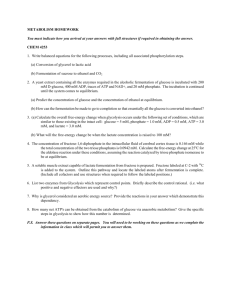

Reaction Engineering

advertisement

Reaction Engineering -> Fermentation Technology (reactors for microbial convertions) 1st lecture: Introduction into Fermentation Technology 2nd lecture: Main reactor types, Monod kinetics, mass balance and growth kinetic for Batch reactor 3rd lecture: Main reactor types, mass balance and growth kinetic for Continuous culture and Fed-batch reactor and applications in the range of micro- and nano- reactors Fermentation Technology SOME SIGNIFICANT DATES IN FERMENTATION BlOTECHNOLOGY -> ca. 3000 B.C. Ancient urban civilizations of Egypt and Mesopotamia are brewing beer. -> 1683 A.D. Leeuwenhoek first describes observations of bacteria -> 1856 Pasteur demonstrates that microorganisms produce fermentations and that different organisms produce different fermentation products. (His commercial applications include the "pasteurization" of wine as well as milk.) -> 1943 Industrial microbiological production of penicillin begins -> 1978 Perlman's formal redefinition of fermentation as any commercially useful microbial product. Fermentation Technology Fermentation Technology -> Fermentation: from latin -> ”fervere” -> to boil (describing the anaerobic process of yeast producing CO2 on fruit extracts) -> Nowadays: more broad meaning!!!! The five major groups of commercially important fermentations: -> -> -> -> -> Process that produces microbial cells (Biomass) as a product Process that produces microbial enzymes as a product Process that produces microbial metabolites (primary or secondary) as a product Process that produces recombinant products (enzymes or metabolite) as a product Process that modifies a compound that is added to the fermentation – transformation process Fermentation Respiration No added terminal e--acceptor Oxidant = terminal e--acceptor ATP: substrate level phosphorylation ATP: (e--transport) oxidative phosphoryl. Glucose Glucose 2 Glyceraldehyde-3-P 2 ATP 2 NADH 2 Pyruvate Regeneration of 2 Lactate + 2 H+ Acetaldehyde +2 CO2 2 Pyruvate CO2 2 Acetyl-CoA Citric acid cycle NAD+ Acetate + Formate H2O in 2 Ethanol H2 + CO2 CO2 GTP NADH, FADH O2 ATP Cytoplasmic membrane out 1 Glucose 2 ATP Slow growth/low biomass yield 2 ATP 2 NADH H+ H+ H+ H+ H+ H+ 1 Glucose 38 ATP Fast growth/high biomass yield Fermentation Technology Streptococcus Hyaluronic acid + lactic acid production Growth cycle of yeast during beer fermentation From: Papazian C (1991), The New Complete Joy of Home Brewing. Alternate modes of energy generation (H2S, H2, NH ) (in 3autotrophs) Fermentation Fermentation Products of Anaerobic Metabolism Growth: basic concepts Precursors Anabolism = biosynthesis Catabolism = reactions to recover energy (often ATP) Fermentation Technology -> Process that produces microbial cells (Biomass) as a product mainly for -> baking industry (yeast) -> human or animal food (microbial cells) Fermentation Technology Fermentation Technology -> Process that produces microbial enzymes as a product mainly for -> food industry Fermentation Technology -> Process that produces microbial metabolites (primary or secondary) as a product Fermentation Technology -> Process that produces microbial metabolites (primary or secondary) as a product Fermentation Technology -> Process that produces microbial metabolites (primary or secondary) as a product Fermentation Technology -> Process that produces microbial metabolites (primary or secondary) as a product Typical fermentation profile for a filamentous microorganism producing a secondary metabolite Time course of a typical Streptomyces fermentation for an antibiotic Fermentation Technology -> Process that produces microbial metabolites (primary or secondary) as a product Fermentation Technology Fermentation Technology Bacterial growth Growth rate = Δcell number/time or Δcell mass/time 1 generation Growth = increase in # of cells (by binary fission) generation time: 10 min - days Growth of bacterial population Exponential growth Geometric progression of the number 2. 