CC 2002 K

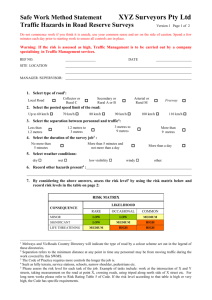

advertisement

CC 2002 K Information, Quantities and Communication Information The construction industry is unique in its organisational nature. Each construction project is unique in it’s planning, organisation and operation. During each construction project the information needed, and the construction problems are all different from each other. It is important that clear information is relayed to whoever needs it. It is important that information is relayed at the right time. It is important that any information is clear and easily understood. All of these help to ensure a successful project delivered on time and as close to budget as possible. Relaying Information It is important that people in a building team work together to complete a project. Information can be relayed on site and to project personnel in a variety of ways. It is important that all the members of a construction team or project communicate effectively with each other to avoid unnecessary conflict. Types and methods of communication. Drawings Day work sheets Bill of Quantities Specifications Purchase orders Method statements Risk assessments Quality procedures Fax message E mail Telephone Programme of work SPECIFICATIONS A Specification is a term used for the set of requirements that are to be met by materials, products or services. The Specification will identify which materials or products are to be used in the build. It will specify how they are to be used. The specification will detail the standard of quality that is to be met any materials or work that is to be carried out. Plastering Specification A specification for plastering will give exact details on the type of plastering required, these may include: Type and manufacturer of beads . Types, materials and methods of fixings. Background preparation. Class, type and manufacturer of plasters. Proportions of any gauged mortars. Tolerances to be expected from workmanship. A specification will accompany any drawings that are produced for the project. The project designer or architect will liaise with the client to transfer their building ideas into a set of drawings and specifications. Architects can use standard specifications that are produced by various organisations to achieve the right quality product for their client. British Standards Sources that produce specifications include : British Standards, Building Research Establishment (BRE) and European Union Standards. The British Standard covering plastering and rendering is BS EN 13914-2 : 2005 British standards The British Standards Institute (BSI) has been in existence for over 100 years. It develops and tests a technical standard and produces a formal document for publication. Codes of practice are produced from the standard, which will cover the use of a product in more detail. Technical literature The purpose of technical literature is to provide details on products and systems. It will tell you the latest products available, what they are, their intended use and applications, and guidance on using them correctly. Technical literature can include manuals, pamphlets, product specification sheets or catalogues. You need to be aware of, and using manufacturers technical literature to be sure you are using the latest up to date products and systems, that meet the latest design and building regulation requirements. British Gypsum British Gypsum’s main source of product and system information is the White Book. This contains a wide range of partitioning and lining solutions, specifications and products, as well as lab test results and an overview of installation details. British Gypsum The White Book is updated regularly to make sure it is the most up to date and comprehensive reference source. The White Book is also available online. British Gypsum also produce the Site Book which gives step by step guidance on installing some of their products. Tendering A tender package is a set of documents used by clients project designer to establish a quoted price for a project. The documents will include a brief explanation of what the project is, where it is and its intended purpose. Tender packages are first sent to main contractors, who in turn will compile their price by parcelling the tender to the relevant sub contractors eg brickwork, roofing or plastering. You do not have to pay to tender for a contract. Tender packages In the tender package the tender process will be clearly stated, where the tender is to be returned to, who to and when the return deadline date and time is. The tender package will include drawings, specifications, bill of quantities and the preliminaries. The preliminaries will outline the basis of the contract that will be awarded, it will set out any damages that the contractor could be liable for, the defects period for the contractors work and the contractors obligations. Quotes and estimates What is the difference? A quotation is a fixed price that cannot be changed once accepted by the customer. This holds true even if you have to carry out more work than expected. If quoting, specify precisely what it covers, any variations outside of this can be charged additionally. Estimates An estimate is