FOOD - Cheap Assignment Help

advertisement

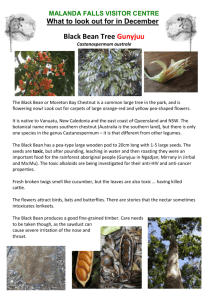

Journal of Food Composition and Analysis 1 (2014) 1−10 Contents lists available at ScienceDirect Journal of Food Composition and Analysis journal homepage: www.elsevier.com/locate/jfca fliF OOD ANALYSI S Physico-chemical properties and urease activity of red kidney bean (Phaseolus vulgaris L.) flour Cyril John A. Domingo Masters of Science in Food Science, Graduate School, University of the Philippines Los Baños, 4031, Philippines. Accepted 17 February 2014 _____________________________________________________________________________ Abstract Physico-chemical properties and urease activity of red kidney bean flour were investigated. Moisture content, ash and TSS were 12.31 % ± 0.12, 3.84 % ± 0.28 and 2.73 °Brix ± 0.12, respectively. The pH of the sample is 6.7, this value is near neutrality. The value for parameters L*, a* and b* were 87.86, 0.17 and 12.82, respectively. This can be associated to the light color of the flour with green and red hue. Low urease activity of 0.2 was also obtained. The phospholipids were analyzed by thin-layer chromatography and found that red kidney bean is comprised of phosphatidyl serine, lysophosphatidyl ethanol amine and two unknown phospholipids which were not identified due to the limited reference Rf values. Gas chromatography was employed on the determination of fatty acid content of the food sample. Results revealed that red kidney bean oil contained moderate to high level of saturated fatty acid in the form of stearic acid (16.50%) and unsaturated fatty acids probably in the form of oleic or linoleic (83.54%). It is very important to know these physico-chemical properties for these dictates a lot in terms of the processing of the sample commodity. Keywords: red kidney bean, compositional analysis, phospholipid, fatty acid, chromatography ______________________________________________________________________________ I. Introduction Common dry bean (Phaseolus vulgaris L.) is one of the most important crops of the world with different physical, biochemical and sensory properties. The global production of the dry beans in 2010 was 22.9 million metric tonnes and five leading producers were India, Brazil, Myanmar, United States and Mexico (FAO, 2012). The different classes of common dry bean include black bean, cranberry bean, great northern bean, kidney bean, navy bean, pinto bean and small red bean. Kidney beans are good source of protein, starch and dietary fibres (Osorio-Diaz et al., 2003). Physico-chemical properties of kidney beans change with postharvest handling and storage conditions resulting in a reduction in their cooking, eating and nutritional quality as well as consumer acceptance (Njintang et al., 2001). Physico-chemical properties of food products are analyzed for various reasons such as compliance with legal labeling requirements, assessment of product quality, C.J.Domingo / Journal of Food Composition and Analysis 1 (2014) 1−10 and determination of nutritive value, detection of adulteration, research and development. Knowledge of the moisture content is often necessary to predict the behavior of foods during processing while ash content provides a measure of the total amount of minerals within a food. Color and pH serves as determinants to food product quality (Nielsen, 2010). Legumes are known to contain urease - an enzyme which acts on non-peptide C-N bones in linear amides and having been known to convert urea to ammonia and CO2 (Teng et. al, 1988). Its inactivation is important in certain feedstuffs fortified with urea for ruminants. Also, the loss of urease activity indicates an inactivation of other enzymes. Most importantly, it is used as one of the quality control parameter in some food products. Oil of legume seeds are mainly constituted by fatty alcohols, wax esters, hydrocarbons, tocopherols, phenolic compounds, volatiles, pigments, phospholipids and triterpenic acids. The ability of an analytical method to characterize a vegetable oil is based on the identification and quantification of those compounds that are expected to be in connection with their origin and quality attributes (Cert et al., 2000). Phospholipids (PLs) are important constituents of oilseeds. The measurement of PLs is important in determining the stability and quality of vegetable oils. Phospholipids are undesirable in oil since they are responsible for oil discoloration during deodorization and steam distillation and losses of neutral lipids during neutralization. They affect the stability of the oil by chelating metals and increasing the