15.2 Single - Factor (One - Way) Analysis of Variance : Independent

Processes and

Technologies

Process (Definition of)

Process: Any part of an organization that takes inputs and transforms them into outputs

Process Flowcharting (definition of)

• Process flowcharting is the use of a diagram to present the major elements of a process

• The basic elements can include tasks or operations, flows of materials or customers, decision points and storage areas or queues

• It is an ideal methodology by which to begin analyzing a process

Flowchart Symbols (1 of 2)

Tasks or operations Examples: Giving an admission ticket to a customer, installing an engine in a car, etc.

Decision Points Examples: How much change should be offered to a customer, which tool should be used, etc.

Flowchart Symbols (2 of 2)

Storage areas or queues

Examples: Sheds, lines of people waiting for a service, etc.

Flows of materials or customers

Examples: Customers moving to a seat, mechanic getting a tool, etc.

Example 2: Flowchart for Inspection

Process

Material

Received from

Supplier

Inspect

Material for

Defects Defects found?

No ,

Continue…

Yes

Return to

Supplier for

Credit

Process Terminology (1 of 2)

Single-stage Process

Stage 1

Multi-stage Process

Stage 1 Stage 2 Stage 3

Process Terminology (2 of 2)

A buffer refers to a storage area between stages where the output of a stage is placed prior to being used in a downstream stage.

Allows stages to operate independently

Multi-stage Process with Buffer

Buffer

Stage 1 Stage 2

Process Planning

Process selection

Make-or-buy decisions

Specific equipment selection

Process plans

Process analysis

Process Selection

Process Selection: Deciding on the way production of goods or services will be organized

Process selection can involve substantial investment in

Equipment

Layout of facilities

Major Implications of Process Selection

• Capacity planning

• Layout of facilities

• Equipment

• Design of work systems

To Accompany Russell and Taylor, Operations Management, 4th Edition, 2003 Prentice-Hall, Inc. All rights reserved.

Factors that Affect Process

Decisions

Required Variety,

Required Volume (how many)

Required Flexibility (degree of)

Process Strategy

Overall approach to produce goods and services

Defines:

Capital intensity

Process flexibility

Vertical integration

Customer involvement

Process Selection and System

Design

Forecasting

Capacity

Planning

Facilities and

Equipment

Product and

Service Design

Layout

Technological

Change

Process

Selection Work

Design

From Function to Process

Function

Product Development

Order Fulfillment

Supply Chain Management

Customer Service

Process

Process Selection

• Variety

– How much

• Flexibility

– What degree

• Volume

– Expected output

Job Shop

Batch

Repetitive

Continuous

Types of Processes

(Process Flow Structures)

Projects

Job shop

Batch production

Mass production

Continuous flow production

Types of Processes (1 of 2)

Determine how to produce a product or provide a service

Projects (nonroutine jobs)

Job shop

Small scale (e.g. copy center making a single copy of a student term paper)

Batch

Moderate volume (e.g. copy center making 10,000 copies of an ad piece for a business)

Types of Processes (2 of 2)

Repetitive- Mass production/assembly

High volumes of standardized goods or services

(e.g. Automobile manufacturer)

Continuous Flow Line

Very high volumes of non-discrete goods (eg.

Petroleum manufacturer)

Product and Service Processes

Process

Type

Job Shop Ineffective Appliance repair

Emergency room

Batch Commercial baking

Classroom

Lecture

Repetitive Automotive assembly

Automatic carwash

Continuous

(flow)

Ineffective Steel

Production

Water purification

Process-Focused Strategy Examples

© 1995 Corel Corp.

Machine

Shop

Hospital

© 1995

Corel

Corp.

Bank

© 1995 Corel Corp.

Repetitive-Focused Strategy - Examples

© 1995 Corel Corp.

Clothes

Dryer

Truck

McDonald’s over 95 billion served

Fast

Food

© 1984-1994 T/Maker Co.

© 1995 Corel Corp.

Product-Focused Examples

Paper (Continuous)

© 1984-1994 T/Maker Co.

