Tribal Case Study: Modeling

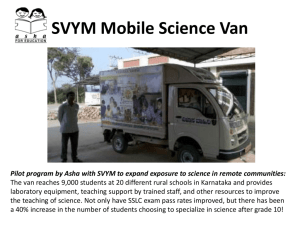

advertisement

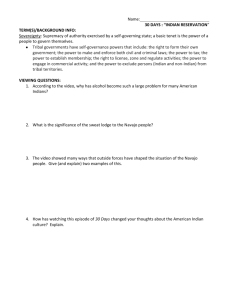

Tribal Case Study: Modeling Les Benedict St. Regis Mohawk Tribe Tribal Case Study: Modeling 2 Tribal Case Study: Modeling 3 Tribal Case Study: Modeling Pulp and paper SO2 Mercury Mercaptan 4 Tribal Case Study: Modeling Aluminum Fluoride POM PCBs 5 Tribal Case Study: Modeling Automotive Styrene PCBs 6 Tribal Case Study: Modeling Assess impacts to tribal airshed Research existing information NYS 7 Tribal Case Study: Modeling Emissions inventory Characterize impacts Quantitative Categorize 8 Tribal Case Study: Modeling Emission Inventory Use of emission Factors Per-capita calculations Models 9 Tribal Case Study: Modeling Model: definition Analogy Help visualize Emulate System of data, inference Mathematical description 10 Tribal Case Study: Modeling Model Estimate source receptor relationships Patterns of concentrations of air pollutants 11 Tribal Case Study: Modeling Models predict Emission rates Concentrations Fugitive releases Points of impact 12 Tribal Case Study: Modeling Patterns Regional – Ozone, haze Local – Urban air shed Global – global warming 13 Tribal Case Study: Modeling Models: characteristics Simple – SCREEN3 Complex – ISC3 14 Tribal Case Study: Modeling Models Conservative Overestimate impacts Important for “risk” scenarios 15 Tribal Case Study: Modeling Emissions inventory tools AP42 Volume 1 EPA emission factors for stationary sources AP42 Volume 2 EPA emission factors for mobile sources 16 Tribal Case Study: Modeling Emissions inventory tools (cont.) Emission Inventory Improvement Program (EIIP) guidance documents Spell out the Process for EIs Factor Information Retrieval (FIRE) Database of factors for HAPs 17 Tribal Case Study: Modeling Emissions inventory tools (cont.) Locating and Estimating Documents Clearinghouse for Inventory and Emission Factors (CHIEF) MODELS 18 Tribal Case Study: Modeling SRMT EI TANKS3 Mobile 5a and 5b 19 Tribal Case Study: Modeling TANKS 3 Petroleum Bulk Storage (PBS) tanks Computer-based DOS system 20 Tribal Case Study: Modeling TANKS3 Calculates VOC and ozone emissions Stage I filling Operational losses 21 Tribal Case Study: Modeling TANKS3 DOS system Developed in FOXPRO Easier to use Menu driven 22 Tribal Case Study: Modeling Mobile 5a & 5b Criteria pollutants from MV VOCs from Stage II Evaporative losses 23 Tribal Case Study: Modeling Mobile 5a & 5b DOS system FORTRAN No GUI Not as easy to use 24 Tribal Case Study: Modeling Computer Aided Management of Emergency Operations (CAMEO) Areal Locations of Hazardous Atmospheres (ALOHA) Mapping Applications for Response, Planning, and Local Operational Tasks (MARPLOT) 25 Tribal Case Study: Modeling CAMEO Chemical search engine Linked to chemical-specific information firefighting techniques, cleanup procedures, and protective clothing Basic information on Tier II facilities that store chemicals Emergency planning resources 26 Tribal Case Study: Modeling ALOHA atmospheric dispersion model used for evaluating releases of hazardous chemical vapors 27 Tribal Case Study: Modeling MARPLOT allows users to "see" their data (e.g., roads, facilities, schools, response assets) Display this information on computer maps Overlay areas contaminated by potential or actual chemical release Maps created from the U.S. Bureau of Census TIGER/Line files 28 Tribal Case Study: Modeling CAUTION Before installing software Check with LAN administrator or your Techie Review operating system requirements 29 Tribal Case Study: Modeling Before you start README files Manuals Instructions First things first! 