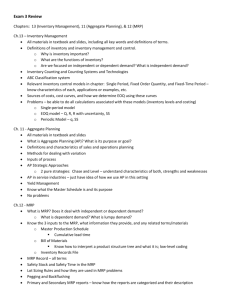

Production Control

advertisement

Material Requirements Planning

or as we in the business like to call it - MRP

Computer Based Production Planning

and Inventory Control System

Scientific Management meets the Computer

1

Where are we?

Strategic

Tactical

Operational

Purpose

Plan acquisition of

resources

Plan utilization of

resources

Execution of resources

Time horizon

2+ years

6 to 24 months

1-3 months

Time period

Yrs/Months

Months

Days/weeks

Level

Top management

Middle management

Plant management

Questions addressed

What products/Levels

Plant sizes/capacities

Plant/warehouse

locations

What technologies?

Inventory levels

Production rates

Work force sizing

Subcontracting

Batch sizes

Job scheduling

Material control

Machine maintenance

Analysis techniques

Break-even analysis

LP product mix

Distribution models

Supply Chain models

Long range forecasting

Location analysis

Forecasting

Aggregate planning

Production smoothing

Inventory models

Facility layout

Make or buy decisions

Project planning

Job scheduling

Task sequencing

Assembly line balancing

Shift scheduling

Worker assignments

MRP/JIT

Group technology

transfer lines

2

Three Approaches to Production Control

or how much to make, when?

• Traditional

– inventory control and job scheduling

• Material Requirements Planning (MRP)

– along with Manufacturing Resources Planning

(MRP-II)

– capacity requirements planning (CRP),

– and Enterprise Resource Planning (ERP)

• Just-in-Time (JIT) Manufacturing

3

Basic Definitions

• MRP (Materials Requirements Planning). MRP is the

basic process of translating a production schedule for an

end product (MPS or Master Production Schedule) to a set

of requirements for all of the subassemblies and parts

needed to make that item.

• JIT Just-in-Time. Derived from the original Japanese

Kanban system developed at Toyota. JIT seeks to deliver

the right amount of product at the right time. The goal is to

reduce WIP (work-in-process) inventories to an absolute

minimum.

4

Why Push and Pull?

• MRP is the classic push system. The MRP system

computes production schedules for all levels based on

forecasts of sales of end items. Once produced,

subassemblies are pushed to next level whether needed or

not.

• JIT is the classic pull system. The basic mechanism is that

production at one level only happens when initiated by a

request at the higher level. That is, units are pulled through

the system by request.

5

Push versus Pull

•Push – MRP

•Forecast driven

•Production Plan by

period

•Parts – explosion

•Uses lot-sizing

techniques

•Pull – JIT

•Production driven by

demands (in the form of

Kanban) from the next

higher level

•Minimizes work-inprocess

•Requires reduced setup

times

6

Advantages

MRP

reacts to changes in

demands

allows for lot sizing to

reduce setup costs

plans for several time

periods into the future

JIT

reduces work-in-process

quickly identify quality

problems before large

inventories of defect parts

smooth flow of material

through the supply chain

7

What problem does MRP try to solve?

• Independent demand – originates outside the

factory system

– Is subject to uncertainty

– Traditional (stochastic) inventory models work well

• Dependent Demand – demand for components that

make up independent demand products

– No uncertainty – demand is known (at least in

principle) once the final assembly schedule is given

– Traditional (stochastic) inventory models do not work

well

8

MRP versus JIT – an Example

• Assembly of a garden spade requires two screws.

• Spades are assembled in batches of 400 on the

first two days of every month

• The weekly demand pattern for screws therefore

is:

800,0,0,0, 800,0,0,0, 800,0,0,0, 800,0,0,0, etc.

9

The MRP Approach

• Using a weekly demand rate of 200, say, holding

and setup costs are such that the EOQ solution is

Q* = 1,400.

