Lectures 3 and 4:

Engineering Design

C. Schaefer

Department of Electrical and Computer Engineering

George Mason University

Administrivia

• Web site URL for new students:

– http://mason.gmu.edu/~cschaef3/

• Semester Project

– Team assignments

– Design Brief

• Complete Intro to Design Process today

• Homework:

– Your choice of either: 3.3, 3.4, 3.5, or 3.10. Prepare a 1 – 2

page report on your findings.

– Homework due at the beginning of next class

Impromptu Design Projects

• Impromptu design teams will normally be no

larger than 4 students

• First Impromptu Design Project Today (see page

25 of the book)

• Next week’s Impromptu Design Project:

– Problem 3.11 in Chapter 3.

– Two minor differences:

• You will be provided 6 feet of aluminum foil

• The boat must fit within a 8” x 6” rectangle (no height

restriction)

• I will bring the pennies and the tub to test your designs.

• You will have 20 minutes to complete your boat so begin

thinking of a design

ENGR107 – Engineering Fundamentals

3

Outline

In this lecture we will

• Introduce you to the engineering design process

• Discuss the basic steps that most engineers follow

when designing a product

• Discuss the importance of considering

sustainability in design

Outline

• Introduce important design factors such as

Teamwork

Project scheduling

Material selection

Economic consideration

Engineering standards and codes

References

• Systems Engineering and Analysis, Second Edition, Benjamin

S. Blanchard and Wolter J. Fabrycky, Prentice Hall, 1990.

(This is the “bible” on systems engineering).

• Engineering: An Introduction to a Creative Profession, Fifth

Edition, George C. Beakley, Donovan L. Evans, John Bertrand

Keats, Macmillan Publishing Company, 1986.

What is Engineering Design?

• Engineering Design is a process of devising a

system, component, or process to meet a desired

need.

• It is a decision-making process, often iterative, in

which the basic sciences, mathematics, and

engineering sciences are applied to convert

resources to meet a stated objective.

• Structured problem-solving activity

Design Process – Basic Steps

Your book outlines these steps:

1. Recognizing the need for a product or a service

2. Problem definition and understanding

3. Research and preparation

4. Conceptualization

5. Synthesis

6. Evaluation

7. Optimization

8. Presentation

Analytic and Creative Problem Solving1

•

•

•

•

•

•

•

•

•

•

Identify the problem.

Define the working criteria or goals.

Research and gather data.

Brainstorm for creative ideas.

Analyze.

Develop models and test.

Make the decision.

Communicate and specify.

Implement and commercialize.

Prepare post-implementation review and assessment.

1Oakes,

et al

Contrast with Scientific Method

•

•

•

•

•

Define the problem.

Gather the facts.

Develop a hypothesis.

Perform a test.

Evaluate the results.

Notice that science is not overly concerned

with implementation, only knowledge

gathering.

Design Process – Basic Steps

Step 1: Recognizing the need for a product

or a service

Design Process – Basic Steps

Step 2: Problem definition and understanding

• This is the most important step in any design

process

• Before you move on to the next step

Make sure you understand the problem

Make sure that the problem is well defined

• Good problem solvers are those who first fully

understand what the problem is

Design Process – Basic Steps

Step 3: Research and preparation

• Collect useful information

Search to determine if a product already exists

Perhaps you could adopt or modify existing

components

Review and organize the information collected in a

suitable manner

Step 4: Conceptualization

Generate ideas or concepts that could offer reasonable

solutions to your problem

Design Process – Basic Steps

Step 5: Synthesis

• At this point you begin to consider details

• Perform calculations, run computer models, narrow

down the type of materials to be used, size the

components of the system, and answer questions

about how the product is going to be fabricated

• Consult pertinent codes and standards for compliance

Design Process – Basic Steps

Step 6: Evaluation

• Analyze the problem in more detail

• Identify critical design parameters

and consider their influence in your

final design

• Make sure that all calculations are

performed correctly

• Best solution must be identified

from alternatives

•

Details of design must be

worked out fully

Design Process – Basic Steps

Step 7: Optimization – minimization or maximization

• Optimization is based on some particular criterion such

as cost, strength, size, weight, reliability, noise, or

performance.

• Optimizing individual components of an engineering

system does not necessarily lead to an optimized

system

Design Process – Basic Steps

Step 8: Presentation

• You need to communicate your solution to the

client, who may be your boss, another group within

your company, or an outside customer

• Engineers are required to give oral and (written)

progress reports on a regular basis to various

groups; consequently, presentation could well be

an integral part of many other design steps

Flow Diagram for Design Process

Conceptual

Design

Preliminary

Design

Detailed

Design

Prototype

Design

Design

Evaluation

Design

optimization

Design

Evaluation

Design

Evaluation

Final

Design

Real-World Engineering Development Process?

