of the largest equipment that travels the area What is the minimum distance from the stable crest of a highwall or stockpile that you can operate the unit? 5Ft 20Ft If you relieve an operator during a shift, you are not required to perform a Pre-shift Examination as long the previous operate did one and the unit is OK. It is OK to operate the unit with a mandatory defect if your supervisor says it is OK If your back-up alarm fails during the shift, it is OK to operate for the rest of the shift You should check your Service and Park Brakes on a grade at least once a day Pre-shift Examinations must be conducted by the operator and all defects reported before the unit is placed into operation Any hazardous condition must be reported to your supervisor immediately It is OK to load a truck if you can not see the operator, but it looks OK It is a good practice to keep windows closed to minimize exposure to dust and noise Safety is the responsibility of every employee False Certifications are punishable under section 110(a) and (f) of the Mine Safety and Health Act Equipment: Manufacturer _________________________________ Model __________________ I certify that I have conducted the above training as specified and that trainee has demonstrated the skills and practices to operate the equipment as specified in a safe manner. ________________________________________________________________________________ Competent Person’s NameCompetent Person’s SignatureDate I certify that I received and understand the above training. I agree to comply with all rules and regulations. I understand that failure to comply will result in disciplinary action to and including termination ________________________________________________________________________________ Employee NameEmployee SignatureDate ________________________________________________________________________________ Supervisor NameSupervisor SignatureDate Competent Person Task Training Guideline Front End Loader Operator Observe the Operator in the following sequence of steps Competent Person shall initial each step as completed Employee is wearing appropriate Personal Protective Equipment Checks the area for traffic and other hazards (slips, trips, etc) when performing walk around Check for fluid leaks and levels, fire extinguisher, linkage, pins, metal stress/cracks Check tires for excessive or deep cuts, loose casings, proper inflation, and excessive wear Wear appropriate clothing that will not get caught when mounting and dismounting Inspects ladder and walkway for breaks, cracks and material buildup – slip and fall hazard Maintains a three-point contact when mounting and dismounting Inspect Cab- ROPS condition, Fire Extinguisher – secure and properly charged. Make sure objects in cab are secure – loose object can interfere with vehicle control Make sure windows are clean and there are no cracks that impair visibility or is a cut hazard Inspect, adjust and buckle seat belts and adjust mirrors Check all gauges before startup, place transmission in neutral and set the park brake. Start engine, lower bucket, check horn, backup alarm, and gauges Let engine idle until it reaches normal temperature, check gauges, warning lights, and idle Check wipers, lights, and hydraulic control for proper operation. Check emergency steering if provided on the unit Check brakes, steering and transmission operation. Sound warning horn before moving the unit Move the equipment to the loading area Check berms for proper height, road conditions, highwall and stockpile stability Observe speed limits, traffic patterns, keep bucket at a safe low level, avoid road hazards Maintain the proper gear when carrying a loaded bucket on grade or reverse Check service brake and park brake on a maximum traveled grade Maintain a clean work area free of debris and material that may be a hazard Keep stockpiles trimmed and free of overhang If loose or unconsolidated rock are observed notify the supervisor and block the area off Checks to make sure truck operators and passengers are in the cab of the truck or are in view at a designated area before loading the truck Check operator for proper loading techniques Maintains proper speed and traffic patterns while moving the unit to the shop or fueling area Parks the unit in designated location for fueling, sets brake, and dismounts properly Wear safety glasses, goggles, and hand protection as required. Uses proper procedure when fueling – no smoking, maintains 3-point contact and is in a secured no fall hazard position during the fueling process, and prevents spillage of fuel Complete fueling process and move unit to designated parking area. Initials ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ I certify that I have conducted the above training as specified and that trainee has demonstrated the skills and practices to operate the equipment as specified in a safe manner. False Certifications are punishable under section 110(a) and (f) of the Mine Safety and Health Act. Trainee_________________________________ Competent Person’s Name Date ___________________________________ Competent Person’s Signature ____________ Date Evaluating the Training Safety Training Orientation Examination Employee Name _________________________________________ Date:_____________________ Review the following questions and circle the correct answer. 1. The Mining Industry is regulated by a. OSHA b. MOSH c. MSHA d. FTC 2. When working on fixed equipment guards are required a. Only when equipment is operating and there are people in the area. b. Optional c. at all times when the equipment is operating. d. never. 