Design-Build - FDOT - Florida Department of Transportation

advertisement

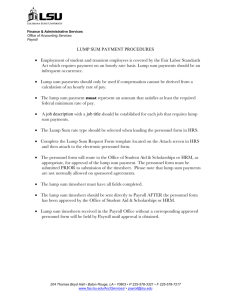

ALTERNATIVE CONTRACTING 1 ALTERNATIVE CONTRACTING LUMP SUM DESIGN BUILD CM@RISK 2 LUMP SUM 3 Lump Sum What is it? Project Selection Construction Contract Administration 4 What is it? Method of Contracting upon which Contractor submits a LS Bid for all work vs. bidding individual Pay Items Intended to reduce design & contract administration costs 5 Project Selection “Simple” Projects Well Defined Scope Low risk of unforeseen conditions Low possibility of changes during all phases 6 Construction Contract Administration Payments based on approved payout schedule (SoV) Inspection Personnel should not be required to document quantities (except for those subject to adjustments i.e. asphalt) Focus on Inspection, Quality and Conformance with contract 7 LUMP SUM Project plans preparation Desired Elements Typical Sections Milling/Resurfacing (and overbuild where appropriate) details Summary boxes when work not shown on Plan Sheets Plan Sheets depict existing conditions & detail work to be performed LUMP SUM Project plans preparation Desired Elements (continued) Plan Sheets detail all work not covered by Typical Section and/or Design Standards Cross Sections (when shoulder point is moved) Signing/Pavement Marking, Signalization and Lighting Plans: Include Pay Items for Reference Purposes Only Include Note: “Pay item number provided only for purpose of describing work to be performed” LUMP SUM STANDARD SPECIFICATIONS 2-3.1 – INTERPRETATION OF QUANTITIES (Lump Sum Contracts) Bidder responsible for determination of quantities LUMP SUM STANDARD SPECIFICATIONS 105-2 ADDITIONAL REQUIREMENTS FOR LUMP SUM PROJECTS Job Guide Schedule Project specific list of materials & quantities Submit 21 days prior to commencement of construction Update Monthly No Commencement until Department Approval Final JGS at Final Acceptance LUMP SUM SPECIAL PROVISIONS SP0030100LS – Award & Execution of Contract 3-1 For the purpose of award, after opening and reading the proposals, the Department will consider the total Contract Lump Sum Price as the bid. On this basis, the Department will compare the amounts of each bid and make the results of such comparison available to the public. Until the actual award of the Contract, however, the Department reserves the right to reject any or all proposals and to waive technical errors that the Department may deem best for the interest of the State. In the event of any discrepancy in the two entries of the Contract Lump Sum Price, the Department will evaluate the bid based on the lump sum price shown in words. LUMP SUM SPECIAL PROVISIONS SP0040100LS – Scope of Work 4-1 Intent & Scope LS Contract w/1 Pay Item Listed in Contract Pay Item Number References superseded by the LS Pay Item Payment for all work made under LS Pay Item Pay Adjustments don’t apply (except for those in 9-2) LUMP SUM SPECIAL PROVISIONS SP0040100LS – Scope of Work 4-3.1 General Defines term “significant change” as Engineer determination Deletes reference to 125% increase / 75% decrease of “original Contract quantity” LUMP SUM SPECIAL PROVISIONS SP0050501LS – Control of the Work 5-1.1 Adds “All reference to separate payment for individual items of work will not apply. The cost for various items of work will be included and paid for under the Contract Lump Sum Price.” LUMP SUM SPECIAL PROVISIONS SP0060100LS – Control of Materials 6-1.3.3 Establishes material sampling & testing acceptance requirements are in accordance with 105-1 & 105-2 for the following: Earthwork Base Hot Bituminous Mixtures Portland Cement Concrete Reinforcing Steel Fabricated Metals LUMP SUM SPECIAL PROVISIONS SP0060100LS – Control of Materials 6-1.3.4 Establishes specific certification requirements for QPL Products Notarized Certification prior to material utilization Manufacturer Letterhead Product Name & Batch Number FPID & Contract Number County Test Result Certification Statement LUMP SUM SPECIAL PROVISIONS SP0060100LS – Control of Materials 6-1.3.5 Establishes specific certification requirements for Non-QPL Products Notarized Certification prior to material utilization Manufacturer Letterhead Material Identification Material Type FPID & Contract Number County Test Result Certification Statement LUMP SUM SPECIAL PROVISIONS SP0080401LS – Prosecution & Progress 8-7.3.1 – Increased Work Department may grant time extension when adding new work or providing for