CHEE_392_-_Words_to_know-Processing[1] - P

advertisement

![CHEE_392_-_Words_to_know-Processing[1] - P](http://s3.studylib.net/store/data/009652514_1-54ca9a81dd105bea22c19783eb204240-768x994.png)

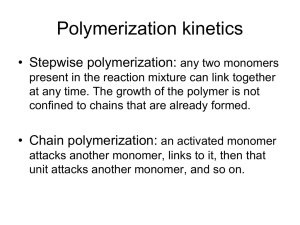

CHEE 392 Project - Controlled Radical Polymerization – Processing Group Client: Mr. Benoit Lessard, M.Eng Benoit.lessard@mail.mcgill.ca MEMO: 1 - 05/11/2009 Group 4: Gomez, Dominique Haroon, Anim Ibrahimian, Nanor MacKay, Sarah Valla, Sebastien To be successful in perusing this project a certain base knowledge in recent polymerization techniques is required. To help you reach a necessary knowledge level, I have compiled a list of words and expressions which will be used often and will be needed to explain your project to others effectively. Please take the time to research the meaning of all these words in the context of Controlled Radical Polymerization. - Controlled free radical polymerization (CRP) http://ocw.mit.edu/NR/rdonlyres/6982222C-2112-4EA8-9D515FC05C593EFB/0/lec32_12062006.pdf A free radical can be defined as “a group of atoms having an unpaired electron (free electron) which can covalently bond to an unpaired electron (Free electron) of an other molecule.” Free Radical initiators are Chemical Compounds which posses a weak Covalent bond that easily break into two free radicals when subjected to heat. Peroxides, Hydro Peroxides are examples of this type H2O2 — 2HO A simplified three stage for the mechanism of free Radical Polymerization of Vinyl monomers is i. Initiation. ii. Propagation. iii. Termination. - Nitroxide mediated controlled free radical polymerization (NMP) - Synthesis, Bulk polymerization, solution polymerization, Chain extension The polymerization of a monomer in the absence of any medium other than a catalyst or accelerator. The monomers are usually liquids, but the term also applies to the polymerization of gases and solids in the absence of solvents. - Solvent, Non solvent, precipitation Reactive blending, extruder, hot press Mixing process that is accompanied by the chemical reaction(s) of components of a polymer mixture. Note 1: Examples of reactive blending are: (a) blending accompanied by the formation of a polymer-polymer complex, (b) the formation of block or graft copolymers by a combination of radicals formed by the mechano-chemical scission of polymers during blending. Note 2: Reactive blending may also be carried out as reactive extrusion or reaction injection molding (RIM). - Differential scanning calorimetry (DSC) - Stress, Strain Modulus of elasticity Glass transition temperature Yield stress, percent elongation Number average molecular weight (Mn), weight average molecular weight (Mw) Polydispersity - Maleic Anhydride, Styrene, Nylon, KratonTM For you and everyone’s safety I recommend all of you to read the MSDS for the following compounds: Tetrahydrofuran (THF) Methanol 1-4 Dioxane Styrene Nitrogen (N2) Maleic Anhydride Nylon Compatibilizer of polymers: http://www.polysurfacesbookstore.com/pages/3085.html http://www.sciencedirect.com/science?_ob=ArticleURL&_udi=B6VPY-4BNJNSJ1C&_user=10&_rdoc=1&_fmt=&_orig=search&_sort=d&_docanchor=&view=c&_searchStrId=11050455 67&_rerunOrigin=google&_acct=C000050221&_version=1&_urlVersion=0&_userid=10&md5=49909c75 a50b952f20a3b30d1d39f3d1 http://www2.dupont.com/Polymer_Modifiers/en_US/uses_apps/compatibilizers/compatibilizers.html The development of polymer blends, composites and laminates is a very active area of science and technology; of great economic importance not only for the plastics industry but also for many other industries where the use of such products is becoming increasingly more common. Even worse is the fact that they also have less compatibility than would be required in order to obtain the desired level of properties and performance from their blends. Compatibilizers are often used as additives to improve the compatibility of immiscible polymers and thus improve the morphology and resulting properties of the blend. Similarly, it is often challenging to disperse fillers effectively in the matrix polymer of a composite, or to adhere layers of polymers to each other or to other substrates (such as glass or metals) in laminates.Continued progress in the development of compatibilization technologies is, hence, crucial in enabling the polymer industry to reap the full benefits of such approaches to obtaining materials with optimum performance and cost characteristics. http://en.wikipedia.org/wiki/Nylon We can talk about nylon, blending compatibilizers, what happens when we blend