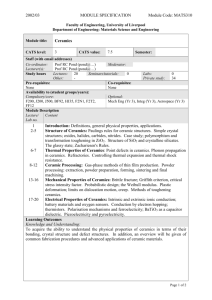

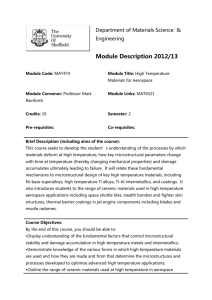

PowerPoint 簡報

advertisement

Modern Ceramic Dr.-Ing. Dipl.-Ing. 郭 瑞 昭 Materials Science & Eng. National Cheng Kung University National Chen Kung University, 20.12. 2004 What is ceramics ? The word ceramics, derives its name from the Greek keramos, meaning “pottery”, which in turn is derived from an older Sanskrit Root, meaning “to burn”. The Greeks used the term to mean “burned earth”. Thus the word was used to refer to a product obtained through the action of fire upon earthy materials. Most people, when they hear the word ceramic, think of art, dinnerware, pottery, tiles, brick and toilets. The above mentioned products are referred to as traditional ceramics. Outline • History • Processing • Structure • Properties • Performance History One of the major problems encountered in the teaching of science, is the frequent lack of any social or historical perspective. Science does not evolve in a vacuum, but is constrained By the mores and morals of society at large. Newton •Newton wrote more voluminously on alchemy than he ever did on the laws of motion. •He spent an inordinate amount of time on arcane religious Philosophy. •He was also a complete misogynist and was probably paranoid. Newton’s consuming interest in the mystical reflects the times in which he lived. Material Ages Stone Age (End of Ice Age) ~2,000,000 BC 8,000 BC Bronze Age 3,200 BC Iron Age 1,200 BC Silicon Age 1950 AD New Material Age 1990- Material Timeline I Neolithic age: 8,000 BC 6,000 BC 5,000 BC 5,000 BC Chalcolithic age: 4,500 BC 4,000 BC Clay tokens are used in Mesopotamia to record business transsactions Copper smelting is developed. Gold, silver and copper ornaments are fashioned from nuggets in e.g. the Balkans. Babylon is built with fired-brick and bitumen mortar. Copper is smelted in Eastern Europe and Egypt. Meteoric iron is used to make small tools and ornaments Material Timeline II Bronze age: 3,500 BC 3,000 BC 1,500 BC Early Iron age: 1,400 BC1,200 BC Earliest known use of Bronze is found in Sumer: first urban civilization Glass is first used in the Middle East as a glaze on pottery Glass vessels are produced in Egypt and Mesopotamia The Hittites in Anatolia introduce methods to produce large quantities of smelted iron. Classification of Ceramics Ceramic Materials Glasses Clay (Amorphous, Products silica based) Glass Ceramics (polycrystalline, eg. Pyroceram) Refractories Alumina, Silica high purity oxides Graphite Abrasives Diamond SiC Silica Sand Alumina Cements Calcium Silicon Advanced Ceramics Si N 4 3 SiC, BC, WC ZrO 2 Ceramic-Matrix Composites (fibre and whisker reinfored) Advanced Ceramics • Advanced ceramic materials have been developed over the past half century • Applied as thermal barrier coatings to protect metal structures, wearing surfaces, or as integral components by themselves. • Engine applications are very common for this class of material which includes silicon nitride (Si3N4), silicon carbide (SiC), Zirconia (ZrO2) and Alumina (Al2O3) • Heat resistance and other desirable properties have lead to the development of methods to toughen the material by reinforcement with fibers and whiskers opening up more applications for ceramics Performance Aerospace Space shuttle tiles, thermal barriers, high temperature glass window, fuel cells Aerospace 955 315 650 1465 Temperatures are in Celsius degrees. Temps marked with an * signify ascent temperatures. *1175 *425 *430 *405 980 * 420 Diagram of space shuttle's ascent and descent temperatures Consumer Uses Glassware, windows, pottery, Corning ware, magnets Dinnerware, ceramic tiles, lenses, home electronics, Microwave transducers Automotive Catalytic converters, ceramic filters, airbag sensors, ceramic rotors, valves, spark plugs, pressure sensors, thermistors, vibration sensors, oxygen sensors, safety Glass windshield, piston Rotor (Alumina) Gears (Alumina) Medical (Bioceramics) Orthopedic joint replacement, prosthesis, dental restoration, bone implants Military Structural components for ground, air, naval vehicle, missiles sensors CeramicHigh-temperature Discontinuous Outer hard skin stability and transparency to Projectile microwave radiation Personnel and Equipment ceramic radomes (front row) on Patriot missiles Inner ductile skin Ceramic Armor System lightweight ceramic armor Computers Insulators, resistors, superconductors, capacitors, Ferroelectric components, microelectronic packaging Other Industries Bricks, cement,membranes and filters, lab equipment Coating Properties of Engineering Ceramics • Ceramics are typically, – hard and brittle – high melting point materials with low electrical – thermal conductivity – good chemical and thermal stability – high compressive strengths Mechanical Properties • Ceramics and glasses are BRITTLE. • They fail in the elastic region. • They fail by crack growth. • They are better in COMPRESSION than TENSION. • Cracks open up in tension, but close in compression Mechanical Properties Mechanical properties depend upon the POROSITY. Structure CERAMICS ARE INORGANIC COMPOUNDS OXIDES - NITRIDES – CARBIDES Ceramics have more complex crystal structures than metals. Structure WHY? • The structure has to accommodate anions of different sizes, and has to preserve charge neutrality. • IONIC or COVALENT bonds. The diversity in their properties stems from their bonding and crystal structures. Two types of bonding mechanisms occur in ceramic materials, ionic and covalent. Often these mechanisms co-exist in the same ceramic material. Each type of bond leads to different characteristics. Processing Ceramics Processing P P injection liquid powder Rubber mold pestle P powder powder Extrusion molding Injection molding P slurry powder product plaster Die pressing Slip casting Slip Casting Sinter and Serve Powder Pressing Process Filling Mould Compaction Green part ejected - then sintered Sintering Process Pressed Ceramic Particles Sintered for a short time Sintered for a long time Microstructure sintering forming Raw powder Formed product Sintered product