unforeseen work rather than overruns in original contract items. LUMP SUM SPECIAL PROVISIONS SP0090103LS – Measurement & Payment 9-1.3 Establishes criteria for the determination of Pay Reductions LUMP SUM SPECIAL PROVISIONS SP0090103LS – Measurement & Payment (cont.) 9-2.1 Establishes those items included in LS Payment Furnishing all materials Performing all work Loss / damage arising out of nature of work Overhead Profit Direct / Indirect Cost LUMP SUM SPECIAL PROVISIONS SP0090103LS – Measurement & Payment (cont.) 9-2.1.1 Establishes criteria for Fuel Adjustments on Contracts with an Original Contract Time in excess of 120 Calendar Days LUMP SUM SPECIAL PROVISIONS SP0090103LS – Measurement & Payment (cont.) 9-2.1.2 Establishes criteria for Bituminous Adjustments on Contracts with an Original Contract Time in excess of 365 Calendar Days or more than 5,000 Tons of Asphalt LUMP SUM SPECIAL PROVISIONS SP0090103LS – Measurement & Payment (cont.) 9-2.2 Establishes Pay Adjustment criteria for: Deficiencies (9-2.2.1) Spread Rate (9-2.2.2) Overbuild (9-2.2.3) Foundations (9-2.2.4) Quality (9-2.2.5) Deleted Work (9-2.2.6) LUMP SUM SPECIAL PROVISIONS SP0090103LS – Measurement & Payment (cont.) 9-5.5.2 Establishes Partial Payment criteria Partial Payments less than $5,000 in any one month are not processed No Partial Payment for aggregate or base material received after paving / base construction begins unless Department suspends paving or base operations Deletes item bid price limitations placed on: Structural Steel / Precast Pre-stressed Items (85%) Other Items (75%) LUMP SUM SPECIAL PROVISIONS SP0090103LS – Measurement & Payment (cont.) 9-11.1 Establishes Invoice Submittal Requirements: Contractor prepares Invoice & submits to Engineer Engineer approves Invoice prior to making payment LUMP SUM SPECIAL PROVISIONS SP0090103LS – Measurement & Payment (cont.) 9-11.2 Establishes Invoice Submittal Requirements: Submit by 12:00 on Monday following estimate cut-off date Invoice based on work completed Invoice must include: Contract/FPID/Invoice Number Invoice Date & period covered LUMP SUM SPECIAL PROVISIONS SP0090103LS – Measurement & Payment (cont.) 9-11.2 Establishes Invoice Submittal Requirements (cont): Basis of Progress Invoice amount: Approximate Quantities Less Previous Payments Less amounts previously retained or withheld Contract Summary: % dollar value of completed work % of days used based on present Contract Days Certify: Fuel & Bituminous Gallons Steel weight for Indexed items DESIGN-BUILD 29 Design-Build Authorization Project Selection Criteria Warranties 30 DESIGN-BUILD AUTHORIZATION 31 Authorization Design Build (D-B) Contracting Authorization – FLORIDA STATUTES D-B Major Projects Authorization – 337.11(7) F.S. Buildings Major Bridge Limited Access Facilities Rail Corridor Estimated cost exceeds $10M 32 Authorization Design Build (D-B) Contracting Authorization FLORIDA STATUTES Minor D-B Projects Authorization –337.025 F.S. Innovative Contracting Statute – Annual Cap of $120M Minor Bridge Resurfacing (no widening/shoulder work) Projects not covered by 337.11(7) F.S. Estimated Cost less than $10M 33 DESIGN-BUILD PROJECT SELECTION 34 Project Selection Design Build (D-B) contracting should be considered on the following types of projects: Demand an expedited schedule and can be completed earlier Require minimal Right of Way acquisition and utility relocation Well defined scope Allow for innovation in the design and/or construction effort Low risk of unforeseen conditions Low possibility of significant changes 35 Project Selection Examples of projects which may be good D-B contracting candidates: Major Bridges Minor Bridges ITS (computer signalized traffic) Intersection improvement (with known utilities) Buildings-office building, rest areas, welcome stations, etc. 36 Project Selection Examples of projects which may be good D-B contracting candidates (continued): Interstate widening Rural Widening Fencing Landscaping Lighting Signing Signalization Guardrail 37 Project Selection Examples of projects which may not be good D-B contracting candidates are: Major bridge rehab/repair with significant unknowns Rehab of movable bridges Urban construction/reconstruction with major utilities, major subsoil, R/W or other major unknowns 38 DESIGN-BUILD CRITERIA 39 Developing Design-Build Criteria Adjusted Score or Low Bid? Adjusted Score • Want (or need) to have input by evaluating the D-B firm and Technical Proposal (prior to bid