Introduction

advertisement

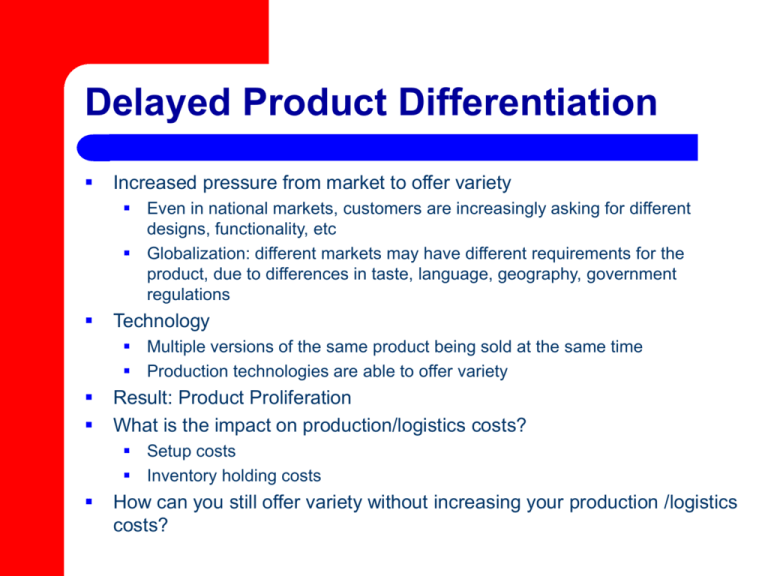

Delayed Product Differentiation Increased pressure from market to offer variety Even in national markets, customers are increasingly asking for different designs, functionality, etc Globalization: different markets may have different requirements for the product, due to differences in taste, language, geography, government regulations Technology Multiple versions of the same product being sold at the same time Production technologies are able to offer variety Result: Product Proliferation What is the impact on production/logistics costs? Setup costs Inventory holding costs How can you still offer variety without increasing your production /logistics costs? Delayed Product Differentiation and Push-Pull Boundary The point of product differentiation is often the push-pull boundary Delayed product differentiation enables reductions in demand uncertainty Reduced demand uncertainty enables the use of pull systems which may be cost efficient due to economies of scale Push Strategy Pull Strategy Tailored Postponement Do not implement postponement for the portion of demand that is certain Reductions in processing costs Implement postponement for only the portion where the demand is uncertain Reductions in inventory holding/obsolescence costs Example: Benetton Option 1: Dye + knit + distribution for a portion of demand Option 2: Knit + dye + distribution for the rest Determine the production quantity (dye + knit) in option 1 for each color, determine the production quantity (knit) in option 2 Design For Logistics Product and process design key cost drivers of product cost Design for manufacturing used design to decrease manufacturing costs Major supply chain costs include transportation costs, inventory costs, distribution costs Design For Logistics Design for logistics uses product design to address logistics costs Key concepts of design for logistics Economic packaging and transportation Concurrent/parallel processing Standardization Economic transportation and storage Design products so that they can be efficiently packed and stored Design packaging so that products can be consolidated at cross docking points Design products to efficiently utilize retail space Examples Ikea World’s largest furniture retailer 131 stores in 21 countries Large stores, centralized manufacturing, compactly and efficiently packed products Rubbermaid Clear Classic food containers - designed to fit 14x14” Wal-Mart shelves Concurrent/ Parallel Processing Objective is to minimize lead times Achieved by redesigning products so that several manufacturing steps can take place in parallel Modularity/decoupling is key to implementation Enables different inventory levels for different parts The Network Printer Example Board Stage 1 (Europe) Stage 1 (Europe) Printer Customer (Europe) Stage 2 + Integration (Far East) Board Printer Stage 2 (Far East) Customer (Europe) Integration (Europe) Plastics, motors, etc. Supplier Integration in product development Competitive forces are driving firms to integrate suppliers into product development Spectrum of Supplier Integration None White Box – Informal integration Grey Box – Formal integration, with collaborative teams Black Box – Interface requirements are given, product is returned Supplier Integration What approach is appropriate? Determine internal competencies Determine product development needs Identify external development and manufacturing needs If future products have components that require external expertise and can be separated from other components, a black box approach makes sense. If components cannot be separated, a grey box approach makes sense. If some expertise can be found in house, a white box approach might make sense. The “Bookshelf” Approach Monitor the development of new technologies Follow suppliers that have developed expertise When appropriate, integrate these new technologies This balances the advantages and disadvantages of being on the cutting edge: No need to gain experience with the technology, because suppliers are doing this for you. Can introduce the technologies when needed. Mass Customization The delivery of a wide variety of customized goods at low cost The key is modular products and processes, so that customer requests can be met Companies need to evolve towards “modular companies”, with managers ensuring that modules are compatible. Needs instant, costless, seamless integration of different modules (components) Consider National Bicycle Bikes manufactured based on customer weight, size, selections of model type, color patterns and components Dell