– solution makes no sense since 600 would be stored for

3 weeks and then another order placed for 1,400

– Treating weekly demand as random makes no sense as

well since it is deterministic

• Order 10,400 at the beginning of the year and

incur only one fixed order and delivery cost per

year

• Ideally use dynamic lot sizing based on costs

– i.e. order some multiple of 800

10

The JIT Approach

• Schedule delivery of 800 screws at the beginning

of each month

–

–

–

–

Incur fixed ordering cost 12 times a year

No inventory to store

If usage varies, can modify delivery sizes

If a defective shipment only screwed for 800 screws

• To be economical, fixed order and delivery costs

must be small

11

MRP Objectives

• Insure availability of materials, component,

and products

• Maintain lowest possible inventory level

• Plan manufacturing activities, delivery

schedules, and purchasing requests

An MRP fact:

“MRP deals with two basic dimensions

in production: Quantities and Timing”

12

The MRP

System

Forecast of future demand

Production Planning

Master Production Schedule

Schedule of production quantities by

Product (end item) and time period

Lot sizing

and capacity

planning

planned-order

releases

Customer

orders

Materials requirements planning system

Explode master schedule to obtain requirements

for assemblies, components, and raw material

Time-phased

Purchase orders

Time-phased

Work orders

13

Input 1 - Master Production Schedule

• This is the forecast for the sales of the end

item over the planning horizon. The data

sources for determining the MPS include:

–

–

–

–

–

Firm customer orders

Forecasts of future demand by item

Safety stock requirements

Seasonal variations

Internal orders from other parts of the

organization.

14

Input 2 - Bill of Materials

Bill of materials

• parent-child (hierarchical) relationships

• quantity per application (QPA)

• production or procurement lead-times

15

Input 3 – Inventory Position

• For all items at all levels for each time

period

– On-hand inventory quantities

– On-order quantities (due-in’s)

Let’s see. We have 3

of these with 5 more

arriving on the 23rd.

16

Input - Output

1. Master Production Schedule

2. Bill of Materials and level codes

3. Inventory status of all items – on-hand and on-order

MRP SYSTEM

Compute for all components:

• Gross requirements

• Planned order and work releases

• Time phasing of net requirements

17

A Three-legged Stool

Stool

Final assembly area

End item

Parent level

Child level

1 seat assembly

Department X

1 seat

Dept X

1 cushion

Vendor B

Raw material – lumber

leg assembly

Department Y

3 legs

Dept Y

6 screws

Vendor A

3 supports

Dept Y

- Paul Bunyon Lumber Co.

6 screws

Vendor A

18

A Three-legged Stool

Production

Lead-times

One week

One week

Stool

Final assembly area

1 seat assembly

Department X

leg assembly

Department Y

Vendor

Lead-times

6 screws One week

Vendor A

One week

Two weeks

1 seat

Dept X

1 cushion

Vendor B

3 legs

Dept Y

3 supports

Dept Y

6 screws

Vendor A

Two weeks

Raw material – lumber

- Paul Bunyon Lumber Co.

19

A Three-legged Stool

Independent Demand

Stool

Final assembly area

Dependent Demand

seat assembly

Department X

1 seat

Dept X

1 cushion

Vendor B

Raw material – lumber

leg assembly

Department Y

3 legs

Dept Y

6 screws

Vendor A

3 supports

Dept Y

- Paul Bunyon Lumber Co.

6 screws

Vendor A

20

Lumpy Demands due to lot sizing

time buckets

dependent

demand

Time period

Assembly X

demand

Production

Assembly Y

Production

Assembly Z

Production

Subassembly A

Requirements

1

2

3

4

5

6

10

30

5

10

7

7

10

10

10

10

5

7

7

5

10

7

7

5

7

7

5

10

7

7

10

30

5

57

7

27

37

27

7

7

7

Assemblies X and Z require one unit of assembly A while

Assembly Y requires two.

SubAsbAper 1 = 30 + 2 (10) + 7 = 57

21

Terminology

• bill of materials – all parent-child

relationships

• level coding – the order in which the

requirements must be computed (indenture

level)

• lead-time offset – due date minus the

planned order release date

22

Product Structure

Two end products (1 and 2)

Four assemblies (A, B, C, and D)

Three parts (d, f, and g)

2

1

A(2)

D

C

A

B

B

d(2)

g

C(2)

D

C

d

g(3)

B

f(3)

B(2)

C

( ) – indicates number of components used on next higher assembly

23

Bill of Materials Matrix - B

End

Product

1 2

1

2

A

D

B

C

d

f

g

A

2

subassemblies

D

B

C

1

1

1

1

2

parts

(components)

g

d

f

3

2

1

2

1

1

3

Why this is an upper

triangular matrix isn’t it!

