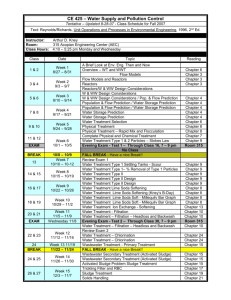

Reactors for Sludge Digestion

advertisement

Technologies for anaerobic wastewater treatment Jan Bartáček ICT Prague Department of Water Technology and Environmental Engineering Jan.bartacek@vscht.cz Anaerobic reactors differenciations Anaerobic reactors Immobilized biomass Suspended biomass Biofilm (on support) Moving carrier Fixed carrier Granular biomass Reactors for Sludge Digestion • On the principle of CSTR (Completely Stirred Tank Reactor) • Either SBR (Semi-Batch Reactors) or continuous • Currently used mostly for sludge digestion Reactors for Sludge Digestion • With moving or fixed top Reactors for Sludge Digestion Reactors for Sludge Digestion Reactors for Sludge Digestion • With moving or fixed top Biogas Biogas Overflow Overflow Raw sludge Digested sludge Raw sludge Digested sludge Reactors for Sludge Digestion • Mixing ▫ Mechanical (only fixed top) Fast or slow Reactors for Sludge Digestion • Mixing ▫ Mechanical (only fixed top) Fast or slow ▫ Biogas recirculation ▫ Sludge recirculation Reactors for Sludge Digestion • Heating ▫ External ▫ Internal ▫ It is advantageous to have large reactors – smaller heat losses Reactors for Sludge Digestion • Egg-shaped digesters Reactors for Sludge Digestion • Egg-shaped digesters Reactors for Sludge Digestion • Egg-shaped digesters ▫ Smaller surface/volume ratio smaller heat losses ▫ Improved mixing properties (mixing with biogas) Reactors for Sludge Digestion • • • • Temperature: 20 – 55 °C Materials: steel, concrete, plastics (smaller) Retention time: 10 – 30 days Pumping cycles: usually several time a day (SBR). Advantageous to get close to continuous systems (e.g. pumping every hour) Development of anaerobic wastewater technologies over time Anaerobic reactors for WWT build in recent years Anaerobic reactors for WWT build in recent years Anaerobic Contac (AC) process • Main difficulty – sludge separation ▫ Solution: less mixing Improved degasification (vacuum) membrane separation Anaerobic Filters (AF) • Usually up-flow ▫ Problems with clogging • Suitable carrier material ▫ originally natural (gravel, coke, bamboo segments) ▫ Recently plastics, ceramics etc. Anaerobic Filters (AF) • Down-flow systems ▫ Less clogging (suspended biomass leaves reactor via bottom ▫ First systems – tubular Relatively small contact area Anaerobic Filters (AF) • Down-flow systems ▫ Less clogging (suspended biomass leaves reactor via bottom ▫ First systems – tubular Relatively small contact area ▫ Normal carriers can also be used "High Rate"Anaerobic Treatment • Bioreactors in which the sludge retention time is separated from the hydraulic retention time. • Anaerobes can be maintained in the reactor at high concentrations, enabling high volumetric conversion rates, while the wastewater rapidly passes through the reactor. • The main mechanism of retaining sludge in the reactor is immobilization onto support material (microorganisms sticking to surfaces, eg. filter material in the "anaerobic filter") or self-aggregation into pellets (microorganisms sticking to each other, eg. sludge granules). Up-flow Anaerobic Sludge Blanket (UASB) reactor biogas effluent granular sludge influent Anaerobic granular sludge Sekiguchi et al. 1999 Applied And Environmental Microbiology, 65(3), 1280-1288. Fernández, et al 2008. Chemosphere, 70(3), 462-474. • Spherical biofilm • Grown without carrier material • Heterogeneous, densely packed biomass • Often stratified (depends on substrate complexicity) • Well settling Up-flow Anaerobic Sludge Blanket (UASB) reactor biogas g-l-s (3-phase) separator effluent deflector granular sludge influent blanket Up-flow Anaerobic Sludge Blanket (UASB) reactor biogas g-l-s (3-phase) separator effluent deflector granular sludge influent blanket www.uasb.org Up-flow Anaerobic Sludge Blanket (UASB) reactor biogas g-l-s (3-phase) separator effluent deflector granular sludge influent blanket Up-flow Anaerobic Sludge Blanket (UASB) reactor Up-flow Anaerobic Sludge Bed (UASB) reactor Expanded and Fluidized bed reactors • Internal Circulation (IC) reactor (Paques B.V.) • Excellent mixing and contact between ww and biofilm Expanded and Fluidized bed reactors • Internal Circulation (IC) reactor (Paques B.V.) • Excellent mixing and contact between ww and biofilm Expanded and Fluidized bed reactors • Internal Circulation (IC) reactor (Paques B.V.) • Excellent mixing and contact between ww and biofilm Expanded and Fluidized bed reactors • Expanded Granular Sludge Bed (EGSB) reactor (Biothane B.V) EGSB vs. UASB • Better mixing • No problems with small inert particles • Treatable wastewater (not in UASB): ▫ Low strength (<<1g/L) and cold (<10°C) wastewater ▫ Long-chain fatty acids (even distribution, no clumps formation) ▫ Wastewater with foaming problems Moving bed reactors • Biofilm on carrier material Expanded and Fluidized bed reactors • Fluidized Bed (FB) reactor • Needs carrier material as biofilm support (can be expensive) • Regeneration of carrier (eliminating overgrown biofilm) Anaerobic effluents • • • • Relatively polluted in COD (~150 – 200 mg/L) Unchanged or even increased Nammon and P-PO4 May contain biomass …post-treatment is needed • Usually “classical” DN systems. Often extensive (ponds or wetlands). • Problem – COD is not well degradable beneficial to mix with other, less polluted wastewater Liquid effluents - P • Most often precipitation ▫ Iron (FeCl2, FeCl3, Fe2(SO4)3) Fe3++ PO43- FePO4 ▫ Struvite NH4+ + Mg2+ + PO43- + 6H2O NH4MgPO4·6H2O Advantages: Constrains: Liquid effluents - N • Nitrification/denitrification • Nitritation/denitritation • Deammonification ▫ SHARON-ANAMMOX Liquid effluents - N • Nitritation/denitritation Liquid effluents - N • Nitritation ▫ How to achieve inhibition of NOB? Low dissolved oxygen concentration (DO) ~ 0.7 mg/L High temperature (25-40 °C) + low retention (SHARON process) High loading rate (NH2OH accumulation) SBR regime (pH changes) Liquid effluents - N • SHARON-ANAMMOX Liquid effluents - N • SHARON-ANAMMOX Liquid effluents - N • SHARON-ANAMMOX Anammox bacteria Liquid effluents - N • SHARON-ANAMMOX ▫ Advantages Low energy demand Low substrate demand ▫ Constrains High temperature needed Slow growth Biogas quality upgrading • Mostly H2S removal • CO2 removal • Drying Biogas upgrading - H2S removal • S2- oxidation to sulphur Thiothrix Thiobacillus Biogas upgrading • THIOPAQ® Biogas upgrading • Microaeration ▫ Controlled air dosing into anaerobic reactors ▫ Dosing: Gas space Inlet/recycle Technologies for anaerobic wastewater treatment Jan Bartáček ICT Prague Department of Water Technology and Environmental Engineering Jan.bartacek@vscht.cz