amount of metal ions. The removal of PLs results in elimination of iron and copper, which increases the oxidative 2 stability and facilitates the refining process (Cert et al., 2000). The separation and identification of PLs can be made by thin-layer chromatography (TLC) (IUPAC, 1987). The analysis of fatty acid methyl esters (FAMEs) is used for the characterization of the lipid fraction in foods and is one of the most important applications in food analysis. The qualitative and quantitative determination of fatty acid constituents is often done by gas chromatography (GC). GC in general assumes that the compounds injected are volatile at the temperature of analysis and that they do not decompose at either the temperature of injection or analysis. In standardized analytical methods, flame ionization detection (FID) is the most widely used. Mass spectrometry (MS) allows obtaining molecular mass data, structural information and identification of compounds (Cert et al., 2000). The major aim of this study is to evaluate and characterize the biochemical and physical properties of red kidney bean flour. More specifically, to evaluate the moisture content, ash, pH, color, urease activity, phospholipids and fatty acids composition of red kidney bean flour. II. Materials and Methods 2.1 Chemicals and Reagents All solvents and chemicals used were analytical-reagent grade. The red kidney bean seeds were obtained from the local market of Los Baños, Laguna. C.J.Domingo / Journal of Food Composition and Analysis 1 (2014) 1−10 2.2 Preparation of Sample The red kidney bean seeds were manually dehulled and were ground using osterizer. One hundred grams of the ground bean was sieved through 20-mesh screen and stored in airtight container at refrigerated temperature until used. Ten grams of 20 mesh powder went through a four times extraction processes by 40ml petroleum ether. The samples after extraction were concentrated using the rotary evaporator (Yamato rotary evaporator model RE-46) and placed in a vial at freezing temperature until used. 2.3 Physico-chemical Properties of Red Bean Flour 3 crucibles was less than 0.001 g. The lost weight is calculated as the moisture of the sample. % MC = Minitial – Mfinal x 100 Minitial The sample from moisture content determination was heated in the furnace for five hours at 550°C. Ash content was derived by dividing the weight of the remaining residue over the original weight of sample. % Ash = Weight of residue x 100 wt. of sample 2.4. Urease Activity 2.3.1 Color, total soluble solids and pH value measurement The surface color of flour was measured using chromameter (CAPSURE). The parameters recorded were *L, *a and *b coordinates. The bean flour was diluted with distilled water at a ratio of 1:10 (sample:water) and then, pH was measured using calibrated pH pen (Milwaukee pH 600) and total soluble solids reading was done using a refractomer. 2.3.2 Compositional assessment The compositional analysis of the bean flour included the determination of moisture content using oven drying method (Memmert Convection Incubator). Dried samples (0.2-0.3 g) were placed in a tared crucible and oven-dried at 105°C overnight. The sample was then allowed to cool at room temperature for 30 minutes in a desiccator. Weights were afterwards recorded and the process of heating and weighing was redone for another 30 minutes. The process was repeated until the difference in the weight of the cooled Approximately 0.20g of flour sample was weighed in into a test tube and was added with 10mL of buffered urea solutions. The samples were mixed and incubated at 30°C for 30 minutes. The blank was prepared by weighing the same amount of sample into a test tube and was only added with 10ml phosphate buffer solution. It was mixed and incubated along with the samples but with a 5 minute interval. The pH of the supernatant liquid was determined at exactly 5 minutes after removal from the bath. The difference between the pH of the test and pH of the blank was used as the index of urease activity. 2.5 Phospholipid Profile 2.5.1 Extraction of phospholipid Phospholipid extraction was carried out using 5g of deffated sample with 100 ml choloform: methanol (2:1) in warring blender as solvent. After filtering, the filtrate was concentrated using a rotary evaporator. One gram of oil sample was dissolved in 4 ml chloroform. C.J.Domingo / Journal of Food Composition and Analysis 1 (2014) 1−10 2.5.2 Thin-layer chromatography Commercial TLC glass sheets coated with silica gel were used in this exercise. 4 increases in prolonged standing of the plates. If no color development was observed, pre-heat the plates at 100oC for 5 minutes before spraying the solution. 