Chapter 7 RECIRCULATED AND REPLACEMENT AIR

advertisement

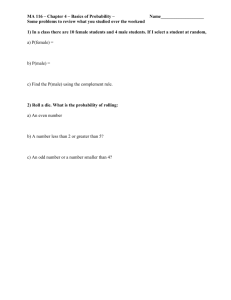

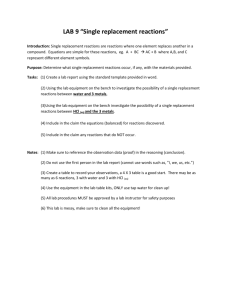

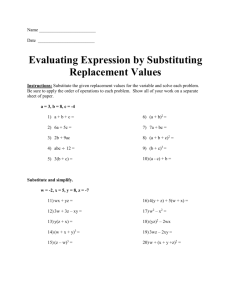

Recirculated and Replacement Air Recirculated And Replacement Air Introduction Replacement air Replacement air distribution Replacement air flow rate Room pressure Environmental control Environmental control air flow rate Air changes Air supply temperatures Air supply vs. Plant heating costs Replacement air heating equipment Cost of heating replacement air Air conservation Evaluation of employee exposure levels Recirculated and Replacement Air 2 Introduction Supply systems are used for two purposes: - To create a comfortable environment and. - To replace air exhausted from a building. The pressure in a building will be lower than atmospheric pressure (case of ‘negative pressure’) if the amount of replacement air supplied to the building is lower than the amount of air exhausted. Recirculated and Replacement Air 3 Replacement Air The amount of air entering a building is equal to the the flow rate of exhaust air. Replacement air is necessary to: Ensure that exhaust hoods operate properly. Insufficient replacement air and a ‘negative pressure’ condition cause an increase in the static pressure. Eliminate high-velocity cross-drafts through windows and doors. Cross-drafts can interfere with the function of exhaust hoods and can also disperse contaminated air from one section of the building to another, besides affecting other processes, unsettling dust and like materials to cause recontamination. Recirculated and Replacement Air 4 Replacement Air Ensure operation of natural draft stacks such as combustion flues. Negative pressures can cause backdrafting of flues, and hence health hazards. For e.G. Combustible products release carbon monoxide. Secondary effects include difficulty in maintaining flames in burners, poor operation of air controls, corrosion damage in stacks and heat exchangers due to condensation of water vapor in flue gases. Eliminate cold drafts on workers. Discomfort is not caused, overall ambient temperature and hence working efficiency is not reduced. Recirculated and Replacement Air 5 Replacement Air Eliminate differential pressures on doors. Differential pressures are a cause of difficulty in opening and closing doors and uncontrolled movements. Conserve fuel. Lack of replacement air results in cold conditions and hence installation of heating equipment is required. Sometimes overheating occurs that leads to uncontrolled circulation of warm air. To tackle this, exhaust fans will be provided that further aggravates the problem.Heat is wasted without curing the problem. Recirculated and Replacement Air 6 Replacement Air Distribution Replacement air distribution is critical especially in process industries like pharmaceuticals, electronics, paints and facilities like indoor firing ranges, particularly non-turbulent air-flow. When turbulence is caused due to mixing effect caused by high-throw diffusers, local exhaust hoods are redesigned to draw in more air to overcome it and hence prevent the upset of contaminant control. Thus energy costs rise. To get rid of turbulence, air may be provided through a supply air plenum, or a perforated duct with the face of the plenum covered with perforations to diffuse air. Critical attention must be given to the feeding of air into the plenum and avoid high-velocity. Recirculated and Replacement Air 7 Replacement Air Flow Rate The replacement air flow rate should be approximately equal to the total air flow rate removed from the building. Factors considered in determination of actual removed flow rate are: Quantity of air removed. Determination of air exhaust locations. Testing. Necessity for a particular piece of equipment. Reasonable projections for future requirements, etc. Recirculated and Replacement Air 8 Room Pressure ‘Negative pressure’ is desirable, when contaminants are to be prevented from escaping into the surrounding areas. For a clean environment to exist, positive pressure conditions are maintained. Either of the conditions are achieved by obtaining a ratio of the exhaust - supply flow differential. Recirculated and Replacement Air 9 Environmental Control It involves the control of following factors: Toxic contaminants. Heat load in the work space. High horsepower demand of machines. High light levels in the plant and corresponding greater heat release and indoor temperature. Depletion in efficiency levels and healthful working conditions. And increase in tolerance limit of products. The control is achieved by various methods adhering to process specifications, using technologies like automated building control and direct digital control (DDC). Recirculated and Replacement Air 10 Environmental Control Air Flow Rate The design supply air flow rate depends on several factors besides health and comfort requirements. They can be enlisted as: Satisfactory dilution of contaminants assuming perfect distribution of air and solvent vapors (the mixing factor ‘k’ is also included). The location of air supply and exhaust outlets such that the air passes. Through the zone of contamination (so that spot ventilation can be considered). ‘Negative pressure’ is desirable, when contaminants are to be prevented from escaping into the surrounding areas. Recirculated and Replacement Air 11 Environmental Control Air Flow Rate The location of air supply and exhaust outlets such that the air passes through the zone of contamination. To attain optimum utilization of air supply it is distributed in the ‘living zone’ of the space i.E. Below 8-10 feet level (where majority of people and processes are located). Multiple point entry provides uniformity of air delivered