Sergio-Chavez-Final-Paper

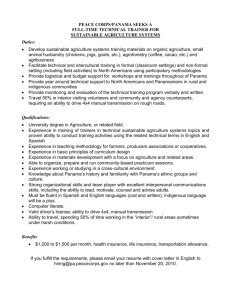

advertisement

A Case Study: A Comparison of Logistics Practices & Facility Layout of Baton Rouge Coca-Cola Production/Distribution Center and Nestle Manufacturer/Distributor in Panama City, Panama. Sergio Chavez Sergio.Chavez@eagles.usm.ed 0-ABSTRACT Nestle Panama SA is a private company in Panama City, Panama and is categorized under Dry Condensed/Evaporated Dairy Prod Manufacturers; in 1937, the first Nestle came to Central America with its move to Panama. It serves Panama City, the capital and largest city in the Republic of Panama; in addition to the local area, Nestle Panama ships internationally. The population of the city proper is 880,691 with the metro surrounding area climbing to 1,272,672. Baton Rouge Coca-Cola Bottling Company is a division of Coca-Cola Bottling Company United, Inc. Their products are distributed under exclusive franchise agreements with The CocaCola Company and other beverage franchise companies in the greater Baton Rouge area and surrounding regions. The Baton Rouge facility acts as a bottler and distribution center. Baton Rouge metropolitan area has a population of 802,484. This paper compared the two facilities and their logistics. It looked at how materials are sorted and stored or warehoused for delivery and type of delivery systems in place. This paper sought to shed light onto the practices of two comparable locations and whether one was more successful than the other and the factors leading to that success. 1-INTRODUCTION 1.1 Definitions The following terms will be beneficial for understanding this comparison between Baton Rouge Coca-Cola Bottling Company and Panama Nestle. Some will apply to only one location and others will apply to both operations. EasiTrax is a “powerful, scalable vending management software and hardware solution” (MEI, 2012). The system is designed to streamline operations, control revenue and inventory, accelerate sales growth, and reduce cost. It is designed to support end-to-end vending and control/monitor assets, cash, products, machines, trucks, and personnel (MEI, 2012). EasiTrax does the following: increase productivity, reduce delivery costs, reduce labor costs, reduce fuel costs, reduce paperwork, reduce waste/loss, reduce inventory levels, streamline operations, increase customer satisfaction, account for product and cash. Telemetry, which is the remote reading of measurement devices through telecommunications (BusinessDictionary.com, 2012); it can be used for multiple applications like credit/debit acceptance and remote monitoring. Telemetry reports errors such as “Bill validator full; Jam in bill validator; Changer communication error; Machine not cooling; Temperature too high; Column jam; Sold out; Coin jam” (Haddon, 2008, p. 2). Vending machines were first patented in the United States in1884, but vending machine design is said to go as far back as 62 A.D. (Segrave, 2002). Soda vending machines were a familiar sight across the United States by 1942 (Segrave, 2002). Physical distribution “is the process of supplying a market, through the dimensions of time and space. The process involved the interaction of various functional elements such as inventory and transportation, to make good available to customers in specific markets at designated times under specified conditions” (Schary, 1970, p. 6). Direct truck distribution involves trucks travelling directly from supplier to destination without stopping. Milk-run truck distribution involves when trucks pick up products at one or more location(s) and delivers them to one or more destination(s). Cross-dock truck delivery moves products from suppliers to a cross-dock and from the crossdock to the destinations (Berman & Wang, 2006, p. 287). Value-added service warehouse is a facility “where key product customization activities are executed, including packaging, labeling, marking, pricing, and returns processing” (Frazelle, 2002, p. 3). 1.2 Overview of the Business Environment in the United States In the United States, the per capita Gross Domestic Product (GDP) of $49,800. The economy is essentially a private market place economy and is market-oriented. This means that business have major control in decisions, like expansion, reduction and product development. There has been growth in what is known as a “two-tier labor market” (CIA, 2013). In this type of market the unskilled and less educated lower tier is paid less and receives less benefits and the top tier, or skilled/professional labor, receives benefits, raises, etc. (CIA, 2013). Imported oil is the major consumption of the United States and prices for crude oil are directly related to “dampening” of the housing market, decreased value of the dollar (the currency), and an increase in the US merchandise trade deficit (CIA, 2013). The country has been in a recession since 2008. Two economic programs were implemented by the government in an attempt to stabilize the financial market and create economic growth—the Troubled Asset Relief Program (TARP) and a fiscal stimulus bill. These two programs along with wars in Iraq and Afghanistan (estimated $900 billion for the wars alone) put a strain on the US economy. Additional strain on the GDP came in the form of Obama Care which increased almost 9% (CIA, 2013). The budget revenues are reported as $2.465 trillion and expenditures are reported at $3.649 trillion. Although the people feel heavily taxed, the ranking for the US is 184 out 215 countries with only 15.7% of the GDP being made up of taxes. To put this into perspective Iraq’s GDP (first) is made up of 79.9% of taxes revenue and Greenland is 79.6% (second). Our neighbors Canada (38.4%) and Mexico (23.8%) rank 54 and 131 respectively (CIA, 2013). The US ranks 193 out of 216 in the amount of deficit. The current unemployment rate for the US is 8.2%. “Long-term problems include stagnation of wages for lower-income families, inadequate investment in deteriorating infrastructure, rapidly rising medical and pension costs of an aging population, energy shortages, and sizable current account and budget deficits—including significant budget shortages for state governments” (CIA, 2013). Over 15% of the population lives below the poverty line. The industries in the US are considered highly diversified and world leading. It is considered a high-technology innovator and the second largest industrial output in world. The major industries are petroleum, steel, motor vehicles, aerospace, telecommunications, chemicals, electronics, food processing, consumer goods, lumber, and mining (CIA, 2013). The main exports commodities estimated at $1.612 trillion are: “agricultural products (soybeans, fruit, corn) 9.2%, industrial supplies (organic chemicals) 26.8%, capital goods (transistors, aircraft, motor vehicle parts, computers, telecommunications equipment) 49.0%, consumer goods (automobiles, medicines) 15.0%” (CIA, 2013). The major export partners are Canada (19%), Mexico (13.3%), China (7%), and Japan (4.5%) (CIA, 2013). The US imports an estimated $2.357 trillion consist of “agricultural products 4.9%, industrial supplies 32.9% (crude oil 8.2%), capital goods 30.4% (computers, telecommunications equipment, motor vehicle parts, office machines, electric power machinery), consumer goods 31.8% (automobiles, clothing, medicines, furniture, toys)” (CIA, 2013). The major import partners are China (18.4%), Canada (14.2%), Mexico (11.7%), Japan (5.8%), and Germany (4.4%). 1.3 Focus of the Topic in United States Baton Rouge Coca-Cola Bottling Company was founded in 1906 by Thomas Daigre. It originally served a population of 12,000, providing both soda fountain Coca Cola and single serve 6.5 ounce glass bottles. Currently Baton Rouge Coca-Cola Bottling Company “produces and markets over 400 different product/package combinations” from its current location, which is LEED (Leadership in Energy and Environmental Design) certified (CCBCU, 2012). Baton Rouge Coca-Cola is a division of Coca-Cola Bottling Company United, Inc. which is headquartered in Birmingham, Alabama and has territory in Alabama, Florida, Georgia, Louisiana, Mississippi, Tennessee, Mississippi, and South Carolina. The Baton Rouge division acts as the headquarters for the Gulf Coast Region, which has six Coca-Cola distributors (CCBCU, 2012). The Baton Rouge facility acts as a bottler and distribution center for the metropolitan area of 802,484 citizens. The Coca-Cola Bottling Company United is the largest privately held U.S. bottler of Coca-Cola, the operations in Baton Rouge are a major part of the company. The new plant was an investment of over $178 million and included additional costs of gaining access to groundwater. (LED, 2013). The Coca-Cola Bottling Company United in Baton Rouge, LA plant has four packaging lines and is considered to be a flexible design. The production center is 781,000 square feet and resides on 112 acres; it opened in October 2008. The four packaging lines produce 4.5 million 8-oz servings/day. “The facility handles 400 SKUs, including products under the Coca-Cola and Dr. Pepper names, and under Southern U.S. brand Big Red. The Coca-Cola products distributed from the site include soft drinks, energy beverages, juices, waters, sports drinks, teas, and more. Of those 400 SKUs, 120 are produced and packaged at the plant” (Mohan, 2011). The production center has one canning line, two PET lines, and one hot-file PET line; there is also established infrastructure for two additional packing lines. There are 98 docks that surround the production area for trucks to deliver raw materials directly to the lines they are designated for. Finished cases of product are put onto pallets in the middle of the warehouse (Mohan, 2011). The can line at top speed can produce 1,800 cans per minute, the sparkling bottles line can produce up to 800 bottles per minute (Beverage World, 2011). The plant is the major manufacturer and distributor in the Southeast and uses some of the most current technology like “online real-time production monitoring system,” “electronically actuated fillers, flow meters on the thermal line that measures the millimters that go into each bottle and quality checks that are conducted to the fifth decimal place as opposed to the second” (Beverage World, 2011, p.47). The plant also uses the Easy Pallet Distribution System designed by Coca-Cola United. Baton Rouge Coca-Cola can be considered a value-added warehouse and production facility that participates in all of the common operations of a warehouse: receiving, prepackaging, putaway, storage, order picking, packaging and/or pricing, sortation and/or accumulation, and unitizing and shipping (Frazelle, 2002). Nestle and The Coca-Cola Company have a joint venture together called Beverage Partners