2008 SACHE Faculty Workshop presentation

2008 SACHE Faculty Workshop

Chemical

Reactivity

Hazards:

2005 SACHE Faculty Workshop

Introduction

The worst process industry disasters worldwide have involved uncontrolled chemical reactions

Thesis: Chemical reactivity hazards must be anticipated and recognized before controls can be engineered

•

Reactivity hazards that are eliminated will not need engineering and administrative controls

•

SACHE has many products that can help educate engineers to understand and safeguard against uncontrolled reactions

Syllabus

Course Texts

Pretest

Key Concepts 1

Midterm Exam

Key Concepts 2

Open-Book Final

Extra-Credit Activities

Course

Texts

Texts

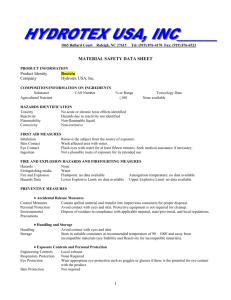

CCPS Safety Alert 2001.

Reactive Material Hazards:

What You Need to Know.

New York: AIChE. 10 pages.

Download for free at http://www.aiche.org/CCPS/Resources/SafetyAlerts/index.aspx

Texts

Johnson, Rudy, Unwin 2003.

Essential Practices for

Managing Chemical

Reactivity Hazards.

New York: AIChE. 193 p.

Register for free access at www.knovel.com/ccps

Texts

CCPS 1995.

Guidelines for Chemical

Reactivity Evaluation and

Application to Process

Design.

New York: AIChE. 210 p.

AIChE members can access for free at www.knovel.com

Texts

CCPS 1995.

Guidelines for Safe

Storage and Handling of

Reactive Materials.

New York: AIChE. 364 p.

AIChE members can access for free at www.knovel.com

Texts

CCPS 1999.

Guidelines for

Process Safety in

Batch Reaction Systems.

New York: AIChE. 171 p.

Available from www.wiley.com

Texts

Hazard Investigation 2002.

Improving Reactive

Hazard Management.

Washington, D.C.: U.S.

Chemical Safety and Hazard

Investigation Board. 150 p.

Download for free at www.csb.gov

Texts

HarsBook: A technical guide for the assessment of thermal hazards in highly

reactive chemical systems.

HarsNet Thematic Network on

Hazard Assessment of Highly

Reactive Systems. 143 p.

Download for free at www.harsnet.net

Texts

P.G. Urben (ed.) 2006.

Bretherick’s Handbook of Reactive Chemical

Hazards (2 vols).

Academic Press. 2,680 pages

~ $400 from Amazon.com; also available electronically

Software

CCPS 2006.

Chemical Reactivity

Training CD-ROM.

New York: AIChE.

$265.50 from wiley.com; free to all SACHE members

Pretest

Pretest

Q1

On the NFPA ‘diamond’, which color(s) or position(s) are associated with chemical reactivity hazards?

0

4

W

OX

3

Pretest

A1

Toxicity

Flammability

0

4

W

OX

3

Special Hazards

Instability

Pretest

Q2

Your new research calls for the piloting of a process involving acetone cyanohydrin.

What should you do first?

Pretest

A2

First, find out the inherent hazards of acetone cyanohydrin.

C

4

H

7

NO

Pretest

A2

First, find out the inherent hazards of acetone cyanohydrin.

CH

3

CH

3

C O + HCN

Pretest

A2

First, find out the inherent hazards of acetone cyanohydrin.