Product – Process Matrix

Dimension Job shop

Job variety Very High

Process flexibility

Very High

Unit cost

Volume of output

Very High

Very Low

Batch

Moderate

Moderate

Moderate

Low

Repetitive

Low

Low

Low

High

Continuous

Very low

Very low

Very low

Very High

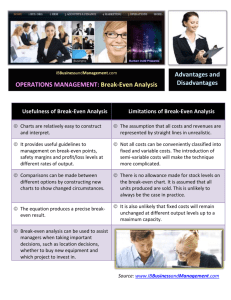

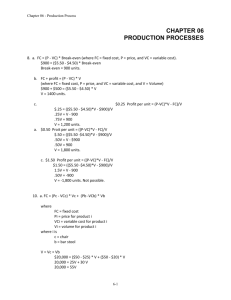

Process Selection with Break-even

Analysis

A standard approach to choosing among alternative processes or equipment

Model seek to determine the point in units produced (and sold) where we will start making profit on the process or equipment

Model seeks to determine the point in units produced (and sold) where total revenue and total cost are equal

Process Selection with

Break-Even Analysis

Total cost = fixed cost + total variable cost

TC = c f

+ vc v

Total revenue = volume x price

TR = vp

Profit = total revenue - total cost

Z = TR - TC

= vp - ( c f

+ vc v

) c f

= fixed cost v = volume (i.e., number of units produced and sold) c v

= variable cost per unit p = price per unit

Solving for

Break-Even Volume

TR = TC vp = c f vp vc v

= c f v ( p - c v

) = c f

+ vc v v = c f p c v

Break-Even Analysis: Example 1

Fixed cost = c f

Variable cost = c v

= $2,000

= $5 per raft

Price = p = $10 per raft

The break-even point is v = c f p c v

2000

= = 400 rafts

10 - 5

Break-Even Analysis: Example 1

$3,000

—

$2,000 —

$1,000

—

Total cost line

Total revenue line

400

Break-even point

Units

Break-Even Analysis: Example 2

Choosing Between Two Processes

Process A Process B

$ 2,000 + $5 v = $10,000 + $2 v

$3 v = $8,000 v = 2,667 rafts

Below 2,667, choose A

Above 2,667, choose B

Break-Even Analysis: Example 2

Choosing Between Two Processes

$20,000 — Total cost of process A

Total cost of process B $15,000 —

$10,000

—

$5,000

—

Choose process A

Choose process B

|

1000

|

2000

|

3000

|

4000 Units

Point of indifference = 2,667 Units

$

Choosing Between Three Processes

Fixed cost Variable cost

$ $

$

400,000

300,000

200,000

Process A Process B Process C

V

1

(2,857) V

2

(6,666)

Fixed cost –

Process A

Volume

Fixed cost –

Process B

Fixed cost –

Process C

Make-or-Buy Decisions

1.

Cost

2. Available Capacity

3. Quality Considerations

4. Speed

5. Reliability

6. Expertise

7. Nature of Demand

Make?

Buy?

Specific Equipment Selection

1. Purchase cost

2. Operating cost

3. Annual savings

4. Revenue enhancement

5. Replacement analysis

6. Risk and uncertainty

7. Piecemeal analysis

8. Breakeven analysis

Transition From Product Design to

Process Design:

Product and Production Documents

Product Documents

• Engineering drawings

– Shows dimensions, tolerances, & materials

– Shows codes for Group Technology

• Assembly drawing

-- Shows exploded view of product

• Bill of Material

– Lists components, quantities & where used

– Shows product structure

Engineering Drawings - Show

Dimensions, Tolerances, etc.

Head

Assembly Drawing

Neck

End

Cap

Handle

Bill of Material Example

Bill of Material

P/N: 1000 Name: Bicycle

P/N Desc Qty Units Level

1001 Handle Bars 1 Each 1

1002 Frame Assy 1 Each 1

1003

1004

Wheels

Frame

2

1

Each

Each

2

2

Assembly Chart (Gozinto Chart)

Bottom bun

Beef patty

Salt

Cheese

Lettuce

Sauce

Onions

Middle bun

Beef patty

Salt

Cheese

Lettuce

Sauce

Onions

Pickles

Sesame seed top bun

Wrapper

SA

SA

First-layer assembly

Second-layer assembly

Completed Big Mac

Assembly Drawing and Assembly

Chart

Process Analysis

The systematic examination of all aspects of a process to improve its operation to make it:

Faster

More efficient

Less costly

More responsive

Basic tools

Process flowchart

Process diagrams

Process maps

Process Flowchart Symbols

Operations

Inspection

Transportation

Delay

Storage

Process Flowchart: Example 1

SUBJECT: Request tool purchase

Dist (ft) Time (min) Symbol

75

Description

D

Write order

D

On desk

D

To buyer

D

Examine

= Operation; = Transport; = Inspect;

D = Delay; = Storage

Process Flow Chart: Example 2: Hamburger Assembly

Dist.

