LCF-HCF

advertisement

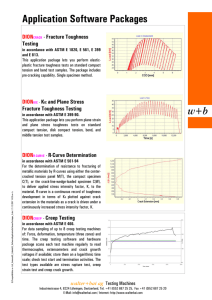

Low Cycle Fatigue (LCF) High Cycle Fatigue (HCF) What is Fatigue? The ASTM definition..... “The process of progressive localized permanent structural change occurring in material subjected to conditions which produce fluctuating stresses and strains at some point or points and which may culminate in crack or complete fracture after a sufficient number of fluctuations.” Translation: “Cyclic damage leading to local cracking or fracture.” Requirements have evolved for Gas Turbine Engines.... Emphasis today is on Cyclic Properties... Design Material Time Requirements Properties Historical Basic Engineering Properties Strength, Creep 1960’s - 1970’s Add ... Fatigue HCF, LCF, TMF Late 1970’s Add ... Damage Tolerance Crack Growth Emphasis today is on Cyclic Properties... High Cycle Fatigue 8 Allowable vibratory stresses Low Cycle Fatigue 8 8 Crack initiation life 1/1000 to small crack 8 Component 8 Safety inspection 8 Inspection size retirement Crack Growth 8 Remaining life from crack interval requirement For Crack Initiation, High Cycle Fatigue (HCF) and Low Cycle Fatigue (LCF) are treated separately. Why? General distinction for Gas Turbines: HCF - Usually high frequency, due to resonant vibration. Failure criteria based on allowable stresses. Millions of Cycles LCF - Usually low frequency, due to engine start/stop or throttle cycles. Accurate life prediction required. Thousands of Cycles Turbine Disk Design Requirements Most Severe Structural Challenge: High structural loads, fatigue, & creep • Environmentally friendly • Fatigue cracking resistance initiation propagation • Creep resistant • Strong • Lightweight • Predictable/Inspectable • Affordable • Environmentally stable Nickel Superalloy Balances All Requirements Combustor, Turbine Components Present a Severe Thermal Fatigue Cracking Challenge • Mechanical fatigue, caused by cyclic thermal strains • High temperature accelerates fatigue damage • Exacerbated by crack tip oxidation Fatigue is a Major Challenge for Many Engine Components, Including Fan Blades • Caused by Load Cycling • Occurs at cyclic loads well below the Ultimate Strength fatigue crack initiation site • High Cycle Fatigue (HCF) Caused by vibration/flutter • Low Cycle Fatigue (LCF) Caused by engine cycling Compressor blade tested in a vibratory fatigue test rig Cyclic vs. Monotonic Curves: Behavior can be significantly different ... From Metal Fatigue in Engineering, H.O. Fuchs and R.I. Stephens, John Wiley & Sons, NY, 1980 Crack Size: How big is big? ... HCF: S-N Curves ... 8 Initially used to address HCF for allowable stress, but what about predicting actual cycles of life? ... 8 HCF cycle prediction is more of a statistical estimate with a large scatter allocation, instead of an exact science P&WA Stress Control HCF Test Apparatus Specimen Fully Reversed Stress/Strain Cycle S/N Plot Basic Cycle Terms to Remember Alternating Stress Amplitude: a Mean Stress: 0 Stress Ratio: Stress Range: max min 2 max min 2 R min max max min 8Soderberg 8Goodman 8Gerber a (USA, 1930) Se a (England, 1899) (Germany, 1874) Se a m m Sy Su 2 1 1 m 1 Se Su (Where Se is the fully reversed endurance limit.) Cyclic Deformation Parameters: Fatigue loop illustration ... Fatigue: How do HCF and LCF fit with Stress vs. Life? ... * Exists in theory only HCF: S-N Curves ... 8 Fatigue Strength is the Maximum Stress that can be repeatedly applied for a specified number of cycles (typically 107) without failure. Titanium alloys are curve fit to 109 cycles. HCF: Notes on Approaches ... 8Soderberg is highly conservative and seldom used 8Actual test data usually falls between Goodman & Gerber Curves 8This is not a large difference in the theories when the mean stress is small in relation to the alternating stress. 