24

use topological sorting

MRP Level Assignments

1

A(2)

2

C

D

A

B

B

g(3)

Level 1

A, D

B

d(2)

g

C

d

Level 0

1, 2

C(2)

Level 3

C, g

D

f(3)

B(2)

Level 2

B

C

Level 4

d, f

25

Topological Sorting

1

rearrange so all

arrows go down

1

4

3

3

7

7

4

6

5

8

9

2

2

5

9

8

note: no loops are present

6

26

Computing Direct Dependent Demands

Let Dn = vector of dependent demand directly resulting

from demand at level n (output vector)

dn = vector of demand at level n (input vector)

Then Dn = dn x B where B is the Bill of Materials Matrix

and D0 = d0 B;

D1 = d1B = D0 B = (d0 x B x B);

D2 = d2 B = (d0 x B x B x B); etc.

Then total demand = D0 + D1 + … + Dm

= d0 x (B + B2 + B3 + … + Bm )

27

Assume independent demand for item 1 = 100 units & item 2 = 200 units

and there is a spare part demand for 20 C’s.

1

D0 = d0 B

= (100, 200, 0, 0, 0, 20, 0, 0, 0) x

1

2 A DB C g d f

0

0

0

0

0

0

0

0

0

2 A D B C g

d f

0

0

0

0

0

0

0

0

0

0

0

2

0

0

1

0

0

0

2

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

1

1

2

0

0

0

0

0

1

0

0

1

2

0

0

0

0

0

3

0

0

1

0

0

0

0

0

0

0

0

0

3

0

0

0

= (0, 0, 200, 200, 200, 100, 600, 20, 60) = d1

Requirement: A

200

D

200

B

200

C

100

g

600

d

20

f

60

28

Level 2 requirement

1

D1 = d1 B

= (0, 0, 200, 200, 200, 100, 600, 20, 60) x

12 A

D

B C

g d f

0

0

0

0

0

0

0

0

0

2 A D B C g

d f

0

0

0

0

0

0

0

0

0

0

0

2

0

0

1

0

0

0

2

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

1

1

2

0

0

0

0

0

1

0

0

1

2

0

0

0

0

0

3

0

0

1

0

0

0

0

0

0

0

0

0

3

0

0

0

= (0, 0, 0, 0, 500, 500, 200, 100, 300) = d2

Requirement: A

0

D

0

B

500

C

500

g

200

d

500

f

300

29

Computing Total Requirements

If B is an n x n triangular matrix, then Bk = 0 for any k n

by matrix multiplication of B x B:

n

bij2 bik bkj bi1b1 j bi 2b2 j ... bi ,i 1bi 1, j

k 1

If i j then b2i,j = 0

30

B2 =

=

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

2

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

1

1

2

0

0

0

0

0

1

0

0

1

2

0

0

0

0

0

3

0

0

1

0

0

0

0

0

0

2

0

0

1

0

0

0

0

0

0

0

0

3

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

2

2

0

0

0

0

0

0

0

0

3

2

4

0

0

0

0

0

0

1

1

2

0

0

0

0

0

5

0

0

1

2

0

0

0

0

3

0

0

3

6

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

2

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

1

1

2

0

0

0

0

0

1

0

0

1

2

0

0

0

0

0

3

0

0

1

0

0

0

0

0

0

2

0

0

1

0

0

0

0

0

0

0

0

3

0

0

0

Therefore b21,8 = 5 is the

level 1 requirement for

component d in product 1.

31

MRP Level Assignments

1

A(2)

2

C

D

A

B

B

g(3)

Level 1

A, D

B

d(2)

g

C

d

Level 0

1, 2

C(2)

Level 3

C, g

D

f(3)

B(2)

Level 2

B

C

Level 4

d, f

32

B3 =

=

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

2

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

1

1

2

0

0

0

0

0

1

0

0

1

2

0

0

0

0

0

3

0

0

1

0

0

0

0

0

0

2

0

0

1

0

0

0

0

0

0

0

0

3

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

4

4

0

0

0

0

0

0

0

2

2

0

0

0

0

0

0

0

0 0

2 9

2 6

4 12

0 0

0 0

0 0

0 0

0 0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

2

2

0

0

0

0

0

0

0

0

3

2

4

0

0

0

0

0

0

1

1

2

0

0

0

0

0

5

0

0

1

2

0

0

0

0

3

0

0

3

6

0

0

0

0

Therefore b32,9 = 9 is the

level 2 requirement for

component f in product 2.