time) • Innovation or potential alternatives exist • Scope is more versatile 40 Developing Design-Build Criteria Low Bid • Straight forward projects –(guardrail, noise walls, milling and resurfacing, etc.) • Scope is well defined 41 Request for Proposals Much of the language is standard from SCO website Grading Criteria Decide what is important Innovation Maintenance of Traffic Aesthetics Environmental Schedule Assign Points Accordingly 42 Two Phase Adjusted Score Design-Build Procurements • ASDB procurement – Two phase process which combines evaluation scores of – Phase I - Expanded Letters of Interest (ELOI) – Phase II - Technical proposal 43 Two Phase Process Phase I Phase II ELOI RFP Evaluate & Score Technical Proposals Short List Evaluate & Score Award Contract Select Design-Builder Calculate Lowest Adjusted Score Using Price Proposal from D-B Firm 44 Issue Escalation & Resolution RFP sets a hierarchy for design issues and construction issues to be resolved through a defined chain of command D-B Firm will be required to set a similar escalation process for both design and construction 45 Issue Escalation & Resolution Design Project Manager Construction Project Mgr District Design Engineer District Const. Engineer Director of Development District Secretary Director of Operations District Secretary 46 STIPENDS Only on ASDB Projects 47 Stipends for unsuccessful firms The Department intends to compensate eligible unsuccessful short-listed Firms for submitting a proposal The eligible unsuccessful short-listed Firms may receive compensation (lump sum) for their efforts in preparing a proposal if the proposal is determined to be responsive The intent to compensate and the amount of compensation will be noted in the RFP This decision will be at the discretion of the contracting District or Central Office. 48 Stipends for unsuccessful firms Federal funds MAY be used. A Stipend is not intended to compensate the Firms for the total cost of preparing the proposal package. In return, the Department reserves the right to use any of the concepts or ideas within the technical proposals, as the Department deems appropriate. 49 CM@Risk 50 CM@Risk Agenda – CM@Risk What is it? – CM@Risk Contract Structure – CM@Risk Process – CM@Risk Advantages – CM@Risk Project Selection Criteria 51 CM@Risk • CM@Risk is an integrated team approach that applies modern management techniques in the planning, design, and construction of a project in order to control time and cost, and to increase the quality and value of the project for the owner. • Team= owner (Department), the architect/engineer and the construction manager (CM) • Transportation or building project 52 CM@Risk Contract Structure OWNER Constructibility Designer CM FIRM (Prime Contractor) SubContractors SubContractors 53 CM@Risk Process • District hires Designer • District hires CM Firm used standard consultant selection process – Early in the design phase, 30% plans – Negotiated CM fee – CM Fee during Design Phase: 1-1.5% of Construction Cost – CM Fee during Construction Phase: 4-8% of Construction Cost 54 CM@Risk Process (continued) • CM Firm provides construction input throughout design development to minimize risks and improve the schedule • Construction components for a project may or may not be added by Supplemental Agreement 55 CM@Risk Process (continued) • FDOT Prepares and Manages the Design – Constructability reviews by CM during design to optimize the design and control costs – CM has no Direct Control over the Design • CM selected thru Professional Services – Limited to Quality Contractors – Qualification Based Selection – Historical Performance of the Contractors is considered 56 CM@Risk Process (continued) • CM Firm Responsible for Construction – Guaranteed Maximum Price (GMP) – The Department pays only for cost of the work, up to GMP. – Generally prohibit self-perform – Enhanced control of subcontractor selection 57 CM@Risk Process (continued) • The role of the CM is to represent the interests of the owner in all phases of the project. • The CM is to perform value engineering, cost estimates, and schedule and budget recommendations during the preconstruction phase to assist in determining the best value based on the budget. 58 CM@Risk Process (continued) • The CM may provide suggestions for alternate designs, construction materials, and processes. • The Department will maintain final approval of all proposed changes. 