CH

3

CH

3

C

OH

C N

Acetone Cyanohydrin

NFPA 49

Severe health hazard; combustible; readily decomposes, producing

HCN; no “special hazards”; reacts with acids, alkalis, oxidizing materials, reducing agents

3

2

1

Acetone Cyanohydrin

International Chemical Safety Card

Extremely toxic, Class IIIB combustible, unstable at elevated temp, decomposes in water

1

4 2

Acetone Cyanohydrin

WISER (

http://wiser.nlm.nih.gov)

• HIGHLY FLAMMABLE: Easily ignited by heat, sparks or flames

• DO NOT GET WATER on spilled substance or inside containers

4

2

2

Acetone Cyanohydrin

DOT

Class 6.1 Poisonous material

Acetone Cyanohydrin

DOT

Emergency Response Guidebook 2004

A water-reactive material that produces large amounts of HCN when spilled in water

Acetone Cyanohydrin

NOAA Chemical Reactivity Worksheet

Chemical Profile

Readily decomposes to acetone and poisonous hydrogen cyanide gas on contact with water, acids (sulfuric acid) or when exposed to heat.

Should be kept cool and slightly acidic (pH 4-5) [Sax,

2nd ed., 1965, p. 388].

Slowly dissociates to acetone, a flammable liquid, and hydrogen cyanide, a flammable poisonous gas, under normal storage and transportation conditions.

Rate of dissociation increased by contact with alkalis and/or heat.

Special Hazards

· Water-Reactive

No rapid reaction with Air

Air and Water Reactions

Soluble in water. Readily decomposes on contact with water to form acetone and poisonous hydrogen cyanide.

General Description

A colorless liquid. Flash point 165°F.

Lethal by inhalation and highly toxic or lethal by skin absorption. Density 7.8 lb / gal (less dense than water). Vapors heavier than air. Produces toxic oxides of nitrogen during combustion (© AAR, 1999).

Acetone Cyanohydrin

NIOSH

Pocket Guide to Chemical Hazards

Incompatibilities & Reactivities:

Sulfuric acid, caustics

Note: Slowly decomposes to acetone & HCN at room temperatures; rate is accelerated by an increase in pH, water content, or temperature.

Acetone Cyanohydrin

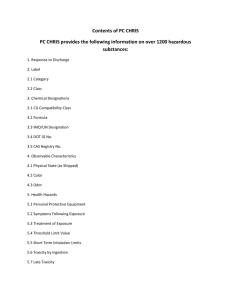

CHRIS

Acetone Cyanohydrin

CHRIS

Acetone Cyanohydrin

SIDS: Stability in Water

60

50

40

30

20

10

0

4.5

5 5.5

6 pH

6.5

7 7.5

Acetone Cyanohydrin

Conclusions

Extremely toxic; must keep contained and avoid all contact

Combustible; must avoid flame, ignition

Dissociates to produce highly toxic and flammable gases; dissociation increases with heat, moisture, alkalinity

Must prevent spills into drains, etc.

Must avoid incompatible materials

Key Concepts

Key Concepts

From 2005 SACHE module on

Chemical Reactivity Hazards

(etc.)

The NOAA Chemical Reactivity

Worksheet predicts the results of mixing any binary combination of the 6,080 chemicals in the CAMEO database, including many common mixtures and solutions.

For each substance, a general description and chemical profile are given, along with special hazards such as air and water reactivity.

CRWorksheet Limitations

Only binary combinations considered

Consequences predicted only for ambient temperature, atmospheric pressure

Possible effects of confinement, catalysts, contaminants, or materials of construction not included

Reaction products not predicted, though flammable or toxic gas generation may be suggested

Preliminary

Screen for

Chemical

Reactivity

Hazards

Summary

Flowchart

Source: Johnson et al. 2003

Incident

April 21, 1995

5 worker fatalities

~300 evacuated

Facility destroyed

Surrounding businesses damaged

Ed Hill, The Bergen Record

Used with permission

WHY?

Those hazards that are not eliminated or reduced to insignificance must be managed throughout the lifetime of the facility, to avoid uncontrolled chemical reactions that can result directly or indirectly in serious harm to people, property or the environment.