Enthusiasm.

Disillusionment.

Panic.

Search for the guilty party.

Punishment of the innocent party.

Fame and honor for the non-participants.

Taken from: OMNI Magazine, July 1980.

Four Primary Phases of the System Life Cycle

Conceptual- Detail

Production

Preliminary Design and and/or

Design

Development Construction

LCC = Acquisition costs +

Product Use,

Phase out,

and Disposal

Sustaining Costs

Life Cycle Costs

20

Automobile LCC Fictional Costs

BMW 3-Series vs. Mercedes C-Class

Acquisition

Costs

Sustaining

Costs

Design Process – Basic Steps

An optimization

procedure

Example 3.1 – Optimization

Given:

To purchase storage tanks with a budget of $1680. Available floor

space is 90 ft2

Manufacturer A:

16 ft3 capacity @ $120 each, requires 7.5 ft2 floor space

Manufacturer B:

24 ft3 capacity @ $240 each, requires 10 ft2 floor space

Find:

Greatest storage capacity within the budgetary and floor-space

limitation

Example 3.1 – Optimization

Solution:

Let x1 = 16 ft3 capacity and x2 = 24 ft3 capacity. Then the

objective function Z we wish to maximize becomes

maximize Z = 16x1 + 24x2

Example 3.1 – Optimization

Region as given by linear

inequality

Feasible solution

Other Engineering Design Considerations

• Engineering economics

• Material selection

• Teamwork

• Conflicts Resolution

• Project scheduling and task chart

• Evaluating alternatives

• Patent, trademark, and copyright

• Engineering standards and codes

Engineering Economics

More in

Chapter

20

• Economic factors always play important roles in

engineering design decision making

• Products that are too expensive cannot be sold at a

price that consumers can afford and still be

profitable to the company

• Products must be designed to provide services not

only to make our lives better but also to make

profits for the manufacturer

Material Selection

• Selection of materials is an important design decision

• Examples of properties to consider when selecting materials

Density

Ultimate strength

Flexibility

Machinability

Durability

Thermal expansion

Electrical & thermal conductivity

Resistance to corrosion

Material Properties

• Material properties depend on many factors

How the material was processed

Its age

Its exact chemical composition

Any nonhomogenity or defect within the material

• Material properties change with temperature and time as the

material ages

• In practice, you use property values provided by the

manufacturer for design; textbook values are typical values

Material Properties

•

•

•

•

•

•

•

•

•

Electrical resistivity

Density

Modulus of Elasticity

Modulus of Rigidity

Tensile strength

Comprehensive strength

Modulus of resilience

Modulus of toughness

Strength-to-Weight ratio

© 2011 Cengage Learning Engineering. All Rights Reserved.

•

•

•

•

•

•

Thermal expansion

Thermal conductivity

Heat capacity

Viscosity

Vapor pressure

Bulk modulus of

compressibility

3-30

Teamwork

• Design team

a group of individuals with complementary

expertise, problem solving skills, and talent

who are working together to solve a problem

or achieve a common goal

• Employers are looking for individuals who not only

have a good grasp of engineering fundamentals

but who can also work well with others in a team

environment

Common Traits of Good Teams

Successful teams have the following components:

• The project that is assigned to a team must have

clear and realistic goals. These goals must be

understood and accepted by all members of the

team.

• The team should be made up of individuals with

complementary expertise, problem solving skills,

background, and talent.

• The team must have a good leader.

Common Traits of Good Teams

• The team leadership and the environment in

which discussions take place should promote

openness, respect, and honesty.

• The team goals and needs should come before

individual goals and needs.

Secondary Roles of Good Team Members

• The Organizer – experienced and confident; trusted by

members of the team and serves as a coordinator for

the entire project

• The Creator – good at coming up with new ideas,

sharing them with other team members, and letting

the team develop the ideas further

• The Gatherer – enthusiastic and good at obtaining

things, looking for possibilities, and developing

contacts

Secondary Roles of Good Team Members

• The Motivator – energetic, confident, and outgoing;

good at finding ways around obstacles

• The Evaluator – intelligent and capable of

understanding the complete scope of the project;

