Minimizing Air Entrainment in High Pressure Die Casting Shot Sleeves

advertisement

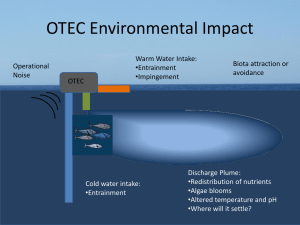

GIFA-Forum – 16.6.2015 Minimizing Air Entrainment in High Pressure Die Casting Shot Sleeves Using flow analysis software to optimize piston velocity M. Barkhudarov, Flow Science, Inc., USA R. Pirovano, XC Engineering, Italy Minimizing Air Entrainment in HPDC Shot Sleeves -1- GIFA-Forum – 16.6.2015 XC Engineering & Flow Science XC ENGINEERING FLOW SCIENCE •Italian society born in 2002 • Founded in 1980, by Dr. Tony Hirt who developed the Volume of Fluid (VOF) method for free-surface tracking at the Los Alamos National Laboratory • Commercial software FLOW-3D first released in 1985 • Develops and sells FLOW-3D, a highly-accurate computational fluid dynamics (CFD) software, with FLOW-3D Cast as an intuitive interface specifically for casting simulations • Offers high performance computing with parallel processing capabilities •Located in Cantù, Italy •Field of activity: virtual simulations and optimization with FLOW-3D®, FLOW-3D® CAST, Flownex IOSO Technology •Provides consultancies, trainings and technical support, as well as the reselling of the softwares Minimizing Air Entrainment in HPDC Shot Sleeves -2- GIFA-Forum – 16.6.2015 Introduction A challenge in HPDC is to achieve optimal conditions in the shot sleeve, controlling the speed of the plunger to: • Avoid unnecessary entrainment of air in the metal • Minimize heat losses in the sleeve Two different solutions to find the best piston velocity profile during the slow shot phase: • A general analytical 2D solution for the flow of metal in a shot sleeve • A numerical parametric optimization, in a fully 3D, viscous and turbulent environment Minimizing Air Entrainment in HPDC Shot Sleeves end of first phase -3- GIFA-Forum – 16.6.2015 First solution: ANALYTICAL METHOD Minimizing Air Entrainment in HPDC Shot Sleeves -4- GIFA-Forum – 16.6.2015 Analytical model • • General solution for the plunger speed as a function of time and of the maximum admitted surface slope Approximations: • The cylindrical shot sleeve is approximated with a channel of rectangular cross-section filled initially with liquid metal to the depth h0 (justified for initial fill fractions in the range of 40-60% [Lopez et al, 2003]) • Shallow water approximation [Lopes et al, 2000] (vertical direction is neglected, h<H) • The flow is modeled in two dimensions • Viscous forces are omitted Minimizing Air Entrainment in HPDC Shot Sleeves -5- GIFA-Forum – 16.6.2015 Analytical model • Location, metal speed and depth in a wave that separates from the surface of the plunger at time t=tp are given by [Lopes et al, 2000]: 3 x(t ) X (t p ) c 0 X ' (t p ) (t t p ) 2 u ( x, t ) X ' (t p ) 1 1 h( x, t ) gh0 X ' (t p ) g 2 2 c 0 gh0 • • The metal speed u, and depth h • In each wave are constant • They depend only on the time of the wave separation from the plunger, tp • They both increase with the speed of the plunger X’ First conclusion: to maintain a monotonic slope of the metal surface in the direction away from the plunger, the latter must not decelerate X ' ' (t ) 0 Minimizing Air Entrainment in HPDC Shot Sleeves -6- GIFA-Forum – 16.6.2015 Analytical model – Controlling the waves • Once a wave detaches from the plunger it travels at a constant speed given by: u c X ' (t p ) gh gh0 3 X ' (t p ) 2 • If the plunger accelerates, each successive wave will move faster: steepening of the surface slope and potentially overturning • Analysis of the evolution of the surface slope between two waves generated at the plunger at close instances, t2>t1, linearized with respect to Dt=t2-t1: 1 c0 X ' (t1 ) X ' ' (t1 ) dh h h 1 2 tan( ) 1 2 dx x1 x2 g c 1 X ' (t ) 3 X ' ' (t ) (t t ) 0 1 1 1 2 2 Minimizing Air Entrainment in HPDC Shot Sleeves -7- GIFA-Forum – 16.6.2015 Analytical model – Controlling the waves 1 c0 X ' (t1 ) X ' ' (t1 ) 1 2 tan( ) g c 1 X ' (t ) 3 X ' ' (t ) (t t ) 0 1 1 1 2 2 • • • If X’’(t1)=0 (costant speed) the slope of the free surface is horizontal If X’’(t1)>0, the slope increases with time When the denominator reaches zero, the slope becomes vertical Initial surface slope for a wave detaching from the plunger: Setting a maximum slope in a wave (when it reaches the end of the shot sleeve): min t t1 max x L t L t1 tan( min ) X ' ' (t1 ) g L X (t1 ) 3 c0 X ' (t1 ) 2 1 3 c0 X ' (t1 ) c0 X ' (t1 ) tan( max ) 2 2 X '' max (t1 ) 1 1 3 c0 X ' (t1 ) c0 X ' (t1 ) tan( max ) L X (t1 ) g 2 2 In this range: •the slope will not exceed the angle defined by αmax at any time, preventing wave overturning and the entrainment of air in the metal •the slope is directed away from the plunger, helping to direct the air into the runner system 0 X ' ' (t ) X '' max (t ) Minimizing Air Entrainment in HPDC Shot Sleeves -8- GIFA-Forum – 16.6.2015 Analytical model – Results • The equation is numerically integrated with respect to t1 using the initial values of the plunger location and speed at t=0: X(0)=0 and X’(0)=0, to obtain the solutions for X(t) and X’(t) • The integration was done for a shot cylinder of length L=0.7 m and height of H=0.1 m and the initial fill fraction of 40%, i.e., h0=0.04 m • An additional constraint of the plunger velocity can be added not to exceed the critical velocity at which the metal surface reaches the ceiling of the channel at h=H [Garber, 1982]: it can be derived from the solution