RETA 2012 Presentation - Long Term - Wagner

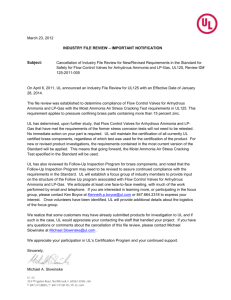

advertisement

How Things Work! RETA 2012 National Conference San Antonio, Texas Long Term Consequences of Water Contamination in Closed Loop Anhydrous Ammonia Refrigeration Systems Lawrence F. “TEX” Hildebrand PSM / RMP Engineer Wagner-Meinert, LLC 7617 Freedom Way Fort Wayne, IN 46818 Tel 260 399 2387: Email thildebrand@wmillc.com Fax 260 489 7473 Overview of the problem • In the long term. . . water, in any amount, in a closed loop ammonia refrigeration system can have very negative and serious consequences. The white paper “Long-Term Consequences of Water Contamination in Closed Loop Anhydrous Ammonia Refrigeration Systems” and this presentation address the negative effects in detail. Overview of the problem –cont’d • Water in a closed loop ammonia refrigeration system is a problem that oftentimes operators and plant owners are unaware of; that can result in extremely high penalties to be paid both in the immediate expense of operating their refrigeration systems in a contaminated condition and in the long-term deterioration of the refrigeration system itself. WHAT IS ANYHDROUS AMMONIA? • Closed loop vapor compression ammonia refrigeration systems are designed to utilize Anhydrous Ammonia (NH3) as the refrigerant. Anhydrous is an adjective which is used to describe a substance or compound that contains no water! All design criteria, manufacturer’s equipment rating data, service information etc. published on this subject by equipment manufacturers is based on this fact. WHAT IS ANYHDROUS AMMONIA? –cont’d • When water is added to, or is allowed to mix with, the ammonia refrigerant, the composition of the substance changes and it is no longer Anhydrous Ammonia (NH3), but changes to Ammonium Hydroxide (NH4+OH-) and this new substance is most often referred to as aqueous ammonia. Proper Specification • The proper specification for Anhydrous Ammonia for closed loop ammonia refrigeration systems contains at least 99.995 percent ammonia, allowing only 33PPM maximum water, and a maximum of 2 PPM oil as impurities. This does not include any appreciable room for air or oxygen as a contaminant. Allowable Water Content •After all relevant sources, scenarios, and consequences have been considered, the ONLY correct choice, the one that is recommended by IIAR, and which is in agreement with the OSHA specification, for closed loop ammonia refrigeration systems is “P” Premium grade (AKA “REFRIGERATION” grade) anhydrous ammonia. http://www.osha.gov/SLTC/etools/ammonia_refrigeration/am monia/ Best Possible Heat Transfer • The cleanliness of the refrigerant is the key to getting the best heat transfer coefficient, least operating cost, most effective use of installed suction capacity of compressors, and longest mean time to failure for the operation of the industrial ammonia-based refrigeration systems. Detriments of Water •Water in a closed loop ammonia refrigeration system is enemy number 1 to the proper operation of the refrigeration system. Its presence in the refrigeration system precipitates the degrading of performance, capacity, cost of operation, and mean time to failure of the associated equipment. Likelihood of Water in Your System •Water contamination in ammonia refrigeration systems is quite common, but mostly unrecognized. *A recent survey of ammonia refrigerant plants was made in Denmark, Norway, and Sweden. This survey covered some 136 individual refrigeration plants. The results clearly indicated that water contamination of 2% to 6% was quite common. Less common, plants showed water contamination levels of 10%, 18%, 24% and 26%. *Per Skaerbek Nielsen , Mech. Engineer Danfoss, “Effects of Water Contamination in Ammonia Refrigeration Systems” Copyright Danfoss A/S, Denmark– November , 2000. Likelihood of Water in Your System Until water boil test procedures are implemented and regularly carried out as a part of regular maintenance inspection procedures for Anhydrous Ammonia Refrigeration Systems, the general assumption will remain that water is not a problem. Yet, as the referenced article clearly spells out, the overwhelming majority of plants surveyed proved to have significant amounts of water. Unrecognized Danger • Water contamination in ammonia refrigeration systems is much more common than most owners / operators realize and the ignorance of these facts does not keep the damage from occurring in your specific plant. The damage caused by its presence takes time to show directly, because it takes time to ravish a refrigeration system with the tragic reality. It is mostly not recognized in the early stages when mitigation would be much less costly than repair and replacement after the damage has occurred. Why be concerned with water contamination in the ammonia refrigerant? • Loss of refrigeration capacity requiring the lowering of suction pressures to meet load conditions. • Increase in horsepower to operate the system at required temperatures. • Increase in compressor suction volume due to handling higher cubic feet per pound at for same evaporating temperature. • Increased energy consumption for same evaporating temperature. • Increased mass flow rate to evaporators required due to volume occupied by water in mixture. • Increase in discharge temperature of the compressors. General