18: Combustion System Efficiency

advertisement

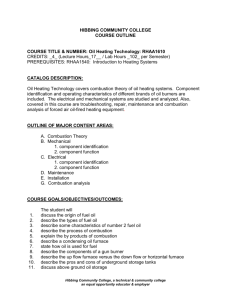

1

COMBUSTION SYSTEM EFFICIENCY

Contributing Members:

Kyle Bowen

Brandon Todd

Neal Patel

Danar Sampurno

Ivan Victoria

http://superiorboiler.com/mohawk.htm

2

Objectives

• To understand how furnaces and boilers utilize

• To model efficiency estimates with numerical methods

combustion

• To discuss how to optimize combustion systems.

• To understand the importance of the air/fuel ratio, and

how it relates to the system’s efficiency.

• To present future research possibilities

http://www.africoal.co.za/optimal-combustion-processes-fuels-excess-air/

% Excess Air that Power Plant boilers typically operate at for various fuels

http://www.sankey-diagrams.com/tag/heat-loss/

3

Furnaces

• Furnaces and Boilers operate by inputting fuel

and air into the furnace and igniting it to release

energy. The figure to the left shows a typical

furnace

• Furnaces and boilers require large amounts of

fuel to operate.

• Many Furnaces and Boilers take in more air than

stoichiometric amounts of air to ensure complete

combustion

http://home.earthlink.net/~jschwytzer/gas_fired_furnace.gif

4

Other Furnace Examples

http://www.onehourairconditioningcharlotte.com/furn

aces.html

http://www.directindustry.com/prod/seco-warwick-sp-z-oo/rotary-hearthfurnaces-16223-134754.html

http://www.enggpedia.com/chemical-engineeringencyclopedia/dictionary/thermodynamics/1778-furnace-types-classification-of-furnace

http://www.diychatroom.com/attachments/f17/63693d13582057

95-furnace-filters-turn-black-quickly-furnace-drawing.jpg

http://koppelservices.com/furnace

-repair-basics/

5

Boilers

• Similar to furnaces, boilers operate by inputting

fuel and air to release energy to boil liquid. The

figure to the left shows an example of a boiler

• Boilers require large amounts of fuel to operate,

especially as the boiling point of the liquid

increases.

• These kind of systems are extremely important

to Chemical Engineers because distillation

columns are greatly important to chemical

plants.

http://www.hauserman-engineering.com/Gasification.html

6

Other Boiler Examples

http://science.howstuffworks.com/transport/enginesequipment/steam2.htm

http://www.fapdec.org/boilers.htm

http://www.johnstonboiler.com/

http://www.aciindustries.com/boiler.htm

https://secure.sceg.com/enercom/library/furntune.asp

7

Combustion System Efficiency

• The ratio of inputted heat energy to output work is very low

for combustion systems. Small increases in efficiency lead

to large fuel savings.

• Increasing the efficiency of the entire system allows for less

fuel consumption, which leads to an increased revenue.

• Gas fired furnaces are widely used, even though they are

significantly less efficient than electric furnaces.

http://www.rayteq.com/images/gas_vs_electric_figure1.png

8

Air To Fuel Ratio

• Combustion of hydrocarbons requires O2 and are of this form:

https://www.thermalfluidscentral.org/encyclopedia/index.php/Basics_(Combustion)

• Air is the cheapest source of O2 however, as shown in the

pie chart, air is only 21% O2. When air is used, extra heat is

required to heat the remaining 79% of the components of

air as well

• Excess Air allows more complete combustion, but it also

requires more fuel in order to heat it.

http://pattiisaacs.files.wordpress.com/2011/12/air-composition-pie-chart2.jpg

9

Air To Fuel Ratio

Improve Combustion System Efficiency, Bill Axon, pg. 43

Improve Combustion System Efficiency, Bill Axon, pg. 41

This graphic shows how the amount of fuel required

greatly increases as % excess air increases

The graph further illustrates how fuel efficiency

increases as stoichiometric Air/Fuel ratio is

approached

10

Air To Fuel Methodology

• In order to simulate efficiency savings, regression

techniques were used with the data from the table

to the left.

• Polynomial Regression and Plotting techniques

were used to create plots of the data to emphasize

various trends from the data.