8P&W has found the most success with the Goodman approach HCF: A Christienson Diagram Contains all of this information ... HCF: An example of Pratt’s Goodman diagram which combines Stress Amplitude and Mean Stress Effects ... 8The discontinuous slope on the x-axis modifies for the yield value instead of the ultimate as required by a traditional Goodman Diagram. HCF: Cyclic limits ... 8107 8109 cycles - Most other alloys cycles - Titanium, certain Nickel Blade Alloys 8109 cycles - ????? (Proposed following the HCF Initiative) Why no actual 109 Testing? 8Present frequency capability is 200 Hz, which is 1.6 years!! 8Assuming 25 tests on two machines, this is 20 years to characterize a single material !!! Target now is 2000 Hz for coupon testing, which is 2 months for a single test. HCF: Elastic Stress-Life Relationship ... HCF Notches: Parameters of Interest ... Parameter Description Kt Concentration Elastic Stress Kf Factor (KfKt) Fatigue Notch (related to grain size) Material constant r Notch radius q Notch sensitivity HCF Notches: Neuber proposed the following relationship ... Kf 1 q Kf 1 Kt 1 Kt 1 1 / r 1 1 / r Where: Se(notched)=Se(unnotched) / Kf 8In the previous equations, the notched value would then be substituted. LCF Testing: Verification ... Three primary ways of verification testing: 8Subcomponents 8Spin Pit 8Ferris Wheel P&WA Strain Control LCF/TMF Test Apparatus LCF Testing: Typical set-up involves uniaxial loading ... Cyclic Fatigue: Testing Parameters of Interest ... Strain Range - e Stress Range - P/A = max - min Max. Tensile Stress - T Mean Stress - m = 0.5*(max + min) Inelastic Strain - ei , ep Temperature - T Cyclic Loading: Key Relationships ... Elastic Modulus, E Stress Ratio, e tot e elastic e inelastic Max. Stress, Min. Stress, ee (monotonic) or (cyclic) e e min R max where e inelastic e plastic e creep max mean 2 min mean 2 Total Strain = Elastic Strain Range + Plastic Strain Range e tot e e e p Where E e tot 1 n ' e p 2 2K ' and 2 E 2 K ' 1 n' LCF: Pratt & Whitney Definition ... 8Nucleation 8Initiation 8The to detectable crack. is a 1/32” crack along the surface. acceptable probability of occurrence of an LCF crack as 1 crack occurring in a sample size of 1000 (1/1000 or B.1) having a 1/32 inch long crack at the predicted minimum life. LCF: Characteristics ... 8From stress/strain cycling in the plastic range at significantly higher stresses than for HCF. 8The stress/strain cycles that cause LCF cracking are produced by significant engine power level changes. 8Microscopic changes in a material that has been subjected to LCF cycling may be seen after only a few cycles. Microscopic dislocations in the crystal structure. The dislocations link up to form cracks. Depends on the stresses and orientation of the individual grain. 8Highly statistical in nature. LCF: What are the parameters? ... LCF: Mean Stress Effects must be included ... 8Simple approach e t 3.4 by J. Morrow: Su Sm N 0.12 e 0.6 N 0.6 E 8Alternative approach f f f by Smith, Watson & Topper (1970): max e a E f 2 N 2 2b f e f E 2 N b c where max=m+ a and ea is the alternating strain Notch LCF: Overall philosophy ... 8Kt < ~1.5 8Local stress-strain 8Smooth calculated LCF curves used 8Kt > ~1.5 8Local stress-strain 8Notch calculated LCF curves used usually mean stress/strain range, temperature corrected Notch LCF: Strain Range-Mean Stress Curves ... Strain Range, e Kt Kmax max Kt Kmin min E max E min Where: Kmax & Kmin are temp. correction factors on strain at max and min stress points K vs. T is derived from LCF tests at various temperatures Kt is the geometric stress concentration factor max & min are the nominal max and min stresses Emax & Emin are elastic moduli at the max and min stress points Notch LCF: Notch Factors ... Kt, K, and Ke relate local behavior to nominal: Notch