2.6 Fatty Acid Profile The developing solvent was composed of 170:25:25:4 (v/v) of chloroform: methanol: acetic acid: water. One ul of extract was spotted on the plate. Then, the spotted plate was placed in the developing chamber, and then dried. 2.5.3 Detection of phospholipids Spots were first made visible using iodine vapor. Dried TLC plates were placed inside the reaction chamber (containing iodine vapor) and spots development were observed in about a few minutes. The brown spots seen were temporary and were encircled softly using a pencil as marker. The markers were then used as a guide to facilitate spraying of other reagents that would make the spots completely visible. For the spot development of amino phospholipids, the plates were heated at 100 °C prior to spraying with the ninhydrin solution. If no perceived spot development was observed on probable phosphatidyl ethanolamine and phosphatidyl serine, then the plates were reheated in oven at 100°C for 15-20 minutes. Development of pink spot was monitored. TLC plates were sprayed with 20% perchloric acid and then heated to 100°C for 5 minutes. If no spot development was observed the plates were reheated at 100°C for 15- 20 minutes. Spot development is gray or black. For phosphorous containing lipid compounds (containing phosphate group), blue spots on white or blue-gray background are indicative results. Color intensity 2.6.1 Esterification Approximately 0.02 grams of oil sample was weighed in a screw capped tube, then added with 4 ml methanolic HCl and then mixed using a vortex mixer. The mixture was incubated in an oven at 50°C for 10 hours, allowed to cool at room temperature and was added with 5 ml hexane layer to extract the ether vigorously. The two layers were then allowed to separate. The hexane layer contains fatty acids methyl ester and was used in the chromatography analysis. 2.6.2 Gas chromatography Roughly one μl of fatty acid methyl ester sample was injected into the HewlettPackard Model 5890A Gas Chromatogram equipped with a hydrogen flame ionization detector under the following conditions: (1.) column, 6ft x 1/8 in. stainless steel tube column packed with 15% diethylene glycosuccinate (DEGS) in Chromosorb W (80/100mesh), (2.) carrier gas, nitrogen (20 ml/minute), (3.) injection temperature at 200°C, (4.) column temperature at 180°C, (5.) hydrogen and air at 10 and 50 psi respectively and (6.) the recorder, HewlettPackard Model 3396 Integrator. Each chromatogram was allowed to run for 30 minutes. The integrator calculates the amount of fatty acids in the sample and expressed as percentage. A standard mixture of 1 µl was injected in the gas chromatography. Equal amounts of methyl esters were present in the standard (i.e. linoleic, linolenic, palmitic stearic and etc.). C.J.Domingo / Journal of Food Composition and Analysis 1 (2014) 1−10 III. Results and Discussion Proximate analysis is an important criterion to assess the overall composition and nutritional status of any ingredient intended for food use (Qayyum et al., 2012). The results of the pysico-chemical analysis of the red kidney bean are presented in Table 1. The moisture content and ash were 12.31 % ± 0.12 and 3.84 % ± 0.28. Present findings are in conformity with values described in previous literature; however, slight variations may be due to varietal differences and environmental conditions. Wani et al. (2013) found that moisture content and ash were 10.40 % ± 0.44 and 3.5 % ± 0.04, correspondingly. The data pertaining to present study are closely related with the work of Sasanam et al. (2011), they delineated 12.39 % ± 4.60 and 3.90 % ± 0.12 moisture and ash contents, respectively. The pH which is the negative logarithmic function of the hydronium ions present in the sample affects the flavor and microbial spoilage of the food (Nielsen, 2010). Acidic environments suggests less or inhibited growth of microorganisms while pH close to neutral makes the food product prone to microbial contamination. The pH value of the sample is recorder at 6.7. This means that the food product requires processing 5 under pressure (higher than 100°C). The pH obtained in the study is quite high compared to the approximate pH reported by USFDA (2007) which ranges from 5.40 to 6.0. The total soluble solids (TSS) of the sample is recorded at 2.73 °Brix ± 0.12 this result is in agreement to the reported value of USDA (2013) which is 2.10 °Brix. Red kidney bean flour color was characterized by the parameters L*, a* and b* using a CAPSURE chromameter. L* indicates brightness (0 = black → +100 = white), a* indicates redness (-60 = green → +60 = red), b* indicates yellowness (-60 = blue → +60 = yellow) and all three axis intersect at their mid points to form a sphere from which any color can be plotted (Wood et al., 2012). Data collected for L* parameter value is 87.86 which is close to 100 which corresponds to the flour’s beige color. Low a* value (0.17) and high b* value (12.82) were obtained indicating its greener and redder hue, respectively. The data is in agreement with the results of Wani et al. (2013). Urease and tripsin inhibitor are proteolyticinhibiting substances which pose a negative impact growth of farm and industrially grown animals since it counters the function of trypsin (digestive enzyme) (Mcnaughton, 1981). Table 1. Physico-chemical properties and urease activity of red kidney bean powder. Sample: Parameters Red kidney Moisture, Ash, (%) pH TSS, Color Urease bean (%) (°Brix) activity (ΔpH) L* 87.86 6.7 2.73 ± 0.12 a* 0.17 0.2 This study 12.31 ± 0.12 3.84 ± 0.28 b* 12.82 Sasanam et 12.39 ± 4.60 3.90 ± 0.12 al. (2011) L* 81.6 Wani et al. 10.40 ± 0.44 3.5 ± 0.04 a* 1.3 (2009) b* 7.9 C.J.Domingo / Journal of Food Composition and Analysis 1 (2014) 1−10 Urease exhibits the same behavior to trypsin inhibitor deactivation; thus, showing a great potential as an index of the safety of a food material (Mcnaughton, 1981). When the substrate urea is present, urease breaks it down into carbon dioxide and ammonia. Since ammonia is a basic compound, its presence raises the pH of the solution. Red kidney bean carried a urease activity of 0.2. The author had not found any relevant information on the urease activity of the said sample. Thus, concluding red kidney bean has reasonably small or absent urease activity. In array of investigations, variations in proximate composition of red kidney bean flour had been observed owing to different environments, genotype and analytical methods (Qayyum et al., 2012). Dry beans contain 1 to 3% lipid depending upon the species, origin, location, climate, season, other environmental conditions, and type of soil on which they are grown. Lipids in beans are made up of triglycerides, accompanied by smaller proportions of free fatty acids, sterols, and sterols esters, phospholipids and glycolipids (Siddig and Uebersax, 2012). Various tests were conducted in order to determine the phospholipids content of red kidney bean oil. Different spray reagents were used in which some were specific for a 6 particular functional group. Positive results can indicate the presence of a certain phospholipid. Also, the retention factor of each spot that developed for each sample was also determined. In comparing the experimental Rf values with the standard, a credible phospholipid identity for the sample in parallel with the results of some other tests can be establish. B A C U U U U U U PS PS U U LP LP PS Origin Figure 1. Thin-layer chromatography of phospholipids from red kidney bean oil viewed in various visualizing agents. (A=Ninhydrin, B=Perchloric and C=Molybdenum; PS=Phosphatidyl serine, LP=Lysophosphatidyl and U=Unknown) Table 2. The Rf values and the spray reaction of the different class of phospholipids present in red kidney bean oil. Visualizing agents Identity of Phospholipid Possible Iodine Perchloric Ninhydrin Molybdedum No. Phospholipids 1 0.04 0.06 0.04 Phosphatidyl serine 2 0.18 0.19 Lysophosphatidyl ethanol amine 3 0.46 0.46 0.47 Unknown 4 0.70 0.76 Uknown C.J.Domingo / Journal of Food Composition and Analysis 1 (2014) 1−10 Table 2 shows that phospholipid no. 1, 2 and 3 are positive to iodine test. Generally, all phospholipids present in red kidney bean oil should yield positive result in iodine. According to (Nelson and Cox, 2004), iodine reacts reversible with the double bonds in fatty acids, such that lipids containing unsaturated fatty acids develop a yellow or brown color. Molybdenum spray on the other hand is for the detection of phosphate ester containing compounds. It is therefore expected that no. 1, 2, 3 and 4 would be positive for molybdenum reaction because of the presence of the phosphate group in the hydrophilic head of phospholipids. However, phospholipid no. 1 gave a negative result for this test. This may due to the fact that though ammonium molybdate spray has long been used for the detection of phospholipids, its result is not satisfactory when thin layer silica gel plates are used and needs a longer time for development of color (Goswami and Frey 1971). Phospholipid no. 1 got a positive result for ninhydrin test, an indication of the presence of free amino group. Based on the