good at judging outcomes correctly

• The Team Worker – tries to get everyone to come

together, does not like friction or problems among

team members

Secondary Role of Good Team Members

• The Solver – reliable and decisive and can turn

concepts into practical solution

• The Finisher – can be counted on to finish his or

her assigned task on time; detail oriented and may

worry about the team’s progress toward finishing

the assignment

Other Factors Influencing Team Performance

• The way a company is organized

• How projects are assigned

• What resources are available to a team to perform

their tasks

• Corporate culture: whether openness, honesty,

and respect are promoted

Conflicts

When a group of people work together, conflicts

sometimes arise. Conflicts could be the result of

• Miscommunication

• Personality differences

• The way events and actions are interpreted by a

member of a team

Conflict Resolution

• Managing conflicts is an important part of a team

dynamic

• In managing conflicts, it is important to recognize

there are three types of people:

Accommodating

Compromising

Collaborative

Conflict Resolution – Type of People

• Accommodating team members - avoid conflicts

Allow assertive individuals to dominate

Making progress as a whole difficult

Could lead to poor team decision

Conflict Resolution – Type of People

• Compromising team members

Demonstrate moderate level of assertiveness

and cooperation. By compromising, the team

may have sacrificed the best solution for the

sake of group unity

Conflict Resolution

• Collaborative Conflict Resolution Approach

High level of assertiveness and cooperation by

the team

No finger pointing

Team proposes solutions

Means of evaluation

Combine solutions to reach an ideal solution

Project Scheduling and Task Chart

A process that engineering managers use to ensure that a project

is completed on time and within the allocated budget

Evaluating Alternatives

• When a design is

narrowed down to a few

workable concepts,

evaluation of these

concepts is needed

before detail design is

pursued

• Each design would have

its own evaluation

criteria

An Example of evaluation worksheet

Sustainability in Design

Sustainability and sustainable engineering can be

defined as

“design and development that meets the needs of

the present without compromising the ability of

future generations to meet their own needs.”

Sustainability in Design

• Engineers contribute to both private and public sectors of

our society

• In private sector, they design and produce the goods and

services that we use in our daily lives to allow us to enjoy a

high standard of living

• In public sector, they support local, state, and federal

mission such as meeting our infrastructure needs, energy

and food security, and national defense

Sustainability in Design

• Increasingly, because of worldwide socioeconomic trends,

environmental concerns, and earth’s finite resources, more is

expected of engineers

• Future engineers are expected to design and provide goods

and services that increase the standard of living and advance

health care, while addressing serious environmental and

sustainability concerns

• In designing products and services, engineers must consider

the link among earth’s finite resources, environmental, social,

ethical, technical, and economical factors

Summary

• You should know the basic design steps that all

engineers follow, regardless of their background, to

design products and services

• You should realize that economics plays an important

role in engineering decision making

• You should realize that the selection of material is an

important design decision

• You should be familiar with the common traits of good

teams

Sport Utility Vehicle (SUV)

Anti-Lock Braking System (ABS)

Identification of Problem

•

•

•

•

What is required?

What must be done and why?

Scope of problem – define problem

boundaries.

Example – Anti-lock Braking System

– Is it possible to successfully retrofit an ABS

developed for compact cars to heavier, sports

utility vehicles?

Research the Problem

• Can we decompose the problem into easily

managed subproblems?

• This step defines, for example;

– Literature review for similar problems and

solutions to those problems.

– Relevant analytical and modeling techniques.

– Testing requirements.

– Design constraints.

– Resource requirements and allocation.

– Project schedule.

Research – ABS Example

• Literature search; Internet search on ABS.

• Constraints (example);

– Retain compact car ABS system architecture.

– SUV ABS costs cannot exceed 110% of current compact car

ABS system cost.

– Time to market – 3 months.

– Performance criteria;

• SUV Total Time to Stop 15% increase over compact car.

• SUV Wheel Lock Skid Time 10% increase over compact car.

• Approach:

– Develop MATLAB model of ABS system.

– Parametric analysis using model.

– Modify system constants.

Solve the Problem

• Develop alternatives. For example;

– Hardware and software design alternatives.

– List of independent variables to vary in modeling or

simulation.

• Modeling

–

–

–

–

–

Conceptual models.

Physical models and engineering mockups.

Graphical models.

Mathematical models.

Computer models.