3. The definition of a berm is a. a barricade to prevent equipment from overturning. b. a type of mobile equipment c. an electrical device d. a shop entrance. 4. Which of the following best describes the Lock out/tag out procedure. a. Have a person stand next to the disconnect to prevent energizing the equipment. b. Let another employee lock out the equipment and attempt to start the equipment before working on it. c. Lock out/tag out the equipment with your lock, notify other employees, and attempt to start the equipment before working on it. d. Lock outs are not required. 5. A Safety Belt and Line is required a. When fall protection is provided b. Never c. When working in excess of 15 feet when no fall protection is provided d. When working in excess of 5 feet when no fall protection is provided 6. A Pre-shift Inspection on fixed equipment is required a. Once per day b. Once per week c. Before the work begins for each shift d. Never 7. A Pre-shift Inspection on mobile equipment is required a. By the supervisor once per day. b. Before operating the equipment by the first operator during the shift. c. Before operating the equipment by each operator during the shift. d. Sometime during the shift. 8. Operators may operate equipment with a. Two or less mandatory defects b. Only when there are no mandatory defects c. When there are mandatory defects if their supervisor says it is OK. d. If the unit is Red Tagged. 9. Walkways and travelways shall be a. Cleaned once per day. b. Cleaned only when there is an MSHA inspection. c. Cleaned when a build-up creates a hazard to persons. d. Cleaned when someone falls and hurts themselves. 10. Personal Protective Equipment shall be worn when a. The supervisor is in the area. b. The MSHA Inspector is on the property c. At all times when a hazards exists or in designated areas. d. Only if you feel like wearing it. 11. When you hear a back-up alarm or warning signal you shall a. Ignore it. b. Look to see where it is coming from and move to a safe place. c. Identify the equipment and direction without looking. d. Listen and keep working. 12. When getting down from equipment you should a. Jump off when you think it is safe to do so. b. slide down the ladder. c. maintain a three point contact. d. Carry your lunch an other equipment while climbing. 13. Inspection of equipment and the work area is a. the responsibility of a supervisor or designated inspector. b. the responsibility of the safety director or safety representative. c. maintenance personnel. d. every employee 14. Haul road berms are required a. only for large quarry equipment b. only if you think there is a chance of running over the edge. c. when any traffic can access the area. d. only if you are going into the area. 15. If you observe a contractor on site with inadequate brakes or unsafe equipment you should a. Ignore it and don't get involved because they are not employees. b. Stay away from them. c. Report them immediately to you supervisor. d. Call the contractors office and express you concern. 16. If your supervisor told you to quickly report to another work area and you notice a tripping hazard on a walkway you should a. Notify your supervisor b. Ignore it and carefully walk around. c. move the object out of the way. d. hope someone else will take care of it. 17. When starting a job you should a. start immediately and work as fast as you can. b. start immediately and work slow. c. take a few minutes and check the area for hazards d. ask someone if it they know if there any hazards present. Answer the following True or False questions. Visitors and Contractors do not have the comply with the Safety Rules Fire Extinguishers must be charged and inspected at all times. Broken handrail does not have to be repaired. It is OK to work between a piece of equipment and the highwall. It is OK to grind or cut with Safety Glasses. Seat belts must be worn at all times It is OK if a co-worker does not wear his hard hat if he does not get caught. Mobile Equipment Operators shall check their service brakes and park brakes every day. It is OK to remove a guard to clean the equipment while it is operating if you are careful. Safety is only the responsibility of the supervisor Employees should read the labels on chemicals before using them. Safe and clean working conditions is the responsibility of everyone. Employees are responsible for wearing and maintain personal protective equipment. Empty compressed gas cylinder are required to be capped and secured. Life jackets are only required when a water hazard exists. It is okay to watch a welding flash if you do wear contacts. Fire extinguishers are only required where a fire hazard exists. Hearing protection is only required if it hurts your ears. Loose or broken conduit is allowed if everyone is aware of the condition. You only have to report serious injuries to your supervisor. Safety is as important as production. Employee Signature ___________________________________________ Date ______________________ Trainer Signature ___________________________________________ Date _______________________ Forms SAFETY TRAINING RECORD COMPANY _________________________ LOCATION_______________ EMPLOYEE ______________________ The following Safety training Program shall be performed before the employee enters the workplace. The employee must be trained in each of the following categories. The employee and trainer shall initial each of the categories to ensure the training was properly conducted by the trainer and understood by the employee. TRAINING CATEGORY Class Field TRAINER INITIAL DATE EMPLOYEE INITIAL DATE Review the "ACT", CFR30 - Parts 56 and 57 Review the Objective of the Program Review the Supervisor's Responsibilities Review the Employee's Responsibilities New Miner/Refresher and First Aid Training Review purpose & requirements of Safety Meetings Accident Investigation and Review Procedure Disciplinary Action Program Visitor Requirements Indepedent Contractor Requirements Blasting and Warning Systems Emergeny Response and Evacuation Plan Hazard Communication Confined Spaces Alcohol and Drug Policy Personal Protective Equipment Requirements Hard Hat and Safety Shoes Eye and Ear Protection Seat Belt Policy Safety Belt and Line Policy Use of Respirators Welding and Cutting Hazards Maintenance and Fixed Equipment Pre-Shift Inspection Procedure Definition and Requirements of Guards Lockout Procedure Electrical Hazards Warning Signals and Signs Fall Hazards and Protection Access Hazards and Safe Access Protection Moving Equipment Hazards and Protection Walkways and Travelway Safety Housekeeping Requirements Mining - Quarry and Roadways Pre-Shift Inspection Procedure Definition and Requirements of Berms Highwall Safety and Maintenance Mobile Equipment Pre-Shift Inspection Procedure Mandatory Safety Defects - Red Tag Out of Service Equipment Safety Loading, Dumping and Hauling Safety Training Certification I certify that the company provided training classroom and I certify that the employee was trained in above field training for the above categories. I understand the categories and understands the hazards and safety hazards and safety procedures discussed and will comply procedures procedures outlined in the Company with the Company Safety Policy and MSHA Requirements. Safety Policy. Employee Signature and Date Trainer Signature, Title and Date ______________________________________________ ______________________________________________ TR/ STREC1-0 2 Contractor Safety Introduction This operation is regulated by the U. S. Department of Labor, Mine Safety and Health Administration (MSHA). The authority for the regulation is the Act of 1977 and the Code of Federal Regulations, Title 30. CFR 30, Part 45: Independent Contractors, Part 46: Training, Part 47, Hazard Communication, Part 50 Reporting and Record Keeping; Part 56: Safety and Health Standards -- Surface Metal and Nonmetal Mines, and Part 100: Criteria and Procedure for Proposed Assessment of Civil Penalties are the primary areas of concern for Independent Contractors. Independent contractors shall comply with all rules and regulations established by Federal, State, and Local agencies and the Company Safety Policy. The Company reserves the right to discontinue the services of independent contractors that fail to comply with these rules and regulations. Independent contractors shall provide the necessary training to their employees to ensure a safe working environment for all personnel. Independent contractors shall provide all necessary personal protective equipment to their employees and train them in the proper use of the equipment. Independent contractors shall provide and maintain equipment that meets all safety requirements. Independent contractors shall provide trained and competent personnel to operate equipment and perform the work. Independent Contractors are responsible for all inspections and records for their personnel and equipment. Independent contractors and their employees shall not participate in any unsafe acts. The Company will provide the contractor with an Independent Contractor General Safety Requirements Package and applicable Site Specific Hazard Awareness Training. The package contains a list of site-specific rules, hazards, and general information regarding compliance requirements of the Mine Safety and Health Administration. Independent Contractors shall provide the required training to all employees before they enter the mine property. Independent Contractors shall complete and submit the Independent Contractor Registration and the Record/Certificate before any work is performed on mine property. All Independent Contractors who are performing work on mine property and are subjected to hazards directly or indirectly associated with mining activities are require to comply with the following regulation: The Act In 1977 Congress enacted the Mine Safety & Health Act (The Act). The Act provided MSHA with the responsibility to protect the miner and establish a safe working environment, including enforcement and penalties. A copy of the Act may be obtained by contacting any MSHA District Office. CFR 30 CFR 30 provides a more detailed interpretation of the law. The Company has provided a copy of several sections of the law in this package. The complete book may be obtained by contacting the U. S. Government Printing Office at 202-512-1806. Program Policy Manual The U. S. Department of Labor, Mine Safety & Health Administration produces a Program Policy Manual that provides specific applications to the regulations found in CFR 30. This manual may be obtained for a small charge. If you wish to order a manual you may contact MSHA at 304-256-3353. Company Safety Guidelines for Independent Contractor The Company has developed a set of safety guidelines to provide the Independent Contractor with a list of potential hazards associated with the operation and specific rules or procedures that shall be observed when on the company property. Independent Contractor Register The Independent Contractor shall complete the Independent Contractor Register and provide a certificate of insurance prior to performing any work on the mine property. General Requirements and Safety Guidelines The operation superintendent or designee shall provide the contract with an operation "walk through" to advise you of all potential hazards and the warning systems specific to this location. Independent contractors are responsible for their actions and the actions of their employees. They shall observe the following general requirements and safety guidelines. 