Inherently Cleaner, Safer Plants

y

Inherently

Cleaner

Processes

Pollution

Prevention

Waste

Management

Environmental

Restoration

POTENTIAL

Processes

Safer

Inherentl ention Prev

RELEASE ion Mitigat ry

AFTERMATH

Recove

Accident

Safe Operation

(with respect to Chemical Reactivity Hazards)

Contain and control all chemical reactivity hazards throughout entire facility lifetime

Reduce hazards or design safeguards such that even if hazard containment or control were lost, no injuries, property damage, environmental damage or business interruption would occur

Eliminate chemical reactivity hazards

Inherently Safer Strategies

MINIMIZE

SUBSTITUTE

MODERATE

SIMPLIFY

Foresee, Avoid, Control

Anticipate chemical reactivity hazards

Identify all reactive materials and all possible reactive interactions

Do whatever it takes to fully understand intended and unintended reactions

• Boundaries of safe operation

• Calculations, literature, testing, experts

Design and operate to avoid unintended reactions and control intended reactions

START

Managing

Chemical

Reactivity

Hazards

NO

Sufficient information to evaluate hazard?

YES

4.5

Assess Chemical

Reactivity Risks

Section 4.1

Develop/Document System to Manage Chemical Reactivity Hazards

4.2

Collect Reactivity

Hazard Information

4.3

Identify Chemical

Reactivity Hazards

4.4

Test for Chemical

Reactivity

4.9

Investigate

Chemical

Reactivity

Incidents

4.10

Review, Audit,

Manage Change,

Improve Hazard

Management

Practices/Program

4.6

Identify Process

Controls and Risk

Management Options

IMPLEMENT; OPERATE FACILITY

4.8

Communicate and Train on

Chemical Reactivity Hazards

4.7

Document Chemical Reactivity

Risks and Management Decisions

Identify,

Characterize

Hazards

NO

4.2

Collect Reactivity

Hazard Information

4.3

Identify Chemical

Reactivity Hazards

4.4

Test for Chemical

Reactivity

Sufficient information to evaluate hazard?

YES

4.5

Assess Chemical

Reactivity Risks

4.6

Identify Process

Controls and Risk

Management Options

4.9

Investigate

Chemical

Reactivity

Incidents

4.10

Review, Audit,

Manage Change,

Improve Hazard

Management

Practices/Program

IMPLEMENT; OPERATE FACILITY

4.8

Communicate and Train on

Chemical Reactivity Hazards

4.7

Document Chemical Reactivity

Risks and Management Decisions

Chemical Reaction Hazard Identification

D.C. Hendershot 2002. “A Checklist for Inherently Safer

Chemical Reaction Process Design and Operation.” CCPS

International Symposium on Risk, Reliability and Security.

Reaction Hazard Identification

1 Know the heat of reaction for the intended and other potential chemical reactions.

There are a number of techniques for measuring or estimating heat of reaction, including various calorimeters, plant heat and energy balances for processes already in operation, analogy with similar chemistry (confirmed by a chemist who is familiar with the chemistry), literature resources, supplier contacts, and thermodynamic estimation techniques. You should identify all potential reactions that could occur in the reaction mixture and understand the heat of reaction of these reactions.

Reaction Hazard Identification

2 Calculate the maximum adiabatic temperature for the reaction mixture .

Use the measured or estimated heat of reaction, assume no heat removal, and that 100% of the reactants actually react. Compare this temperature to the boiling point of the reaction mixture. If the maximum adiabatic reaction temperature exceeds the reaction mixture boiling point, the reaction is capable of generating pressure in a closed vessel and you will have to evaluate safeguards to prevent uncontrolled reaction and consider the need for emergency pressure relief systems.

Reaction Hazard Identification

3 Determine the stability of all individual components of the reaction mixture at the maximum adiabatic reaction temperature.

This might be done through literature searching, supplier contacts, or experimentation. Note that this does not ensure the stability of the reaction mixture because it does not account for any reaction among components, or decomposition promoted by combinations of components. It will tell you if any of the individual components of the reaction mixture can decompose at temperatures which are theoretically attainable.