causes & effects as it concerns the refrigeration system & components. • Emulsification of tramp oil throughout the refrigeration system. • Increase in component failure due to acids. • Erosion of any component that is throttling liquid. • Increase in maintenance required; i.e. clogging strainers, regulators sticking, etc. • Color of the oil drained from the oil pots. • Sight glasses that you can’t see through because they are coated with scum on the inside. • Deterioration of compressor oil. • Malfunctioning of thermal expansion valves. Increased maintenance budget and unexpected (unplanned) expenses that have to be met. • Cost of increased energy consumption. • Cost of increased use of repair parts and consumables. • Cost of increased to stock additional repair parts necessary to cover emergency shut down situations. • Cost of increased (unplanned) maintenance man hours spent. • Need to re-adjust work schedule; vacations, time off, etc. • Cost of increased down time of critical operational processes, including re-scheduling production or needing to schedule overtime to make up for lack of normal production capacity. Keeping Anhydrous Ammonia Pure! • The best way to escape the necessity of dealing with the entire composite list of the budgetary issues discussed in the previous section is to KEEP YOUR AMMONIA REFRIGERANT ANHYDROUS. In plain English “Keep the water out!” If, after the boil out tests previously recommended are carried out, the evidence shows a higher than acceptable level of water, set in motion a constructive plan of action to remove the contamination from your refrigeration system and restore it to the health and performance of Anhydrous (Refrigeration) grade ammonia. Keeping Anhydrous Ammonia Pure! • If the refrigeration system is not already so equipped, it is strongly suggested that a liquid filtration system should be installed in the liquid line outlet of the high pressure receiver (HPR), or controlled pressure receiver (CPR) that will remove any solids in the liquid stream at a particle size of 0.5 micron or larger. Keeping Anhydrous Ammonia Pure! • When making a selection of a liquid filtration system it is necessary to carefully investigate to ensure that all the components of this filtration system are totally compatible with the ammonia refrigeration system. Note: Only particulate matter can be removed. Keeping Anhydrous Ammonia Pure! • There is not, at present, any absorbent or adsorbent type filter cartridge that will remove water from the ammonia. Be very careful NOT to install halocarbon type cartridges in “an ammonia refrigeration system”. Keeping Anhydrous Ammonia Pure! • The bonding cement used in the manufacture of this type of cartridge will immediately be destroyed by the liquid ammonia and the result would be brown or black particulate matter from such a cartridge scattered throughout the ammonia system. Keeping Anhydrous Ammonia Pure! • Be fore-warned; the clean up after such an event will be costly and quite time consuming, even requiring possible plant shutdowns to accomplish. How can water be removed from the Ammonia Refrigeration System? • When water or water vapor enters, by whatever means, into the pressure envelope of the closed loop anhydrous ammonia refrigeration system it immediately combines with the anhydrous ammonia to form an aqua ammonia mixture, aka ammonium hydroxide (HN4+OH-). How can water be removed from the Ammonia Refrigeration System? • Once this mixture is formed, the water component can only be removed through a process of distillation. How can water be removed from the Ammonia Refrigeration System? • That is to say, the mixture must be caused to boil at a low enough temperature so that the ammonia component will leave the boiling pool as essentially pure ammonia vapor and the remainder will be a highly concentrated mixture of water with a low percent of ammonia still in the mixture. How can water be removed from the Ammonia Refrigeration System? • Be advised, however, time is of the essence to stop the ancillary damage that will be caused by the by-products of this contamination. The sludge, acids, particulate matter, etc. all are multiplied and compounded by the amount of time in which the contamination continues. How can water be removed from the Ammonia Refrigeration System? • Once these contamination processes have started, even taking all of the water out may not completely stop the degradation of the refrigeration system completely without further remediation requirements. How can water be removed from the Ammonia Refrigeration System? • On severely contaminated systems that have been allowed to remain in that condition for a long period of time it may be necessary to use a flushing solution mixed into the ammonia liquid to slowly restore the internal cleanliness of the refrigeration system. How can water be removed from the Ammonia Refrigeration System? I. A number of commercial distilling packages are available. Any one of these; dehydrator, anhydrator, or whatever else the package may be named, will produce a stream of essentially pure ammonia vapor plus a separate stream of mixture of water with approximately 28% ammonia still in the mixture. How can water be removed from the Ammonia Refrigeration System? II. The Dump and replace the charge method. Oftentimes, when it is first discovered that