machines

advertisement

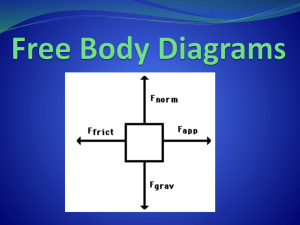

FRAMES Similar to trusses, frames are generally fixed, load carrying structures. The main difference between a frame and a truss is that in a frame at least one member is a “multi force member” (çoklu kuvvet elemanı). A multi force member supports three or more forces or at least two forces and one or more couples. In contrast with a truss, the force or moment can be exerted to any point on the frame member; it does not have to be applied the joint as in the trusses. MACHINES Machines are structures which contain moving parts and are designed to transmit input forces or couples to output forces or couples. Therefore a machine is an assembly of rigid and sturdy members that are capable of generating work by means of some kind of motion. A mechanism is a term used to describe the physical devices which enable the parts of a machine to conduct the intended movements. A machine may contain several mechanisms. Machines are designed to change forces, enhance and amplify their magnitudes and transmit them. Whether a machine is as simple as a hand tool or as complex as an airplane, the main aim is to convert input forces into output forces. The main difference between a frame and a machine is that although frames are rigid structures, machines are not. Machines may be fixed to some supporting surface or body, but they will always consist moving parts. The forces acting on each member of a connected system are found by isolating the member with a FBD and applying the equations of equilibrium. The principle of action and reaction must be carefully observed when we represent the forces of interaction on the separate FBDs. It would be appropriate to identify the two forces members in the frame, if there is any, before starting with the solution. In order to determine the forces in a frame or machine, it is divided into a sufficient number of members or groups of members, but initially the support forces to be used in the analysis must generally be determined from the equilibrium of the whole frame. The structure is then, dismembered and the equilibrium of each member is considered separately. The equilibrium equations for the several parts will be related through the terms involving the forces of interaction. It should be kept in mind that when going from one member to the other, the direction of the interaction force must be changed in accordance with Newton’s third law. In general the FBDs of pins in the structures are not drawn; pins are considered as a complementary part of one of the two members it connects. It must be clearly decided which member the pin will belong to. Whereas, the FBD of a pin will be considered if: It connects three or more members, It connects a support and two or more members, A load is directly applied to the pin. The mechanical efficiency of a machine: Mechanical Efficiency work output h energy input Machines are considered as “ideal machines” when the work output is equal to the energy input. It is impossible to build such machines. In a real machine friction forces always generate useless work which causes loss of energy, therefore, work output is always less than the energy input. In other words, the mechanical efficiency is always less than one, h<1. Mechanical Advantage: Mechanical advantage is the ratio of the output force of a machine to the input force necessary to work the machine. This concept is totally different from the mechanical efficiency and should not be mixed with it. Mechanical advantage is generally greater than one. Output Force Mechanical Advantage Input Force SAMPLE FRAMES AND MACHINES Small bolt cutter operated by hand for cutting small bolts and rods is shown. For a hand grip P=150 N. Determine the force Q developed by each jaw on the rod to be cut. The forces acting on the two parts of the bolt cutter behave as mirror images of each other with respect to x-axis. Thus, we can not have an action on one member in the +x direction and its reaction on the other member in the –x direction. Consequently the forces at E and B have no x-components and CD is a twoforce member. Mechanical advantage 1. Compute the force supported by the pin at A for the slip-joint pliers under a grip of 100 N. 2. The clamp shown in the figure is frequently used in welding operations. Determine the clamping force on the two metal pieces at E and the magnitudes of the forces supported by pins A, B and D. 3. The elements of a floor jack are shown in the figure. CDFE forms a parallelogram. Calculate the force in the hydraulic cylinder AB corresponding to the 10 kN load. What is the force in link EF? 4. When the crank AB is vertical, the beam CD is horizontal and cable makes a 20o angle with the horizontal. Compute the moment M required for equilibrium of the frame. 5. The car hoist allows the car to be driven onto the platform, after which the rear wheels are raised. If the loading from both rear wheels is 6 kN, determine the force in the hydraulic cylinder AB. Neglect the weight of the platform itself. Member BCD is a right-angle bell crank pinned to the ramp at C. 6. Determine the vertical clamping force at E in terms of the force P applied to the handle of the toggle clamp, which holds the workpiece F in place. 7. The pruning mechanism of a pole saw is shown as it cuts a branch S. For the particular position drawn, the actuating cord is parallel to the pole and carries a tension of 120 N. Determine the shearing force P applied to the branch by the cutter and the total force supported by the pin at E. The force exerted by the light return spring at C is small and may be neglected. F 8. In the frame shown determine the forces acting at pins A, B and D. 9. The mechanism in the figure is used to raise the bucket of a bulldozer. The bucket and its contents weigh 10 kN and have a center of gravity at H. Arm ABCD has a weight of 2 kN and a center of gravity at B, arm DEFG has a weight of 1 kN and a center of gravity at E. The weights of the hydraulic cylinders can be neglected. Determine the forces in the hydraulic cylinders CJ, BF and EI and also determine all the forces acting at arm DEFG. 10. The linkage shown is used on a garbage truck to lift a 9000 N dumpster. Points A-G are pins, and member ABC is horizontal. For the position shown, when the dumpster just fully lifts off the ground, determine the force hydraulic cylinder CF. Roller at G is contact with the dumpster. 11. A hydraulic lift-table is used to raise a 1000 kg crate. It consists of a platform and two identical linkages on which hydraulic cylinders exert equal forces. In the figure only one linkage and one cylinder are shown. Members EDB and CG are each of length 2a and member AD is pinned to the midpoint of EDB. If the crate is placed on the table, so that half of its weight is supported by the system shown, determine the force exerted by each cylinder in raising the crate for q=60o, a=0.70 m and L=3.20 m. Show that the result obtained is independent of the distance d. 12. The mechanism is designed to keep its load level while raising it. A pin on the rim of the 80 cm diameter pulley fits in a slot on arm ABC. Arm ABC and DE are each 80 cm long and the package being lifted weighs 80 kN. The mechanism is raised by pulling on the rope that is wrapped around the pulley. Determine the force P applied to the rope and all the forces acting on arm ABC when the package has been lifted 80 cm as shown. SOLUTION FBD of Platform FBD of DE 69.28 mm Two force member: ED FBD of ABC FBD of the pulley 13. A simple folding chair comprised of two identical frames, one on each side, is shown in the figure. The half frame shown carries half the weight of a 70 kg person. Determine all the forces acting on member BF. Neglect the weights of the connecting elements (not shown) and the seat, and also the friction at points A, B and F. Detail of contact at F Dimensions in “mm” Geometry of the Chair SOLUTION Two force member: EG Equilibrium of the whole system: FBD of DC GE two force member FBD of BF