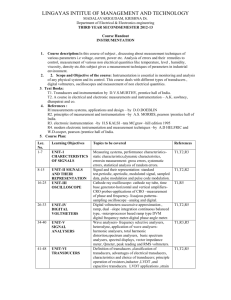

Theory Of Oscilloscope

advertisement

Sensors and Transducers 1 Warm-ups origami… 2 Objectives At the end of this chapter, the students should be able to: describe the principle of operation of various sensors and transducers; namely.. Resistive Position Transducers. Capacitive Transducers Inductive Transducers 3 Introduction Sensors and transducers are classified according to; the physical property that they use (piezoelectric, photovoltaic, etc.) the function that they perform (measurement of length, temperature, etc.). Since energy conversion is an essential characteristic of the sensing process, the various forms of energy should be considered. 4 Introduction There are 3 basic types of transducers namely self-generating, modulating, and modifying transducers. The self-generating type (thermocouples, piezoelectric, photovoltaic) does not require the application of external energy. 5 Introduction Modulating transducers (photoconductive cells, thermistors, resistive displacement devices) do require a source of energy. For example, a thermocouple is self-generating, producing a change in resistance in response to a temperature difference, whereas a photoconductive cell is modulating because it requires energy. The modifying transducer (elastic beams, diaphragms) is characterized by the same form of energy at the input and output. The energy form on both sides of a modifier is electrical. 6 Definition The words 'sensor' and 'transducer' are both widely used in the description of measurement systems. The former is popular in the USA whereas the latter has been used in Europe for many years. The word 'sensor' is derived from entire meaning 'to perceive' and 'transducer' is from transducer meaning 'to lead across'. 7 Definition A dictionary definition of 'sensor' is `a device that detects a change in a physical stimulus and turns it into a signal which can be measured or recorded; The corresponding definition of 'transducer' is 'a device that transfers energy from one system to another in the same or in the different form'. 8 Features of Sensors The desirable features of sensors are: 1. accuracy - closeness to "true" value of variable; accuracy = actual value - sensed value; 2. precision - little or no random variability in measured variable 3. operating range - wide operating range; accurate and precise over entire sensing range 4. calibration - easy to calibrate; no "drift" - tendency for sensor to lose accuracy over time. 5. reliability - no failures 6. cost and ease of operation - purchase price, cost of installation and operation 9 Sensors Types A list of physical properties, and sensors to measure them is given below: 10 Sensors Types 11 Common Sensors Listed below are some examples of common transducers and sensors that we may encounter: Ammeter - meter to indicate electrical current. Potentiometer - instrument used to measure voltage. Strain Gage - used to indicate torque, force, pressure, and other variables. Output is change in resistance due to strain, which can be converted into voltage. Thermistor - Also called a resistance thermometer; an instrument used to measure temperature. The operation is based on change in resistance as a function of temperature. 12 Sensors Types • There are several transducers that will be examined further in terms of their principles of operations. • Those include : 1. 2. 3. 4. 5. Resistive Position Transducers Strain Gauges Capacitive Transducers Inductive Transducers And a lot more… 13 Resistive Position Transducers • The principle of the resistive position transducer is that the measured quantity causes a resistance change in the sensing element. • A common requirement in industrial measurement and control work is to be able to sense the position of an object, or the distance it has moved. • One type of displacement transducer uses a resistance element with a sliding contact linked to the object being monitored. • Thus the resistance between the slider and one end of the resistance element depends on the position of the object. 14 Resistive Position Transducers • • • The output voltage depends on the wiper position and therefore is a function of the shaft position. In figure below, the output voltage Eout is a fraction of ET, depending on the position of the wiper. The element is considered perfectly linear if the resistance of the transducer is distributed uniformly along the length of travel of wiper. Eout R2 ET R1 R2 15 Resistive Position Transducers Example 1 An RPT with a shaft stroke of 5.5 inches is applied in the circuit as below. The total resistance of the potentiometer is 4.7kΩ. The applied voltage is ET= 3V. When the wiper is 0.9 in. from B, what is Eout? 16 Strain Gauges • • The Strain Gauge is an example of a passive transducer that uses electrical resistance variation in wires to sense the strain produced by a force on the wire. It is a very versatile detector and transducer for measuring weight, pressure, mechanical force or displacement. 17 Strain Gauges The construction of a bonded strain gauge shows a fine wire looped back and forth on a mounting plate, which is usually cemented to the element that undergoing stress. 18 Strain Gauges • • • For many common materials, there is a constant ratio between stress and strain. Stress is defined as the internal force per unit area. F S A S – Stress (kg/m2) F – Force (kg) A - Area (m2) • The constant of proportionality between stress and strain for the curve is known as the modulus of elasticity of the materials, E or Young’s Modulus. 19 Capacitive Transducers • The capacitance of a parallel plate is given by: k= dielectric constant A= area of the plate o o=8.854x10-12 F/m d= plate spacing kA C d • Since the capacitance in inversely proportional to the spacing of the parallel plates, any variations in d will cause a variation in capacitance. 20 Capacitive Transducers • Some examples of capacitive transducers 21 Capacitive Transducers Example 2: An electrode-diaphragm pressure transducer has plates whose area is 5x10-3 m2 and distance between plates is 1x10-3. Calculate its capacitance if it measures air pressure with k=1. 22 Inductive Transducers • Inductive Transducers may be either the selfgenerating or the passive type transducers. • In the Self-Generating IT, it utilises the basic electrical generator principle that when there is relative motion between conductor and magnetic field, a voltage is induced in the conductor. • An example of this is Tachometer that directly converts speeds or velocity into an electrical signal. 