Reliability Failure Analysis Request Form

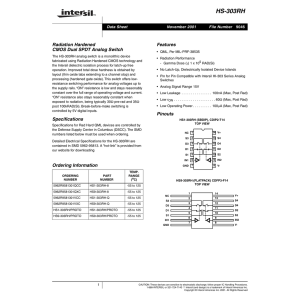

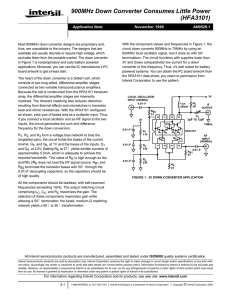

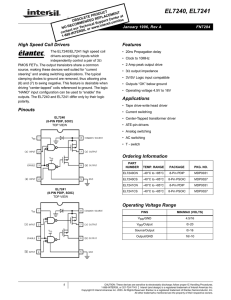

advertisement

Reliability Failure Analysis Request Form The FAR (Failure Analysis Request) is designed to verify a product problem and determine corrective action through the evaluation of a small quantity. The process begins with the customer contacting the Area Sales Office or the Customer Return Services (CRS) group at (321)724-7400 or creturn@intersil.com. The customer will be requested to fill out the FAR form completely in order for the factory to understand the problem experienced by the customer and aide the analysts in their efforts to determine the root cause of the failure and corrective action. The CRS group will then assign a tracking number and give instructions as to where to ship the parts along with the completed FAR form. Failure Analysis Request (FAR) FAR Requestor Customer FAR#: Distributor Intersil Sales or Sales Representative will be the main contact person for the FAR. Requestor Name: Customer Name: Distributor Name: Contact Name: Contact Name: (First & Last Name) (First & Last Name) (First & Last Name) Street Address: City: State: Country: Postal (Zip): Phone# Email: Street Address: City: State: Country: Postal (Zip): Phone#: Email: Street Address: City: State: Country: Postal (Zip): Phone#: Email: Customer Type: Customer Location: Customer Project Name & Application: End Customer Name: Region: Intersil Part Number: Customer Reference#: Field Apps Engineer (FAE) email: Type of Issue: Issue Detected at: Approximate Hours of Operations Before Failure: Test Temperature in Celsius : Lot Quantity: Quantity Tested: Quantity Failed: Quantity Returned for Analysis: Trace Code: 1=Standard 2=TS16949 (Signed Automotive TS16949 Agreement Only). Division if multiple locations are located in the same city, else city name. Project name assigned by customer and Application Type (Example: L33 / Laptop Computer) End user/Customer name 1=China 4=Korea 7=Taiwan 2=Europe 5=North America 3=Japan 6=SE Asia Full Part number as on Sales Order SCAR#, Reference#, Etc. FAE Email address 1=Administrative (wrong parts, wrong qty, labels, packing, shipping damage, etc.). Supply photos & details on separate attachment. 2=Electrical (Parametric or functional failure) 3=Visual/Mechanical (Bent leads, solderability, chipouts, visual defects, etc). Supply photos & details on separate attachment. 1=Incoming ICT (Unit level test at contractor/customer location) 2=Board (Fails on a board at contractor or customer location) 3=System (Fails in system beyond the board at contractor or customer location. Also, used for 0KM automotive failure.) 4=Field Failure (End user in field or application actual use) 1=0 hrs (failed during power up) 2= >0 to 48 hours (worked initially then failed). * 3= >48 hours (latent issue)* *(Actual time can be placed in Problem Description Section) 25C is room temp. otherwise specify temperature Estimation of Lot, Batch, Project, etc. rates at the time the unit was identified. Used to estimate failure rates of the issue reported. Used to estimate failure rates Used to estimate failure rates Qty should be <10 Trace Code branded on the units for lot traceability FAR Form Rev 7 Device/System History: 1=Production Ramp-up 2=Production normally running without incident 3=Production running/chronic issues. 4=Experiment/Stress testing 5=Product/Application Changed 6=New Development Application RMA Pending: (Yes or No) & Quantity Problem Description-Detailed description of the failure to include pins, voltages, measurements obtained versus expected: Is this a known or repeat Issue (Yes/No) Failures Verified (Yes/No) Y/N: Qty: Lot size on hold that could require a RMA. Determines if this is an issue previously seen or identified on a previous analysis for this customer. Identifies if failures were returned with or without verification to isolate the failure. ABA verification consists of removing a suspect device from the failing product and placing it on a known good product, along with placing a known good device on the failing product. If not performed on all units, then highlight in Verification Procedure. ABA Performed (yes or No) Describe Failure Verification Procedures Used: Schematics, test conditions, waveforms, measurements etc. attached (Yes or No) Details of the customer application and test conditions are needed to evaluate beyond ATE production test. Customer to provide as much details as possible (i.e. schematics, test conditions, waveforms, measurements, photos, etc.) to aid in the evaluation. Special Requirements for HS Video (TWxxxx) products: Please describe the failure feature in detail and list all processing that occurred prior to the failure. Attach any pictures or videos to show the symptom if possible (Use additional sheets as needed): Setup Conditions: (Circle or check all that apply) Register values: Default Input source: Composite___ Describe test pattern: Video Format: Yes___ If No; please provide customer's register setting as separate file. S-Video___ Title NTSC___ No___ PIP Component___ OSD PAL___ Scene Digital RGB___ Digital YUV___ Other: Describe ________________ SECAM___ Analog RGB Resolution ___________ Sync Type: Digital RGB Resolution ___________ Format: DSS___ 601___ ACS___ 656___ DCS___ 16 bit___ 18 bit___ 24bit___ Other ______ Please check all multiple inputs and provide detailed timing if the input signal is non-standard format Output panel resolution ____________ Ambient operation temp: Room____ Panel type: TTL___ LVDS___ TCONLESS___ Temp (specify) _________________ What is supply voltage if not nominal supply voltages per data sheet? ___________________ Application is a: Car Navigation System___ Backup display___ AV / DVR / Monitor___ Other _____________ Additional information: FAR Form Rev 7