30 Tribal Case Study: Modeling DOS-based systems E.g. FORTRAN Require INPUT files Data entry very specific in format and placement Uses abbreviations Truncation 31 Tribal Case Study: Modeling Using models Plan for their use Provide adequate time Work plans Budgeting It takes weeks to months to Learn Collect data 32 Tribal Case Study: Modeling Using models Seek expert help EPA modelers/developers State modelers/developers Other users 33 Tribal Case Study: Modeling Using models Understand limitations Understand intended uses Screening level Risk exposure 34 Tribal Case Study: Modeling TANKS 35 Tribal Case Study: Modeling TANKS Version 3.1 was used Storage Tank Emissions Calculations Earlier versions 1.0, 2.0, 3.1 designed strictly for DOS environment Written with FOXPRO 36 Tribal Case Study: Modeling TANKS Version 4 is latest version TANKS4 designed for Windows Win 95, 98 or NT Written using Visual Basic Do not install on a LAN 37 Tribal Case Study: Modeling TANKS Storage tank Estimates Volatile organic compounds (VOCs) HAPS Does not predict values for any receptor point 38 Tribal Case Study: Modeling TANKS Chemical data Meteorological data Storage Tank Information 39 Tribal Case Study: Modeling TANKS Vertical or horizontal fixed roof (a) Typical fixed-roof tank. 40 Tribal Case Study: Modeling TANKS Internal or external floating roof tanks 41 Tribal Case Study: Modeling TANKS Domed External floating roof tanks (d) Domed external floating roof tank. 42 Tribal Case Study: Modeling TANKS Underground tanks 43 Tribal Case Study: Modeling TANKS Data is entered through a series of menus Storage tank info Stored liquid info 44 Tribal Case Study: Modeling TANKS Batch mode operation Single file mode Database for over 100 organic liquids Database for over 240 cities More liquids and cities can be added 45 Tribal Case Study: Modeling TANKS Steps Read documentation Installed program Worked with sample data Become familiar with the program Learned data requirements 46 Tribal Case Study: Modeling TANKS No “special” features Standard key-board entry Some F1-F12 functions to learn 47 48 Tribal Case Study: Modeling TANKS Overview Provides information about the program Describes general features 49 Tribal Case Study: Modeling TANKS 4 Key Elements needed to generate emissions information Tank information Fitting information Site information Liquid information 50 Tribal Case Study: Modeling TANKS Tank information Type ID number A description State Company 51 Tribal Case Study: Modeling TANKS Tank information Dimensions Length, width, diameter, radius, slope, etc. Annual throughputs (gallons/year) Turnovers/year - # times emptied/filled 52 Tribal Case Study: Modeling TANKS Tank information Paint color Breather vent settings Liquid heights Working volumes Whether tanks is heated or not 53 Tribal Case Study: Modeling TANKS Tank information Condition of tank shell Roof condition and