Improve Combustion System Efficiency, Bill Axon, pg. 41

11

MATLAB Program For Following Slide

clear

% Fuel savings by cutting back 50% excess air to 10%

%x= Furnace exit gas temperature (Farenheit)

%y= Fuel Savings (%)

x=[2600 2400 2200 2000 1800 1600 1400 1200 1000 800 600 400];

y=[81.1 59.5 45.3 35.3 27.7 21.8 17.1 13.2 9.98 7.25 4.91 2.88];

%Initialization

N=1;

i=1;

P = polyfit(x,y,N);

yp=polyval(P,x);

erri=(yp-y).^2;

err(1,i)=sqrt(sum(erri(:)))/length(y);

%While loop optimizes the degree of polynomial used for the fitting.

%Loop terminates whenever the sum of the squared errors increases or when

%the degree is 3.

while (N<3)

N=N+1;

i=i+1;

ypold=yp;

P = polyfit(x,y,N);

yp=polyval(P,x);

erri=(yp-y).^2;

err(1,i)=sqrt(sum(erri(:)))/length(y);

a=abs(err(i)/err(i-1));

if a>1, yp=ypold;N=N-1;break,end

end

% Plots the data

figure(2)

plot(x,y,'oblack',x,yp,'.blue')

xlabel('Furnace Exit Temperature, x (F)')

ylabel('Fuel Savings , y (%)')

legend('Data',['N=',num2str(N)],2)

title('Fuel Savings by cutting from 50% to 10% Excess Air')

12

Fuel Savings

• As the exit temperature of the Combustion system

increases, fuel savings from decreasing excess air

greatly increase. This is fitted by a cubic polynomial

(N=3).

• This shows that the Air/Fuel ratio is extremely

important to the efficiency of high temperature

combustion systems.

• For low temperature furnaces, the there is still

beneficial fuel savings for decreasing excess air.

13

MATLAB Program For Following Slide

clear

%x=Percent of Excess Air you are operating at (%)

x=[15 20 30 40 50 70];

%y= rows are percent fuel savings achieved by cutting back to 10% excess

%the multiple columns are values at different Furnace Exit Gas Temperatures

y=[7.44 14.9 29.8 44.6 59.5 89.3;...

4.41 8.82 17.6 26.5 35.3 52.9;...

2.73 5.45 10.9 16.4 21.8 32.7;...

1.25 2.5 4.99 7.49 9.98 15];

%Initialization

n=length(y(1));

N=0;

i=0;

error=[];

a=0.5;

yp=y;

%The while loop optimizes the degree of the polynomial used to fit the data

%It calculates the sum of the squared errors for a given degree and

%compares it to the error of the previous degree. Will not exceed cubic

while (N<3)

N=N+1;

i=i+1;

for h=1:n

ypold(h,:)=yp(h,:);

P=polyfit(x,y(h,:),N);

yp(h,:)=polyval(P,x);

error(i)=sum((yp(h,:)-y(h,:)).^2);

if i>1

a=error(i)-error(i-1);

end

if a>=1,yp=ypold; break, end

end

end

%Plot of of the X values (% excess air) vs the Y values (Fuel

savings in %)

%Plot displays regressions for multiple temperatures as well as data

points

plot(x,yp(1,:),'-black',x,yp(2,:),'--g',x,yp(3,:),'.r',x,yp(4,:),':blue'), hold on

plot(x,y(1,:),'xblack',x,y(2,:),'og',x,y(3,:),'.r',x,y(4,:),'+blue')

xlabel('% Excess Air from which to cut back to 10%'), ylabel('Fuel

Savings in Percent')

title('Fuel Savings versus Excess Air at various temperatures')

legend('2400 F','2000 F', '1600 F','1000 F',2)

%display degree of polynomial

N

14

Fuel Savings

• As Furnace Exit Gas Temperature increases,

the effect of cutting back on excess air

increases dramatically.

