Module 1-D Intermodal

advertisement

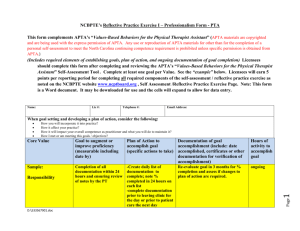

Module 1-D Railway Intermodal Transportation © APTA and AREMA - 2015 What is “Intermodal”? • Passenger • A journey that involves two or more transportation modes between origin and destination • People self-transfer between modes at a connection point • Freight • A shipment that uses two or more transportation modes between origin and destination • Bulk: single cargo transloaded from one mode to another • Unitized: Package transferred from one mode to another • Must physically move cargo between modes at a terminal • Unitized (container or trailer) intermodal drives growth © APTA and AREMA - 2015 2 Rail Passenger Intermodalism • Rail serves some portion(s) of trip • Intercity (passenger rail) • Suburban (commuter rail, rail rapid transit) • Urban (rail rapid transit, light rail transit, streetcar) • Most rail travel is intermodal when door-door trip is considered • Intermodal connections are an important factor for traveler using rail modes • Rail must connect at station/stop locations © APTA and AREMA - 2015 3 Potential Connecting Modes • Pedestrian • Personal bicycle • Bikeshare service • Personal motor vehicle • Traveler driven • Chauffeured • Taxicab • Rental car • Transit bus • Airliner • Ferry • Intercity rail* • Light rail/streetcar* • Rail rapid transit* • People mover • Chairlift • Personal rapid transit *Involved in rail-rail connection © APTA and AREMA - 2015 4 Traveler Choice of Passenger Rail • Traveler generally has multiple options for trip • Desirability of rail use in trip depends upon: • • • • • • • • Nature of trip Traveler characteristics Travel time for rail portion(s) of trip Cost for rail portion(s) of trip Existence of connections between rail and other modes Time required to make connection Physical ease of transfer to/from rail Seamlessness of transfer to/from rail • Facilitating intermodal connections helps build rail market share © APTA and AREMA - 2015 5 Aspects of Connectivity • Physical • Can we transfer from one mode to the other? • Temporal • Is the timing of the transfer process convenient? • Cognitive • Can we easily figure out how to make the transfer? • Transactional • Can we seamlessly conduct the transfer transaction? • Comfort, Safety, and Security • Do we perceive the transfer as comfortable and safe? • Reliability • Can we effect the transfer dependably? © APTA and AREMA - 2015 6 Direct Physical • Rail serves common station or point with other modes. • Transfer requires a short walk. • Rail mode may also accommodate personal vehicle (e.g., bicycle, ATV, snowmobile, auto) with passenger © APTA and AREMA - 2015 7 Indirect Physical • AirTrain links facilities at Newark Liberty International Airport with the nearby Northeast Corridor rail line. • Passengers can easily transfer between airlines and rail services offered by Amtrak and New Jersey Transit. • AirTrain also connects with airport parking, hotel shuttles, and car rental services. • AirTrain operates 24/7/365 and has 3-minute headways during peak hours. • Fare ($5.50) is included in the rail ticket price. © APTA and AREMA - 2015 8 Temporal • Services connected should have sufficient temporal separation to permit transfer • Temporal separation should not unduly lengthen trip time • Traveler’s desired trip start and end times, trip purpose are a factor • Travelers benefit from ease in obtaining schedule information for each participating mode © APTA and AREMA - 2015 9 Cognitive • Can the traveler easily understand how to make the transfer? • During pre-trip planning • When making the transfer • Maps and signing in stations are important aids to the unfamiliar traveler • Most important in large facilities • Facility performance can degrade when connecting passengers are poorly informed or confused © APTA and AREMA - 2015 10 Other Aspects • Transactional • Traveler should be able to easily purchase intermodal trip • Seamless trip purchase/reservation would be ideal (“virtual travel agent”) • Single ticketing also a good goal • Comfort, safety and security • Must provide traveler with reassurance of these items • Rail sometimes has a negative connotation in one or more areas • Reliability • Traveler will avoid rail service perceived to be unreliable • Real-time data helps traveler deal with disruptions • Transaction system should help rebook if trains cancelled or late © APTA and AREMA - 2015 11 Intermodal Freight Operations • Railroad intermodal transportation is typically described as either: • Trailer on flatcar (TOFC) • Container on flatcar (COFC) • Intermodal is a seamless service marketed by railroad, motor carrier, steamship line, or third party • Roles of modes • • • • Motor carriers perform pick-up and delivery Railroads perform land-side line-haul Steamship lines perform intercontinental movement Barge may also play a role in domestic service • Terminal facilities provided by port, steamship line, railroad, customer, or third party © APTA and AREMA - 2015 12 Intermodal Activities © APTA and AREMA - 2015 13 Intermodal Truck/Rail Comparison Truck Source: BNSF Railway Intermodal Train Unit of Shipment 1 truckload 1 train (250 truckloads) Labor (2000 mile trip) 1 person 26 people (1 train) Frequency of Service Daily / Hourly Daily (if volume warrants) Often less than daily Annual Volume Required for Daily Service 365 91,250 Transit Mile/day: 500 Average MPH: 50 Operates: 10 hrs/day Mile/day: 500 Average MPH: 21 Operates: 24 hrs/day Route Infrastructure Unlimited use of Federal and State road system Use of privately owned rail network with limited use of alternate networks Route Options Virtually unlimited: many route options between origin and destination Normally just one viable route between origin and destination © APTA and AREMA - 2015 14 Rail Intermodal Freight Traffic Milestones • Railroads begin offering TOFC service in the early 1950s • many small, non-mechanized terminals • service in general freight trains • 1955-Railroads create Trailer Train Corporation (now TTX) to manage intermodal railcar pool • 1968-1970: ISO standards for containers published • 1976: Railroad Revitalization and Regulatory Reform Act sets path for deregulation of rail container traffic • 1977: first double stack rail car introduced • 1980: Staggers Rail Act further deregulates rail container traffic • 1980s: Global trade propels container traffic growth • 2000s: Trucking companies popularize domestic use of COFC © APTA and AREMA - 2015 15 Growth of Rail Intermodalism Annual Intermodal Volumes (Sources: AAR & IANA) 16000000 14000000 Units 12000000 10000000 8000000 6000000 4000000 2000000 0 1975 1980 1985 1990 1995 2000 2005 2010 2015 Year The economic recession affected recent intermodal trends, in common with all freight movement. © APTA and AREMA - 2015 16 US Rail Intermodal Flows in Tons-2011 Source, U.S. FHWA • Rail lines serve as a “land bridge” for Pacific rim goods destined for the east coast and Europe © APTA and AREMA - 2015 17 Intermodal Containers • Allow unitized movement of goods • Domestic and international versions • Configurations include box, tank, flatbed • Stackable • Dimensions • length • 20 ft, 40 ft, 45 ft for international use • 48 ft, 53 ft for domestic use • width: 96″ international, 102″ domestic • height: 4 ft, 8 ft, 8.5 ft, 9.5 ft © APTA and AREMA - 2015 18 © Sea Box, Inc. Graphics © Sea Box, Inc. © APTA and AREMA - 2015 19 Intermodal Trailers • Common lengths are 28 ft, 48 ft, 53 ft; width is 102″ max. • 80,000 lb GVW with tractor • Modified construction to withstand railroad service loads • reinforced doors • lift rails • All configurations used; dry van and refrigerator most common © APTA and AREMA - 2015 20 Railcars • Flatcar • • • • Traditional car with deck May be outfitted for TOFC or single stack COFC 89’ length permits two marine containers Some are semi-permanently connected • Spine car • • • • Lightweight design without full deck May be outfitted for TOFC or single stack COFC Often combined into permanently connected units (3, 5, or 10) Each unit handles a single trailer or container • Well car • • • • Lightweight design without deck Designed to provide clearance with double stacked containers Some can handle trailers in well Often combined into permanently connected units (3 or 5) © APTA and AREMA - 2015 21 Maxi-Stack IV Double-Stack Car • Articulated 3-platform design optimizes balance between tare weight and cargo weight • Container sizes • Well: 20 to 53 ft containers • Upper: 40 to 57 ft containers • Platform load limit: 116,800 pounds © APTA and AREMA - 2015 22 Loading Equipment Gantry crane (upper left) • transfer only • 25–50 ton lift capacity • span 32-76 ft • 5-8 container lift height 2) Straddle loader (upper right) • transfer/storage • 50 ton capacity • span 15-20 feet • 2-5 container lift height 3) Side loader (lower right) • transfer/storage • 22–45 ton lift capacity • 2-3 container lift height © APTA and AREMA - 2015 23 Carless Technologies The RoadRailer® may be handled over the highway like any conventional semitrailer © APTA and AREMA - 2015 24 Or coupled in trains of up to 150 trailers Coupler Mate Bogie © APTA and AREMA - 2015 25 1. Hostler trailer positions trailer. 2. Trailer air suspension lifts rear of trailer, tractor backs trailer onto rail bogie. 3. Trailer air suspension is vented. Steel coil springs lift tires clear of rail. 4. Tractor backs trailer to coupling with balance of train. 5. Tractor leaves leading trailer on landing gear. Air lines are connected and landing gear is raised on second trailer. 6. Rail locomotive backs CouplerMate® to trailer. Air lines are connected and landing gear is raised on all trailers. Source: Wabash National Corporation © APTA and AREMA - 2015 26 Freight Intermodal Terminal Elements • Provision for loading/unloading railcars • Box storage (long term or temporary) • Vehicle storage (railcars/trailers/chassis) • Check-in/check-out control • Vehicle and box servicing/repair • Security and lighting • Office and administration • Information systems • Vehicle scales © APTA and AREMA - 2015 27 Major U.S. Intermodal Terminals © APTA and AREMA - 2015 28 Terminal Categories • Low volume (<100,000 annual lifts) • • • • • side loader operation rail loading tracks of 500-1000 ft length 110 feet separation between tracks separate parking areas for road vehicles one way highway traffic circulation • Medium volume (100,000-500,000 annual lifts) • rail loading tracks 1,000-3,000 ft stubbed or flow-through • side loader or straddle loader operation • High volume (>500,000 annual lifts) • rail unloading tracks 3,000 to 8,000 ft, flow through preferred • straddle loader or gantry operation • In all cases, a linear design is preferable © APTA and AREMA - 2015 29 Selected Recent Terminal Projects Cost (M) Annual Size Opened capacity, lifts (acres) Parking Company Location State UP Rochelle IL CSX Chambersburg PA UP Joliet IL $ 370.0 2010 CSX North Baltimore OH $ 175.0 NS McCalla AL $ NS Rossville TN NS Greencastle BNSF $ 181.0 1200 N/A 85 N/A 500000 785 3400 2011 630000 500 4000 97.5 2012 N/A $ 112.0 2012 N/A 316 2200 PA $ 97.0 2013 N/A 200 670 Edgerton KS $ 250.0 2013 500000 433 1810 NS Charlotte NC $ 92.0 2014 200000 200 N/A UP Santa Teresa NM $ 400.0 2014 225000 300 N/A CSX Winter Haven FL $ 100.0 2014 300000 318 N/A N/A 2003 720000 2007 N/A © APTA and AREMA - 2015 Remarks Not presently reachable by doublestacks On 3900 acre dist. park site; 1.2M lifts/yr at buildout 5 RMG cranes; 2000 acres available for dist. Park; 2M containers/yr handled at buildout Birmingham area $52.5M federal share; Memphis area $45M Pennsylvania share 600 acres available in Logistics Park; 5 gantry cranes; 4300 stacking spots; $35 million from state of Kansas; 1.5M lifts/yr at buildout $15.7M federal share Cost includes crew and refueling