to get the file - Mechanical and Materials Engineering

advertisement

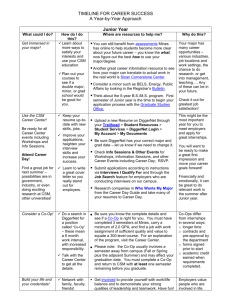

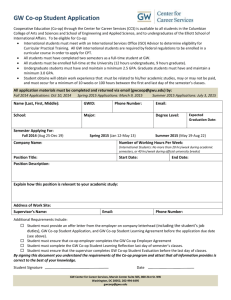

The Professional Choice Cooperative Education at the University of Cincinnati Education Gives Structure Professionals need Muscles Best Professional Preparation Available Solid academic course work and professional experience Dean Schneider invents Cooperative Education in 1906 at UC. Now UC has over 4,000 students and 1,500 employers. Dean Herman Schneider 1872 -1939 How the Program Works • Faculty driven academic program • Multiple progressive work terms • Breadth / depth of work experiences • Experiences must be career and / or discipline related • Only paid work experiences • Most students start co-op in the winter or spring of sophomore year How the Program Works •Two alternating sections • Year-round participation with approximately 5 weeks vacation per year • Students will be certified to co-op by the college of engineering • Students are assigned a Professional Practice faculty adviser by discipline Intro to Co-op Section II 1 2 3 5/6 4 Industry 1 2 3 4 5 6 Section I F W S S Freshmen F W S S Sophomore F W S S Pre-Junior F W S Junior S F W S Senior Co-op Timeline 1st Year: Intro to Co-op 2nd Year: Job Search and Start Co-op 3rd Year: Co-op Rotations 4th Year: Co-op Rotations 5th Year: Graduate Advantages of Co-Op Smooth Transition More Marketable Networking with Professionals Maturity, Self Confidence Confirm Major and Career Direction Helps Pay Part of the Costs of School Alternation of School/Work Keeps You Fresh Test Drive Your Chosen Field Concrete Skill Development Strong Support System at UC Some Employers That Hire Engineering Co-op Students • • • • • • • • • • • • General Electric Procter & Gamble Company Ethicon Endo-Surgery Duke Energy Corporation Cincinnati Bell General Cable Corporation General Motors Bayer Becker Engineers Toyota Cognis Corporation Ford Motor Company Rockwell Automation • • • • • • • • • • • • • Dow Chemical Texas Instruments Wright Patterson Air Force Base Honda of America BP Messer Construction Cummins Engine Belcan Bayer Corporation Intel Corning Precision Lens Ellis and Watts NASA Co-op Employers expect Professionals Co-op students: •Follow identical policies and procedures as fulltime employees •Act as professionals doing their best work at their particular stage of development • Transfer learning between classroom learning and workplace Realities of Co-Op Co-op Expenses Full Time Student Co-op Fee Each Term May impact Extra Curriculars May Impact Financial Aid Package Housing and Relocation Your Responsibility Learning Objectives and Reports Each Term Earn about $40,000 - $45,000 before you graduate Eighteen Months of Paid Work Experience Five Years to Graduate Co-op is about Learning and Developing As a Professional Ryan Stobbs Mechanical Engineering, 2007 “The military came to the company wanting to test the durability of a new turret design” “You fire several hundred 50 caliber machine gun bullets and drive it through the desert for several hundred miles” Daniel Seig Mechanical Engineering 2007 “I held increasing responsibilities leading up to hardware ownership of the fuel supply system. ” “While redesigning the fuel manifold brackets I got to work in the test cells and conduct my own vibrations test” Ronnie Rackley II Mechanical Engineering 2008 “My career goals right now are to not graduate and become a co-op for life. Its the best job out there.” “Within the first week I knew everyone’s name and have become close friends with a lot of people here.” Daniel Peterson Mechanical Engineering 2008 “I worked on a brand new gas turbine, the LMS100.” “It was incredible working on a brand new product, especially one that is going to revolutionize the field of power generation!” Christopher Stough Mechanical Engineering 2008 “makes customized brewkettles, lauter tuns, fermenters and most other things for breweries” “I've worked on laying out piping and other process systems for fermenters and brewkettles.” Lance Kelly Mechanical Engineering 2008 Transportation Research Center Inc. “investigating the relationships between human injury and physical mechanical properties ” “The Injury Biomechanics Research Lab (IBRL), a nationally recognized center for trauma research.” Andrew Inman Mechanical Engineering 2008 “I worked with the compressed air system in Toyota's Facilities Control Engineering” “co-op friend of mine got us a ride on the test track Jeffrey Hoffa Mechanical Engineering 2008 “a test track which we used to test experimental components on complete vehicles ” “It's pretty nice to get paid to break things! ” Benjamin Stoney Mechanical Engineering 2007 “I was a fullyfunctioning assembly engineer, owning the build-up of a B2 bomber engine” “It is a great feeling knowing that I was supporting our troops at home and abroad without even being enlisted. ” Ryan Vannatta Mechanical Engineering 2006 “During the summer I went four wheeling, fishing, camping, horseback riding, white water rafting, participated in a rodeo” “During the winter while I was there I went snow mobiling, Off-roading, Skiing, and Ice Fishing” International Co-op Program Japan Germany Mexico Chile UC Structure of ICP Intro to Co-op Orientation to International Co-op Intensive Language ICP Schedule 1 F W S S Freshmen F W 2 S S Sophomore 3 F W 4 S S Pre-Junior 5/6 F W S Junior S F W S Senior ICP Language Training Two week Intensive Language refresher in country Courses during academic quarters Intensive language training for six weeks in shortened 4th co-op Some Employers That Hire ICP Co-op Students • • • • • • • • • • • • • • 3M Ahresty Audi Bayer AG BMW AG Robert Bosch Gmbh CTI Engineering Daimler-Chrysler Aerospace Degussa AG GE Aircraft Engines General Motors Powertrain Dephi Automotive BF Goodrich Hewlett Packard Kawasaki Steel • • • • • • • • • • • • • • Kayser – Threde GmbH KA0 / Andrew Jergens Group Lockwood Greene Lufthansa LuK Powertrain, Inc. Mechanical Dynamics Motoren-und Turbinen Union NKK Corporation PCI Computer Systems Pliz GmbH & Co. Siemens Toyobo Company Ltd Volkswagen Wacker Chemie GmbH What are YOUR Questions?