23 Tachometers • Examples of a Common Tachometer 24 Linear Variable Differential Transformer (LVDT) • Passive inductive transducers require an external source of power. • The Differential transformer is a passive inductive transformer, well known as Linear Variable Differential Transformer (LVDT). • It consists basically of a primary winding and two secondly windings, wound over a hollow tube and positioned so that the primary is between two of its secondaries. 25 Linear Variable Differential Transformer (LVDT) • Some examples of LVDTs. 26 Linear Variable Differential Transformer (LVDT) • An example of LVDT electrical wiring. 27 Linear Variable Differential Transformer (LVDT) • An iron core slides within the tube and therefore affects the magnetic coupling between the primary and two secondaries. • When the core is in the centre , the voltage induced in the two secondaries is equal. • When the core is moved in one direction of centre, the voltage induced in one winding is increased and that in the other is decreased. Movement in the opposite direction reverse this effects. 28 Linear Variable Differential Transformer (LVDT) •In next figure, the winding is connected ‘series opposing’ -that is the polarities of V1 and V2 oppose each other as we trace through the circuit from terminal A to B. •Consequently, when the core is in the center so that V1=V2, there is no voltage output, Vo = 0V. 29 Linear Variable Differential Transformer (LVDT) • When the core is away from S1, V1 is greater than V2 and the output voltage will have the polarity of V1. • When the core is away from S2, V2 is greater than V1 and the output voltage will have the polarity of V2. • That is the output of ac voltage inverts as the core passes the center position. • The farther the core moves from the centre, the greater the difference in value between V1 and V2, and consequently the greater the value of Vo. 30 Linear Variable Differential Transformer (LVDT) • Thus, the amplitude of Vo is a function of distance the core has moved. If the core is attached to a moving object, the LVDT output voltage can be a measure of the position of the object. • The farther the core moves from the centre, the greater the difference in value between V1 and V2, and consequently the greater the value of Vo. 31 Linear Variable Differential Transformer (LVDT) Among the advantages of LVDT are as follows: • • • • It produces a higher output voltages for small changes in core position. Low cost Solid and robust -capable of working in a wide variety of environments. No permanent damage to the LVDT if measurements exceed the designed range. 32 Linear Variable Differential Transformer (LVDT) Example 3: An ac LVDT has the following data; input 6.3V, output 5.2V, range ±0.50 cm. Determine: a) Plot of output voltage versus core position for a core movement going from +0.45cm to -0.03cm? b) The output voltage when the core is -0.35cm from the center? c) The core movement from center when the output voltage is -3V? d) The plot of core position versus output voltages varying from +4V to -2.5V. 33 Piezoelectric Transducers When a mechanical pressure is applied to a crystal of a Rochelle salt, quartz, or tourmaline type, a displacement of the crystals that will produce a potential difference will occur. • • This property is used in piezoelectric transducers; where a crystal is placed between a solid base and force-summing element, as shown below: 34 Piezoelectric Transducers • When externally force is applied to the plates, a stress will be produced in the upper part of the crystal. • This deformation will produce a potential difference at the surface of the crystal. This produces an electromotive force across the crystal proportional to the magnitude of the applied pressure. This effect is called piezoelectric effects. • • The induced charge on the crystal is proportional to the impressed force and given by: Q = dF; where d = piezoelectric constant. 35 Temperature Transducers • The temperature transducers can be divided into four main categories: o o o o Resistance Temperature Detectors (RTD) Thermocouples Thermistors Ultrasonic transducers 36 Resistance Temperature Detectors (RTDs) • Detectors of resistance temperatures commonly employ platinum, nickel, or resistance wire elements, whose resistance variation with temperature has a high intrinsic accuracy. • They available in many configurations and sizes and as shielded and open units for both immersion and surface applications. 37 Resistance Temperature Detectors (RTDs) • Some examples of RTDs are as follows: 38 Resistance Temperature Detectors (RTDs) • The relationship between temperature and resistance of conductors can be calculated from this equation: R Ro (1 T ) where; R= resistance of the conductor at temp t (oC) Ro=resistance at the reference temp. = temperature coefficient of resistance = difference between operating and reference temp. 39 Resistance Temperature Detectors (RTDs) Example: A platinum resistance thermometer has a resistance of 220Ω at 20oC. Calculate the resistance at 50oC? Given that 20oC=0.00392. 40 Thermocouples • A thermocouple is a sensor for measuring temperature. It consists of two dissimilar / different metals, joined together at one end, which produce a small unique voltage at a given temperature. This voltage is measured and interpreted by the thermocouple. •The magnitude of this voltage depends on the materials used for the wires and the amount of temperatures difference between the joined end and the other ends. 41 Thermocouples • Some examples of the thermocouples are as follows: 42 Thermocouples • Common commercially available thermocouples are specified by ISA (Instrument Society of America) types. • Type E, J, K, and T are base-metal thermocouples and can be used up to about 1000°C (1832°F). • Type S, R, and B are noble-metal thermocouples and can be used up to about 2000°C (3632°F). 43 Thermocouples • The following table provides a summary of basic thermocouple properties. 44 Thermocouples •Calibration curves for several commercially available thermocouples is as below: 45 Thermocouples • The magnitude of thermal emf depends on the wire materials used and on the temperature difference between the junctions. • The effective emf of the thermocouple is given as: E c(T1 T2 ) k (T T ) 2 1 2 2 •Where; c and k – constant of the thermocouple materials T1 - temperature of the ‘hot’ junction. T2 - temperature of the ‘cold’ or ‘reference’ junction. 46 Thermocouples Example During experiment with a copper- costantan thermocouple, it was found that c= 3.75x10-2 mV/oC and k = 4.50x10-5 mV/oC. If T1= 100oC and the cold junction T2 is kept in the ice, compute the resultant electromotive force, emf? 47