WE 8-2-13 JHA vs PJB Which is Better

advertisement

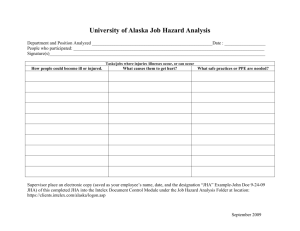

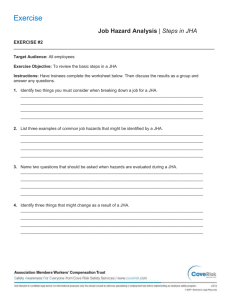

So which one is more important or should be considered better? On one hand we have the Job Hazard Analysis or JHA—JHA’s are developed by examining work activities, careful consideration of potential hazards and establishing mitigating steps that should be taken to perform work safely. On the other hand there is the Pre-Job Brief or PJB— designed and conducted to openly discuss work activities, work hazards, and mitigating steps to resolve hazards and safety concerns. This week we are going to examine both and determine exactly which one is better or more effective for use in eliminating hazards to perform work safely and successfully. Let’s Get Focused Permission to Board The recreational boating season in New England runs from May thru October…for those of us who only like to boat in the warmer months its limited to June thru September. In our home, May is our prep month when we gather all the boating gear that has been stored all winter and get it cleaned up and ready to load on board. The boat then goes through our safety check; making sure all flares are up to date, the emergency blow horn is in working order, all life vests are in good condition, our fire extinguisher is in the green, all dock lines have no chafing marks, etc. On our boat, Research Vessel Patricia Grace, we have backups for our backups when it comes to anything safety related. We have two hard wired VHF radios that we monitor at all times when running, one channel for the Coast Guard and one channel for shipping traffic; we store one handheld radio (batteries fully charged) in case we lose power. We have a hard wired spot light as well as a handheld spot light. We always carry extra life vests and each of our dogs wear a life vest with safety lights attached. We have a script on hand in case of an emergency Coast Guard call so there is no hesitation on what information to relay. Our navigation system includes a GPS chart plotter, radar and bottom sounder, and is excellent when it works; however, our paper charts never fail us. Nothing like losing all your electronics while navigating a rocky harbor in rough seas with the wind howling…”grab the chart!” We look forward to the random Coast Guard boarding to check our safety gear – it’s our own backup to make sure we remembered everything. The picture below is of one our dogs who decided to swim over for a peanut butter cookie after we were boarded (notice she has her life vest on!). As much fun as it is out on the water – I normally don’t fully relax until we are safely back to the dock. I know that at any moment anything can go wrong, the weather can turn, the wind and seas can kick up, yes it’s happened – while at anchor we were hit by another boater who was not paying attention – luckily we were and we avoided a worse situation, someone (or a pet) can fall overboard, and the list can go on. That is why my husband and I take every precaution; we always check the weather and tides before we depart, and both of us are always on alert. Boating is a great pleasure as long as the day ends with you safely guiding your boat to the mooring, dock or loading on the trailer. Whether it’s boating, jets skiing, swimming, or hanging in the air conditioning, safely enjoy the rest of the summer! Amy Friel - Executive Assistant to the CEO Diversity Quote “Wit lies in recognizing the resemblance among things which differ and the difference between things which are alike. Madame de Stael Job Hazard Analysis JHA’s are necessary required to identify and address existing conditions that pose actual or potential safety hazards. Once identified, hazards can be eliminated or otherwise addressed by using (1) engineered design changes; (2) procedural/administrative controls such as LOTO; (3) personal protective equipment (PPE); (4) insulating protective equipment (IPE); or (5) other appropriate means or a combination of methods to protect ourselves from safety hazards. OSHA's hazard assessment requirements that affect electric power workers include: • 1910.269(a)(3) - the "269" standard, which requires that before any work begins, current worksite conditions that could affect safety be identified. This includes potential hazards associated with a task, such as electrically-related exposures (for example, contact and flash), as well as anything occurring or present in the general area that could present a hazard. Other typical hazards that need to be addressed include hot or cold pipes, nearby work done by others, moving traffic, weather conditions, confined/enclosed spaces, falls, trench cave-ins, pole-top and manhole rescue needs, and other activities or conditions that could present a hazard. • And 1910.132, which requires that employers complete a hazard assessment to identify the potential hazards to eyes, face, head, feet, and hands and the personal protective equipment (PPE) needed for a task. Most utilities have already addressed this requirement and implemented general policies and procedures for wearing hard hats, safety shoes, safety glasses, gloves, hearing protection, etc. (See 1910.132(d) and (g)) Pre-Job Briefings Once the hazards have been identified through a JHA or hazard assessment, each of us must be made aware of such hazards and how they will be addressed. This is where the PJB comes in— hazard information is provided to workers through required job briefings, which should be designed to supplement our training. PJB’s, also known as "tailboards" or "toolbox talks," communicate any existing or potential hazards to workers before a job begins or if hazards or potential hazards are discovered while working. If unanticipated hazards are discovered, work must stop, a new hazard assessment must be conducted, and a new job briefing held before work resumes. Safety Culture Alignment PJB’s and JHA’s clearly align with BHI Energy’s safety culture and is identified in our #1 Core Value. Sound leadership in safety is exhibited when we ensure JHA’s are developed, implemented and understood and that effective PJB’s are conducted: Start of the Day or Shift Prior to starting a new task After an extended break or lunch When conditions change Both PJB’s and JHA’s help to align safety and business processes and can identify situations where these may be in conflict with each other. They also afford each of us the opportunity to be actively engaged in identifying and controlling work-specific hazards and risks. Our Goal The goals of PJB’s and JHA’s are to provide effective tools and knowledge to effectively address: • Reducing Risk • Removal of exposure to workplace hazards • Reinforcing SAFE work behaviors If we are not focused on doing these things and using this proven systematic approach to improving safety on a daily basis, then we are wasting