Process Costs

advertisement

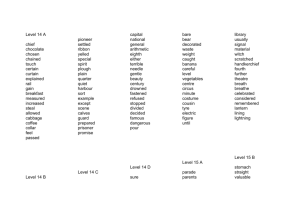

IENG 217 Cost Estimating for Engineers Estimating Operational Methods Cost estimating relationships Time estimating relationships Performance time data Cost Estimating Relationships Parameters Ca = -23.3 + 20(length) bar stock length ( 5 inches ) used in CER ( $76.70 ) is often called a parameter – it is not CER is actually a parametric equation Cost Estimating Relationship ( I x V x Cur / 1000 ) x 12 in./ ft. C pc S x 60 min / hr. x M where C pc power cost per foot I welding current, amperes V welding voltage Cur utility power cost, dollars per KWhr S travel speed of arc welding process,in. per minute M machine efficiency, percentage Cost Estimating Relationship Typical arc welder draws 200 amps for a 20 volt arc welding process. If we have a 10 in/min welding travel speed and a 95% machine efficiency, estimate the cost per foot of a weld if the utility costs are $0.08 per KWhr. Cost Estimating Relationship WWII military aircraft constructed of aluminum (regression; 10 contractors) F 0.001244 A1.160 S1.371 Q1D.281 where F flight test operations cost,(1970 base year ) A=weight without engines, fuel, pounds S=maximum airspeed, nautical miles / sec QD number of flight test airframes Performance Time Data Time Study Work Sampling Performance Time Data Alg. 1. 2. 3. 4. 5. 6. 7. 8. Collected several measurements from ops. Classify elements into common group Regress element time against one or more independent causal variables Determine if TER is constant or variable If TER is constant, determine value If TER is variable, convert to time table or eq. Collect all constant variable elements for operation If accuracy is acceptable, use information for estimating designs Constant or Variable ? 5 time measurements taken on a manual handling task Weight, lb. 1 3 4 5 7 Time, min. .15 .20 .30 .40 .50 Regression yields y 0.06 0.0625 x Constant or Variable ? Test 1 ymax ymin x 100 P1% ymin Test 2 yave x 100 P2 % yt yt total dependent value for x of operation elements Constant or Variable ? 5 time measurements taken on a manual handling task (test 1, P1 = 100%) Weight, lb. Time, min. yhat 1 3 4 5 7 .15 .20 .1225 .30 .40 .50 .4975 ymax ymin .4975 .1225 3.06 306% ymin .1225 Carriage / Support Assembly Regression Element Load Carriage Machine Carriage Unload Carriage Align to support Spot Weld Assem Unload / Store Parameter (xi) Carriage Length Carriage Length Support girth Support girth No. Welds Carriage Length a 0.20 1.20 0.40 0.15 0.15 0.30 b 0.08 0.20 0.04 0.10 0.12 0.02 Carriage / Support Assembly Element Load Carriage Machine Carriage Unload Carriage Align to support Spot Weld Assem Unload / Store xmin 5.00 23.00 7.00 5.30 12.40 6.80 xave 6.20 27.20 7.40 7.20 15.20 7.00 xmax 8.00 29.30 8.20 8.40 18.80 7.20 SUM = ymin 0.60 5.80 0.68 0.68 1.64 0.44 9.83 yave 0.70 6.64 0.70 0.87 1.97 0.44 11.32 ymax 0.84 7.06 0.73 0.99 2.41 0.44 12.47 Test 2 = .7/11.32 = 6.2% Carriage / Support Assembly Element Load Carriage Machine Carriage Unload Carriage Align to support Spot Weld Assem Unload / Store Test I Test II Conclusion Carriage / Support Assembly Element Load Carriage Machine Carriage Unload Carriage Align to support Spot Weld Assem Unload / Store Test I 40.0% 21.7% 7.1% 45.6% 46.9% 1.8% Test II 6.2% 58.7% 6.2% 7.7% 17.4% 3.9% Conclusion Var Var Const Var Var Const Carriage / Support Assembly Element Load Carriage Machine Carriage Unload Carriage Align to support Spot Weld Assem Unload / Store Test I 40.0% 21.7% 7.1% 45.6% 46.9% 1.8% Constant Elements Unload Carriage Unload / Store Total Time Std Time w/Allow Test II 6.2% 58.7% 6.2% 7.7% 17.4% 3.9% Conclusion Var Var Const Var Var Const Time 0.70 0.44 1.14 1.31