LCF: Surface stresses and strains in stress concentration areas are important and need to be calculated ... Three methods used most often: 8Linear Rule - elastic equivalent stress method 8Neuber Rule - ideally for plane stress cases 8Glinka Method - energy based method Notch LCF: Linear Rule ... Notch LCF: Neuber Rule ... Notch LCF: Neuber Rule for Cyclic Loading must be solved incrementally... Reversed loading cyclic e curves assumes kinematic hardening and relates e using cyclic e curve with a 2X stress-strain multiplier from the new reference origin. Notch LCF: Glinka Relationship ... Cumulative Damage: How is it done? ... Definition - The means by which the damage associated with a complex stress history may be calculated or estimated by allowing the combining cycles of different stress magnitudes. Why is this needed? 8Military combat missions have many in-flight throttle excursions. 8Reduce mission into major and minor (or sub) cycles 8Major (Type I) cycle is the largest overall strain excursion in the mission. 8Full power excursions from intermediate, or above, to idle and back are called Type III cycles. 8These excursions generally impact the overall life. 8Excursions of smaller magnitude (Type IV) are generally not damaging.* * This may be untrue for some components Cumulative Damage: Methodology ... 8Many different methods have been proposed 8Linear cumulative damage - Miner’s Rule - appears to do the best job for the type of stress excursions encountered in jet engine operation. 8Miner’s Rule states: ni Ni 1 Where: Ni is life capability for stress excursion I ni is the actual number of occurrences of excursion I 8The basic assumption is that fatigue damage is cumulative and the life capability of a part will be exhausted when the sum of the life fractions reaches 1.0 Cumulative Damage: Cycle counting using the ASTM Rainflow technique determines pairs ... The pairs are A-D, B-C, E-F, and G-H. Cyclic Stress-Strain Behavior: Derived from loci of cyclic endpoints ... Constitutive Modeling Approach 3.5E+07 Constant 1 3.0E+07 Constant 2 Parameter 2.5E+07 Constant 3 2.0E+07 1.5E+07 1.0E+07 5.0E+06 0.0E+00 0 500 1000 1500 2000 Temperature (F) Rate dependent test data and model correlation Model parameter temperature dependencies ANSYS analysis of constitutive specimen Constitutive Modeling Approach specimen correlation specimen prediction component analysis Understanding Metallurgical Aspects of Fatigue Metallurgical Aspects... Relevant Topics: 8 Crystal Structure 8 Deformation Mechanisms 8 Crack Initiation .. Sequence of Events 8 Visual Aspects - Fractography Deformation for crystal structures can be visualized like a sliding row of bricks... Metals have a highly ordered crystal structure... Cubic Arrangement Hexagonal Close-Packed Structure Zn, Mg, Be, a-Ti, etc. Two predominant deformation mechanisms in metals... Dislocation: occurs at all temperatures, but is predominant at lower temperatures. Diffusion: important at higher temperatures, especially above one half the melting temperature Can you find the Illustrated Dislocation Defect? Edge dislocation. (a) “Bubble-raft” model of an imperfection in a crystal structure. Note the extra row of atoms. (b) Schematic illustration of a dislocation. [Bragg and Nye, Proc. Roy. Soc. (London), A190, 474, 1947.] Pure metals are easily deformed. Several methods are used to inhibit deformation... 