33

Total Requirements matrix (R)

Let ri,j = total number of units of item j required to

produce one unit of item i where ri,i = 1 by definition.

therefore:

R = I + B + B2 + B3 + … + Bn + 0 + …

recall:

1

1

x

(1 x)

1 x

n 0

n

Therefore R = (I – B)-1

34

B=

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

2

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

1

1

2

0

0

0

0

0

1

0

0

1

2

0

0

0

0

0

3

0

0

1

0

0

0

0

R = (I – B)-1 =

0

0

2

0

0

1

0

0

0

0

0

0

0

0

3

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

2

0

1

0

0

0

0

0

0

0

1

0

1

0

0

0

0

0

2

3

1

2

1

0

0

0

0

5

7

2

5

2

1

0

0

0

2

6

1

2

1

0

1

0

0

9 15

7 21

4 6

5 15

2 6

1 3

0 0

1 0

0 1

35

let d = vector of independent demands which includes demands for

end products, spare assemblies, and spare components

Q = total production requirements vector

then

Q = d R = d (I – B)-1

item

1

demand 20

2

A

D

B

C

g

d

f

30

0

10

0

5

0

0

0

Q = d R = (20, 30, 0, 10, 0, 5, 0, 0, 0) x

1

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

2

0

1

0

0

0

0

0

0

= (20, 30, 40, 40, 150, 365, 240, 445, 1095)

0

1

0

1

0

0

0

0

0

2

3

1

2

1

0

0

0

0

5

7

2

5

2

1

0

0

0

2

6

1

2

1

0

1

0

0

9 15

7 21

4 6

5 15

2 6

1 3

0 0

1 0

0 1

36

from earlier example:

d R = (100, 200, 0, 0, 0, 20, 0, 0, 0) x

1

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

2

0

1

0

0

0

0

0

0

0

1

0

1

0

0

0

0

0

2

3

1

2

1

0

0

0

0

5

7

2

5

2

1

0

0

0

2

6

1

2

1

0

1

0

0

9 15

7 21

4 6

5 15

2 6

1 3

0 0

1 0

0 1

= (100, 200, 200, 200, 800, 1920, 1400, 2320, 5760)

Requirement:

A

D

B

200 200

800

C

1920

g

1400

d

2320

f

5760

37

MRP Procedure

• Netting: Determine net requirements

– gross requirements –[on-hand inventory + scheduled receipts]

• Establish lot sizes

– divide net requirements into production lots or order quantities

• Time Phasing: Determine planned order release dates

– Offset due dates with lead-times

• BOM Explosion: Expand to next level

– Generate gross requirements of all components on next level

• Iterate: Repeat until all levels have been processed.

38

Master Production Scheduling

Qj,t = scheduled receipts (order or lot size quantity)

of item j during period t

Rj,t = gross requirement of item j during period t

Ij,t = expected on-hand inventory of item j at the beginning

of period t

Nj,t = net requirements for item j in period t

Nj,t = max{0, Rj,t – Qj,t – Ij,t}

Note: Rj,t = max{ forecast for period t, customer orders period t}

39

Master Production Scheduling (cont.)

Ij,t = expected on-hand inventory of item j at the beginning

of period t

Qj,t = scheduled receipts (order or lot size quantity)

of item j during period t

Rj,t = gross requirement of item j during period t

I jt max 0, I j ,t 1 Q j ,t 1 R j ,t 1

40

MRP - Example

CURENT INVENTORY STATUS AND LEADTIMES

level

item

on-hand

inventory

at t=0

L0

L0

L1

L1

L2

L3

L3

L4

L4

1

2

A

D

B

C

g

d

f

120

85

0

10

500

160

0

1200

4000

reorder

lead-time

(weeks)

1

1

2

2

1

1

2

1

2

41

Example - demands

Week

Item

I1

I2

A

D

B

C

g

d

f

1

2

3

4

5

6

7

8

9

50

20

20

30

30

25

40

35

40

10

30

35

25

20

15

25

15

30

30

10

10

20

100

5

Master Production Schedule

42

Example – level 0

Week 1

Item 1

R1

50

Q1

I1

120

N1

OR

2

3

4

5

6

7

8

9

20

30

40

30

25

15

30

70

50

40

120

20

100

60

30

5

10

0

30

Week 1

Item 2

R2

20

Q2

I2

85

N2

OR

2

3

4

5

6

7

8

9

30

25

10

35

20

25

30

65

35

35

100

10

75

65

30

10

15

120

120

100

OR – order releases

(based on lot-sizes of 120 and 100)