type Vacuum settings in pounds per square inch gauge (PSIG) Pressure settings (relief valves) 54 Tribal Case Study: Modeling TANKS Default settings Others you will need to research and obtain There is a lot of work to do before running the program 55 Tribal Case Study: Modeling TANKS Data must be Accurate Valid Documented 56 Tribal Case Study: Modeling Bob’s Electric &. Maintenance Gasoline Alley -P.O. Box 196 Hogansburg, New York 13655 Petroleum Marketing Equipment Sales -Installation -Service ST. REGIS MOHAWK TRIBE ENVIRONMENT DIVISION ATTENTION: Les Benedict 8/29/98 OPW MODEL 523-1100 UNIVERSAL MODEL 46--2080 ENTERPRISE BRASS WORKS MODEL 802303 PRESSURE 8 OZ/PSJ PRESSURE 8 OZ/PSJ PRESSURE 8 OZ/PSI VACUUM 1/2 OZ/PSI VACUUM 1/2 OZ/PSI VACUUM 5 OZ/PSI 57 58 Tribal Case Study: Modeling TANKS Information is critical Tank supplier Owner operator Installer Inspection 59 Tribal Case Study: Modeling TANKS Information affects results of the model Tank color Pressure settings Heat adsorption Release of vapors Design Surface area affected by heat 60 Tribal Case Study: Modeling TANKS Information affects results of model Turnover Throughput Vapor displacement 61 Tribal Case Study: Modeling TANKS Information affects results of model Fitting information Seal around floating roof tanks Relates to vapor loss along edge 62 Tribal Case Study: Modeling TANKS Site Information Daily average temperature degrees F Annual maximum temperature degrees F Annual minimum temperature degrees F 63 Tribal Case Study: Modeling TANKS Site information Average wind speed, mph Annual average solar insolation factor, Btu/ft*ft*day 64 65 Tribal Case Study: Modeling TANKS Site information From TANKS database Use nearest city Or, obtain information from National Climatic Data Center (NCDC) EPA Technology Transfer Network website 66 67 68 Tribal Case Study: Modeling TANKS Liquid Information 69 70 71 72 Tribal Case Study: Modeling TANKS Liquid information From database From other sources NIOSH Guide CAMEO CAS 73 Tribal Case Study: Modeling TANKS Liquid information The selection is assisted by Chemical Abstract Service (CAS) number Chemical name Look out for synonyms 74 Tribal Case Study: Modeling TANKS Report Generation Storage Loss Working Loss Withdrawal loss Rim seal loss Fitting loss Deck Seam loss 75 Tribal Case Study: Modeling TANKS Report Generation Brief Summary Detailed 76 Tribal Case Study: Modeling TANKS Report Generation Printed Exported Excel Lotus 77 ÉÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ ÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ» º TANKS Program 3.1 11/17/98 º º Emissions Report - Summary Format PAGE 1 º º Tank Identification and Physical Characteristics º ÈÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ ÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍͼ Identification Identification No.: 17 City: Hogansburg State: NY Company: Rez Gaz Type of Tank: Horizontal Fixed Roof Description: Borderline Tank 1 78 Tribal Case Study: Modeling Tank Dimensions Shell Length (ft): 21.3 Diameter (ft): 8.0 Volume(gallons): 8000 Is tank underground? (Y/N): N Turnovers: 24.0 Net Throughput (gal/yr): 192000 Paint Characteristics Shell Color/Shade: Shell Condition: White/White Good 79 Tribal Case Study: Modeling Breather Vent