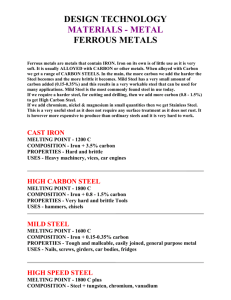

Ferrous Alloys

advertisement

Ferrous Alloys Chapter 12 – 4th Edition Chapter 13 – 5th Edition Where Does Iron Come From? Naturally occurring iron exists as ironoxide (rust) Iron ore mine in Labrador, Canada http://upload.wikimedia.org/wikipedia /commons/f/f1/Iron_ore_mine01_(xndr).jpg Iron is also recycled The only naturally occurring metallic iron on earth comes from meteorites The largest meteorite discovered in Antarctica is about 2 feet by 2 feet by 1.5 feet. Due to its size it was not able to be thawed in the 100% nitrogen atmosphere and therefore the ice inside melted. The liquid water dissolved minerals inside the meteorite, and when it evaporated, white salts were left on the surface of the meteorite. NASA Lyndon B. Johnson Space Center, Houston, TX. http://www2.ifa.hawaii.edu/newsletters/images/23largeMete orite.jpg Iron oxide is converted to metallic iron in a blast furnace The main chemical reaction producing the molten iron is: Fe2O3 + 3CO → 2Fe + 3CO2[32] Preheated blast air blown into the furnace reacts with the carbon in the form of coke to produce carbon monoxide and heat. The carbon monoxide then reacts with the iron oxide to produce molten iron and carbon dioxide Blast Furnace http://en.wikipedia.org/wiki/File:VysokaPec.jpg 1. Hot blast from Cowper stoves 2. Melting zone 3. Reduction zone of ferrous oxide 4. Reduction zone of ferric oxide 5. Pre-heating zone 6. Feed of ore, limestone and coke 7. Exhaust gases 8. Column of ore, coke and limestone 9. Removal of slag 10. Tapping of molten pig iron 11. Collection of waste gases Pig Iron An intermediate product – the result of smelting with iron ore and carbon Iron and typically about 4% carbon Also includes sulphur phosphorus and other impurities Brittle and not very useful http://www.manufacturer.com/images/buyLeads/www.alibaba.com/1118/u/Pig_iron.jpg Steel It wasn’t possible to make steel until about 1850 We don’t call it steel unless it is less than 2% carbon An open hearth furnace was used to burn off the excess carbon up until the 1990’s Carbon can also be burned off with Electric Furnace Oxygen Furnace Sheet and Tube Open Hearth Furnace – Youngstown Ohio Steel is a major structural component Photo by Ian Britton http://www.freefoto.com/preview/42-12-6?ffid=42-12-6 The Palmer is named for a U.S. seal hunter who sailed along the west coast of Antarctica in 1820 looking for seal rookeries. Many believe he was the first to discover the continent. Photograph courtesy Woods Hole Oceanographic Institution http://www.nationalgeographic.com/sealab/antarctica/ship.html Carbon composition Steel generally has less than about 0.7% C, but can have up to 2.11% C. Look at the iron phase diagram to remind yourself why 1600 C d L 1400 C 1200 C g 1000 C 800 C a 600 C 400 C Fe Steel 1% C Cast Iron 2% C 3% C 4% C 5% C 6% C 6.70% C Steel and Iron The phase diagram only strictly applies to an iron – carbon combination Steel and iron often have other alloying elements in them, which modify the phase diagram Stainless Steel Phase Diagram at 9000C 18-8 Stainless steel is the most common composition – The terminology refers to 18%Cr and 8% Ni – with the balance Fe (and other trace elements) http://www.sv.vt.edu/classes/MSE2094_NoteBook/96ClassProj/experimental/ternary2.html Stainless Steel Solidus Temperatures http://www.sv.vt.edu/classes/MSE2094_NoteBook/96ClassProj/experimental/ternary2.html Cast Iron Has quite a bit more cementite in it than steel That makes it hard and brittle But cementite is a “metastable” compound, that can decompose into iron and graphite with the appropriate thermal treatment http://www.trademadesimple.co.uk/companies/ olymberyl-manufacturers/images/cast-ironstove-hf332-1.jpg http://www.georgesbasement.com/Microstructures/CastIronsHighAlloy SteelsSuperalloys/Lesson-1/Introduction.htm George Langford, Sc.D., Massachusetts Institute of Technology, Wrought Iron This iron is ductile and malleable and can be “wrought” into a final shape Wrought iron was the primary high strength structural material until steel became available in the 19th century http://upload.wikimedia.org/wikipedi a/commons/b/bd/Eiffel_tower_from_ below.jpg The Eiffel Tower was made from Puddle Iron – a form of Wrought Iron Heat Treatments Process Annealing Heat the steel just below the eutectoid Removes the effect of cold work Austenitizing Heat into the a region to dissolve the carbon Microstructure We’ve already discussed the formation of the eutectoid microstructure If you force the phase change to occur just below the equilibrium transformation temperature you get spheroidite Large spheroidal particles Steel is easily machined Low strength and hardness After machining it is heat treated again to improve the properties Alloying Elements May… Modify the phase diagram Modify the TTT curve Strengthen the steel by precipitation hardening Reduce Corrosion Stainless Steel >12% Chromium May also contain large amounts of nickel In some stainless steels the austenite structure survives at room temperature Makes the steel especially corrosion resistant Non Magnetic Iron Nickel Phase Diagram http://www.calphad.com/graphs/Fe-Ni%20Phase%20Diagram.gif Alloy Steel Alloying elements make it harder to predict the effect of heat treatments The equilibrium structures are not always known Even if they are – they aren’t always achieved Shopping? Moderate chromium steels can form Martensite, which is hard and corrosion resistant Austenitic steel is more corrosion resistant and more ductile (less brittle) Stainless steel has a broad range of properties You want Martensite for your knives and Austenite for your bowls Remember – Austenite is not magnetic Ian O'Leary (c) Dorling Kindersley Surface Treatments Coatings Tin, Zinc (galvanized), Aluminum Surface Hardening Heating, followed by quenching Diffusion of carbon or nitrogen Welding Problems with welds do not usually occur in the weld itself The area around the weld is heated, and changes the microstructure Excessive grain growth Formation of Martinsite (makes it brittle) Titanic A detailed analysis of small pieces of the steel plating from the Titanic's wreck hull found that it was of a metallurgy that loses its elasticity and becomes brittle in cold or icy water, leaving it vulnerable to dentinduced ruptures. The pieces of steel were found to have very high content of phosphorus and sulphur (4x and 2x respectively, compared to modern steel), with manganese-sulphur ratio of 6.8:1 (compare with over 200:1 ratio for modern steels). High content of phosphorus initiates fractures, sulphur forms grains of iron sulphide that facilitate propagation of cracks, and lack of manganese makes the steel less ductile. The recovered samples were found to be undergoing ductile-brittle transition in temperatures of 32 °C (for longitudinal samples) and 56 °C (for transversal samples—compare with transition temperature of -27 °C common for modern steels—modern steel would became so brittle in between -60 and -70 °C).