Traction Problems

Checking for Traction

Problems

©Dr. B. C. Paul 2000 revised 2008

Note – The methods outlined here are common practice in industry and can be found in a wide range of books. The slides specifically include tables from the Caterpillar Performance

Handbook and the book Surface Mining from SME

The Traction Problem

Gradability and Retarder Charts give peak speed that engine can transfer power to wheels for

Does not guarantee the tire can transfer to ground without spinning

Max transfer of force

• F = coefric * Weight * cos(pheta)

The Traction Calculation

Coef of friction depends on road material primarily

• Generally get from table

Cos(pheta) term is usually almost 1

• for 10% grade cos(pheta) = 0.995

• Common practice to take as unity

Weight is weight on Drive

Wheels (in lbs) - important distinction for two wheel drives

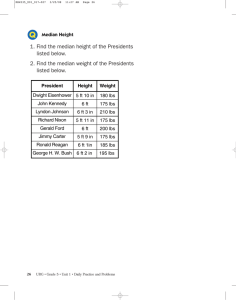

Getting Coef of Friction from Table

Crushed Rock or

Gravel Would Be

Common in a Quarry

Also Need Distribution of Weight from Specs

Example

Cat on the Hill

• Empty weight is 87000 lbs

• Distribution empty is 53% to rear wheels or 46,000 lbs

• Loaded weight is 204,000 lbs

• Distribution Full is 67% to rear wheels or

137,000 lbs

• Note that this truck was weight limited and reached gross weight limit - volume limited truck would not.

Example Cont.

It’s a Quarry so road is gravely sometimes rains so worse case may be wet gravel

• From Table 0.35 is coef of friction

Could have considered icy conditions after freezing rain

• But would you run that way?

• Quarries often close in winter because of slabbing from face

Plugging into the Tire

Spin Equation

137,000 lbs * 0.35 * 0.995 =

48,000 lbs loaded

46,000 lbs * 0.35 * 0.995 =

16,000 lbs empty

Like Wow Man - Awsome

Numbers. Now What do I do with them?

Determining if Tire

Spinning is Occurring

Answer comes in lbs force that can be transferred between the tire and the ground

This has the form of Rimpull

Compare the number to the

Rimpull required to propel the truck (or keep it from sliding down hill out of control)

Getting the Rimpull

Rimpull to hold back empty truck

• 43.5 tons * 115 lbs/ton = 5,000 lbs

Wait! Hold Everything - That’s downhill so 115 lbs/ton must be negative

• The tire doesn’t know who’s pulling who - only whether the friction is enough to balance the force

Making the Comparison

For Empty Truck Going Downhill

• Rimpull Required is 5,000 lbs

• Traction Force Available is 16,000 lbs

• 5,000 < 16,000 so I’m OK

For Loaded Truck

• Rimpull Required is 29,000 lbs

• 29,000 < 48,000 lbs

Gee This is So Much Fun I

Can’t Wait to Do it for Every

Segment on My Haul Road

Actually - You Don’t Have to

We are comparing two numbers

• Rimpull Needed = lbs/ton * Total

Tons Weight

• Traction Available = coefric * Drive

Wheel Weight

In Simple Terms

• RN = K

1

Dweight

* Tweight TA = K

2

*

The Discovery

Both Equations are a Linear

Function of Weight

• On a ton for ton basis the rimpull needed is the same loaded or unloaded

• Traction depends on portion of that weight on drive wheels

• The Traction Value is minimum when the truck is empty

Checking in Critical

Spots

If the Empty Truck won’t spin the loaded Truck won’t

Look for points of maximum total grade - gives maximum rimpull

Look for points of low coef of friction - minimizes Traction

Check Those Points

Application to Our

Example

Our haul road is uniform so we have no minimal coef of friction

Our haul road is uniform so we have no higher rolling resistance

Thus maximum grade will be the worst case coming out where the two resistances are additive

The Critical Check Point

Loaded Truck Coming Out and

Empty Truck Going in - We’ve already checked

There is a non routine point what if we have to take a truck out empty?

• In checking truck and road compatibility usually check things that are realistic

Check to See if We Can

Get Out Empty

43.5 tons * 285 lbs/ton = 12,400 lbs

Compare

• Rimpull Needed 12,400 lbs

• Traction Available 16,000 lbs

I’m Still Ok

How Does FPC Do It?

You have entered haulage profile and frictional forces

You have picked trucks and all tables including weight distributions are loaded

FPC checks all segments for spinning

• If a problem occurs it gives an error message

FPC only checks regular haul segments

• What if you need to bring an empty truck out of the pit when a loader break-down occurs?