Settings Vacuum Setting (psig): Pressure Setting (psig): -0.50 0.50 Meteorological Data Used in Emission Calculations: Burlington, Vermont (Avg Atmospheric Pressure = 14.7 psia) 80 Tribal Case Study: Modeling ÉÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ ÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ » º TANKS Program 3.1 11/17/98 º º Emissions Report - Summary Format PAGE 2 º º Liquid Contents of Storage Tank º ÈÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ ÍÍÍÍÍÍÍÍÍÍÍÍ 81 Tribal Case Study: Modeling Liquid Bulk Daily Liquid Vapor Liquid Temperatures Mol. Mass Surf. Vapor (deg F) Mass Temp. Vapor Pressures (psia) Mol. Basis for Vapor Pressure Mixture/Component Month Avg. Min. Max. (deg F) Avg. Min. Max. Weight Fract. Fract. Weight Calculations -------------------------------------------------------------------------------------------------------------------------------------------------------------------Gasoline (RVP 10) All 45.48 40.85 44.12 3.8815 3.5266 4.2648 66.000 92.00 Option 4: RVP=10.00, ASTM Slope=3.0 50.11 ÉÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ 82 Tribal Case Study: Modeling ÉÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ ÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ» º TANKS Program 3.1 11/17/98 º º Emissions Report Summary Format PAGE 3 º º Individual Tank Emission Totals º ÈÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ ÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ 83 Tribal Case Study: Modeling Annual Emissions Report Losses (lbs.): Liquid Contents Standing Working Total ------------------------------------------------------------------------Gasoline (RVP 10) 80.49 1171.11 1251.60 Total: 1171.11 80.49 1251.60 84 Tribal Case Study: Modeling TANKS Information compiled into EI More readable format 85 Tribal Case Study: Modeling Gasoline Marketing: VOC and Ozone Emissions, Baseline Year 1995 Activity Stage I Stage II VOC Emissions Tons/Year Typical Ozone Season Daily Emissions 0.050 0.001757 Tons 355.39 0.976 Tons Trucks In Transit 0.0526 0.0014 Tons Working Losses 23.76 1.319 Tons/day 86 Tribal Case Study: Modeling TANKS Overall Model becomes easy to use Understand inputs Research, document, validate data GIGO 87 Tribal Case Study: Modeling MOBILE 5 88 Tribal Case Study: Modeling MOBILE 5 Emission factor model Motor vehicles on highway Calculates Stage II refueling emissions 89 Tribal Case Study: Modeling MOBILE 5 Typical Engine Combustion FUEL + AIR ==>> UNBURNED HYDROCARBONS + NITROGEN OXIDES + CARBON MONOXIDE + CARBON DIOXIDE + water 90 Tribal Case Study: Modeling MOBILE 5 Computer based FORTRAN code Input files Output files DOS system 91 Tribal Case Study: Modeling MOBILE 5 Calculates HC CO NOx Gasoline Diesel 92 Tribal Case Study: Modeling MOBILE 5 Light duty vehicles Light duty trucks Heavy duty vehicles Motorcycles Diesel light duty vehicles Heavy duty vehicles 93 Tribal Case Study: Modeling MOBILE 5 Input file features Control Section One-time data section Scenario Section 94 Tribal Case Study: Modeling MOBILE 5 Control Section Specifies values for variables Flags Contain possible settings Numeric Results in specific action 95 Tribal Case Study: Modeling MOBILE 5 SPDFLG Specifying one speed for all eight vehicle types Or of