Light wood frame

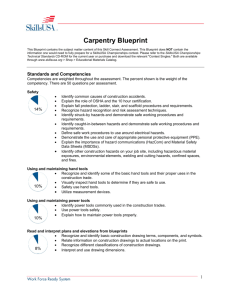

advertisement

Chapter 5 Light Wood Frame Construction Light Wood Framing Advantages Flexible Easily constructed Economical Disadvantages Burns rapidly, Decays if exposed to moisture Changes volume with moisture changes Framing unattractive (must be covered) History - Prior to mid-1800s Timber Frame timber with masonry timber with earth fill Interior walls were simple plank structure Trees were plentiful, and labor was intense. Craftsmen were available, but tools were limited – and had to be operated by hand. History - mid 1800s Light wood framing advanced by Development of water powered saw mills Machine made nails became available Earliest Version of Lt. Wood Framing Balloon Framing Long lengths of material was plentiful Wood members were small & easily handled Provided for lateral stability Balloon Framing Erection of wall framing members on a wood sill secured to the foundation and lapped against the floor joists. Second floor joists lapped into the wall framing system. Roof framing then set on top of wall plates. Roof rafters tied to ceiling joists secured lateral displacement of exterior walls. Components were light in comparison to timber structures, and erection required minimal labor than before. The practice was a more efficient use of material. DISADVANTAGES OF BALOON FRAMING Long, straight lengths of material diminished in availability as more structures were built. When buildings caught fire, the wall cavity of balloon framing allowed fire & smoke to chimney all the way to the roof, and structures burned rapidly. Since the wall and floor structure were built integrally, most of the framing work was done off the ground, where level conditions might not exist. • • • • • PLATFORM FRAMING With the disadvantages of balloon framing, the platform frame system evolved. The floor structure was first built onto the foundation sill, then decked to provide a ‘platform’ on which to work. Ground-floor walls were erected with a top plate to receive the second floor joists, which became a sill on which to erect the upper floor joists – which, when decked became another platform. Single floor framing was more plentiful because of shorter lengths. wall studs wall studs sub floor sub floor floor joists floor joists sill foundation BALOON sill foundation PLATFORM studs and joists are lapped wall studs single 2"x4" plate second floor joists temporary ledger BALOON second floor joists wall studs 2 - 2"x4" plate PLATFORM roof deck rafters ceiling joists 2 - 2"x4" plate fascia wall studs Building Sequence Architect Plans and Designs the Facility – Then Prepares Design and Construction Documents Involve a selected Contractor, who: Obtains Building Permit Purchases necessary materials Selects Sub-Contractors for each phase of work Excavation for utilities, foundations Install Underground utility lines (electrical, plumbing) Foundation construction Floor Construction Erect Framing for Structure Build construction pad & set batter boards Batter boards enable accurate layout of foundation A transit ensures accurate angles in layout A level is used to ensure proper grades & elevation Excavate & Place Foundations Materials Typically Used: Site Cast Concrete Concrete Masonry Units Reinforcing Steel Tie wire Anchor Bolts Foundation and Basement Wall Construction Construction for support of loads Damp proofing and/or perimeter insulation Foundation Wall Systems Sill Anchor Dampproofing Concrete or CMU Wall Gravel for Drainage Drainage Stone under floor slab with Vapor Barrier Perforated Drainage Pipe Concrete grade beam Utility installation is simultaneous with foundation work Installation of Plumbing Drainage Piping Underground Plumbing Example of grade beam monolithic with concrete floor Wall Load Granular Base Thickened Slab on grade Installation of plastic vapor barrier under concrete floor Vapor Barrier Granular SubBase Foundation Insulation Some building codes require perimeter insulation at foundations – especially in cold climates. Insulate the Crawl Space or Basement Walls Attach to Platform or on Ground Vapor Barrier Building the Platform Frame in Wood Floor With Crawl Space Sequence of Assembly Install sills with insect barriers Bolt sill members to the Foundation Install floor framing and bridging Install floor decking Attachment to the Foundation Sill Material Treated for resistance to insects & decay in damp climates. Install insect shields Sill Attachment with anchor bolts Floor Framing Options FRAME WITH DIMENSION LUMBER FRAME FLOORS USING TRUSSES FRAME FLOORS WITH “I” JOISTS Floor Framing Spacing & Splicing Spacing Factors that determine joist spacing: Floor Loading & Span Length Strength of Joist Material Used Type & thickness of floor decking Designation - Inches “o.c.” (on center) Typical - 12” , 16”, or 24” – to fit standard lumber lengths) Bridging for Floor Framing Floor Framing Using Steel Anchors Decking over Floor Framing Materials Used Plywood or OSB Concrete or gypsum is poured over second floor decks for sound deadening Installation Deck is laid perpendicular to floor joists End joints are staggered to brace joists Power nails, screws, construction adhesive Building Sequence for Ground Floor Walls Layout Sole plates installed to define wall locations Wall Framing - Lay out studs & assemble with single top wall plate Tilt up walls on the Platform & fasten to sole plate Install second layer of top wall plate to tie all partitions and walls together. Install Wall Sheathing Corner bracing required for lateral stability – usually OSB or plywood at all exterior corners Framing Terminology Top Plate Doubled Stud Header Sheathing Decking Sole Plate Headers Headers are beams installed over openings to carry weight of second floor or roof loads. Sizing Factors: Load, Span, Material Materials: dimension lumber, Laminated wood, or Steel Erecting the Wall Framing Build framing on the Platform & Tilt-up, brace, and fasten to sole plates. Double Top Plate Joist Support Tie Framing Together Double Top Plate Header Supports Double Header Corner Framing Sole Plate Anchorage Wall Sheathing Materials: OSB or Plywood for corner bracing Insulating Sheathing - (no structural qualities) Exterior Wall Sheathing: Joins & stabilizes the structure Resists uplift Resists racking & lateral forces Provides surface for finish material Building Sequence PLATFORM & 2ND Story Walls Erect 2nd Story Platform Similar to 1st Floor Sequence Install 2nd Floor access (stairs) Erect 2nd Story Walls & Sheathing Similar to 1st Floor Sequence Building Sequence Attic Floor & Roof Options Build-in-place ceiling joists, rafters, and bracing, OR Prefabricated Trusses, OR Combination Roof Framing Built-in-Place Ridge Board Rafters Collar Ties LOOKOUTS TO FORM OVERHANGS GABLE FRAMING Prefabricated Roof Trusses Note Strand Orientation Hurricane Clip Metal clips in decking prevent uneven deflection Roof Profiles Flat Roof Single Pitch Roof Profiles Gable Roof Hip Hip Roof Ridge