• For lower temperature exit gases (i.e. 1000 F),

the fuel savings for cutting back on excess air

is less pronounced and less important to

overall efficiency

• For higher temperature exit gases (i.e. 2400 F),

the fuel savings are dramatic for decreasing

excess air

15

MATLAB Program For Following Slide

clear

% Available heat is a function of fluegas temperature and 50% excess air

%x= Furnace exit gas temperature (Fahrenheit)

%y= available heat (%)

x=[300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800

1900];

y=[84.02 81 77.93 74.82 71.67 68.48 65.24 61.97 58.66 55.31 51.93 48.51 45.05

41.56 38.03 34.47 30.87];

%Initialization

N=1;

i=1;

P = polyfit(x,y,N);

yp=polyval(P,x);

erri=(yp-y).^2;

err(1,i)=sqrt(sum(erri(:)))/length(y);

%While loop optimizes the degree of polynomial used for the fitting.

%Loop terminates whenever the sum of the squared errors increases or when

%the degree is 3.

while (N<3)

N=N+1;

i=i+1;

ypold=yp;

P = polyfit(x,y,N);

yp=polyval(P,x);

erri=(yp-y).^2;

err(1,i)=sqrt(sum(erri(:)))/length(y);

a=abs(err(i)/err(i-1));

if a>1, yp=ypold;N=N-1;break,end

end

% Plot x vs y

figure(2)

subplot(1,2,1)

plot(x,y,'oblack',x,yp,'-blue')

xlabel('Temperature, x (F)')

ylabel('Available Heat, y (%)')

legend('Data',['N=',num2str(N)])

title('% Available Heat as function of Fluegas

Temperature')

%Plot for extrapolation

subplot(1,2,2)

fplot(@(x) P(1)*x^3+P(2)*x^2+P(3)*x+P(4),[200 2500]);

xlabel('Temperature, x (F)')

ylabel('Available Heat, y (%)')

legend('50% Excess Air')

title('% Available Heat as function of Fluegas

Temperature')

16

Furnace Losses

•

As the figure to the left shows, there are several

areas of heat loss in a furnace.

•

The most prominent of these sources are sensible

heat losses from exiting Fluegas.

•

The Fluegas losses can be minimized by adjusting

temperature and operating excess air.

Improve Combustion System Efficiency, Bill Axon, pg. 42

http://www.vesma.com/tutorial/furnaces.htm

17

Available Heat Methodology

• In order to view trends in available heat based

upon excess air and fluegas temperature,

regression techniques were used with the data

from the table to the left.

• Polynomial Regression and Plotting techniques

were used to create plots of the data to emphasize

various trends from the data.

Improve Combustion System Efficiency, Bill Axon, pg. 41

18

Available Heat Output

The Fluegas temperature has a dramatic effect on the amount of

useful heat output the system produces. Thus it is incredibly

important to minimize Fluegas temp in your system.

This regression plot gives is extrapolated from 0 F to 2500 F to allow

estimate the amount of available heat for a system with different

fluegas temperatures.

19

MATLAB Program For Following Slide

clear

%x=Percent of Excess Air you are operating at (%)

x=[0 5 10 25 50];

%y= Percent of Available heat as percentage of gross heat input

%the multiple columns are values at different Fluegas Temperatures

y=[86.14 85.93 85.72 85.08 84.02;...

79.68 79.19 78.71 77.25 74.82;...

65.91 64.85 63.79 60.61 55.31;...

58.64 57.29 55.93 51.85 45.05];

%Initialization

n=length(y(:,1));

N=0;

i=0;

error=[];

a=0.5;

yp=y;

%The while loop optimizes the degree of the polynomial used to fit the data

%It calculates the sum of the squared errors for a given degree and

%compares it to the error of the previous degree. Will not exceed cubic

while (N<3)

N=N+1;

i=i+1;

for h=1:n

ypold(h,:)=yp(h,:);

P=polyfit(x,y(h,:),N);

yp(h,:)=polyval(P,x);

error(i)=sum((yp(h,:)-y(h,:)).^2);

if i>1

a=error(i)-error(i-1);

end

if a>=1,yp=ypold; break, end

end

end

%Plot of of the X values (% excess air) vs the Y values (Fuel

savings in %)

%Plot displays regressions for multiple temperatures as well as data

points

plot(x,yp(1,:),'-black',x,yp(2,:),'--g',x,yp(3,:),'.r',x,yp(4,:),':blue'), hold on

plot(x,y(1,:),'xblack',x,y(2,:),'og',x,y(3,:),'.r',x,y(4,:),'+blue')

xlabel('% Excess Air'), ylabel('Available Heat (% of gross heat

input)')

title('Available Heat as function of % Excess Air')

legend('300 F','600 F','1200 F','1500 F')

%display degree of polynomial

N

20

Effect of Temperature on Available Heat Output

• For low Fluegas temperatures, the

available heat is roughly constant for all

% excess air

• As Fluegas Temperature increases,

losses in output heat are greater as %

excess air increases.