an educated guess of what a job may cost, but isn’t binding. To take account of possible unforeseen developments, you should provide several estimates based on various circumstances, including the worst case scenario. Estimates An estimate should be written on headed paper and include a full breakdown of the required works and costs. An estimate should state what the estimated price is for, and should include the following : Estimates Overall price Breakdown which lists the components of the price. Schedule, detailing when you can start the work. A time period the estimate is valid for. Any payment terms you may have. Your full business contact details. Quotation A Quote will commit you to the price you specify. Only use a quote if the work you are quoting has clear requirements – in terms of labour, materials etc. Only use if your costs are stable. You are confident the work is not going to be more complicated than expected. Quotation A written quote should include: Overall price Breakdown of price, what is covered, what is not. Period the quotation is valid for. Time schedule for when the work will be done. Your business full contact details. Your payment terms or schedule. Contact details. What the price covers Breakdown of price Total price Payment terms and schedule Contact name Estimating Quantities It is important to be able to accurately measure, calculate and estimate quantities of materials to ensure a job runs smoothly, on time and keeps to budget. Plastering materials and payments are calculated by using Area. Work and wages are worked out by the square metre. Units of measurement The construction industry measures everything using the metric system : millimetres, centimetres and metres. Plaster, plasterboards and bricks are calculated using square metres (area). Screed, concrete is measured using cubic metres (volume). Plaster beads, cornice or skirting boards are measured using linear metres (length). Area Area is the surface of the floor or wall you are to work on. Area is measured in SQUARE units. m2 means square metres. Square metres To find the area of a wall in Square metres : Measure the length of the wall in metres. Measure the height of the wall. Multiply the two measurements together : Length x Height = Area ( m2) Square Metres (Area) A wall 4 m long by 2 m high. 4m x 2m = 8 m2. The area of this wall is 8m2. If the wall was divided into 1m2 squares, there would be 8 squares. Calculating materials To find how many plasterboards are needed to board a ceiling : Find the area of the ceiling e.g: 4 m x 3 m = 12 m2 ( area of ceiling) Find the area of the plasterboard. Multiply the length by the width of the board being used to board the ceiling : 1.800 x .900 = 1.62 m2( area of one board) Divide the area of the ceiling by the area of a plasterboard. 12 m2 ( area of ceiling ) divided by 1.62 m2 ( area of one plasterboard ) = 7.40 This means it will take 7.40 plasterboards to plasterboard a 12 m2 ceiling. You always round up the end number, so you will need 8 plasterboards to complete the ceiling. Allowing for waste Making sure you have ordered the correct amount of materials is essential, if the job is to be completed on time and to your budget. Buying too much material is wasteful and will cost you money. Not ordering enough materials will cost you time in completing the job, and could cost you money, as the job will stop while you wait for new supplies. Wastage allowance It is good practice when calculating materials to allow an extra amount for wastage. The usual allowance in plastering is to allow 10 % for wastage. Divide the number of plasterboards or bags that you will need by 10 to calculate the extra number of materials you will need. Calculating waste. Example : A 16 m2 ceiling divided by 1.62 m2 (area of a board) equals 9.87. Round up 9.87 equals 10. It will need at least 10 boards to plasterboard the ceiling. We need to add 10% for wastage when cutting boards to fit. 10 divided by 10 equals 1. Add 1 to 10 equals 11. We need to order 11 boards to plasterboard the ceiling. Volume and Cubic Metres Materials such as screed and concrete are ordered by the cubic metre. When calculating materials for these jobs you need to be aware of the depth that the finished materials need to be. Eg. A screed floor could be 40mm deep. The symbol for a cubic metre is m3. Calculating cubic metres. To calculate the cubic metres (volume) of a floor: Measure the length =12m Measure the width =4.5m Measure the depth =0.25m Multiply the three measurements together. Calculating volume Volume = length x width x depth Example :12 m x 4.5 m x 0.25m = 13.5 m3 If a screed floor is 50mm deep the 50mm becomes 0.050m. If a screed floor mix ratio is 3 : 1 This means 3 parts sand, 1 part cement. Divide the volume of your floor by 4 to calculate how much sand or cement you will need to order. Eg. 2 m3 divided by 4 equals 0.5 m3 Therefore 1 part cement equals 0.5m3. 3 parts sand equals 1.5 m3. A 25kg cement bag is about 0.045m3. 0.5 m3 divided by 0.045 = 11 bags. We need 1.5m3 of sand. Slightly damp sand has a volume of 1.5 tonnes to the m3. 1.5 tonnes of sand = 1 m3 There are 1,000kg of sand in a tonne. There are 40 25kg bags of sand in a tonne. 