facilities; Total acres 2200 2-10000 ft arrv/dpt tracks; 3 RMG cranes; 932 acres avail for dist. Park 30 Roberts Bank, BC Marine Terminal Container storage 8 rail tracks @3,500 ft Truck gates (14 lanes) Access road Area: 210 acres Marine berths: 3 (3,609 ft) Daily truck trips: 1,800 Other trips: 2,100 Annual TEU capacity: 900,000 Ground storage: 41,250 TEUs 10 Post Panamax gantry cranes Marine berths (52 ft depth) Image from GoogleEarth © APTA and AREMA - 2015 31 Marion, AR Intermodal Terminal Union Pacific Mainline Storage Tracks (8) Ramp Tracks (4) Annual box capacity: 375,000 Ground storage: 2,600 boxes Ramp track capacity: 326 cars Storage track capacity: 748 cars Length shown ≈ 2 mi Parcel width ≈ 960 ft Access Road Truck Gates 8 lanes Image from GoogleEarth © APTA and AREMA - 2015 32 Future Issues for Intermodal Freight • Improving the railroad system • adding capacity to handle more business • matching truck service characteristics • increasing efficiency of intermodal equipment • Funding needed improvements • private sector • public sector • public-private partnerships • Developing a short-haul intermodal system • currently, intermodal is competitive for shipments >750 mi • 88% of truck trips are 500 mi or less • rail has a small overall market share © APTA and AREMA - 2015 33 Intermodal Trains and Railway Infrastructure • Intermodal trains must be service competitive with trucks • maximum speeds of 50-70 mph typical; such speeds • consume track capacity • require appropriate control system • require high train power/weight ratio • require higher track and alignment standards • schedule requirements provide operating challenge • Train lengths to 7,500 ft routine; may reach 10,000 ft if conditions permit • adequate passing siding length needed on single track lines • multiple main track provides better capacity and operational flexibility, at higher cost • careful terminal design needed to avoid conflict with mainline operations • Double stack trains need adequate clearances (20’ 3” min) © APTA and AREMA - 2015 34 Intermodal Corridors Meridian Speedway Crescent Heartland Terminal location Proposed terminal Norfolk Greensboro Birmingham Charleston Macon Savannah Shreveport Jacksonville New Orleans © APTA and AREMA - 2015 35 Copyright Restrictions and Disclaimer Presentation Author David B. Clarke Director Center for Transportation Research University of Tennessee, Knoxville 600 Henley Street, Suite 309 Knoxville, TN 37901 865-974-1812 dclarke@utk.edu It is the author’s intention that the information contained in this file be used for non-commercial, educational purposes with as few restrictions as possible. However, there are some necessary constraints on its use as described below. The materials used in this file have come from a variety of sources and have been assembled here for personal use by the author for educational purposes. The copyright for some of the images and graphics used in this presentation may be held by others. Users may not change or delete any author attribution, copyright notice, trademark or other legend. Users of this material may not further reproduce this material without permission from the copyright owner. It is the responsibility of the user to obtain such permissions as necessary. You may not, without prior consent from the copyright owner, modify, copy, publish, display, transmit, adapt or in any way exploit the content of this file. Additional restrictions may apply to specific images or graphics as indicated herein. The contents of this file are provided on an "as is" basis and without warranties of any kind, either express or implied. The author makes no warranties or representations, including any warranties of title, noninfringement of copyright or other rights, nor does the author make any warranties or representation regarding the correctness, accuracy or reliability of the content or other material in the file. © APTA and AREMA - 2015 36