Rf value obtained in Table 1, no. 1 is positively identified as phosphatidyl serine because it is close to the Rf value of 0.06. Meanwhile, phospholipid no. 2 with an Rf value of 0.18 and had a positive result on iodine and molybdenum tests is believed to be lysophosphatidyl ethanol amine. This compound contains a free amino group which yields a positive result (red-violet 7 shown in Fig. 1. However, the contrary was obtained which may due to the low concentration of the phospholipid present in the sample to effect a positive reaction on ninhydrin test. Lastly, phospholipid no. 3 and 4 were not identified because there were no literature Rf equivalents for both compounds. From the data presented it can be deduced that both compounds consist of free amino group because they yield a positive result in ninhydrin test. Further tests are therefore required to confirm the identity of phospholipid no. 3 and 4. The measurement of PLs is important in determining the stability and quality of vegetable oils. Phospholipids are undesirable in the oil since they are responsible for oil discoloration during deodorization and steam distillation. They affect the stability of the oil by chelating metal ions, therefore increasing oxidative processes (Arruda and Dimick, 1991). Lastly, the fatty acid profile of red kidney bean oil is presented in Table 3. According to the data of Siddig and Uebersax (2012), the major fatty acids of red kidney beans are linoleic and linolenic acids corresponding to a concentration of about 26.9% and 50.6%, respectively. This constitutes to about 85.8% total unsaturated fatty acids present in red kidney bean. Table 3. Retention time and percent concentration of fatty acids in red kidney bean oil. Standard Red kidney bean oil Identity (ME Retention Retention time, % Conc. (Siddiq % Conc. form) time, Rt (min) Rt (min) and Uebersax, 2012) (This study) Palmitic, C16 18.04 13.4 Stearic, C18 21.44 21.93 0.74 16.50 Oleic, C18:1 24.61 22.73 8.3 83.54 Linoleic, C18:2 26.9 Linolenic, C18:3 27.56 50.6 Arachidic, C20 29.26 spots) when sprayed with ninhydrin as C.J.Domingo / Journal of Food Composition and Analysis 1 (2014) 1−10 8 Other fatty acids components of red kidney bean such as stearic and palmitic acid which constitutes to about 8.3% total saturated fatty acids. Figure 2. Chromatogram of fatty acid methyl ester (FAME) standards that were used. Peaks from left to right: Hexane, Palmitic Acid ME (C16), Stearic Acid ME (C18), Oleic Acid ME (C18:1), Linolenic Acid ME (C18:3) and Arachidic Acid ME (C20). Comparison of the relative retention time of an unknown component with that of a reference compound analyzed under the same conditions and related to the same standard makes the identification of the component more feasible. The chromatogram of red kidney bean sample (Fig. 3) generated two peaks with retention times of 21.93 (peak 1) and 22.73 (peak 2) corresponding to concentrations of 16.50% and 83.54%, respectively. Comparing with the standards (Fig. 2), peak 1 was probably stearic acid while peak 2 may be oleic or linoleic acid. Retention times frequently vary slightly from one analysis to another, so in the direct comparison of the retention time of a sample component, it is important that every time a sample is analyzed, standards or reference compound should be run along with it. In the case of peak 2, recorded retention time fall between the retention times of stearic and oleic acid. Based on the literature, stearic acid is not a major fatty acid component of red bean but in this study it yields high percent concentration. This may be due to the hydrogenation of unsaturated fatty acids such as oleic, linoleic and linolenic acids which leads to conversion to a saturated fatty acid, which in this case, maybe stearic acid. IV. Summary and Conclusion Figure 3. Chromatogram of fatty acid methyl ester (FAME) component of red kidney bean oil. Peaks from left to right: Hexane, Stearic Acid ME (C18) and Oleic Acid ME (C18:1) or Linoleic Acid ME (C18:2). The physico-chemical attributes of food products are important parameters to consider because it dictates process designs and manufacture of food products. Results of this study show that red kidney bean has low moisture content (12.31 ± 0.12), little amount of ash (3.84 ± 0.28) and near to neutral pH (6.7). The approximate, expected C.J.Domingo / Journal of Food Composition and Analysis 1 (2014) 1−10 moisture content of a food can affect the choice of the method of measurement. Ash content represents the total mineral content in foods. Determining the ash content is important for it is a part of proximate