0

30

100

43

Gross requirements –lower level period 7

D0 = d0 B

= (120, 100, 0, 0, 0, 0, 0, 0, 0) x

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

2

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

1

1

2

0

0

0

0

0

1

0

0

1

2

0

0

0

0

0

3

0

0

1

0

0

0

0

0

0

2

0

0

1

0

0

0

0

0

0

0

0

3

0

0

0

= (0, 0, 240, 100, 100, 120, 300, 0, 0)

Gross

Requirement:

A

240

D

100

B

100

C

120

g

300

44

note: lot for lot

re-order policy

OR – order releases

(based on lot-sizing)

Example – level 1

Week

Item A

R

Q

I

N

OR

1

2

3

4

5

6

7

8

9

0

0

0

0

0

240

15

0

0

0

240

240

0

0

0

0

0

240

0

15

0

240

15

Week

Item D

R

Q

I

N

OR

1

2

3

4

5

6

7

8

9

0

10

0

100

0

0

10

10

10

0

0

10

100

100

0

0

0

0

100

0

0

100

10

240

100

lead-time

2 weeks

45

Gross requirements –lower levels period 5

D1 = d1 B

= (0, 0, 240, 100, 0, 0, 0, 0, 0) x

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

2

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

1

1

2

0

0

0

0

0

1

0

0

1

2

0

0

0

0

0

3

0

0

1

0

0

0

0

0

0

2

0

0

1

0

0

0

0

0

0

0

0

3

0

0

0

= (0, 0, 0, 0, 440, 100, 0, 480, 0)

Gross

Requirement:

B

440

C

100

d

480

46

use topological sorting

MRP Level Assignments

1

A(2)

2

C

D

A

B

B

g(3)

Level 1

A, D

B

d(2)

g

C

d

Level 0

1, 2

C(2)

Level 3

C, g

D

f(3)

B(2)

Level 2

B

C

Level 4

d, f

47

OR – order releases

(based on lot-sizing)

Example – level 2/3

Wagner-Whitin with

A=$150, h=$.60

Week

Item B

R

Q

I

N

OR

1

2

3

4

5

6

7

8

9

440

560

0

20

100

0

440

15

100

0

100

120

100

0

0

440

0

15

0

100

0

0

100

Week

Item C

R

Q

I

N

OR

1

2

- level 3

100

15

115

0

15

555

120

100

3

4

5

6

7

8

9

120

120

0

1150

100

0

120

200

0

0

1150

0

100

0

0

120

0

200

0

1250

320

least unit cost

48

OR – order releases

(based on lot-4-lot)

Week

Item g

R

Q

I

N

OR

Example – level 3/4

1

- level

0

2

3

4

5

6

7

8

9

0

575

0

0

300

100

0

0

0

300

300

0

0

575

0

0

0

300

0

100

0

300

575

300

100

Week 1

2

Item d - level 4

R

480

120

Q

I

1200

720

N

OR

3

4

5

6

7

8

9

1250

0

480

350

0

0

0

600

600

120

0

230

0

0

0

49

Example – level 4

Week

Item f

R

Q

I

N

OR

1

2

- level 4

0

360

4000

110

4000

3

4

5

6

7

8

9

3750

110

3640

0

0

960

0

0

0

0

0

0

960

0

0

0

960

This is a great level.

50

item C

periods 4 - 8

Lot sizing and MRP

least unit cost heuristic:

net

lot

period rqmt size

weeks

in inv

wk 4

wk 5

wk 6

wk 7

wk 8

1150

100

0

120

200

Iteration 2

wk 7

120

wk 8

200

carry-cost

per lot

Inv

$ per

Unit

Unit

Setup

Cost

Total

(unit)

0

60

0

.05

.87

.80

.87

.85

1370

1570

0

1

2

3

4

276

756

.20

.48

.73

.64

.93

1.12

120

320

0

1

0

120

0

.38

8.33

3.13

8.33

2.51

0

1250

setup cost = $1000

holding cost = .60 /unit-period

unit cost = $1

51

Lot Sizing with Capacity Constraints

Known requirements in each period versus capacities

ri = requirement in period i

ci = production capacity in period i

yi = production level in period i

r1 , r2 ,..., rn

c1 , c2 ,..., cn

Find y1 , y2 ,..., yn where

j

j

c r

i 1

i

i 1

i

yi ci , for 1 i n

for j 1,..., n

52

Example 7.7

r = (20, 40, 100, 35, 80, 75, 25)

c = (60, 60, 60, 60, 60, 60, 60)

Check for feasibility:

period

1

2

3

4

5

6

7

additive

rqmt

20

60

160

195

275

350

375

Additive

capacity

60

120

180

240

300

360

420

53

The simple 2-step algorithm

1.