Reaction Hazard Identification

3

(continued)

If any components can decompose at the maximum adiabatic reaction temperature, you will have to under-stand the nature of this decomposition and evaluate the need for safeguards including emergency pressure relief systems.

Reaction Hazard Identification

4 Understand the stability of the reaction mixture at the maximum adiabatic reaction temperature.

Are there any chemical reactions, other than the intended reaction, which can occur at the maximum adiabatic reaction temperature? Consider possible decomposition reactions, particularly those which generate gaseous products. These are a particular concern because a small mass of reacting condensed liquid can generate a very large volume of gas from the reaction products, resulting in rapid pressure generation in a closed vessel.

Reaction Hazard Identification

4

(continued)

Again, if this is possible, you will have to understand how these reactions will impact the need for safeguards, including emergency pressure relief systems.

Understanding the stability of a mixture of components may require laboratory testing.

Reaction Hazard Identification

5 Determine the heat addition and heat removal capabilities of the pilot plant or production reactor.

Don’t forget to consider the reactor agitator as a source of energy – about 2550 Btu/hour/horsepower.

Understand the impact of variation in conditions on heat transfer capability. Consider factors such as reactor fill level, agitation, fouling of internal and external heat transfer surfaces, variation in the temperature of heating and cooling media, variation in flow rate of heating and cooling fluids.

Reaction Hazard Identification

6 Identify potential reaction contaminants.

I n particular, consider possible contaminants which are ubiquitous in a plant environment, such as air, water, rust, oil and grease. Think about possible catalytic effects of trace metal ions such as sodium, calcium, and others commonly present in process water. These may also be left behind from cleaning operations such as cleaning equipment with aqueous sodium hydroxide.

Determine if these materials will catalyze any decomposition or other reactions, either at normal conditions or at the maximum adiabatic reaction temperature.

Reaction Hazard Identification

7 Consider the impact of possible deviations from intended reactant charges and operating conditions.

For example, is a double charge of one of the reactants a possible deviation, and, if so, what is the impact? This kind of deviation might affect the chemistry which occurs in the reactor – for example, the excess material charged may react with the product of the intended reaction or with a reaction solvent. The resulting unanticipated chemical reactions could be energetic, generate gases, or produce unstable products. Consider the impact of loss of cooling, agitation, and temperature control, insufficient solvent or fluidizing media, and reverse flow into feed piping or storage tanks.

Reaction Hazard Identification

8 Identify all heat sources connected to the reaction vessel and determine their maximum temperature.

Assume all control systems on the reactor heating systems fail to the maximum temperature. If this temperature is higher than the maximum adiabatic reaction temperature, review the stability and reactivity information with respect to the maximum temperature to which the reactor contents could be heated by the vessel heat sources.

Reaction Hazard Identification

9 Determine the minimum temperature to which the reactor cooling sources could cool the reaction mixture.

Consider potential hazards resulting from too much cooling, such as freezing of reaction mixture components, fouling of heat transfer surfaces, increase in reaction mixture viscosity reducing mixing and heat transfer, precipitation of dissolved solids from the reaction mixture, and a reduced rate of reaction resulting in a hazardous accumulation of unreacted material.

Reaction Hazard Identification

10 Consider the impact of higher temperature gradients in plant scale equipment compared to a laboratory or pilot plant reactor.

Agitation is almost certain to be less effective in a plant reactor, and the temperature of the reaction mixture near heat transfer surfaces may be higher (for systems being heated) or lower (for systems being cooled) than the bulk mixture temperature. For exothermic reactions, the temperature may also be higher near the point of introduction of reactants because of poor mixing and localized reaction at the point of reactant contact.

Reaction Hazard Identification

10

(continued)

The location of the reactor temperature sensor relative to the agitator, and to heating and cooling surfaces may impact its ability to provide good information about the actual average reactor temperature. These problems will be more severe for very viscous systems, or if the reaction mixture includes solids which can foul temperature measurement devices or heat transfer surfaces. Either a local high temperature or a local low temperature could cause a problem. A high temperature, for example, near a heating surface, could result in a different chemical reaction or decomposition at the higher temperature.