analysis for nutritional evaluation. The pH value tells us that if the food product has a pH less than 4.6, processing with boiling water is enough to preserve the product while those with pH 4.6 and above needs processing under pressure. Total soluble solids (2.73 °Brix ± 0.12) and color (L* 87.86, a* 0.17 and b* 12.82) can be used to indicate quality of food products. Red kidney bean oil gave positive result for the presence of phospholipids. Results showed the presence of phosphatidyl serine, lysophosphatidyl ethanol amine and two unknown phospholipids which were not identified due to the limited reference Rf values. Gas chromatography is an indispensible tool on the determination of fatty acid content in different food samples. In this study, identification of the fatty acids was based on their retention time as compared to standards and literature percent (%) concentration values. Results indicated that the chromatogram of red kidney bean oil had shown 2 recognizable peaks and identified as stearic acid ME (C18) and oleic acid ME (C18:1) or linoleic acid ME (C18:2) corresponding to concentrations of 16.50% and 83.54%, respectively. V. Recommendations Although only possible phospholipids and fatty acids present in red kidney bean oil were reported, these claims have been based in some theoretical aspects, other studies and the experiment itself. Verification steps are needed in order to really conclude that these phospholipids identified from various 9 food samples are really the phospholipids detected. It is important to note that there are a lot of factors that needs to be considered in order to have a reliable, reproducible data after the compositional analysis, thin-layer and gas chromatography. Considerations will not just for the sample preparation, but mostly for the parameters that will be used or applied in the analytical process. VI. Bibliography AOAC.(2000).Official Method of Analysis.Vol.I and II. Association of Official Analytical Chemist. Washington, D.C. Baloch, M. S. and M. Zubair (2010). Effect of nipping on growth and yield of chickpea. J. Anim. Plant Sci. 20(3):pp.208-210. Cert, A., Moreda, W. and Perez-Camino, M.C. (2000). Chromatographic analysis of minor constituents in vegetable oils. Journal of Chromatography A, 881.pp. 131–148 Goswami, S.K. and Frey, C.F. (1971). Spray detection of phospholipids on thinlayer chromatograms. Journal of Lipid Research. pp.509-510. IUPAC.(1987) Standard Methods for the Analysis of Oils, Fats and Derivatives, International Union of Pure and Applied Chemistry, Blackwell, Oxford, 7th ed., Method 5302. IUPAC.(1987). Standard Methods for the Analysis of Oils, Fats and Derivatives, International Union of Pure and Appliedmethod 18.074. Chemistry, Blackwell, Oxford, 7th ed., Method 5301. Mcnaughton, J.L. (1981). Color, Trypsin Inhibitor and Urease Activity as it C.J.Domingo / Journal of Food Composition and Analysis 1 (2014) 1−10 affects growth of broilers. JAOCS: Vol. 1 (March). pp.321-324. Nelson, D.L. and M.M. Cox. (2004). Lehninger Principles of Biochemistry. 4th edition. W H Freeman & Co. pp. 364-365. Nielsen, S.S.(2010). Food Analysis. 4th. Springer Science Business Media, Inc., New York. Njintang, Y. N., Mbofung, C. M. F., & Waldron, K. W. (2001). In vitro protein digestibility and physicochemical properties of dry red bean (Phaseolus vulgaris) flour: effect of processing and incorporation of soybean and cowpea flour. Journal of Agricultural and Food Chemistry, 49, 2465-2471. Osorio-Diaz, P., Bello-Perez, L. A., SayagoAyerdi, S. G., Benitez-Reyes, M. D., Tovar, J., & Paredes-Lopez, O. (2003). Effect of processing and storage timen on in vitro digestibility and resistant starch content of two bean (Phaseolus vulgaris) varieties. Journal of Science of Food and Agriculture, 83, 1283-1288 Quayyum, M.M.N., Butt, M.S., Anjum, F.M. and Nawaz, H.(2012). Composition analysis of some selected legumes for protein isolates recovery. The Journal of Animal & Plant Sciences, 22(4): pp. 1156-1162 Siddiq, M. and Uebersax, M.(2012). Dry Beans and Pulses: Production, Processing and Nutrition. John Wiley & Sons. pp. 109-111. USFDA/CFSAN.(2007.Approximate pH of Foods and Food Products. Wani, I.A., Sogi, D.S.,Wani, A.A., Gill, B.S.(2013).Physico-chemical and functional properties of flours from Indian kidney bean (Phaseolus vulgaris L.) cultivars. LWT - Food Science and Technology 53.pp.278284. 10 Wood, J., Knights, E., Harden, S. and Choct, M. (2012).Milling Performance and Other Quality Traits Affected by Seed Shape in Isogenic Lines of Desi Chickpea (Cicer arietinum L.). Journal of Agricultural Science; Vol. 4, No. 10.