specifying different speeds for each vehicle type This flag can be set to 1, 2, 3, or 4 96 Tribal Case Study: Modeling MOBILE 5 SPDFLG Value Action 1 User supplies one value of average speed for all vehicle types 2 User supplies eight values of average speed, one for each vehicle type 97 Tribal Case Study: Modeling MOBILE 5 SPDFLG Value Action 3 User supplies one value of average speed for all vehicle types, and a set of trip length distribution records for use in calculating running loss emission factors for each scenario, in the Scenario data section 98 Tribal Case Study: Modeling MOBILE 5 SPDFLG Value Action 4 User supplies one value of average speed for all vehicle types, and a single set of trip length distribution records for use in calculating running loss emission factors for all scenarios, in the One-time Data section 99 Tribal Case Study: Modeling Example Input File Mobile 5a --------------------------------------------------------------------------------------------PROMPT St. Regis Mohawk Tribe - EI 95 1 TAMFLG 1 SPDFLG 1 VMFLAG 1 MYMRFG 1 NEWFLG 1 IMFLAG 1 ALHFLG 1 ATPFLG 1 RLFLAG 2 LOCFLG - LAP record will appear once, in one-time data section. 1 TEMFLG 4 OUTFMT - 112-column descriptive format. 1 PRTFLG - Print exhaust HC, CO and NOx results. 1 IDLFLG 3 NMHFLG - Calculate emissions for volatile organic hydrocarbons. 2 HCFLAG - Print sum of all HC component emissions. SRMR Summer 95. A 57. 80. 09.0 09.0 92 1 1 1 Local Area Parameter record 1 95 45.0 70.0 20.6 27.3 20.6 07 Scenario description record 1 95 45.0 70.0 20.6 27.3 20.6 01 Scenario description record 0000000000000000000000000000000000000000000000000000000000000000000000000000000000 ------------------------------------------------------------------------------------------------ 100 Tribal Case Study: Modeling Example Output File Mobile 5a 1 St. Regis Mohawk Tribe - EI 95 MOBILE5a (26-Mar-93) 0SRMR Summer 95. Minimum Temp: 57. (F) Maximum Temp: 80. (F) Period 1 RVP: 9.0 Period 2 RVP: 9.0 Period 2 Yr: 2002 0VOC HC emission factors include evaporative HC emission factors. 0________________________________________________________________________________ 0Emission factors are as of July 1st of the indicated calendar year. 0Cal. Year: 1995 Region: Low Altitude: 500. Ft. I/M Program: No Ambient Temp: 74.3 (F) Anti-tam. Program: No Operating Mode: 20.6 / 27.3 / 20.6 Reformulated Gas: No 0Veh. Type: LDGV LDGT1 LDGT2 LDGT HDGV LDDV LDDT HDDV MC All Veh + ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ Veh. Spd.: 45.0 45.0 45.0 45.0 45.0 45.0 45.0 45.0 VMT Mix: 0.631 0.181 0.084 0.031 0.003 0.002 0.061 0.007 0Composite Emission Factors (Gm/Mile) VOC HC: 1.44 1.87 2.51 2.07 4.52 0.39 0.57 1.29 3.26 1.70 Exhst HC: 0.82 1.12 1.58 1.27 1.51 0.39 0.57 1.29 1.12 0.99 Evap. HC: 0.25 0.33 0.45 0.37 2.19 1.84 0.34 Refuel HC: 0.17 0.22 0.23 0.22 0.37 0.17 Runing HC: 0.14 0.14 0.20 0.16 0.36 0.14 Rsting HC: 0.06 0.06 0.05 0.05 0.09 0.30 0.06 101 Tribal Case Study: Modeling ________________________________________________________________________________ 0Emission factors are as of Jan. 1st of the indicated calendar year. 0Cal. Year: 1995 Region: Low Altitude: 500. Ft. I/M Program: No Ambient Temp: 74.3 (F) Anti-tam. Program: No Operating Mode: 20.6 / 27.3 / 20.6 Reformulated