Reaction Hazard Identification

10

(continued)

A low temperature near a cooling coil could result in slower reaction and a buildup of unreacted material, increasing the potential chemical energy of reaction available in the reactor. If this material is subsequently reacted because of an increase in temperature or other change in reactor conditions, there is a possibility of an uncontrolled reaction due to the unexpectedly high quantity of unreacted material available.

Reaction Hazard Identification

11 Understand the rate of all chemical reactions.

It is not necessary to develop complete kinetic models with rate constants and other details, but you should understand how fast reactants are consumed and generally how the rate of reaction increases with temperature. Thermal hazard calorimetry testing can provide useful kinetic data.

Reaction Hazard Identification

12 Consider possible vapor phase reactions.

These might include combustion reactions, other vapor phase reactions such as the reaction of organic vapors with a chlorine atmosphere, and vapor phase decomposition of materials such as ethylene oxide or organic peroxide.

Reaction Hazard Identification

13 Understand the hazards of the products of both intended and unintended reactions.

For example, does the intended reaction, or a possible unintended reaction, form viscous materials, solids, gases, corrosive products, highly toxic products, or materials which will swell or degrade gaskets, pipe linings, or other polymer components of a system? If you find an unexpected material in reaction equipment, determine what it is and what impact it might have on system hazards. For example, in an oxidation reactor, solids were known to be present, but nobody knew what they were. It turned out that the solids were pyrophoric, and they caused a fire in the reactor.

Reaction Hazard Identification

14 Consider doing a Chemical Interaction

Matrix and/or a Chemistry Hazard

Analysis .

These techniques can be applied at any stage in the process life cycle, from early research through an operating plant (Mosley et al. 2000). They are intended to provide a systematic method to identify chemical interaction hazards and hazards resulting from deviations from intended operating conditions.

ASTM E 2012-00

“Standard Guide for the Preparation of a

Binary Chemical Compatibility Chart”

Scenario-based

Inadvertent Mixing Scenarios

SCENARIO

1 Mix one liter of household ammonia cleaner into four liters of household chlorine bleach in an open bucket, with intention of immediate use

CONDITIONS

NORMAL?

1

Yes

R, NR or

?

2

R

INFORMATION SOURCES; COMMENTS

Based on sodium hypochlorite solution

MSDS. Generates heat and toxic vapors; can form explosive nitrogen trichloride under certain conditions

2 Inadvertently pump up to 1400 kg of 38°C cyclohexane at 0.3 kg/s into closed, temperature-controlled storage tank of between 700 and 2800 kg of acrylic acid with

200 ppm MEHQ inhibitor, maintained at 20°C

No ?

Compatibility information only known for ambient conditions; no reaction with cyclohexane expected, but may be hot enough to increase dimer formation and possibly initiate polymerization

1

Does the contact/mixing occur at ambient temperature, atmospheric pressure, 21% oxygen atmosphere, and unconfined? (IF NOT, DO NOT ASSUME THAT PUBLISHED DATA FOR AMBIENT CONDITIONS APPLY)

2

R = Reactive (incompatible) under the stated scenario and conditions

NR = Non-reactive (compatible) under the stated scenario and conditions

? = Unknown; assume incompatible until further information is obtained

Johnson and Lodal, "Screen Your Facilities for

Chemical Reactivity Hazards," CEP, Aug. 2003

Inadvertent Mixing Scenarios

cyclohexane at 0.3 kg/s into closed, temperature-controlled storage tank of

200 ppm MEHQ inhibitor, maintained at 20°C

between 700 and 2800 kg of acrylic acid with

200 ppm MEHQ inhibitor, maintained at 20°C

Inadvertent Mixing Scenarios

SCENARIO

CONDITIONS

NORMAL?