21-22 1 and 2 number of generation that has taken place Arithmetic scale - slope Logaritmic scale - straight line arithmetic scale Bacterial growth: exponential growth Semilogarythmic plot Straight line indicates logarithmic growth Bacterial growth: logarithmic growth X cell mass at time t X0 cell mass at time t0 Bacterial growth: calculate the generation time t g= n t = time of exponential growth (in min, h) g = generation time (in min, h) n = number of generations 1 generation Bacterial growth: batch culture Turbidimetric measurements -> Optical Density Limits of sensitivity at high bacterial density „rescattering“ more light reaches detector consequence -> no relyable values over 0.7 Typical pattern of growth cycle during batch fermentation I. II. III. IV. V. VI. VII. VIII. Lag phase Acceleration phase Exponential (logarithmic) phase Deceleration phase Stationary phase Accelerated death phase Exponential death phase Survival phase From: EL-Mansi and Bryce (1999) Fermentation Microbiology and Biotechnology. Batch culture: Lag phase no Lag phase: Inoculum from exponential phase grown in the same media Lag phase: Inoculum from stationary culture (depletion of essential constituents) After transfer into poorer culture media (enzymes for biosynthesis) Cells of inoculum damaged (time for repair) Batch culture: exponential phase (balanced growth) Exponential phase = log-phase Maximum growth rates μmax „midexponential“: bacteria often used for functional studies Max growth rate -> smallest doubling time Batch culture: Deceleration Phase Batch culture: stationary phase Growth rate -> m = 0 Bacterial growth is limited: - essential nutrient used up - build up of toxic metabolic products in media Stationary phase: - no net increase in cell number - „cryptic growth“ (cell growth rate =cell death rate) - energy metabolism, some biosynthesis continues - specific expression of „survival“ genes - secondary metabolites produced Batch culture: death phase Bacterial cell death: - sometimes associated with cell lysis - 2 Theories: - „programmed“: induction of viable but non-culturable - gradual deterioration: - oxidative stress: oxidation of essential molecules - accumulation of damage - finaly less cells viable Diauxie When two carbon sources present, cells may use the substrates sequentially. Glucose — the major fermentable sugar — glucose repression. Glucose depleted—cells derepressed — induction of respiratory enzyme synthesis — oxidative consumption of the second carbon source (lactose) — a second phase of exponential growth called diauxie. E.coli ML30 on equal molar concentrations (0.55 mM) of glucose and lactose Factors affecting microbial growth • • • • • Nutrients Temperature pH Oxygen Water availability Microbial growth media Media Complex Defined Purpose Grow most heterotrophic organisms Grow specific heterotrophs and are often mandatory for chemoautotrophs, photoautotrophs and for microbiological assays Selective Suppress unwanted microbes, or encourage desired microbes Differential Distinguish colonies of specific microbes from others Enrichment Similar to selective media but designed to increase the numbers of desired microorganisms to a detectable level without stimulating the rest of the bacterial population Reducing Growth of obligate anaerobes MacConkey Agar: Temperature 3 cardinal temperatures: Usually ca. 30°C Temperature class of Organisms Maximum temperature Thermal protein inactivation: - Covalent/ionic interactions weaker at high temperatures. - Thermal denaturation: covalent or non-covalent reversible/ irreversible - heat-induced covalent mod.: deamidation of Gln and Asn Genetics: - Missense mutations: reduced thermal stability (Temp.