(Ft)

1.5

Time

(Mins)

-

.05

Chart

Symbols

Process Description

Meat Patty in Storage

Transfer to Broiler

1.0

.5

.5

3.5

2.50

.05

.05

.15

.10

.20

.05

3.15

Broiler

Visual Inspection

Transfer to Rack

Temporary Storage

Obtain Buns, Lettuce, etc.

Assemble Order

Place in Finish Rack

TOTALS

(2.50+.20)/3.15=85.7%

Process Flowchart: Example 3

Date: 9-30-02

Analyst: TLR

Location: Graves Mountain

Process: Apple Sauce

Description of process

3

4

5

1

2

6

7

8

9

10

11

Page 1 0f 3

Unload apples from truck

Move to inspection station

Weigh, inspect, sort

Move to storage

Wait until needed

Move to peeler

Apples peeled and cored

Soak in water until needed

Place in conveyor

Move to mixing area

Weigh, inspect, sort

Total

20

30

360

15

20

5

30

480

100 ft

50

20

20 ft ft ft

190 ft

Service Process Design

Techniques for Improving Service

Productivity (1 of 2)

Strategy Technique

• Separation

• Self-service

• Structure service so customers must go where service is offered

• Self-service so customers examine, compare and evaluate at their own pace

• Postponement

• Customizing at delivery

• Focus

• Restricting the offerings

Techniques for Improving Service

Productivity (2 of 2)

• Modules

• Automation

• Scheduling

• Training

• Modular selection of service.

Modular production

• Separating services that lend themselves to automation

• Precise personnel scheduling

• Clarifying the service options

• Explaining problems

• Improving employee flexibility

More Opportunities to Improve

Service Processes

Methods

Layout

Human Resource

Technology

Technologies

Technology

Technology: The application of scientific discoveries to the development and improvement of products and services and operations processes.

Technology innovation: The discovery and development of new or improved products, services, or processes for producing or providing them.

Kinds of Technology

Operations management is primarily concerned with three kinds of technology:

Product and service technology

Process technology

Information technology

All three have a major impact on:

Costs

Productivity

Competitiveness

Technology as a Competitive

Advantage

Innovations in

Products and services

Cell phones

PDAs

Wireless computing

Processing technology

Increasing productivity

Increasing quality

Lowering costs

Eases flexibility

Technology Acquisition

Technology can have benefits but …

Technology risks include:

What technology will and will not do

Technical issues

Economic issues

Initial costs, space, cash flow, maintenance

Consultants and/or skilled employees

Integration cost, time resources

Training, safety, job loss

Advantages Created by

HighTechnology

Advantages:

Increased precision

Increased productivity

Increased flexibility, increased product variety

Decreased cost (labor, material, inventory, transportation and quality costs)

Improved product features and quality

Decreased pollution

Decreased size

Decreased power requirements.

Information Technology

Management Information Systems (MIS)

Move large amounts of data

Decision Support Systems (DSS)

Add decision making support

Expert System

Recommend decision based on expert knowledge

Enterprise Software

Collect, analyze, and make decisions based on data

ERP - Enterprise Resource Planning

Managing wide range of processes

Human resources, materials management, supply chains, accounting, finance, manufacturing, sales force automation, customer service, customer order entry

Finding hidden patterns through data mining

Advanced Communications

Electronic data interchange (EDI)

Internet, extranets

Wireless communications

Teleconferencing & telecommuting

Bar coding, RFT

Virtual reality

Process Technology: Automation

Machinery that has sensing and control devices that enables it to operate

- Fixed automation

- Programmable automation

Manufacturing Hardware Technology

Numerically controlled (NC) machines

Controlled by punched tape

Computer numerical controlled (CNC)

Controlled by attached computer

Direct numerical control (DNC)

Several NC machines controlled by single computer

Robotics

Flexible manufacturing systems (FMS)

Includes automated material handling

Production Process &

Technology Alternatives

# Different Products or Parts

High

General Purpose, NC,

CNC

CIM

Flexible

Manufacturing

System

Dedicated

Automation

Low

Low

Volume of Products or Parts

High

Flexible Manufacturing Systems

(FMS)

Programmable machine tools

Controlled by common computer network

Combines flexibility with efficiency

Reduces setup & queue times

Flexible Manufacturing System

CNC

Machine Finished goods

Computer control room

Automatic tool changer

CNC

Machine

Pallet

Terminal

Parts

Manufacturing Software Technology

Computer Aided Design and Computer Aided

Manufacturing (CAD/CAM)

Computer Integrated Manufacturing (CIM)

CAM refers to the use of specialized computer programs to direct and control manufacturing equipment. When CAD information is translated into instructions for computer aided manufacturing, CAM, the result of these two technologies is known as CAD/CAM