Ch. 5: Factory Location as a Cost

Ch. 5: Factory Location as a Cost-

Minimizing Exercise

Transportation, cost minimization and location

Aly Konkol, Carine Lefevre

Neoclassical Location Theory

Form of economic determinism in which location of factories is ‘dictated’ by economic forces

Interprets firm as an Economic Man ( Homo

Economicus ) with perfect information and rationality

Competition ensures than only economically rational outcomes survive

Follows tradition begun by Alfred Weber in 1929

Two schools of neoclassical location theory

Profit-maximizing

Focus more on distribution costs

Incorporate effects of rival behavior on

location

Applied mainly to personal and retail services

Cost-minimizing

Focus more on transportation costs of inputs

Incorporate effects of location conditions on spatial variations in cost structures

Applied mainly to manufacturing

Types of inputs in costminimization theory

Ubiquitous: can be obtained in any location

Pure: experience no change in physical characteristics during processing

Impure: experience change in physical characteristics during processing

Material Index (MI) for impure materials

•

•

MI = weight of localized raw materials weight of final product

If MI>1, then activity is input-oriented

If MI<1, then activity is output-oriented

Isodapane Analysis

1.

2.

Used when an activity has more than one impure input from different sources

Calculate isotims (lines of equal transportation cost around each location factor)

Sum relevant isotims to identify least total transportation cost location (P)

Labour, external economies, etc.

Similar cost surfaces such as labor and external economies of scale can be combined with transportation cost surfaces to form a total cost surface

If L or E is inside the critical isodapane (where savings equal increased transportation cost), factory should relocate there

Spatial Margins to Profitability

As long as revenues exceed costs, plant locations are viable

Viable locations defined by spatial margins to profitability

Graphically summarized by a space-cost transect derived from a cost surface

Allows personal location preferences to be taken into account

Principle of Substitution

Location of factories uses substitutions or trade-offs among various factors

Ex. Procurement and distribution costs

For a factory of a given size, can also substitute among factors of production (land, labor, capital)

Graphing Substitution

Isoquant (line of equal output or scale) shows different combinations of two inputs, X and Y

Isocost lines show the relative costs of X and Y based on their slopes

When isoquant and isocost lines are combined, point on isoquant where costs are lowest determines ideal input combination

Endless variety of substitutions

Christaller’s Central Place Theory

Range of a good: maximum distance consumers will travel to purchase good, or maximum distance good can be transported to consumers economically

According to law of demand, demand will decrease with increased distance from factory

Threshold population: minimum level of demand necessary to sustain factories of at least minimum economically viable size

Inner range of a good: distance within which threshold population exists

More Central Place Theory

Additional factories are possible until all demands are met and surplus profits are eliminated

Ensures that threshold population exists within inner range of good

Assumes demand is evenly distributed and rival factories produce identical goods

Even More Central Place Theory!

Predicts an optimal location pattern for minimizing distribution costs

Factories serve hexagonalshaped market areas

Ensures all possible demands are met in spatially distributed market

Notes on C.P.T.

If factories produce different goods with distinctive thresholds and ranges, most accessible locations will attract factories whose goods have largest threshold/range requirements, as well as lowest

Less accessible locations attract only lowest

Hotelling’s Duopoly Model

Uncertainty over rival behavior may encourage concentration

Two sellers supplying a homogeneous product to a spatially distributed, linear market would locate at the center of the market

Any other location would be unstable because of uncertainty

Distribution costs would be minimized if sellers communicated and located at quartiles

Adopt-Adapt Dichotomy

Firms must “adapt” to changes in markets, resources, technology, or competition, or else they fail

Firms can also be “adopted”, or saved, by the actions of others (eg. government)

Adoption chances are much better for larger companies than smaller, and can be unintended through unexpected currency devaluations, etc.

Location Adjustment Possibilites

Adjustments to changes in economic environment can be in space , organization , or time dimension

Space : adjust operations onsite, change them between sites, develop new sites

Organization : small firms can respond faster, multi-plant firms have more decision-making capabilities

Location Adjustment Possibilities,

Related to Time

Short-term: small firms can use plant more intensively or use more labor, large firms can shift orders among plants

Medium-term: limited for small firm, large firms can do some expansion/consolidation

Long-term: new site locations, M&As

Locational Evolution

Old factories in “obsolete” locations may still be viable because they have paid off investments in fixed capital, which is cheaper than building a new factory

In general: many small firms and plants --> fewer, more dispersed,and larger plants

Product innovation --> process innovation

Industrial Location Policies

Advocated government policies include increasing worker and capital mobility

Regional equilibrium is achieved between core and peripheral regions when demand drives labor prices up in core regions, so firms relocate to peripheral regions for cheaper labor

Eventually, wage rates rise in peripheral regions too, but movement of workers to core region decreases wage pressure

More Industrial Location Policies

In the 1950s and 1960s, subsidies were granted to locate factories on social and political rather than economic grounds

This promoted inefficiency and an unneccesary duplication of facilities

Market solutions were not seen as relevant

During the 1980s and 1990s, many countries reduced or eliminated industrial location policy

Cost Structures and Locational

Orientation

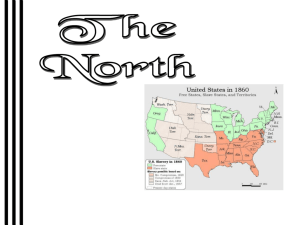

Locational patterns of industries vary because of different cost and revenue structures

Cost structure calculations are based on actual production costs or hypothetical costs of production for brand new state-of-the-art mills

Primary manufacturing: material and transportation costs remain important

Secondary manufacturing: labor inputs are relatively more important

Primary Manufacturing: ex.

Sawmills

Input-oriented, principal raw material is timber

Compare PNW and US South regions with hypothetical mills as of mid-1980s

Wood costs are relatively lower in South, but energy costs are relatively lower in PNW

(overall cheaper in South)

Scale economies have been pushing down average costs of production

Secondary Manufacturing: ex. Auto

Industry

Traditionally has been located in industrialized countries to take advantage of skilled labor and scientific/engineering expertise (external economies)

Seek lower-cost labor in Mexico and Brazil,

South Korea, and Spain

Although Japanese wage rates are average,

Japan has a cost advantage through

“management systems and techniques”

(organization), which increase productivity

Conclusion

Neoclassical location theory emphasizes the

“relentless and rational pursuit of lower costs and more profits”

Criticism (Barnes 1987): denies or simplifies roles for local agency and local and political context, so demeaning the richness of economic geography

Regions are only spaces where capital may or may not be deposited