and minimizes. The re-entry of contaminated air that occurs when large volume of air is to be delivered. During cold weather, large amount of air is removed by mixing rapidly. The cooler air with the warmer air in the space. Recirculated and Replacement Air 12 Air Changes ‘Number of air changes per minute or per hour’ is the ratio of ventilation rate (per minute or per hour) to the room volume. The required ventilation depends upon the intensity of a problem and not the size of a room and hence no. Of air changes per unit time is a poor criteria for control and has limited applicability. Recirculated and Replacement Air 13 Air Supply Vs. Plant Heating Costs Even if supply air were drawn into the building, there is an additional loading on heating systems and the fuel costs will rise. For efficient heat transfer and independence of operation, the same flow rate of outdoor air can be introduced through separate replacement air heaters, without exceeding the overall fuel costs. In order for an equilibrium to be established, the heat outflow from the building must balance the heat inflow. Design the supply system to provide sufficient heating to counter air entering the building through infiltration, to prevent freezing so as to obtain additional energy saving during downtime. Recirculated and Replacement Air 14 Replacement Air Heating Equipment The basic requirements of air heater are: Continuous operation capability Constant pre-selected discharge temperature under varying conditions of temperature Air heaters are classified by property of source of heat as: Steam heaters (single coil, multiple coil and bypass) Hot water units Indirect fired gas and oil units Direct fired natural gas and LPG units Recirculated and Replacement Air 15 COST OF HEATING REPLACEMENT AIR Equations for estimating replacement air heating costs on hourly and yearly basis: QN C q 0.154 Q dg T c Yearly cost (C2) q Hourly cost (C1) 0.001 where: Q = air flow rate in cfm N = required heat in BTU/hr/1000cfm T = operating time in hours or week q = available heat per unit of fuel dg = annual degree days c = cost of fuel in $ / unit. Recirculated and Replacement Air 16 Air Conservation Four methods to reduce heating and cooling costs: Reduction in the total flow of air handled. Delivery of untempered outdoor air to the space. Recovery of energy from the exhaust air and. Recovery of warm, uncontaminated air from processes. Reduced flow rate. It is achieved by taking stock of all exhaust and supply systems in the plant and marking them as necessary, replaceable and obsolete, and handling the airflow rate by implementing the changes. Untempered air supply. Cold outdoor air can be supplied untempered or moderately tempered to dissipate sensible heat loads on the workers and provide effective temperature relief from radiant heat loads. Recirculated and Replacement Air 17 Air Conservation Energy recovery Involves use of heat exchange equipment to extract heat from the air stream before exhaust by using any of the following equipment : Heat exchangers, heat wheel, fixed plate exchanger, heat pipe, run around coil exchangers, etc Factors of consideration for selection of a heat exchanger are: Nature of exhaust system Isolation of contaminated exhaust stream Temperature of exhaust system Space requirements Nature of air stream Need for a bypass Involves recirculation (return) of air from industrial exhaust systems Recirculated and Replacement Air 18 Air Conservation Selection of monitors Four basic components of a complete monitoring system: Signal transfer Detector/ transducer Signal conditioner Information processor The choice of detection method depends on whether the contaminants are particulates or non- particulates Recirculated and Replacement Air 19 Evaluation Of Employee Exposure Levels CR 1 CE KRCM 1 KR 1 Where: CR= air cleaner discharge concentration after recirculation in mg / m3 Η = fractional air cleaner efficiency CE = local exhaust duct concentration before recirculation in mg / m3 KR = fraction of recirculated exhaust stream that is composed of the recirculation return air (0 to 1.0) CM = replacement air concentration in mg / m3 Recirculated and Replacement Air 20 Evaluation Of Employee Exposure Levels CB QB CG CM 1 f Co CM f KBCR 1 KB CM QA Where: CB = 8 - hr TWA worker breathing zone concentration After recirculation, mg/m3 QB = total ventilation air flow before recirculation QA = total ventilation air flow after recirculation CG = general room concentration before recirculation, mg/m3 F = fraction of time workers spend at work-station Co = 8 - hr TWA breathing zone concentration at work station before Recirculation KB = fraction of worker’s breathing zone air that is composed of recirculation ( 0 to 1.0) Recirculated and Replacement Air 21 Design of Recirculated Air Systems Systems should be designed to bypass to the outdoors and not to recirculate. Humid air from wet collectors can cause high humidity and hence auxiliary ventilation may be required. Since exit concentration of collectors varies with time, design of data and testing programs should consider all operational time periods. Layout and design of recirculation duct should provide adequate mixing with other supply air and avoid uncomfortable drafts on workers. Recirculated and Replacement Air 22 Design Of Recirculated Air Systems In lieu of a monitoring system, a secondary air cleaning system is more reliable and is easy to maintain. Odor and nuisance value of contaminants should be compared to official TLV values. Records should be maintained for routine tests, maintenance procedures and recirculating systems. Periodic testing of workroom should be done. Appropriate signs should be displayed in prominent places. Recirculated and Replacement Air 23