1. Report all accidents that occur on mine property to MSHA and the company. 2.Wear hard hats, safety glasses, goggles, protective footwear, left vests, safety belts and lines, and other personal protective equipment as required by regulation or established by the Company. 3. Wear seat belts at all times when operating equipment on mine property. 4. Observe and comply with lockout procedures. 5. Not participate in unsafe acts. 6. Identify and correct unsafe conditions. 7. Not expose any personnel to unsafe or hazardous conditions. 8. Provide the proper training to your employees. 9. Observe and comply with all blasting and warning systems. 10.Observe all traffic patterns. 11.Conduct inspections of the work area and equipment as required by MSHA. 12.Maintain proper ground conditions within their area of responsibility. 13.Maintain equipment in a safe operating condition. 14.Operate equipment in a safe manner. 15.Maintain compliance with all conditions of CFR 30 and the Program Policy Manual. Hazard Training Pit Area - Hazards Type Hazard Potential Hazard Safety Procedure Mobile Equipment Stuck by equipment Equipment shall be inspected prior to each use by each operator. Mandatory requirements are, operating horn, backup alarm, brakes, seat belt, fire extinguisher, lights, and undamaged windshield. Road Hazards Drop off that may cause a vehicle to upset or enter impounded water areas. Collision with other vehicles Berms shall be maintained to a height of at least mid-axle height of the largest vehicle that travels the roadway. Observe traffic and warning signs. Electrical Overhead wires, buried cables, electrical outlets. Excavate in designated areas, do not travel with truck beds in a raised position and use lockout/tagout procedures. Plant Area - Hazards Type Hazard Potential Hazard Safety Procedure Machinery Moving machine parts, pinch points, caught in moving parts, burns, etc. Guards and railings are provided and must be in place while equipment is operating. Warning sirens will be sounded prior to the start of equipment. Stay clear when alarms sound. Electrical Overhead wires, buried cables, electrical outlets. Excavate in designated areas, do not travel with truck beds in a raised position and use lockout/tagout procedures. Inspect wiring, extension cords and tools for bare wire or loose connections. Plant Area - Hazards Type Hazard Potential Hazard Safety Procedure Fall Fall from high places, working in high places where no fall protection is provided. Handrails are provided to prevent fall. Use safety belts and line when working in excess of 5 feet where no fall protection is provided. Fire Flammable and combustible fluids, oxygen and acetylene tanks can result in fire or explosions. Burn and smoke inhalation. Keep trash and flammable materials contained in proper storage, do not smoke in flammable or combustible storage areas, secure cylinders in storage and cover gauges when not in use, cover/cap cylinders when transporting. Identify locations of fire extinguishers and inspect monthly for proper charge. Mobile Equipment Stuck by equipment Each operator shall inspect equipment prior to each use. Mandatory requirements are, operating horn, backup alarm, brakes, seat belt, fire extinguisher, lights, and undamaged windshield. Cutting and Welding Burns from sparks and welding flash burns to the skin and eyes. Observe welding area warnings. Maintain a safe position when working or accessing these areas. Personal Injury Injuries to head, eyes, ears, skin from falling or airborne objects or noise from machinery. Wear appropriate personal protective equipment in designated areas at all times. Road Hazards Drop off that may cause a vehicle to upset or enter impounded water areas. Collision with other vehicles Berms shall be maintained to a height of at least mid-axle height of the largest vehicle that travels the roadway. Observe traffic and warning signs. General Safety Rules: Emergency Evacuation In the event of an emergency an alarm will sound for three long blasts. Report to the nearest production office for instructions. Injuries and Accidents Report all injuries and accidents to an authorized company representative immediately. Unsafe Conditions Contractors shall report all unsafe conditions immediately to an authorized company representative. Contractors agree to not cause, participate, or expose the company employees to any unsafe conditions or acts. Personal Protective Equipment Wear personal protective equipment when on mine property. Safety Harness and Lanyard or Safety Belt and Lanyard shall be use when working above 5 feet and no fall protection is available and at all times when persons are in a bucket or manlift. Traffic and Haulage Obey traffic patterns, road signs, and speed limits. Operators must wear seat belts at all times. Operators shall remain in their vehicles at all times during the loading and unloading process. Water Safety Contractors shall wear left jackets and lines when working around water where a drowning hazard exists. Excavation and Plant Erection Contractors shall install adequate berms, barriers, and signs to warn and protect company personal from hazards within their area of responsibility. MSHA Independent Contractor Identification Number. CFR 30, § 45.3 Identification of Independent Contractors, allows any contractor to obtain a permanent MSHA ID. MSHA's Program Policy Manual, Part 45 - General Enforcement Policy for Independent Contractors, provides more specific information regarding identification requirements. MSHA's policy holds independent contractors responsible for violations committed by the contractor or their employees or subcontractors. A MSHA identification number is only required if the independent contractor is cited for a violation or the independent contractor is performing one or more of the following types of services. 