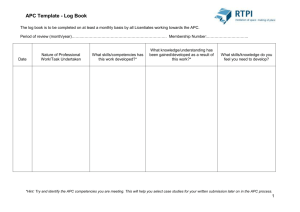

Now

advertisement

Biopharm production methods need effective real-time monitoring and control to guarantee a low-cost, safe and high quality production. Modern multidisciplinary concepts are the key to effective manufacturing in biotechnology, allowing real-time product release. New production methods and the market demand for faster development of production processes (shorter time to market) imply a need for a better understanding of the process. The increased emphasis on production efficiency (shortening of throughput delays, up scaling, shift from batch to continuous production methods, increased capacity and yield) needs real-time process information. On the other hand, product safety methodologies result in an increased need for track of product quality throughout the manufacturing process. Also the FDA (Food and Drug Administration) is encouraging a more risk-based and science-based approach instead of current empiric production methods. The FDA’s PAT (Process Analytic Technologies) initiative is one of the current focus topics. Process Modelling IPD MES Figure 2: Bioreactor Process Analytical Technologies (PAT) Improving the process begins with monitoring the process and building awareness on the typical behaviour. For the bio-pharm API production chain, the key process step to monitor is the bioreactor. Process analytic technologies (PAT) act as the “eyes” inside the bio-reactor. In bioreactor-processes the need for realtime process information is particularly high due to the complexity and unpredictability of the process. Recent PAT developments allow instantaneous in-line measurements (of the liquid and gaseous bio-reactor phase) to get a whole picture or fingerprint of the process. Process Analytics Process Automation Figure 1: Multidisciplinary approach to Bio-reactor optimisation The use of PAT for both physical and chemical status monitoring and also for biological or performance monitoring, is a big step forward in improving process understanding and allowing process optimisation. Information on individual parameters (physical, chemical and biological), the so-called absolute values and also relative measurements, as a measure of change, gives total quality information on the process. These developments provide a holistic view on the process and give better insights into what exactly is happening during the bioreactor process. These tools speed decisions on the batch endpoint, quality or efficiency of a certain process stage. New sensor technologies and also new approaches which can handle a wider range of process parameters allow strict control of operational conditions throughout the bio-pharm process. PAT closes the information gap for defining better control strategies and ultimately optimise the whole process Start End Figure 3: Process fingerprint monitoring of a bio-reactor However, to improve the control of the bio-reactor, a number of physical and chemical parameters must be continuously monitored. Previously, substrate and nutrient contents, metabolite formation and bio-mass concentration were obtained through off-line laboratory methods. Results are not obtained until several hours after sampling and results are fed into the process computer offline. This markedly limits the possibility of controlling and optimising bioreactor processes. Figure 4: Methodology for Advanced Process Control (APC) of Bio-reactor processes The integrated Advanced Process Control solution for bioprocess control which Siemens has developed as part of the Life Science Solution consists of APC Tools integrated into the Simatic PCS 7 process control system. These tools are interfaced via an OPC client channel to the WinCC server, and make use of the SCADA database (Historian) and data obtained by the used Process Analysers. APC therefore represents an important link between the planning and scheduling functions of the execution level and control functions. By using APC, Simatic PCS7 is expanded by a powerful process optimisation function and ensures not only a more efficient process control but also greater transparency in production leading to shorter batch runs and increased quality consistency. Consistency in quality is an important condition for Real-time product release / Parametric release. Figure 5: Process Control Strategy for Real Time product release Conclusion New process monitoring tools (PAT), new control structures and advanced process control result in an integrated concept for a “transparent” bioreactor. These multidisciplinary tools are the key to ... ...quickly gain knowledge about the key variables of their particular process ...find out how to minimise by-products (for a simpler downstream processing) and maximise product yield ...have a high process reproducibility (consistent quality) and early identification of unsuccessful batches …control even delicate processes 24 hours a day and meet future FDA requirements for real-time product release and a science-based risk approach Figure 6: Overview of the bio-reactor optimisation and real-time product release concept For more info, please contact: Siemens – RHQ Pharma & Fine Chemicals +32 3 735 0600 e-mail rhq-info@siemens.com Or visit us at www.siemens.com/pharma