1

2 Inadvertently pump up to 1400 kg of 38°C cyclohexane at 0.3 kg/s into closed, temperature-controlled storage tank of between 700 and 2800 kg of acrylic acid with

200 ppm MEHQ inhibitor, maintained at 20°C

No

1

Does the contact/mixing occur at ambient temperature, atmospheric pressure,

21% oxygen atmosphere, and unconfined? (IF NOT, DO NOT ASSUME THAT

PUBLISHED DATA FOR AMBIENT CONDITIONS APPLY)

Inadvertent Mixing Scenarios

SCENARIO

CONDITIONS

NORMAL?

1

R, NR or ?

2

2 Inadvertently pump up to 1400 kg of 38°C cyclohexane at 0.3 kg/s into closed, temperature-controlled storage tank of between 700 and 2800 kg of acrylic acid with

200 ppm MEHQ inhibitor, maintained at 20°C

No ?

2

R = Reactive (incompatible) under the stated scenario and conditions

NR = Non-reactive (compatible) under the stated scenario and conditions

? = Unknown; assume incompatible until further information is obtained

Inadvertent Mixing Scenarios

SCENARIO

CONDITIONS

NORMAL?

1

R, NR or

?

2

INFORMATION SOURCES; COMMENTS

Compatibility information only known for

2 Inadvertently pump up to 1400 kg of 38°C cyclohexane at 0.3 kg/s into closed, temperature-controlled storage tank of between 700 and 2800 kg of acrylic acid with

200 ppm MEHQ inhibitor, maintained at 20°C

?

Compatibility information only known for

cyclohexane expected, but may be hot enough to increase dimer formation and possibly initiate polymerization

Inadvertent Mixing Scenarios

SCENARIO

2 Inadvertently pump up to 1400 kg of 38°C cyclohexane at 0.3 kg/s into closed, temperature-controlled storage tank of between 700 and 2800 kg of acrylic acid with

200 ppm MEHQ inhibitor, maintained at 20°C

CONDITIONS

NORMAL?

1

R, NR or

?

2

INFORMATION SOURCES; COMMENTS

No ?

Compatibility information only known for ambient conditions; no reaction with cyclohexane expected, but may be hot enough to increase dimer formation and possibly initiate polymerization

G.W. Boicourt, “Experimental Safety: What You

Need for Effective Process Safety Evaluation,”

Proceed. 30 th Annual Loss Prev. Symp., 2/96.

Inadvertent Mixing Scenarios

SCENARIO

2 Inadvertently pump up to 1400 kg of 38°C cyclohexane at 0.3 kg/s into closed, temperature-controlled storage tank of between 700 and 2800 kg of acrylic acid with

200 ppm MEHQ inhibitor, maintained at 20°C

CONDITIONS

NORMAL?

1

R, NR or

?

2

INFORMATION SOURCES; COMMENTS

No ?

Compatibility information only known for ambient conditions; no reaction with cyclohexane expected, but may be hot enough to increase dimer formation and possibly initiate polymerization

GuideWord/

Deviation

AS WELL AS

Cyclohexane

Added

Cause

Connecting valve left open

Freq Consequences

Containment rupture explosion

Fire

Toxic reaction products release

Severity

On Off

Chemistry Hazard Analysis Scenarios

Guideword Deviation

No No Catalyst C added

More High temperature; greater than

70°C

As well as Rust, as well as normal materials

Consequences

No reaction when Reactants A and B are mixed; if Catalyst C is added after the entire charge of Reactants A and B has been completed, a rapid and violent reaction can occur

Side reactions have been observed in similar systems above 70°C, and may also occur with this chemistry

The effect of contamination with iron or rust is unknown

Comments/Actions

Develop kinetic and thermodynamic data on this reaction

Investigate the behavior of the reaction at elevated temperature

Determine the effect of iron/rust contamination

Mosley, Ness, and Hendershot, "Screen Reactive Chemical

Hazards Early in Process Development," CEP, Nov. 2000

NO

4.2

Collect Reactivity

Hazard Information

4.3

Identify Chemical

Reactivity Hazards

4.4

Test for Chemical

Reactivity

4.9

Investigate

Chemical

Reactivity

Incidents

4.10

Review, Audit,

Manage Change,

Improve Hazard

Management

Practices/Program

IMPLEMENT; OPERATE FACILITY

Sufficient information to evaluate hazard?