8 Dispersion strengthening 8 Solid solution strengthening 8 Precipitation hardening 8 Microstructure control (grain size and morphology, precipitate control, etc.) Solid Solution Strengthening: Perturbations to crystal lattice retard dislocation motion... Precipitation Hardening: Local areas of compositional and/or structural differences retard dislocation motion... Grain Boundary Strengthening: Crystallographic and/or compositional boundary. Strengthens at low temperature; but weak link at high temperature... Grain Boundary Resistance: Will resist dislocation motion at the boundary... Grain Boundaries Illustrated: Notice the vacancies and excess atoms at boundaries... Grain Boundary Mechanics: Crystallographic and/or compositional boundary. Strengthens at low temperature; weak link at high temperature... Persistent Slip Band Formation: A product of cyclic deformation important to fatigue initiation for ductile metals ... From Metal Fatigue in Engineering, H.O. Fuchs and R.I. Stephens, John Wiley & Sons, NY, 1980 Diffusion: A high temperature deformation mechanism ... Diffusion: Usually considered at temperatures above half the melting point (K) ... Melting Point (F) 1/2 Melting Point (F) Aluminum 1220 379 Titanium 3035 1288 Nickel 2647 1094 Iron 2798 1170 Cobalt 2723 1132 32 -213 Ice Grain Boundary Sliding: A diffusion controlled deformation process ... Grain Boundary Sliding: Can provide large deformation at boundary with relatively small intergranular deformation ... Fatigue Crack Initiation: Occurs when enough local deformation damage accumulates to produce a crack ... 8 from dislocations - as in slip 8 from diffusion - as in grain boundary sliding 8 or from both Fracture Stages: Steps of an Idealized Fatigue Process ... Stage I Crystallographic Fracture, along a few planes, brittl appearance, at angle to principal loading direction. Stage II Usually transgranular, but numerous fracture planes to principal loading direction. Striations often seen at high magnification for more ductile alloys. Stage III Final fracture; brittle, ductile or both. Fracture Stages: Fatigue origin often at a Mechanical or Metallurgical Artifact ... Schematic of stages I and II transcrystalline microscopic fatigue crack growth. Typical Fatigue Fractures: Several Common Features ... 1. Distinct crack initiation site or sites. 2. Beach marks indicative of crack growth arrest. 3. Distinct final fracture region. Fatigue Features: Initiation sites . . . Fatigue Features: Beach marks ... Fatigue Features: Final Fracture ... Final Fracture Fatigue Area Ramberg-Osgood Relationship: Describes cyclic inelastic behavior ... IN100, (Tests Conducted in Air at 650°C, Frequency, = 0.33 Hz) Typical Failure Modes: General Characteristics ... Failure Mode Overstress Some General Characteristics Rapid fracture, may be ductile or brittle, large deformation, often transgranular, often the final stage of some other fracture mode. Creep/Stress Rupture Usually long term event, large deformation, intergranular, elevated temperature High Cycle Fatigue transgranular Often short term event, small deformation, Low Cycle Fatigue Moderate time event, moderate deformation, fracture dependent on time/temp. Thermomechanical Fatigue Moderate time event, subset of LCF with deformation due largely to thermally induced stresses, fracture usually shows heavy oxidation/alloy depletion Cyclic Behavior Must be Modeled: After Tensile yield, there are two models which describe compressive behavior ... Isotropic - assumes symmetrical behavior in tension and compression. Kinematic - assumes yield stress, following inelastic deformation, is degraded ... Hardening Models: Defines the Bauschinger effect ... Cyclic Effects on Stress-Strain Behavior: Progressive changes occur during cyclic loading ... Material: Copper in 3 Conditions From Metal Fatigue in Engineering, H.O. Fuchs and R.I. Stephens, John Wiley & Sons, NY, 1980 Summary: 8 Cyclic properties are important to our product. Principal deformation mechanisms are slip at low temperature and diffusion at high temperature. 8 8 Cracking can be crystallographic, transgranular, or intergranular. Simple deformation models can be used to consolidate data and predict loca stresses and strains. 8