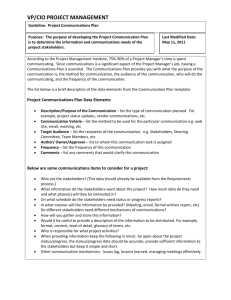

ASMI/CHC Joint Guideline Launch Presentation

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

• The CHC’s Raw Material Supplier

Technical Committee and

Manufacturing and GMP

Technical Committee

• ASMI’s Manufacturing Working Group.

• GSP Working Party:

• Michael Gepp (Pathway),

• Cathrine Dahlgren (Xena

Technologies),

• Devlin Gardner (Ensign

Laboratories).

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

Overview of the guidelines

1. Guideline for the Quality & Safety of Raw Materials used in Complementary

Medicines (the CHC Guideline for Raw Materials); and

2. Good Supplier Practice (GSP).

Supporting Vendor Qualification Questionnaires - common to both Guidelines

•Supplier Vendor Qualification Questionnaire

•Raw Material Manufacturer Vendor Qualification Questionnaire

•Transmissible Spongiform Encephalopathies (TSE) Questionnaire

•Free From Information Questionnaire

•Packaging Material Manufacturer Vendor Qualification Questionnaire

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

Genesis of these guidelines

• CHC and ASMI working independently with slightly different focus.

• Similar aims – contributing to the assurance of quality starting materials.

• Same backdrop of events in the media and issues & risks being managed by our members.

The CHC - primarily addressing documentation requirements for raw materials to assist industry in their efforts to certify the quality and safety of raw materials being used in complementary medicines.

ASMI - addressing the broader issues associated with the supply chain of starting materials focusing where agents, brokers, distributors, and suppliers act as an intermediary between the raw material or packaging material manufacturer and medicine manufacturer.

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

Early in the development work (2010), it was realised that to maximise the incentive to Suppliers there was significant benefit in both associations maintaining & using a single set of Vendor

Qualification Questionnaires.

Late in 2011 it was agreed to collaborate as the guidelines being developed by each industry association were complementary.

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

Why develop these guidelines?

• Quality and vendor assurance (VA) of starting materials is currently the responsibility of medicine manufacturers. Suppliers are often used to procure materials. Therefore VA is conducted by many medicine manufacturers ,for the same material from the same manufacturing site, via the same supplier.

• Little specific guidance is available for local starting material suppliers to the Australian medicine manufacturing industry. There are few licensing requirements to set up as a supplier of starting materials.

• A clear opportunity existed to involve suppliers more proactively in the vendor qualification process.

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

Is there a benefit to the Suppliers?

BENEFITS

Transparency of requirement/ expectation

Business Efficiencies

Reduced paper work.

Increased quality of paperwork.

Improved relationships with principals and with customers.

Streamlined vendor approval process.

CURRENT SITUATION THE OPPORTUNITY

No Specific Guidance for Suppliers

• Each medicine manufacturer provides their own questionnaire for internal assessment.

• Each questionnaire is essentially asking very similar questions to obtain the same information.

Specific Guidelines Available for Suppliers

• Provision of an industry wide agreed format for internal assessment.

• Significant reduction of site qualification questionnaires to be completed.

• Each site qualification questionnaire can be maintained, and issued on request.

GUIDELINE FOR RAW MATERIALS

Future Vision Preferred Supplier Status

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

What are the benefits to Sponsors/Manufacturers?

BENEFITS CURRENT SITUATION THE OPPORTUNITY

Transparency of requirement/ expectation

Improved Service from

Suppliers

Better / Faster turnaround of data.

Greater Levels of Quality

Assurance.

Improved relationships with the Supplier.

Streamlined vendor approval process.

No Specific Guidance for

Suppliers

• Each Medicine

Manufacturer provides their own questionnaire for internal assessment.

• Each questionnaire is essentially asking very similar questions to obtain the same information.

Specific Guidelines

Available for Suppliers

• Provision of an Industry wide agreed format for internal assessment.

• Significant reduction of site qualification questionnaires to be completed.

• Each Site qualification questionnaire can be maintained, and issued on request.

GUIDELINE FOR RAW MATERIALS

Reduces the cost of poor quality

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

The Qualification Questionnaires are designed for:

• ease of completion:

• for non-English speaking starting material manufacturers.

Supporting documentation is requested where deemed necessary for verification purposes.

• in a locked Word document format which can be completed and maintained electronically.

• ease of use within your existing vendor qualification system.

• requiring only a cover letter for issue and

• an assessment form for internal review.

• provision of extensive detail to provide insight into the vendor’s capabilities.

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

Review and update

The guidelines and supporting questionnaires will be reviewed every three years. A facility has been established to provide suggestions for changes. If necessary, urgent/ important amendments can be made outside of the three year review cycle.

The Request for Change Form is with the Guidelines on the CHC & ASMI websites and is provided on your epack.

Frequently asked Questions

A list of FAQ’s has been prepared for each Guideline and these are available on the websites and provided on your epack.

These documents will be living documents and will be updated as questions are asked.

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

Launch Plan and Rollout

Stage 1 involving sponsors and medicine manufacturers. (Today)

Stage 2 involving broader roll out to raw material suppliers/brokers and agents on 22 May 2012.

Speakers will include:

• An OMQ representative speaking on Supplier Qualification and common deficiencies found at audit.

• ASMI & the CHC’s Overview of the Guidelines

• A range of industry perspectives on the Guidelines

• An expert Industry & TGA Panel

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

To maximise the effectiveness of the launch

We need you to:

1. Start implementing the guidelines within your Vendor

Qualification systems to start gaining the benefits.

2. Invite your local suppliers, agents, distributors, brokers

(RMs and Printed & Primary Packaging) as your guests to the Stage 2 launch preceded by a Networking lunch. Your epack contains a standard invitation letter to be put on your company’s letterhead and personalised to your supplier’s details.

3. Consider sharing with us your company logo as an endorsement of the Guideline to include on a slide in the stage 2 presentation, as an indication of the extent of use.

4. Consider measuring your experiences on implementation

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

SUCCESS?

Achieving the benefits of this vision through the Guidelines and Questionnaires will require discipline from the Industry:

1. To use the questionnaires as they are without changing them.

2. To note ideas for change and immediately submit a completed Request for Change form.

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

Future Opportunities

•Extend an invitation to other industry associations for use of the Guidelines &

Questionnaires to broaden usage and create greater demand for compliance.

•Development of a product specific raw material master file containing a summary of the information typically requested by manufacturers, such as pack size, shelf life, storage conditions, kosher and halal status.

•Sustainability/Ethical procurement questionnaire.

•Encourage suppliers to provide a full vendor assurance package, including either:

• a material manufacturing site audit, report and closure; or

•TGA GMP clearance or equivalent; in order to achieve preferred supplier status.

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE

Questions?

GUIDELINE FOR RAW MATERIALS

2012 Joint Guideline Launch

GOOD SUPPLIER PRACTICE