YES

4.5

Assess Chemical

Reactivity Risks

4.8

Communicate and Train on

Chemical Reactivity Hazards

PHAs; Ensure Risk Control

4.6

Identify Process

Controls and Risk

Management Options

4.7

Document Chemical Reactivity

Risks and Management Decisions

Chemical

Reactivity

Hazards

Identify, characterize hazards

Intentional Chemistry

Unintentional Chemistry

• Materials Reactive with

Ubiquitous Substances

– Spontaneously Combustible

– Peroxide Forming

– Water Reactive

– Oxidizing

• Self-Reactive Materials

– Polymerizing

– Decomposing

– Rearranging

• Reactive Interactions

– Incompatibilities

– Abnormal Conditions

Normal Situation - Reactives

Reactive materials contained

Reactive interactions

(incompatibilities) avoided

Intended reactions controlled

Chemical

Reactivity

Hazards

Potential Loss Event

Impacts

• People

• Property

• Environment

Abnormal Situation - Reactives

Loss of containment

Reactive interaction

(incompatibility)

Loss of reaction control

Chemical

Reactivity

Hazards

Deviation

Chemical Reactivity: Loss Events

Johnson and Unwin, “Addressing Chemical Reactivity

Hazards in Process Hazard Analysis,” 18th Annual

International CCPS Conference, NY: AIChE, Sept. 2003.

Loss Event

• Fire

• Explosion

• Release

Loss Events Associated with Reactivity Hazards

Hazard Type Typical Uncontrolled Chemical Reaction Consequences

Intentional

Chemistry

Containment rupture explosion (uncontrolled reaction resulting in liquid/vapor heating or gas generation inside inadequately relieved vessel or enclosure that is incapable of withstanding peak pressure)

Fire (e.g., excess heating or loss of cooling in unconfined configuration allows autoignition temperature to be attained)

Toxic reaction products release (e.g., off-gas treatment system fails)

Spontaneously

Combustible

Materials

Peroxide

Formers

Containment rupture explosion (self-ignition of vapor, dust or mist inside inadequately relieved vessel or enclosure that is incapable of withstanding peak pressure)

Fire (e.g., self-ignition of flash fire, jet fire, pool fire, pile fire, or building fire)

Toxic combustion gases release

Condensed-phase explosion (e.g., explosive decomposition of unstable peroxide initiated by heat, friction, spark, or mechanical shock)

Fire (e.g., follow-on effects from condensed-phase explosion, such as flammable liquid containment rupture and ignition)

Hazard Type Typical Uncontrolled Chemical Reaction Consequences

Water-

Reactive

Materials

Explosively violent reaction (e.g., reaction of sodium with water)

Containment rupture explosion (reaction with water resulting in liquid/vapor heating or gas generation inside inadequately relieved vessel or enclosure that is incapable of withstanding peak pressure, or flammable vapors generated by reaction with water ignited inside inadequately relieved vessel or enclosure that is incapable of withstanding peak pressure)

Flash fire (e.g., ignition of unconfined flammable vapors generated by reaction with water)

Toxic vapor release (toxic vapors generated by reaction with water, or decomposition reaction initiated by heat of reaction with water)

Oxidizers Fire (initiated or accelerated by presence of oxidizer)

Condensed-phase explosion (initiation of detonable mixture of oxidizer with reducing substance)

Containment rupture explosion (ignition or spontaneous ignition of oxidation reaction inside inadequately relieved vessel or enclosure that is incapable of withstanding peak pressure)

Toxic combustion gases release

• Note that many oxidizers are subject to decomposition, so also have possible Self-Reactive Material consequences