2.

Find next period in which demand > capacity

Back-shift demands to period(s) having excess capacity

0. r = (20, 40, 100, 35, 80, 75, 25)

c = (60, 60, 60, 60, 60, 60, 60)

1. 40 60 60

r = (20, 40, 100, 35, 80, 75, 25)

c = (60, 60, 60, 60, 60, 60, 60)

2. 40 60 60 55 60

r = (20, 40, 100, 35, 80, 75, 25)

c = (60, 60, 60, 60, 60, 60, 60)

3. 50

60

40 60 60 55 60 60 25

r = (20, 40, 100, 35, 80, 75, 25)

c = (60, 60, 60, 60, 60, 60, 60)

Feasible but not necessarily optimal!

Final answer:

y = (50, 60, 60, 60, 60, 60, 25)

54

The Improvement 2-Step

• Start at end and work backwards

• Determine if it is cheaper to shift entire production lot to

prior periods having excess capacity

Assume k = $450 and h = $2:

0. r = (100, 79, 230, 105, 3, 10, 99, 126, 40)

c = (120, 200, 200, 400, 300, 50, 120, 50, 30)

1. r’ = (100, 109, 200, 105, 28, 50, 120, 50, 30)

c = (120, 200, 200, 400, 300, 50, 120, 50, 30)

Cost = 9 x 450 + 432 = $4,482

2. r’= (100, 109, 200, 105, 28, 50, 120, 50, 30)

c = (120, 200, 200, 400, 300, 50, 120, 50, 30)

y = (100, 109, 200, 105, 58, 50, 120, 50, 0)

Cost = 8 x 450 + (432 + 2 x 30 x 4) = $4,272

Find feasible solution

Look for improvement

55

More Improvement

•

•

Start at end and work backwards

Determine if it is cheaper to shift entire production lot to prior periods having

excess capacity

Assume k = $450 and h = $2:

1. r’ = (100, 109, 200, 105, 28, 50, 120, 50, 30)

c = (120, 200, 200, 400, 300, 50, 120, 50, 30)

Cost = 9 x 450 + 432 = $4,482

2. r’= (100, 109, 200, 105, 28, 50, 120, 50, 30)

c = (120, 200, 200, 400, 300, 50, 120, 50, 30)

y = (100, 109, 200, 105, 58, 50, 120, 50, 0)

Cost = 8 x 450 + (432 + 2 x 30 x 4) = $4,272

2. r’= (100, 109, 200, 105, 28, 50, 120, 50, 30)

c = (120, 200, 200, 400, 300, 50, 120, 50, 30)

y = (100, 109, 200, 105, 108, 50, 120, 0, 0)

Cost = 7 x 450 + (432 + 240 + 300) = $4,122

Let’s do another one…

56

Assume k = $450 and h = $2:

Do it again?

2. r’= (100, 109, 200, 105, 28, 50, 120, 50, 30)

c = (120, 200, 200, 400, 300, 50, 120, 50, 30)

y = (100, 109, 200, 105, 108, 50, 120, 0, 0)

Cost = 7 x 450 + (432 + 240 + 300) = $4,122

No! Don’t

do it. It

will cost

more.

2. r’= (100, 109, 200, 105, 28, 50, 120, 50, 30)

c = (120, 200, 200, 400, 300, 50, 120, 50, 30)

y = (100, 109, 200, 105, 228, 50, 0, 0, 0)

Savings = $450

Cost = $2 x 120 x 2 = $480

Look at shifting 50 units in period 6 to period 5

and the resulting 158 units in period 5 to period 4

Final answer: y = (100, 109, 200, 263, 0, 0, 0, 0, 0) with cost = $3,638

57

There are still problems…

The problem is that even if lot sizes at

some level do not exceed production

capacities, there is no guarantee that

when these lot sizes are translated into

gross requirements at a lower level, that

they will not exceed capacities.