Gas: No 0Veh. Type: LDGV LDGT1 LDGT2 LDGT HDGV LDDV LDDT HDDV MC All Veh + ______ ______ ______ ______ ______ ______ ______ ______ Veh. Spd.: 45.0 45.0 45.0 45.0 45.0 45.0 45.0 45.0 VMT Mix: 0.633 0.180 0.084 0.031 0.004 0.002 0.061 0.007 0Composite Emission Factors (Gm/Mile) VOC HC: 1.47 1.92 2.58 2.13 4.71 0.39 0.57 1.32 3.27 1.74 Exhst HC: 0.84 1.16 1.62 1.31 1.58 0.39 0.57 1.32 1.14 1.02 Evap. HC: 0.26 0.34 0.48 0.39 2.29 1.84 0.35 Refuel HC: 0.17 0.22 0.23 0.22 0.37 0.18 Runing HC: 0.14 0.14 0.20 0.16 0.37 0.14 Rsting HC: 0.06 0.06 0.05 0.05 0.09 0.30 0.06 102 Mobile 5b Input 1 St. 1 1 1 1 1 1 1 1 1 2 1 3 1 1 1 3 SRMR 1 95 1 95 Tribal Case Study: Modeling PROMPT Regis Mohawk Tribe - EI 95 TAMFLG SPDFLG VMFLAG MYMRFG NEWFLG IMFLAG ALHFLG ATPFLG RLFLAG LOCFLG - LAP record will appear once, in one-time data section. TEMFLG OUTFMT - 112-column descriptive format. PRTFLG - Print exhaust HC, CO and NOx results. IDLFLG NMHFLG - Calculate emissions for volatile organic hydrocarbons. HCFLAG - Print sum of all HC component emissions. Summer 95. A 57. 80. 09.0 09.0 92 1 1 1 Local Area Parameter record 45.0 70.0 20.6 27.3 20.6 07 Scenario description record 45.0 70.0 20.6 27.3 20.6 01 Scenario description record 103 Mobile 5b Tribal Case Study: Modeling Output 1 St. Regis Mohawk Tribe - EI 95 MOBILE5b (14-Sep-96) 0 -M170 Warning: + Exhaust emissions for gasoline fueled vehicles beginning in 1995 have been reduced as a result of Gasoline Detergent Additive Regulations (1994). -M154 Warning: + Refueling emissions for LDGV and LDGT after 1998 model year have been reduced as a result of the Onboard Refueling Vapor Recovery Regulations (1994). 0SRMR Summer 95. Minimum Temp: 57. (F) Maximum Temp: 80. (F) Period 1 RVP: 9.0 Period 2 RVP: 9.0 Period 2 Start Yr: 2002 0Total HC emission factors include all evaporative HC emission factors, except for refueling emissions. 104 Tribal Case Study: Modeling 0Emission factors are as of July 1st of the indicated calendar year. 0Cal. Year: 1995 I/M Program: No Ambient Temp: 74.3 (F) Region: Low Anti-tam. Program: No Operating Mode: 20.6 / 27.3 / 20.6 Altitude: 500 Ft. Reformulated Gas: No 0 Veh. Type: LDGV LDGT1 LDGT2 LDGT HDGV LDDV LDDT HDDV MC All Veh + ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ Veh. Speeds: 45.0 45.0 45.0 45.0 45.0 45.0 45.0 45.0 VMT Mix: 0.631 0.181 0.084 0.031 0.003 0.002 0.061 0.007 0Composite Emission Factors (Gm/Mile) Total HC: 1.33 1.72 2.37 1.92 4.24 0.38 0.55 1.31 3.36 1.587 Exhaust HC: 0.88 1.19 1.66 1.34 1.60 0.38 0.55 1.31 1.22 1.053 Evaporat HC: 0.25 0.33 0.45 0.37 2.19 1.84 0.337 Refuel L HC: 0.17 0.22 0.23 0.22 0.37 0.175 Runing L HC: 0.14 0.14 0.20 0.16 0.36 0.142 Rsting L HC: 0.06 0.06 0.05 0.05 0.09 0.30 0.056 105 Tribal Case Study: Modeling 0Evaporative Emissions by Component Weathered RVP: 9.0 Hot Soak Temp: 76.4 (F) (Hot Soak: g/trip, Diurnals: g, Crankcase: g/mi, Refuel: g/gal, Resting: g/hr) Running Loss Temp: 77.3 (F) Resting Loss Temp: 69.6 (F) Hot Soak 1.28 5.98 WtDiurnal 2.70 10.33 Multiple 6.77 Crankcase 0.01 0.00 Refuel 3.68 Resting 0.07 0.12 1.46 2.08 1.64 7.22 4.39 8.09 5.50 29.86 8.63 0.02 11.06 0.02 9.36 0.02 35.35 0.03 3.68 0.07 3.68 0.07 3.68 0.07 3.68 0.10 ___________________________________________________________________________________ ____________________________ 106 -M154 + Tribal Case Study: Modeling Warning: Refueling emissions for LDGV and LDGT after 1998 model year have been reduced as a result of the Onboard Refueling Vapor Recovery Regulations (1994). 