there is a significant amount of water contamination in the refrigeration system, the concept that simply replacing the charge of ammonia will solve the problem appears to be the easiest way to remediate the problem. How can water be removed from the Ammonia Refrigeration System? II. The Dump and replace the charge method. This may be a viable solution, but oftentimes when this approach is carried out, the water contamination levels previously measured quickly seem to return to levels close to the contamination recorded prior to undertaking the clean up procedure. How can water be removed from the Ammonia Refrigeration System? II. The Dump and replace the charge method. The problem is that most piping systems, as installed, have many low spots without adequate provision for gravity draining the contaminated mixture from the system completely. How can water be removed from the Ammonia Refrigeration System? II. The Dump and replace the charge method. Thus, the evacuation procedure must be relied on to boil out the remaining contaminated ammonia and water. How can water be removed from the Ammonia Refrigeration System? II. The Dump and replace the charge method. Unless sufficient time, utilizing a vacuum pump of correct cfm capacity with the capability of deep vacuum suction capacity is employed, coupled with a heated nitrogen gas sweep to thoroughly cleanse the entire system, this method will turn out to be less than expected in successfulness. How can water be removed from the Ammonia Refrigeration System? II. The Dump and replace the charge method. In a short time frame, the hidden water will show up in its usual haunts and the system remains contaminated. How can water be removed from the Ammonia Refrigeration System? II. The Dump and replace the charge method. This may be a practical solution if the water contamination is confined to only a local area of the ammonia refrigeration plant (i.e. to clean up after rupture of a secondary fluid heat exchanger after a repair has been made). How can water be removed from the Ammonia Refrigeration System? II. The Dump and replace the charge method. Dumping and re-charging the high side vessel(s) should only be considered if there was a recent leak causing significant contamination levels of water contamination in the high side. Options for applying a distillation process I. Hire an outside service contractor to do a complete plant clean up in a relatively short period of time. II. Rent and install temporarily a large system to clean up the entire system in a relatively short period of time, then consider a permanent solution. III. Purchase, and install permanently, a traditional Still or Remediator to remove water from the refrigeration system. Options for applying a distillation process IV. Purchase, and install permanently, a small automatic Still that provides for continuous, safe, and automatic water & oil removal. Careful consideration should be given to this system as perhaps the most synergistic approach to the good health of your ammonia refrigeration plant. Consider this as a preventative measure, similar to an auto purger to prevent major contamination from occurring in the first place. Effect of water contamination in Ammonia Refrigeration System • The following 2 slides show graphs indicating the degradation of suction volume and increase in energy required to operate the refrigeration system when water contamination is present in the refrigerant. • For more detailed breakdown of effects see Case Study, chapter 13 of the Paper. Photos of damage to components on water contaminated systems The photos in the following slides are from a number of contaminated systems which necessitated clean up methods. PHILLIPS 701 Pilot Valve Parts (1) New Parts Damaged Parts 44 PHILLIPS 701 Pilot Valve Parts (1) 45 PHILLIPS 701 Pilot Valve Parts (2) 46 Strainer basket New for comparison Old From -40 Deg. F. Liquid Makeup from Controlled Pressure Receiver 47 Strainer basket 48 Strainer basket 49 Liquid Line Shut-off Valve 50 TXV Cage Assembly New Used (1) 51 Damaged TXV Cage Assembly Used (1) Used (1) 52 Damaged Phillips Pilot Float Valve Cartridge Used 53 Damage on In-Line Check Valve Parts 54 Preventative Maintenance Ensure that an ammonia still is installed and is functioning properly. Utilize System Opening Policy (Line Breaking Permit Procedure). Perform periodic inspections for negative pressure leaks (shaft seals, valve stems, etc.) 55 Preventative Maintenance (Cont’d). In plants where CO2 is used in the process, special care should be placed on proper ventilation systems to preclude the CO2 concentration from entering the Refrigeration System, through possible vacuum leaks or during service/maintenance operations. 56 Preventative Maintenance (Cont’d). Regular oil samples from all compressors should be analyzed for water, particle count, wear debris, Total Acid Number (TAN), and properties of the lubricant, i.e. viscosity, additive depletion, etc. Trend charts for monitoring change are useful. 57 Preventative Maintenance (Cont’d). Oil sample from new oil (to establish baseline) should be included with compressor oil samples. Periodic samples from oil in oil pots should be sent to lab for analysis to determine Total Acid Number (TAN), water content, and particle count. 58 Wrap up Any questions? Wrap up Thank you all for attending!