Quality Control

Quality Control

Control is a critical issue facing every

manager in every organization today

Quality

control

The

Purpose and Important of Quality

Control

Basic

systems

allocating financial resources,

developing human resources,

analyzing financial performance

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

2

Quality Control

Definition of quality:an essential or distinctive

characteristic ,property ,or attribute .For example=the

chemical qualities of alchocol

Definition of control:means of regulation or check or a

standard of comparison used in a statistical or scientific

experiment.

Definition of quality control:a system for verifying and

maintaining a desired level of quality in an existing

product or service by careful planning, use of proper

equipment, continued inspection ,and corrective action

as required.

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

3

Organizational Control

Routine

checks

Zero

Defects

Monitoring

QC

Minimum

standard

inspection

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

4

Quality control is of the expected

benefits ;

To prevent the production of coarseness

In the products they push changes other

than to reduce the number of incorrect parts

previously detected

At least create a fast and efficient quality

examination system costs

Reduce lost time workers and machinery to

increase production

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

5

Historical Development of Quality Control

Three types of control

Quality control, for the first time in 1947, Armand

Vallin Feigenbaum by revealed in Japan

In 1961, Armand Vallin Feigenbaum authored the

book total quality Control and quality control have

brought a new approach.

In the same years Japan Joseph Juran and William

Edwards Deming's ideas began to base and total

quality management has been applied.

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

6

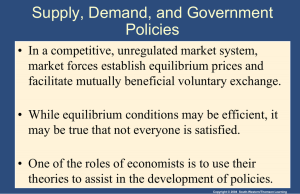

Organizational Control Focus

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

7

The Purpose and Important of

Quality Control:

The basic purpose of a quality control system to prevent the

production of coarseness.

Quality control purposes;

Improving product quality (size, volume, material,

hardness and other properties)

Reduce the costs of business and quality

Reduction of customer complaints and consumer

protection

The acquisition of competitiveness in foreign markets

Preventing waste of national wealth

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

8

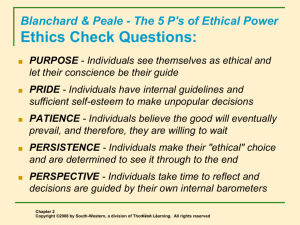

Stages Of The Control Process:

Includes self-control on behavior – personal values & attitudes

1)

2)

3)

4)

5)

The selection process will be checked

Determination of control unit

Determination of the performance of the topic and

purpose criteria will be checked

Determination of the difference between the intended

and the actual performance and interpretation

Actual measurement of performance

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

9

The Seven Basic Tools of quality

Control:

Seven quality tool, a comprehensive weapons store for quality control.

1)

Ishikawa diagram

1)

Check sheet

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

10

3)

Control chart

3)

Histogram

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

11

5)

Pareto Diagram

6)

Scatter plot

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

12

7)

Flow chart

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

13

TOTAL QUALITY MANAGEMENT

1)

Marketing

2)

Engineering

3)

Purchasing and Production

4)

Mechanical inspection and Functional testing

5)

Transport,placement and service

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

14

Quality Control Cycle;

Working at the same workplace or similar jobs that

employers are to analyze, solve problems, and collected at

regular intervals they create small working groups. Not

enough organization to apply the features of quality circles,

enterprise administrators will need to carry some qualities.

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

15

Purposes of Quality Control Cycle;

1)

Improve the quality

2)

Improve your employess

3)

Promote relations

4)

To reduce costs

5)

Develop the culture of those who work

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

16

Quality Control Circles Have Properties ;

①

②

③

④

Volunteering

All members participation

The vitality and continuity

Rewarding

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

17

Quality Circle Process

Team

Creates Quality

Circle and

Collects

Information

Team

Selects

Problems to Be

Solved

Team

Gathers Data and

Analyzes

Problems

Feedback from Mangers to Quality Circles

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

18

Team

Recommends

Solutions

Decision by

Top Management

Cost of prevention

of defects

Cost of warranty

claims

19

Costs

of

quality

Cost of scrap and

rework

defective

Copyright © 2005 by South-Western, a division of Thomson

Learning. of

All rights

reserved.

products

Cost of detecting

defects in the final

product

QUALİTY CİRCLE

The QC circle was

formally organized

in Japan in 1962 by

Japanese Union of

Scientists and

Engineers(JUSE)

and the man who

initiated the idea is

Dr.Kaoru Ishikawa

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

20

Quality of inputs

monitored

Quality of outputs

monitored

Random disturbances

Transformation

İnputs

process

Statistical process control

Feedback mechanisms

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

21

Outouts

Process of QC

For specific point in time

Identification of problem

Problem selection

Problem analysis

Recommendation to the Top management

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

22

Problem’s stages

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

23

ISO 900

second

party

audit

ISO 900

third

party

audit

Six Sigma

Quality system

Acceptanc

e sampling

Control charts

for variables

Statistical

process

control

Control charts

for altributes

ISO 900

Six Sigma

internal

audit

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

24

Service

quality

management

Control

charts for

number of

defects

Industry

related

standart

audit

ISO

1.

International Organisation for

Standardisation

Geneva

140 members

1979 - Genesis

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

25

Need for quality

Increased productivity

Reduced cost of repairs

Increases loyal customer base

Better profits

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

26

a)

Wikipedia

THANK YOU FOR PATİENCE

Copyright © 2005 by South-Western, a division of Thomson Learning. All rights reserved.

27