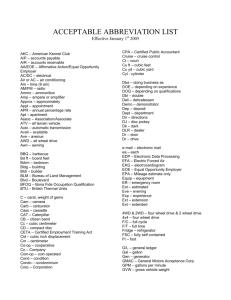

Decision Matrix

Alternative Solutions

Criteria

Weight

Ease of Ass 35%

Score

Functionality 25%

Score

Cost

25%

Score

Stability

15%

Score

Total Score 100%

1

2

4

5

140

5

175

125

6

150

7

105

520

4

6

8

200

8

280

8

5

150

200

7

125

3

9

45

570

Rating

R=9

200

7

175

9

135

670

Example

9 - 10'

7-8'

5 - 6'

3 - 4'

0 - 2'

280

8

200

6

5

8

210

8

Rating scale R

Excellent

Good

Fair

Poor

Unsatisfactory

3

9 W = 25

225 RxW

9x25 = 225

10

135

790

175

150

805

Solve the Problem

• Experimentation

– Computer simulation.

– Testing, for example;

• Ground tests.

• Flight testing.

• Synthesis

– Subproblem solutions are merged.

– E.g., manufacturing and engineering resolving

issues associated with manufacturability.

Solve Problem – ABS Example

• ABS hardware and system architecture fixed

with exception of interface to SUV.

• Control software can be modified.

• Matlab simulation.

• Skid pad testing to verify simulation results.

• Presentation of results to Product

Development Team.

ABS Braking Simulation Model

ABS Braking Model

100

0.2

1

TB.s+1

Desired

relative

slip

Bang-bang

controller

Kf

s

Brake

pressure

Hydraulic Lag

1/I

brake torque

Force &

torque

s

tire torque

ctrl

m*g/4

mu-slip

friction curve

Weight

slp

s

Vehicle

speed

Mux

yout

Vehicle speed

(angular)

1

-1/m

Wheel

Speed

1/Rr

Rr

Ff

1

STOP

1

s

Stopping distance

1.0 - u(1)/(u(2) + (u(2)==0)*eps)

Relative Slip

Double click to

run model and

plot the results

Developed by Larry Michaels

The MathWorks, Inc

Simulation Results

Vehicle speed and wheel speed

80

Vehicle Weight = 1600lbs

Hydraulic Lag – 0.01 sec

70

60

Vehicle speed (wv )

Speed(rad/sec)

50

40

30

20

Wheel speed (ww )

10

0

0

5

10

Time(secs)

15

Simulation Results

Vehicle speed and wheel speed

80

Vehicle Weight = 2900 lbs

Hydraulic Lag – 0.01 sec

70

60

Vehicle speed (wv )

Speed(rad/sec)

50

40

30

20

Wheel speed (ww )

10

0

0

2

4

6

8

10

Time(secs)

12

14

16

18

Simulation Results

Vehicle speed and wheel speed

80

Vehicle Weight = 2900 lbs

Hydraulic Lag – 0.03 sec

70

60

Vehicle speed ( w )

Speed(rad/sec)

v

50

40

30

20

Wheel speed ( w )

w

10

0

0

2

4

6

8

10

Time(secs)

12

14

16

18

Simulation Results

Vehicle speed and wheel speed

80

Vehicle Weight = 2900 lbs

Hydraulic Lag – 0.007 sec

70

60

Vehicle speed (wv )

Speed(rad/sec)

50

40

30

20

Wheel speed (ww )

10

0

0

2

4

6

8

Time(secs)

10

12

14

16

Presentation

Anti-Lock Braking System Simulation Results

Baseline

Vehicle

Weight

(lbs)

Hydraulic

System

Time

Constant

(sec)

Total

Time to

Stop

(sec)

Wheel

Lock Skid

Time (sec)

1600

2900

2900

2900

0.010

0.007

0.010

0.030

14.00

15.80

16.00

16.50

0.25

0.25

0.80

2.00

Best Solution

Testing - ABS

Presentation

Total Time to Stop (sec)

TTS vs. Hydraulic Time Constant

16.60

16.40

Wt = 2900 lbs

16.20

16.00

15.80

Is this relationship linear or

nonlinear?

15.60

15.40

0.007

0.010

0.030

Hydraulic System Time Constant (sec)

Presentation

Wheel Lock Skid

Time (sec)

Wheel Lock Skid Time vs. Hydraulic

Time Constant

2.50

2.00

Wt = 2900 lbs

1.50

1.00

0.50

0.00

0.007

0.010

0.030

Hydraulic System Time Constant (sec)

Results

• Performance Criteria Satisfied.

• Total Time to Stop

– Required – 15% increase over compact car.

– Actual – 12.8% increase.

• Wheel Skid Lock Time

– Required – 10% increase over compact car.

– Actual – 0% increase over compact car.

• Time to market – 1.5 months for S/W revisions.

• Cost – Less than a 2% increase.

Engineering Design

Questions?