Weekly Presentation - the Student Web Server!

advertisement

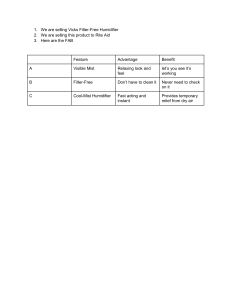

Indoor Growing Environment (IGE) Adam Wolfe (CSC) Levie Kirkland (CET) Brandon Lewis (CET) Schedule – Where are we? Start Date Duration Preparation of I.G.E. 1/27/2014 7 Program Lights 2/3/2014 7 Program Timer 2/10/2014 7 Test Sensors/Report to MCU 2/17/2014 7 Test Components from MCU 2/24/2014 7 Program The Application 2/26/2014 12 Report LCD Screen Info from Sensors 3/3/2014 14 Report Web Page/Wireless from Sensors 3/17/2014 9 Obtain/Program Optimal Settings for Food Producing Plants 3/26/2014 12 Test Application 4/7/2014 7 Test System 4/14/2014 7 Wrap Up 4/21/2014 4 Current Progress: “Program Lights” (2/3/14 – 2/10/14) We used test components and actual components We used code to turn the lights on and off We were able to obtain readings from the sensor and use those values to turn on/off the fan (thermostat) This is essential to our project because it forms the basis of our environmental control system, using inputs from sensors to affect some appropriate output. We can now use this code to activate a bigger relay to control all of our electric powered components Current Tasks: “Program Timer” (2/10/14 – 2/17/14) Much of our system depends on timed events Lights need to be turned on and off at specified times Nutrient solution needs pumped into the growing area at specified times Real time data needs to be reported to the system for display on the LCD screen and website Arduino Uno doesn’t have a traditional “clock” for us to use Real Time Clock We acquired a RTC chip to be used in conjunction with the MCU This will allow us to control the environment for whatever period of time needed SainSmart Tiny Real Time Clock Module for Arduino IGE System Container We selected a vertical tool shed to contain our system Assembled size: 31 by 23 by 72 inches (width by depth by height) Capacity: 27 by 19 by 68 inches (width by depth by height) These dimensions make this shed the perfect size for our components Buying a container frees up time to work on system development The design of the container will also help conceal any wires and electronic components better than a wood container/cabinet Vertical Tool Shed Heating the System Heat for our growing system will be generated by an aquarium heater inside of the nutrient reservoir This warmed solution will be pumped into the grow table, thus heating the entire growing area Humidifying the System We decided to use a “cool mist” humidifier to add humidity to our system as needed We originally planned to use a pump and sprayer Research showed that method to be complicated and ineffective We are going to use a cool mist humidifier because it is effective at humidifying a small area We will control the humidifier with the MCU and relay and turn on for a set amount of time as needed Ultrasonic Humidifier - Cool Mist Looking Forward Once the timer is operating, we will move on to the next step – Test Sensors/Report to MCU Some is already completed, must concentrate on the reporting data to memory which is necessary for LCD screen and website Continue building the actual physical system – last of the components ordered