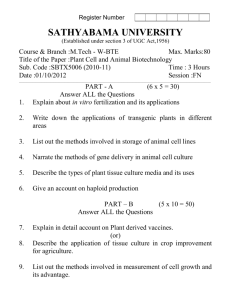

full notes theory(1)

advertisement