1) Mine development, including shaft and slope sinking 2) Construction or reconstruction on mine facilities, including building or rebuilding preparation plant and mining equipment, and building additions to existing facilities. 3) Demolition of mine facilities 4) Construction of dams 5) Excavation or earthmoving activities involving mobile equipment 6) Equipment installation, such as crushers and mills 7) Equipment service or repair of equipment on mine property for a period exceeding five consecutive days at a particular mine 8) Material handling within mine property, including haulage of coal, ore, refuse, etc., unless for the sole purpose of direct removal from or delivery to mine property. 9) Drilling and blasting. MSHA does not require an independent contractor to obtain an identification number during the pre-bid or bid process. An identification number shall be obtained prior to the start of any work if the independent contractor performs within any of the nine types of work described above. All independent contractors are held responsible for compliance with the Act, standards, regulations, rules and policies, regardless if they have an identification number. The mine operator may also be held responsible if certain overlapping conditions exist. Therefore, if the company discovers a violation it will discontinue the services of an independent contractor until the condition is corrected. Independent Contractor Training CFR 30, Part 46, requires the Company to provide the Independent Contractors with hazard awareness safety training prior to performing work on Mine Property. Site Specific Hazard Awareness Training provides a comprehensive understanding of the hazards that are specific to that mine property. The Independent Contractor shall not allow a new employee or employee who has not received Site Specific Hazard Training to enter the Mine Property until the training has been provided. Additional training varies depending on what category the contractor is in and the level of exposure to hazards. The contractor agrees to meet all requirements set forth in CFR 30 Part 46. The Contractor is responsible for providing the appropriate training under Part 46 to each employee before they enter the mine site. Part 46 Requirements 46.3 Training plans 46.4 Training plan implementation. 46,5 New Miner Training 46.6 Newly hired experienced mine training 46.7 New Task Training 46.8 Annual Refresher Training. 46.9 Records of Training 46.10 Compensation of Training 46.11 Site Specific Training 46.12 Responsibility of independent contractor training Independent Contractor Reporting Requirements Independent contractors who require an MSHA ID are subject to the record and reporting requirements of CFR 30, part 50. CFR 30, Part 50.20 requires contractors with an MSHA ID to report applicable accidents, injuries and illnesses on form 7000-1. CFR 30, Part 50.30 requires contractors with an MSHA ID to complete and submit Form 7000-2 - Quarterly Employment Report. CFR 30, Part 50.40 requires the contractor to maintain records at the office closest to the mine for a period of five years after submission. CFR 30, Part 50.41 allows the records to be examined by an authorized representative of the Secretary of Labor upon request. All reports are the responsibility of the contractor to complete and maintain. Failure to comply with this section may result in citations and fines to the contractor. Additional information, forms and explanations may be obtained by contacting the MSHA District office in your area. INDEPENDENT CONTRACTOR REGISTRATION Company Name-Fairfax, Allegany, Laurel, etc. Name of Mine/Facility Savage Stone Savage Quarry M.S.H.A. ID Contractor Name Business Address _________________________________________________________________________ Street Address or P.O. Box _______________________________ _________________ City ________________ State Zip Code Telephone Numbers Business Number: ______________________ Mobile Number: ______________________ Facsimile Number: ______________________ Pager Number: ______________________ Contact Persons Name Title MSHA Identification Number (if applicable) Federal Identification Number (Required for Trucking) Type of Work to be Performed Excavating Welding Reclamation Other (specify) ___ ___ ___ Drain Truck Electrical Plant Service ___ ___ ___ Pit Truck Plumbing Trucking ___ ___ ___ Equipment Installation Mobile Mechanic Drilling & Blasting ___ ___ ___ Please provide a general description of the work you will be performing and the location on the mine site. Independent Contractors are subject to and agree to comply with the requirements of 30 CFR, Parts 45, 46, 56, MD DOT, Federal DOT and Company Safety Rules. The company shall provide applicable hazard training to the contractor before the work begins. Authorized Signature of Contractor __________________________________________________ Date___________________________ Date Received ________________________________ Processed by _______________________________________________________