Hazard Type Typical Uncontrolled Chemical Reaction Consequences

Self-Reactive

Materials

(Polymerizing,

Decomposing,

Rearranging)

Condensed-phase explosion (e.g., heat, friction, spark, or mechanical shock initiation of decomposition proceeding at detonation velocity)

Containment rupture explosion (e.g., by self-reaction resulting in liquid/vapor heating, gas generation, or evolution and ignition of flammable vapors inside inadequately relieved vessel or enclosure that is incapable of withstanding peak pressure)

Toxic vapor release (e.g., from toxic decomposition products or heat from self-reaction resulting in vaporization of toxic component)

Flash fire (e.g., by ignition of flammable off-gases)

Pile fire (e.g., by self-heating to autoignition temperature)

Incompatible

Materials

Condensed-phase explosion (e.g., by initiation of detonable mixture)

Containment rupture explosion (e.g., by liquid/vapor heating, gas generation, or evolution and ignition of flammable vapors inside inadequately relieved vessel or enclosure that is incapable of withstanding peak pressure)

Toxic vapor release (e.g., from toxic reaction products or from heating and vaporization of toxic component)

Flash fire (e.g., by ignition of flammable off-gases)

Hazardous material spill (e.g., loss of containment due to reaction with wrong material of construction)

Extra-

Credit

Activities

SACHE Case Histories

Batch Polystyrene Reactor Runaway

The Bhopal Disaster

Methacrylic Acid Tankcar Explosion -video

Explosion and Fire Caused By a Runaway

Decomposition

Rupture of a Nitroaniline Reactor

Seveso Accidental Release

Mini Case Histories

SACHE Reactivity Products

Hazards Awareness and Reduction

An Introduction to Reactive and

Explosive Materials (video)

Acrylic Monomers Handling

The Hazards of Hydroxylamine

Chemical Reactivity Hazards (web-based)

Introduction to Inherently Safer Design

SACHE Reactivity Products

Emergency Relief Systems

Design for Overpressure and

Underpressure Protection

Unit Operations Laboratory Experiment for Runaway Reactions and Vent Sizing

Relief System Design for Single- and

Two-Phase Flow

Runaway Reactions -- Experimental

Characterization and Vent Sizing

RMR

Reactivity Management Roundtable

Kickoff Meeting

Las Vegas, Nevada

October 23, 2003

Most Recent Activities

• NOAA CRW updating

• Warehousing matrix

• TurboTax ® -type chemical reactivity hazard identification

DIERS Users Group

AIChE Design Institute for Emergency

Relief Systems

DIERS Users Group Meetings

See http://www.diers.net/diersweb/home.aspx

for schedule and information

DIERS Conference

3rd International Symposium on

Runaway Reactions and

Pressure Relief Design

Cincinnati, Ohio

October 31 - November 4, 2005

Held in conjunction with

2005 AIChE Annual Meeting

DIERS Conference Topics

1 Theoretical and Experimental Reactivity Screening

2 Best Practices and Standards for Managing

Chemical Reactivity

ERS Design for Reactive Systems

3 – Computational Methods

4 – Experimental Methods

5 – Fire Exposure

6 Effluent Handling Design for Reactive Systems

Loss Prevention Symposium

43rd Annual Loss Prevention Symposium

Tampa, Florida

April 27-29, 2009

Fires, Explosions and Reactive Hazards

Case Histories and Lessons Learned

Continuing Education Courses

AIChE / ASME onsite: “Identifying and

Managing Chemical Reactivity Hazards”

Mary Kay O’Connor Process Safety Ctr

2008 SACHE Faculty Workshop

Chemical

Reactivity

Hazards

Contact Information

Robert W. Johnson

Unwin Company

1920 Northwest Blvd, Suite 201

Columbus, OH 43212-1197 USA

(

614) 486-2245 rjohnson@unwin-co.com

www.unwin-co.com