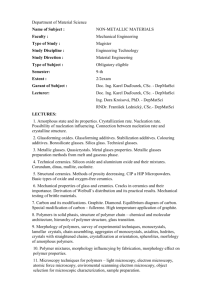

Advantages Disadvantages Uses

advertisement

Specification section 1.3 What do you need to learn? The advantages and disadvantages of the following thermoplastics when manufacturing products: Acrylic, Polyethene, Polyvinyl Chloride, High Impact Polystyrene and Acrylonitrile-Butadiene-Styrene (ABS). • • • The advantages and disadvantages of the following thermosetting plastics when manufacturing products: Polyester Resin and Urea Formaldehyde. Understand and describe the following properties when selecting and using polymers in product manufacture: Plasticity and Durability Polymers 1.3 What is a Thermoplastic? Thermoplastics can be re-heated and therefore shaped in various ways. They become mouldable after reheating as they do not undergo significant chemical change. Reheating and shaping can be repeated. The bond between the molecules is weak and become weaker when reheated, allowing reshaping. Thermoplastics tend to be composed of 'long chain monomers'. These types of plastics can be recycled. These plastics possess a common property, they soften when heated and are often used in schools to vacuum form shapes. Polymers 1.3 Acrylic (Known also as PERSPEX) This is the most common plastic in a school workshop. It is purchased usually in the form of sheets and comes in a range of colours. It can be transparent, translucent or opaque. It is resistant to most acids and weather conditions. Transparent – It is clear and light can pass through, think of a window. Translucent - An object that allows light to pass through but is not transparent, think tracing paper. Opaque – Light cannot go through the object. Advantages Fairly cheap, stiff, hard, durable, good electrical insulator, machines and polishes well Disadvantages Scratches easily and brittle Uses Signs, covers of storage boxes, aircraft canopies and windows, covers for car lights, wash basins and baths Polymers 1.3 Polyethene Can be moulded into almost any form due to its excellent moulding qualities. It is available in large sheets and used for the production of a variety of products because of its two different densities: High density: Which is rigid, hard, can be sterilised and is resistant to corrosion. Example of products made: Buckets, Bowls, Milk crates Low density: Which is tough, soft, flexible, available in a variety of colours and a good electrical insulator. Example of products made: Squeezy bottles for shampoo and washing up liquid, Toys, Carrier Bags Advantages LD - Tough, lightweight, durable, good resistance to chemicals, flexible, fairly soft, good electrical insulator HD - Hard, stiff and able to be sterilised Disadvantages Harmful to the environment – Animals, water ways and some are not recyclable Uses Packaging, especially bottles, toys, packaging film and bags. 'Plastic' bottles, tubing, household equipment Polymers 1.3 Polyvinyl Chloride (PVC) It is a tough material which can be purchased as a hard material or alternatively a flexible form. It can be welded or bonded with an adhesive. It has a range of uses including water pipes, raincoats, records, coating on electrical wires and many more. Advantages Stiff, hard, tough, lightweight, good chemical resistance Disadvantages Poor weatherability and easily scratched Uses Pipes, guttering, bottles, window frames Polymers 1.3 Polystyrene Polystyrene is one of those polymers that's all over the place. Polystyrene is an inexpensive and hard plastic. The outside housing of a computer is made of polystyrene, as well as the housings of things like hairdryers, TVs and kitchen appliances. Model cars and airplanes are made from polystyrene, as well as disposable razors and CD cases. There's also foam packaging and insulation, and a lot of the moulded parts on the inside of a car, like the radio knobs. Advantages Disadvantages Light, hard, stiff, Brittle, low impact transparent, with good water polystyrene breaks very resistance easily, not strong Uses Toys, especially model kits, packaging, castes for televisions, 'plastic' boxes and containers Polymers 1.3 Acrylonitrile-Butadiene-Styrene (ABS) ABS has many characteristics and is used for casings for kitchen equipment (e.g. food processors), toys, telephones, car components and tool handles to name a few. It is strong, tough, hard wearing, light weight, durable and has a good surface finish. Advantages Disadvantages Strong, tough, hard, light, Not weather resistant and durable, good surface finish, opacity (opaque) resists chemicals Uses Casings for kitchen equipment (e.g. food processors), toys, telephones, car components, tool handles Polymers 1.3 What does Durability mean? If a material withstands wear and tear, weather and corrosion then the product is durable (long lasting). It usually is noticed by a change in appearance when it starts to wear out. Corrosion is the main area affecting durability and can often be overlooked which can have serious effects on structures such as bridges whose durability can be affected by rust. Ultra violet light can affect materials, particularly plastics which can become very brittle with the effects of the sun. In general though, plastics are less likely to corrode than most materials but strength is not usually associated with plastics. Polymers 1.3 What is a Thermosetting plastic? Once ‘set’ these plastics cannot be reheated to soften, shape and mould. The molecules of these plastics are cross linked in three dimensions which result in a rigid molecular structure. Thermosetting plastics will soften when heated for the first time. This allows them to be shaped, but because they are set in a rigid and permanently stiff molecular structure, they cannot be reheated and reshaped like thermoplastics. The bond between the molecules is very strong and therefore cannot be recycled. Polymers 1.3 Many adhesives (glues) are thermosetting plastics. A good example is ‘Araldite’ which is an epoxy resin that hardens when a second chemical is added (a catalyst). It will bond most materials including woods and metals as well as some plastics. Polyester Resin If resins are combined with a material such as fibre glass the result is a very tough material that can resist impact. This type of material is known as a glass reinforced plastic (GRP) and is used in car body repairs, sailing boats, corrugated sheet because of its lightness, toughness and resistance to water. Advantages Stiff, hard, good electrical insulator and cost effective Disadvantages Brittle unless laminated, short shelf life, emissions are harmful Uses Casting and encapsulation, bonding of other materials • Polymers 1.3 Urea Formaldehyde (UF) Urea Formaldehyde has physical properties of high hardness and high toughness, making it suitable for strong, knock-resistant electrical fittings. It is also scratch resistant and a very good electrical insulator, making electrical fittings manufactured from this polymer safe to use. Advantages Stiff, hard, strong and a good electrical insulator Disadvantages Brittle Uses Electrical fittings, handles and control knobs Polymers 1.3 What does Plasticity mean? Plasticity means the ability of a material to be changed in shape permanently. This diagram shows the ‘plasticity’ of molten aluminium by pouring it into a mould. Once the aluminium has cooled down, it can be removed from the casting sand. It has a new shape.