Soldering Training: Skills, Equipment, Safety & Quality

advertisement

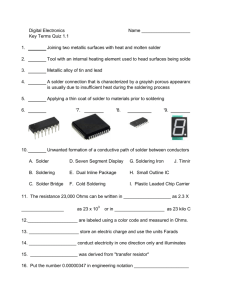

What you should know about soldering Be able to: http://www.youtube.com/watch?v=I_NU2ruzyc4&feature=player_embedded You should be able to clean PCBs and Parts You should be able to select the correct tip for a given spot size for the Paste dispenser You should be able to read the value of surface mount resistors You should be able to determine the value and polarity of a surface mount capacitor You should be able to select and place components: o Requires data sheets for all components o Requires temperature rating for all components o Requires a correctly labeled schematic o Requires a correctly labeled board layout You should know the melting temperature of Solder and Solder Paste You should be able to properly care for a soldering iron You should be able to clean the flux off the completed PCB You should be able to find and fix bad solder joints and solder bridges You should be able to put vias into boards and solder them You should be able to remove IC's from printed circuit boards using the IR and Hot Air Rework de-soldering stations without damaging the board or the component You should be able to use solder wick to remove solder from a PCB You should be able to describe in detail the process of inspecting, cleaning, then populating a PCB You should be able to apply flux to your PCB You should be able to care for the soldering iron tip You should be able to follow static protection precautions Be able to use vacuum tweezers Be able to list different types of solders and fluxes and what the differences between them are http://www.youtube.com/watch?v=3NN7UGWYmBY&feature=player_embedded http://www.youtube.com/watch?v=_5lksMvmqQc&feature=channel You should be able to safely operate the following equipment: o EFD 1000 Solder Paste Dispenser o Pick and Place o Microscopes o Weller WLC100 Soldering Iron o Hot air rework station o IR Rework Station Be able to state the hazards of lead-based solders and follow safety precautions Be able to look up an MSDS for all chemicals used in soldering Be able to explain what ROHS compliance is Example Quiz Questions What are some characteristics of a good soldering job and good solder joints? How is a via soldered? Should you solder both the top and bottom of all through-hole components? Explain your answer. Describe the process of surface-mount soldering. What is the biggest concern when de-soldering a component? Explain how you can heatsink a through-hole component while soldering to avoid frying the component. How do you know what the maximum temperature a component can withstand is? How do you measure the temperature of a component while you are soldering it? Explain how a solder joint should look after it is soldered. As the gauge of a wire increases, the allowable current through that wire ________. (increases/decreases) Why is a sponge necessary when soldering? What is ‘tinning’ and why is it necessary? Show how to place a solder rivet in a board for a via Explain the steps taken from receiving an unpopulated PCB to handing a populated board over to the next team. (Don’t forget cleaning and continuity). On the CN1501 Temperature Controller, which program is used for normal PCBs? What is the temperature profile for reflow soldering? What does each step do? What are the different types of flux and when would you use them? What do you do with a PCB after you have finished soldering it but before you use it? Explain ROHS. Useful web links How to Solder- a web page on proper soldering techniques from the UK Another soldering tutorial A complete on-line tutorial A primer about solder pastes from EFD EFD home page.