0Emission factors are as of Jan. 1st of the indicated calendar year. 0Cal. Year: 1995 I/M Program: No Ambient Temp: 74.3 (F) Region: Low Anti-tam. Program: No Operating Mode: 20.6 / 27.3 / 20.6 Altitude: 500. Ft. Reformulated Gas: No 0 Veh. Type: LDGV LDGT1 LDGT2 LDGT HDGV LDDV LDDT HDDV MC All Veh + ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ Veh. Speeds: 45.0 45.0 45.0 45.0 45.0 45.0 45.0 45.0 VMT Mix: 0.633 0.180 0.084 0.031 0.004 0.002 0.061 0.007 0Composite Emission Factors (Gm/Mile) Total HC: 1.36 1.77 2.43 1.98 4.42 0.38 0.55 1.34 3.37 1.626 Exhaust HC: 0.90 1.23 1.70 1.38 1.67 0.38 0.55 1.34 1.24 1.077 Evaporat HC: 0.26 0.34 0.48 0.39 2.29 1.84 0.350 Refuel L HC: 0.17 0.22 0.23 0.22 0.37 0.175 Runing L HC: 0.14 0.14 0.20 0.16 0.37 0.143 Rsting L HC: 0.06 0.06 0.05 0.05 0.09 0.30 0.056 107 Tribal Case Study: Modeling 0Evaporative Emissions by Component Weathered RVP: 9.0 Hot Soak Temp: 76.4 (F) (Hot Soak: g/trip, Diurnals: g, Crankcase: g/mi, Refuel: g/gal, Resting: g/hr) Running Loss Temp: 77.3 (F) Resting Loss Temp: 69.6 (F) Hot Soak 1.31 5.99 WtDiurnal 2.82 10.32 Multiple 7.01 Crankcase 0.01 0.00 Refuel 3.68 Resting 0.07 0.12 1.51 2.17 1.71 7.48 4.64 8.60 5.83 30.92 9.21 0.02 11.61 0.02 9.93 0.02 35.94 0.03 3.68 0.07 3.68 0.07 3.68 0.07 3.68 0.10 ____________________________________________________________________________________ ____________________________ 108 Tribal Case Study: Modeling MOBILE 5 Mobile Emissions, St. Regis Mohawk Reservation, Baseline Year 1995. Tons/Year. Pollutant Hydrocarbons Summer Winter 0.015 0.0727 CO 0.0698 0.382 NOx 0.0155 0.0527 0.0016 Tons NA Typical Ozone Daily Emissions 109 Tribal Case Study: Modeling MOBILE 5 MOBIL 4.1 Used in 1992 Coupled with CAL3QHC 110 Tribal Case Study: Modeling MOBILE 5 Differences in emission rates Accounted for 50,000 mile deterioration 111 Table 12. Comparison of Model Year Contribution to the FleetAverage LDGV Emission Rate for Calendar Year 1995 (MOBILE4.1 Versus MOBILE5a) I/MScenarioa 1981+ HC No I/M 0.297 Basic I/M 0.262 Enhanced I/M No I/M Basic I/M Enhanced I/M NOx No I/M Basic I/M Enhanced I/M 0.285 0.244 0.222 0.226 MOBILE4.1 MOBILE5a Pollutant/ Pre-1981 1981+ Pre-1981 0.703 0.738 CO 0.715 0.756 0.778 0.774 0.168 0.214 0.192 0.224 0.786 0.808 0.776 0.183 0.151 0.176 0.817 0.849 0.824 0.135 0.137 0.832 0.865 0.863 112 Tribal Case Study: Modeling MOBILE 5 CAL3QHC 1 hr and 8 hr CO concentrations at intersections Dependent upon vehicle, road-way and met conditions Developed in 1978 Still used CAL3QHCR – requires local met data 113 Tribal Case Study: Modeling Summary Select the model appropriate to needs Understand uses Understand limitations Study Documentation 114 Tribal Case Study: Modeling Summary (cont.) Learn to operate it Test runs Test files included Consult with others who use it Consult with developers 115 Tribal Case Study: Modeling Summary (cont.) Adequate time to learn program Understand inputs Do homework for data Document data 116 Tribal Case Study: Modeling Your Success is Guaranteed! Thank You 117