-sens. mutants) - Heat shock response: proteases, chaperonins (i.e. DnaK ~ Hsp70) Minimal Temperature Proteins: - Greater a-helix content - more polar amino acids - less hydrophobic amino acids Membranes: - temperature dependent phase transition Thermotropic Gel: Hexagonal arranged Membrane proteins inactive (mobility/insertion) Tm „Fluid mosaic“ Protein function normal - homoviscous adaptation (adjustment of membrane fluidity) „Homoviscous adaptation“ Homoviscous adaptation = adjustment of membrane fluidity - lowered Tm - More cis-double bonds - Reduced hydrophobic interactions - high Tm - Few cis double bonds - optimal hydrophobic interactions - mesophiles - thermophiles Fatty acid composition of plasma membrane as % total fatty acids E. coli grown at: 10°C 43°C C16 saturated (palmitic) 18 % 48 % C16 cis-9-unsat. (palmitoleic) 26 % 10 % C18 cis-11-unsat. (cis-vaccinic) 38 % 12 % Growth at high temperatures Molecular adaptations in thermophilic bacteria Proteins - Protein sequence very similar to mesophils - 1/few aa substitutions sufficient - more salt bridges - densely packed hydrophobic cores lipids - more saturated fatty acids - hyperthermophilic Archaea: C40 lipid monolayer DNA - sometimes GC-rich - potassium cyclic 2,3-diphosphoglycerate: K+ protects from depurination - reverse DNA gyrase (increases Tm by „overwinding“) - archaeal histones (increase Tm) Bacterial growth: pH (extremes: pH 4.6- 9.4) Most natural habitats Growth at low pH Fungi: - often more acid tolerant than bacteria (opt. pH5) Obligate acidophilic bacteria: Thiobacillus ferrooxidans Obligate acidophilic Archaea: Sulfolobus Thermoplasma Most critical: cytoplasmic membrane Dissolves at more neutral pH Growth at high pH - Few alkaliphiles (pH10-11) - Bacteria: Bacillus spp. - Archaea - often also halophilic - Sometimes: H+ gradient replaced by Na+ gradient (motility, energy) - industrial applications (especially „exoenzymes“): -Proteases/lipases for detergents (Bacillus licheniformis) -pH optima of these enzymes: 9-10 Bacterial growth: Oxygen O2 as electron sink for catabolism toxicity of Oxygen species Aerobes: growth at 21% oxygen Microaerophiles: growth at low oxygen concentration Facultative aerobes: can grow in presence and absence of oxygen Anaerobes: lack respiratory system Aerotolerant anaerobes Obligate anaerobes: cannot tolerate oxygen (lack of detoxification) Fermentation Process Fermenter Fermenter Major functions of a fermentor 1) Provide operation free from contamination; 2) Maintain a specific temperature; 3) Provide adequate mixing and aeration; 4) Control the pH of the culture; 5) Allow monitoring and/or control of dissolved oxygen; 6) Allow feeding of nutrient solutions and reagents; 7) Provide access points for inoculation and sampling; 8) Minimize liquid loss from the vessel; 9) Facilitate the growth of a wide range of organisms. (Allman A.R., 1999: Fermentation Microbiology and Biotechnology) Fermenter Regulation versus Biological Processes Biotechnological processes of growing microorganisms in a bioreactor 1) Batch culture: microorganisms are inoculated into a fixed volume of medium and as growth takes place nutrients are consumed and products of growth (biomass, metabolites) accumulate. 2) Semi-continuous: fed batch-gradual addition of concentrated nutrients so that the culture volume and product amount are increased (e.g. industrial production of baker’s yeast); Perfusion-addition of medium to the culture and withdrawal of an equal volume of used cell-free medium (e.g. animal cell cultivations). 3) Continuous: fresh medium is added to the bioreactor at the exponential phase of growth with a corresponding withdrawal of medium and cells. Cells will grow at a constant rate under a constant condition. Biotechnological processes of growing microorganisms in a bioreactor Batch culture versus continuous culture Continuous systems: limited to single cell protein, ethanol productions, and some forms of waste-water treatment processes. Batch cultivation: the dominant form of industrial usage due to its many advantages. (Smith J.E, 1998: Biotechnology) Advantages of batch culture versus continuous culture 1) 2) 3) 4) 5) 6) 7) Products may be required only in a small quantities at any given time. Market needs may be intermittent. Shelf-life of certain products is short. High product concentration is required in broth for optimizing downstream processes. Some metabolic products are produced only during the stationary phase of the growth cycle. Instability of some production strains require their regular renewal. Compared to continuous processes, the technical requirements for batch culture is much easier.