40 bags of sand = 1 tonne. 60 bags of sand = 1.5 tonnes = 1m3 We need 60 bags + 30 bags = 1.5m3 Linear metre A linear metre is a unit of measurement. A linear metre is a measure of one metre in a straight line. Items such as plaster beads, skirting board, cornice and coving are measured and ordered by the linear metre. DRAWINGS Drawings used in construction are used to communicate technical information to the different parties involved in the build process. Architects use standardised symbols, methods and language so that everyone can understand the information within the drawing. Block or Site plan A Block or Site plan shows the proposed site from a birds eye view. It shows the site in relation to the surrounding area. It will show the location of roads and buildings. It will always show the direction of North. Floorplans Floorplans are used to show the proposed layout of rooms, walls and doorways in a building. They will contain information such as the location of sockets, radiators, doorways, stairs and the type of wall constructions. Elevation Drawings These will show the front, side and rear of a building. They will show how the architect imagines the building will look when completed. These are useful for the local authority who need a visual image of the proposed structure for the planning approval process. Detailed Drawings These are used to highlight or ‘zoom in’ on components use in the construction. Detailed drawings are used to show the tradesperson how different materials interface and join together. They are used to make the technical aspects of components clear to the construction team. Sections Sections show the inside of any part of the building or component. They are used to provide a visual explanation of different parts of a building or component. A section through a cavity wall will show the location of a cavity tray over a lintel. Reflected plan A reflected plan is used to show the layout of a ceiling. It can be used to show how plasterboards are to be fixed in relation to the joists or if areas of a ceiling are to receive no plasterboard. Scale In order to draw a full size building, the drawing must be drawn to scale for it to fit onto the drawing sheet. A scale is a ratio to show how the size of a real object compares to the size of the same object when it is drawn or made as a model. A scale drawing is an exact replica of something, but reduced in size. A scale of 1:10 means that 1 cm on the drawing equals 10 cm in real life. This means that the drawing is 10 times smaller than the real object. Symbols Symbols are used to identify and represent the different materials and components used in the build. The same symbols are used by all designers to ensure everyone can understand the information on different drawings by different designers. Bill of Quantities A Bill of Quantities is another method of relaying information about a project. This document is used as part of the tendering process. The Bill of Quantities are prepared by Quantity Surveyors. All the materials, parts, labour and their costs for the project are itemised. This enables a contractor or sub contractor to price the work they are bidding for. A QS will prepare a BOQ by a ‘taking off’ process where the cost of a building is estimated from measurements in the architects drawings. They can create a cost estimate in regard to the area of walls, floors and also the number of doors, windows and the plumbing, heating and electric systems. Bill of quantities need to be read in conjunction with the specification for the project when creating a price. Read them carefully, check for linear metres as well as square metres. Make sure you understand where the area of work is : is it high up? Will it need scaffolding? What is the background? Will it need special preparation? Programmes of Work Programmes of work or Gantt charts are used to plot and monitor the progress of works on site. It is easy to see what should have been completed and by when. Programmes of work will normally be found in the site office. The Gantt Chart (program of work) is the most common charting technique. A Gantt chart will always show the start and end dates of a project. A Gantt chart can be used to show the current status of the project against the proposed schedule by shading the completed task elements or by using a vertical ‘Today’ line. Gantt Chart A timeline is stretched across the top of the page. Tasks The tasks involved in completing the project are listed down the left side of the page. Horizontal lines extend from left to right across the page. The horizontal line for each task starts below the timeline date that marks the proposed start date of the task. The length of the task line grows as the length of the time allocated for the task grows. The line for the task ends below the corresponding end date for the task. Some tasks can overlap others to speed up progress on site. Why are Gantt charts useful? CLARITY : When a Gantt chart is used, the entire project plan is presented visually. You will always know what you should be doing, when you should be doing it, and how long you should be spending on the task. Why are Gantt charts useful? Communication : Project plans need to be shared with all