59 CM@Risk Process (continued) • During the design phase, usually about 60% plans, the CM will submit a GMP for acceptance by the Owner/ Department. • The CM warrants that the project will be built not to exceed the GMP and assumes the risk by holding all of the subcontracts to perform the work. 60 CM@Risk Advantages • Time – Eliminates Bidding and Contract Execution Time – Bidding Prior to Completion of Design – Flexibility to Re-Bid – Procure materials early – Reduction in Time Overruns – Contractor participation can speed up design – Construction can begin prior to: right-of-way clear, all permits issued, utilities identified or finalized 61 CM@Risk Advantages • Cost – Approximately Same Costs (Based on Risk) – Requires CM Fee – Claims Reduced, Reduced Cost Overruns • Risk – Construction Contract between CM and subcontractors – Shifted from Owner/Department to CM Firm; subletting the construction work – Reduce Quantity Risk 62 CM@Risk Advantages (continued) • Innovation – Excellent Use of Contractor and Designer Linkage • Technical – Qualifications Based Selection of Best Contractor – Allows for Significant Changes During Construction 63 CM@Risk is NOT a standard practice • Section 337.025 Florida Statutes applies to all project types as part of the innovative practices package and the Department is required to comply with the $120 million annual contracting monetary cap. 64 CM@Risk is NOT a standard practice • As a result, all projects must have approval from Central Office. • All requests should be sent to the State Construction Office for the Chief Engineer’s approval • On Federally funded projects, the Department must have specific authorization from Federal Highway Administration (FHWA), Special Experimental Projects (SEP)-14. 65 CM@Risk Project Selection • In selecting a project delivery method, gauge the level of complexity, uniqueness and innovative approaches of a project so as to maintain control of the project. • No single project delivery strategy is appropriate for all projects and there are some key factors to consider: 66 CM@Risk Project Selection (continued) • Size of Project – The more complex and costly a project, the greater the need for professional management and advice • Owner Capabilities – Assess in-house capabilities in evaluating project procurement methods and construction management or use a General Engineering Consultant 67 CM@Risk Project Selection (continued) • Time Consideration – If the project needs to be constructed in a compressed timeframe, methods adaptable to fast-track construction of components can be considered, but weighed against increased cost and risk of fast tracking. – An unrealistic schedule should not be used on a CM@Risk project. This can drive up the cost. 68 CM@Risk Project Selection (continued) • Likelihood of Changes – If the scope of work cannot be defined adequately upfront or if requirements are likely to change considerably during the project, this factor should be evaluated against potential cost of such changes. – CM can negotiate better prices subject to owner’s approval and changes can be done in a timely manner to reduce delay claims. 69 CM@Risk Types of Projects • Buildings/Vertical construction projects where construction methods and specifications vary between professionals (i.e. architect and construction trades). • Projects with budget constraints which threaten the delivery of the project and where CM alternatives can help contain the costs. 70 CM@Risk Types of Projects (continued) • Projects that allow for innovative funding scenarios • Complex construction projects where construction input will be most beneficial during the early phases of design. 71 CM@Risk Types of Projects (continued) • Major Projects where there is a good balance of risk to reward. Project has significant utility relocations and can be investigated by the CM and the CM can provide insight in the design. • Corridor Projects • Bridge Rehabilitation (Bascule) • Unusual or out-of-the ordinary projects, use of new technology; ITS 72 CM@Risk • The Department plans to use CM@Risk for appropriate type projects. Project selection should be coordinated with the State Construction Office. • CM@RISK should not be considered on the following types of projects: Milling and Resurfacing, Guardrail, Signing, Landscaping, Lighting, Signalization, and Sidewalks 73 CM@Risk • Additional information can be found on the State Construction Office website: http://www.dot.state.fl.us/construction/CONSTADM/C M@Risk/CM@Risk%20Main.htm 74 QUESTIONS? 75