our time. Identifying and controlling hazards and using those controls to reduce risk will reinforce safe work behaviors over and over again. The Answer In many professional opinions, a JHA, done correctly, is the best tool to ensure that an effective and quality PJB is performed and that the right safety, health and environmental information is entered into written procedures. Thus, we should take full advantage of this tool to help ensure that the right information is identified and communicated for optimum safety performance. But the final answer is: Both. They are both equally necessary in order to have a well rounded safety process that is not only focused on the identification aspect of hazards and necessary precautions but also the presentation of the information for everyone’s benefit. If the tools is in your toolbox and available, why wouldn’t you use it? How PJB’s and JHA’s affect Human Performance Imagine a world without either the PJB or JHA tools. This could have us operating in continuous Knowledge-Based, Skill-Based and Rule-Based mode. Without these tools, we may not have the correct knowledge or information to be positive that we are working safely. This could se us up for a Knowledge-Based Error. WE cannot solely depend on tribal knowledge. While past experience and knowledge is good, sometimes retrieving this from the old “upstairs filing cabinet” can be less than adequate. Both JHA’s and PJB’s can be effective at preventing lapses, misjudgments, etc. that can quickly have us in a Skill-Based Error situation. These have both often been used to identify and mitigate barriers to working safely and even improving work practices for current and future work. These have not only improved safety but enhanced efficiency and reduced cost as well. When all of these things can be achieved concurrently, we have a fully aligned health & safety and business process. To avoid Rule-Based Error situations, we must follow rules and procedures. If we don’t develop JHA’s or conduct PJB’s as expected, we’re already there! Also, both JHA”s and PJB’s can successfully identify poorly-written procedures, programs and processes. An error committed due to a poorly-written rule is also a Rule-Based Error. In either case, it’s critical to use both of these tools to avoid any sort of potential error likely situation. The Centers is the area that will eventually trickle down to our results. Our Centers will also influence the safe or unsafe decisions that we may make. Our objective will be to stay in the “Intellectual Center”. This week’s safety topic is a prime example of actions we can take to help us stay in our Intellectual Center. By performing and documenting a JHA, we drive ourselves to remain focused and thinking about our work activities along with pitfalls and hazards that could potentially be encountered during performance. This is the knowledge part—it is during the JHA development that we begin to predict unsafe outcomes. As we move through the process and onto presentation— the PJB centers us and prepares us for the task performance. We actively engage in open discussion about the day’s activities, focusing on the activity at hand and each other—looking for signs or influences from the other 3 Centers; Emotional, Moving, and Instinctive. The objective is to identify and eliminate these influences before they can effect our safe work performance. See It, Own It, and Fix It……...stay Intellectually Centered on Safe Work Performance. Handling of an Extremely Heavy Gas Cylinder Results in Injury Lesson ID: LL13-0019 (Source: User Submitted) Originating Organization or Contracting Company: Lawrence Berkeley National Laboratory Date: 7/9/2013 Statement: This lessons learned is a follow-on to a previously issued lessons learned, which highlighted the importance of handlers and users understanding the hazards related to the size, shape and weight of a gas cylinder. This lessons learned focus is on a Lawrence Berkeley National Laboratory (LBNL) incident where a gas cylinder fell and rolled onto a graduate student’s right foot, causing multiple broken bones in the foot. This incident re-enforces the importance of understanding the hazards associated with handling compressed gas cylinders. Discussion: On April 24, 2013, at approximately 11:55, at the compressed gas racks located outside between Building 6 and 7, an LBNL graduate student lost control of a large compressed gas cylinder while trying to transfer between the gas storage rack and a gas cart. The gas cylinder fell and then rolled onto the graduate student’s right foot, pinching the foot between the cylinder and the ground. Emergency medical assistance was called and the graduate student was treated at the scene by the Alameda County Fire Department and paramedics. The graduate student was then transported to Alta Bates Emergency for further treatment and X-rays of the foot. Diagnoses were multiple broken bones in the right foot. Analysis: Three factors contributed to the accident: 1. The configuration of the cylinder rack, which included an angled transition or "ramp" (see photograph #1): The cylinder tipped on the cylinder rack ramp and could not be controlled. 2. The weight of the cylinder (341.5 Lbs): This 6000 (6K) psi rated cylinder is 2.6 times heavier than a typical K (133 Lbs) cylinder. 3. The recognition of the cylinder weight: There is no visual difference, or very little visual difference, between the 6K and a standard K type cylinder (see photograph #2). There are several lessons that can be learned from this incident: 1. Cylinders that look similar in size, shape and color may be dramatically different in weight. 2. Different procedures, equipment and tools may be necessary when handling cylinders of excessive weight, size and shape. 3. Users should learn to identify cylinders by the stamped markings located on the top sides (see photograph #3). These are the markings required by regulation. Users should make it a practice to look at the markings before handling a cylinder. Do not expect any additional labeling from a vendor or manufacturer. Actions: While LBNL may replace cylinder racks with "ramped" surfaces, all sloped surfaces cannot be removed from the facility. LBNL plans to: 1. Enhance existing training by producing a training video. The training video will address such subjects as how to identify cylinders by markings, how to handle cylinders safely, which carts and equipment to use, and how to recognize when assistance is needed (e.g. heavy cylinders, handling on sloped surfaces). 2. Distribute a series of additional Lessons Learned Briefings in the coming months covering these topics plus additional gas cylinder safety issues. 3. Develop procedures to track 6K cylinders onsite and to provide additional "Heavy" labels (see photograph #4) for 6K type cylinders while they are present at LBNL facilities.