58

let

AI = setup cost for item i

hi = holding cost for item i

Iit = inventory level ending period t

Qit = order quantity of item i, period t

zit = 1 if item i is ordered period t; otherwise 0

mi,s(i) = number units of i required to produce s(i)

Rt = end item requirement in period t

Optimal Multilevel Lot Sizing

N

Min

T

A z

subject to:

i 1 t 1

i it

I1,(t 1) Q1t I1t Rt

hi I it

for 1 t T

I i ,(t 1) Qit I it mi , s (i )Qs (i ),t 0 for 1 t T , 2 i N

Qit zit M

for 1 t T , 2 i N

Qit , I it 0,

zit 0 or 1

59

Weaknesses and Problems

MRP is based upon a flawed model!

• assumes infinite production capacity

– MRP identifies what is to be done to meet the master

schedule

– capacity planning usually occurs after the fact

– capacity lot-sizing at one level will not solve overall

capacity problem

• deterministic system

– lead-times & demands

– lead-times do not consider plant loading

– lead-times are inflated to compensate creating more

problems

– lead-times may be dependent on lot sizes

60

System Nervousness

Caused by Rolling Horizon

Only 1st period decision of a N-period problem is implemented.

Using the Wagner-Whitin algorithm:

t

Dt

Qt

1

190

190

2

210

400

3

190

0

4

210

400

5

190

0

t

Dt

Qt

1

190

400

2

210

0

3

190

400

4

210

0

5

190

400

A = $400 / order

h = $1 per item

6

210

0

Q1 = 190 if odd number of periods

Q1 = 400 if even number of periods

61

More Problems

• Random numbers of defective items

• Data Integrity

–

–

–

–

machine unavailability

engineering changes

discrepancies in inventory records

changes in demands (forecasts), costs, or lead-times

• Lead-times dependent upon lot sizes

• Reject or rework rates must be addressed

62

After MRP?

• MRP II – Manufacturing Resource Planning

–

–

–

–

includes MRP-I

adds financial, accounting, and marketing functions

MPS becomes a decision variable

capacity resource planning (CRP) an integral feature

• ERP – Enterprise Resource Planning

–

–

–

–

–

includes MRP-II

entire firm operates on the same data

client-server with a single relational database

multi-location (international) support

includes customer orders, distribution, delivery

schedules, etc.

63

More on ERP

• Enterprise systems are commercial software

packages that enable the integration of

transactions-oriented data and business processes

throughout an organization (and perhaps

eventually throughout the entire interorganizational supply chain).

• Enterprise systems include ERP software and

related packages as advanced planning and

scheduling (APS), sales force automation,

customer relationship management, product

configuration, etc.)

64

More of More on ERP

• Most companies have failed to implement ERP

packages successfully or to realize the hoped-for

financial returns on their ERP investment.

• Standish Group Study of ERP Implementations:

– 35% are Cancelled

– 55% overrun their budgets

– Less than 10% are on time and under budget

• Implementation Averages

– Cost: 178% over budget

– Schedule: 230% longer

– Functionality: –59% or: the system will only perform

41% of the functions it was intended to perform.

65

Why Implementations Fail

•

•

•

•

•

•

People Don’t want the systems to succeed

People are comfortable and don’t see the need

for the new system.

People have unrealistic expectations of the new

system.

People don’t understand the basic concepts of

the system.

The basic data is inaccurate.

The system has technical difficulties.

66

What about APS?

• APS is Advance Planning and Scheduling:

The technique that deals with analysis and

planning of logistics and manufacturing over the

short, intermediate and long-term periods. APS

describes any computer program that uses

advanced mathematical algorithms or logic to

perform optimization or simulation on finite

capacity scheduling, sourcing, capital planning,

resource planning, forecasting, demand

management and others.

67

The Five Main Components Of an

APS System

•

•

•

•

•

demand planning

production planning

production scheduling

distribution planning

transportation planning

Gosh there are

five of them.

68

MRP and APS

• APS considers all constraints and capacities

simultaneously using mathematical models (linear

programming or some derivative) and yields a

production plan (either short term or longer term).

• MRP can take this plan and execute the acquisition

of materials.

• MRP is more transaction focused and an older

product than APS

• APS is more modeling oriented.

69

Homework

Hey! This MRP stuff is okay.

Can we have some homework

problems to try it out? Please.

From your textbook: chapter 7: 4,5,6,23,24,25,27,28

+ handout

70