21

Improving Excess Air Control

•

•

•

•

Below figure is a pressure balanced regulator

Offers improved control over furnace environment

Can maintain constant furnace temperature

Can maintain Air/Fuel Ratio

Improve Combustion System Efficiency, Bill Axon, pg. 43

• Above figure is a mechanically linked valve

control

• Difficult to maintain constant excess air content

Improve Combustion System Efficiency, Bill Axon, pg. 44

22

Improving Excess Air Control

The figure to the left is an Electronic Mass-flow control system

Improve Combustion System Efficiency, Bill Axon, pg. 44

Pros:

• highest level of control over composition and furnace

conditions

• Compensates for Ambient Temperatures and other system

variances

• Little human input or knowledge required

Cons:

• Very expensive

• May be unnecessary for qualified human valve operator

http://community.cengage.com/Chilton/cfsfilesystemfile.ashx/__key/CommunityServer.Blogs.Components.WeblogFiles/davids_5F00_blog/2068.gasoline.direct.fuel.injectors.jpg

23

Furnace Pressure On Efficiency

• Furnace Pressure affects heat losses.

• With a lower (negative) furnace pressure than

external temperature, colder external air infiltrates

the furnace as portrayed by the graph.

• A greater (positive) furnace pressure increases the

amount of heat lost due to hot gas forced out of the

furnace.

http://www.nwfpa.org/nwfpa.info/component/content/article/50-process-heat/252-furnace-pressurecontrollers

http://www.nwfpa.org/nwfpa.info/component/content/article/50-process-heat/255-reduce-air-infiltration-in-furnaces

24

Furnace Pressure On Efficiency

•

The overall effect of cold air infiltration and hot air loss is

increased costs.

•

The figure to the left depicts how the operating costs of an

experimental furnace at positive and negative furnace

pressures

•

The graph shows that air infiltration due to negative pressure

causes prices to increase much quicker than gas loss due to

positive pressure.

•

For optimal conditions, furnace pressure should be as close to

zero as possible. Valves to control the pressure inside the

furnace would be beneficial to maintain an economically optimal

pressure inside the furnace.

25

Why is this important to Chemical Engineers?

http://csd-new.newcastle.edu.au/simulations/distillation.html

http://www.quarkology.com/12-chemistry/92-production-materials/92Asynthetic-polymers.html

http://www.indiamart.com/bioenergyengineering/distillation-column.html

http://poweryoung.org/energy.cfm@page=oil_home-basics

http://www.tutorvista.com/content/physics/physics-ii/fission-andfusion/fractional-distillation.php

26

Why is this important to Chemical Engineers?

• One of the most important units in any plant is the

distillation column

• Distillation columns require heat to boil the input

mixture. This is typically done with some sort of

combustion boiler

• Improved efficiency with the combustion system

will lead to lower energy and fuel costs and thus

increase the revenue of the plant.

http://www2.emersonprocess.com/en-us/news/pr/pages/1308-mol.aspx

27

Areas for Future Research

• Optimal excess air for different fuel types at

different temperatures

• Quantitative analysis on the effect of

boiler/furnace pressure or Heat Output

• Analysis of how mixing the boiler liquid can

increase the heat transfer from combustion

• Research in how furnace shape and design can

decrease the necessity for excess air.

• Economic cost analysis of improving technology

for combustion systems vs. fuel savings

http://www.fundamentalform.com/html/doe_report-1.html

28

Conclusion

• The air to fuel ratio is incredibly important to combustion system efficiency and

any attempt to minimize excess air within a process can lead to increased

revenue

• Numerical Methods can be applied to better understand and predict trends and

give estimates for projected savings from process improvements

• For Chemical Engineers, these systems are greatly important to distillation

columns in plants and refineries. An understanding of combustion efficiency

improvements can be a great asset to a chemical engineer.

http://www.ivaonline.com/IMG/jpg/Sealed_Quench_Furnace_MKe_MKg_with_open_antechamber_zoom.jpg