parties concerned with the project. These parties could be management, employees, contractors, suppliers or anyone else involved with creating or managing the project. Presenting a visual plan is much easier than trying to explain the project verbally or in writing. Why are Gantt charts useful? Organisation: A Gantt chart helps you to stay organised. A Gantt chart ( program of work) forces you to plan a project from start to finish. Chain of Command A construction project needs a team of people with very different roles and responsibilities to work closely together. For this team to work successfully, and for the project to run smoothly, each team member needs to know what they are responsible for, and who they are to report to. The Project Team There are three main categories of work in the construction sector. Professional: these people will generally have a degree or similar qualification. Job roles are : Building Surveyors, Civil Engineers, Architects or Structural Engineers and Site Agents. Craft The Craft sector of construction are skilled trades that require some level of qualification. Skilled trades are generally qualified up to level 2 (Diploma, NVQ), although electricians and plumbers usually need to go to level three. Job roles include : Bricklayers, Plasterers, Joiners and Electricians. Operative The next sector is the Operative. These are semi or unskilled jobs that do not require the person to have any qualifications. These would be general labourers who do labour intensive or unskilled work on the site such as digging holes and trenches, loading or preparing materials for the craft workers and general clearing up of the site. The chain runs from the most important person through a list of personnel with varying degrees of responsibility. Architect : leads the design team. Transfers the clients wishes and requirements into sketches and initial concepts for the building design. Architect Technician: produce all the technical drawings, plans and sections that are used during the build. Quantity Surveyor : they are the cost consultants for the construction industry. Before a tender is compiled they do all the cost planning, produce specifications and Bill of Quantities. They will prepare all tender and contract documents and source sub contractors if needed, for certain elements of the project. They value all on-going work on the project and are responsible for approving and organising any payments to contractors, sub contractors and suppliers. Site Engineer : they perform a technical, organisational and supervisory role on a construction project. They are responsible for marking out the site, applying designs and plans and liaising with sub contractors. Typical roles for site engineers include setting out (marking the position of structures) and levelling the site, surveying the site, checking drawings and ensuring calculations are accurate for the work, liaising with any consultants, sub contractors, supervisors, QS’s and the general workforce on the project. Contract Manager : they are responsible for the management of contracts with clients, vendors, partners or employees. It involves the negotiating of terms and conditions in contracts and ensuring compliance with the terms and conditions, they will also document and agree any changes that may arise whilst the contract is in place and being used. They help to ensure that the client is fully informed of progress on site, and of any problems or situations that may arise and may need discussing between client, architect and contractor. Site manager / Agent : this is the person in charge of the building contract and therefore has to be aware of, and in control of all aspects of site operations, including the planning of site progress. It is the managers responsibility to keep the operation to the agreed build time and cost plans. The typical roles for a site agent include : leading regular site meetings with personnel including Quantity Surveyors, Engineers, Foreman, Sub Contractors and the Client. They are responsible for Quality Control checks, including inspections of work, testing materials and frequent tours of site. They are to make sure that the project runs to schedule and to budget, they also have to find solutions to problems that may cause delays, such as late deliveries of materials. Foreman / Supervisor : the foreman or supervisor is the person who is in charge of their particular group of tradesmen. The foreman / supervisor will generally have many years experience in the particular trade. They will have specialised knowledge of their trade, have good communication, organisational and problem solving skills. They will liaise with the site agent to ensure their workers are where they are supposed to be with reference to the programme of work, inform the site agent of any problems or hold ups associated with their trade, and organise the materials and work load of their workers. General operative : labourers are unskilled and carry out the basic labour intensive work on site. Under the direction of a foreman or supervisor they will clean or clear a site, load materials or un load deliveries, dig holes or trenches for cables and any other basic work which needs to be done.