for the metal depth h(t,x) [Tszeng and Chu, 1994]: X cr' 2 gH gh0 Solutions of the equations for the plunger position (a), acceleration (b), velocity (c) and velocity as a function of distance along the length of the shot channel (d), at different maximum surface slopes max: 1 – 90°, 2 – 60°, 3 – 45°, 4 – 30°, 5 – 15° and 6 – 5°. The horizontal dashed lines on plots c and d represent the critical plunger velocity Minimizing Air Entrainment in HPDC Shot Sleeves -9- GIFA-Forum – 16.6.2015 Analytical model – Validation Realistic conditions are used: • Viscous flow and circular channel cross-section • L=0.7m, D=0.1m, h0=0.04m (as before) • Velocity of the plunger function of time, from the solution for max=5° • Heat transfer and solidification are not included (negligible) Several aspects match the analytical solution: • The slope of the wave largely stays within the 5° limit • The circular shape does not affect much the free surface in the transverse direction • The metal touches the top of the channel at t=1.37s (th. 1.35s) • The velocity of the plunger at that time is 0.725 m/s (th. 0.73m/s) • The first wave arrives at x=L at t=1.15s (th. 1.12s) Differences in the two solutions: • A viscous boundary layer develops at the bottom of the shot sleeve • The flow near the free surface moves faster than the metal below it, resulting in a sort of a surge wave (larger than 5°) • There is a reflection of the wave around 1.3 sec, and as a result air may be entrained in the last stages of the process Minimizing Air Entrainment in HPDC Shot Sleeves - 10 - GIFA-Forum – 16.6.2015 Second solution: NUMERICAL OPTIMIZATION Minimizing Air Entrainment in HPDC Shot Sleeves - 11 - GIFA-Forum – 16.6.2015 Numerical optimization To overcome the limits of the analytical theory, it’s possible to perform a numerical optimization in order to find the best piston velocity curve in a fully 3D and realistical environment Coupling between IOSO and FLOW-3D • FLOW-3D is one of the best software for this kind of analysis, because of its capabilities to track fastly and accurately the free surface of the fluid, to evaluate the amount of air entrained and to manage moving objects coupled with the fluid • IOSO is an optimization software able to interact with several software packages in order to run simulations, obtain data and find the optimal configuration in the lowest number of iterations, managing several parameters and objectives. Minimizing Air Entrainment in HPDC Shot Sleeves - 12 - GIFA-Forum – 16.6.2015 Numerical optimization - Optimization parameters The parameters are based on a standard Buhler machines: • • Up to 20 points (for 1° and 2° phase) of “velocity” vs “run length” can be setup A linear interpolation is adopted betweeen one point and another one. 2 1.6 1.2 Usually, for 1° phase, 5-6 points are used 0.8 10 design parameters: 6 velocities + 4 run lengths 0.4 To fix an upper limit for the velocity and to prevent from “reversed” initial run lengths (ex.: 3° length < 2° length) the design variables are defined as ratios of some quantity: • velocity = ratio * velMax (0.0<ratio<1.0) • run length = ratio * remaining length (0.0<ratio<1.0) 0 0 50 100 150 200 Minimizing Air Entrainment in HPDC Shot Sleeves 250 300 350 - 13 - 400 450 500 GIFA-Forum – 16.6.2015 Numerical optimization - Optimization results 2 Objectives: find the fastest first phase (minimize simulation time), but not so fast to entrain air and bubbles (minimize “air entrainment”) Minimizing Air Entrainment in HPDC Shot Sleeves - 14 - GIFA-Forum – 16.6.2015 Numerical optimization - Optimization results 2 Objectives: find the fastest first phase (minimize simulation time), but not so fast to entrain air and bubbles (minimize “air entrainment”) Minimizing Air Entrainment in HPDC Shot Sleeves - 15 - GIFA-Forum – 16.6.2015 Numerical optimization - Optimization results (air entrained minimized) Velocity magnitude Entrained air Minimizing Air Entrainment in HPDC Shot Sleeves - 16 - GIFA-Forum – 16.6.2015 Numerical optimization - Optimization results (air entrained minimized) Minimizing Air Entrainment in HPDC Shot Sleeves - 17 - GIFA-Forum – 16.6.2015 Numerical optimization - Results compared to theory Similarities: Minimizing Air Entrainment in HPDC Shot Sleeves 1. The initial acceleration of the plunger from t=0 to about t=0.6 are similar 2. The leveling off of acceleration happens almost at the same time. 3. The constant critical velocity in theory and the part where it stays constant until the end, after metal reaches the ceiling is somewhat arbitrary - 18 - GIFA-Forum – 16.6.2015 Conclusions and future developments • The analytical method calculates a good acceleration curve, that conservatively minimize in most of the cases the amount of air entrained (this method is actually implemented as a simple calculator in FLOW-3D) • With a numerical optimization it’s possible to determine a more accurate curve, that optimize more than one objective simultaneously • This kind of technology can be extended to different analysis: • Switching time to the second phase • Optimization of the geometry of the feeding and gating system in order to obtain a uniform filling • Waves generated by the filling of the cylinder Minimizing Air Entrainment in HPDC Shot Sleeves - 19 - GIFA-Forum – 16.6.2015 Thank you for your attention M. Barkhudarov, R. Pirovano Minimizing Air Entrainment in HPDC Shot Sleeves - 20 -