Worldwide, which produces Nestea and Enviga. CCBCU works closely with The Coca-Cola Company. Physical distribution “is the process of supplying a market, through the dimensions of time and space. The process involved the interaction of various functional elements such as inventory and transportation, to make good available to customers in specific markets at designated times under specified conditions” (Schary, 1970, p. 6). The type of distribution is “milk-run truck distribution” in which the trucks typically pick up product from the one location on Plank Road and deliver to multiple destinations (Berman & Wang, 2006, p. 287). The product distribution is pre-determined using telemetry, or remote reading of the vending machines through telecommunications (BusinessDictionary.com, 2012); it reports errors such as “Bill validator full; Jam in bill validator; Changer communication error; Machine not cooling; Temperature too high; Column jam; Sold out; Coin jam” (Haddon, 2008, p. 2). Baton Rouge Coca-Cola Bottling Company utilizes EasiTrax for full-service, which is a vending management solution designed to streamline operations, control revenue and inventory, accelerate sales growth, and reduce cost. It is designed to support end-to-end vending and control/monitor assets, cash, products, machines, trucks, and personnel (MEI, 2012). EasiTrax does the following: increase productivity, reduce delivery costs, reduce labor costs, reduce fuel costs, reduce paperwork, reduce waste/loss, reduce inventory levels, streamline operations, increase customer satisfaction, account for product and cash. For tracking what ships to retail venues, Baton Rouge Coca-Cola uses BASIS, in which orders are either called in or are entered into hand-helds by employees and then uploaded. 1.4 Overview of the Business Environment in Panama Panama uses a dollar-based economy and relies heavily on established services sector for over 75% of its GDP. “Services include operating the Panama Canal, logistics, banking, the Colon Free Zone, insurance, container ports, flagship registry, and tourism” (CIA, 2013). There is projected economic growth from the Panama Canal expansion project that will be finished in 2015. The expansion will allow larger ships to cross the canal—the canal will be more than doubled. “The United States and China are the top users of the Canal.” Panama City is improving its infrastructure (scheduled to be completed in 2014) with a metro system. “Panama's booming transportation and logistics services sectors, along with aggressive infrastructure development projects, have lead the economy to continued high growth in 2012” (CIA, 2013). Another source of growth for the country is foreign investment. Even though there has been a strong economy, there is great disparity among the population, and Panama is second in the worst income distribution in Latin America. Approximately 30% of the population lives in poverty but it has been decreasing in recent years along with unemployment. The unemployment rate is 4.4% (CIA, 2013). Panama’s relationship with the US, beyond using the canal, includes the USPanama Trade Promotion Agreement which went into effect in 2012. Panama also entered into numerous taxation treaties with various countries in order to be removed from the Organization of Economic Development's gray-list of tax havens. Panama’s GDP is $56.83 billion and it is ranked 91 out of 229. The GDP grew a over 10% the last year, and Panama ranks 7th out of 220 versus the US which ranks 134th with just over 2%. There is a shortage of skilled labor and an abundance of unskilled labor (CIA, 2013). Panama exports $17.97 billion and exports gold, bananas, shrimp, sugar, iron and steel waste, pineapples, and watermelons. Panama’s main export partners are US (13.1%), South Korea (12.5%), Honduras (10.2%), Japan (9.3%), India (7%), Canada (4.4%), and Mexico (4.2%). It imports $24.04 billion and import commodities include fuel products, medicines, vehicles, iron and steel rods, and cellular phones. Panama’s major import partners are Japan (23.5%), China (23%), Singapore (18.1%), US (13%), and South Korea (6%). Table 1, below, from the USDA (2012), provides just a few of the food processors in Panama. Table 1: Select Food Producers/Distributers in Panama 1.5 Focus of the topic in Panama In 1937, the first Nestle came to Central America with its move to Panama. Nestle Panama SA is a private company in Panama City, Panama and is categorized under Dry Condensed/Evaporated Dairy Prod Manufacturers. It is considered a manufacturer that manufactures and wholesales canned dairy products including milk, tea, coffee, infant foods, and confectionery (Figure 1). Figure 1: Codes from Highbeam Business: http://business.highbeam.com/companyprofiles/info/500825/nestle-panama-s-a Nestle Panama is a private manufacturing company (Figure 2). It employs between 100 and 250 employees. Figure 2: Company Intelligence Report from Free Sales Website http://free.salesfuel.com/CoIntell/CoDetailsPersonnel.aspx?CompanyID=36210 Nestle Panama produced six thousand tons of evaporated milk, processed chesses, tomato based sauces in 2006. That same year, sales abroad for Nestle Panama reached $7.5 million. Nestle Panama exports to Guatemala, El Salvador, Honduras, Nicaragua, Costa Rica, Haiti, and other Caribbean islands and has plans to expand. This expansion includes sending products like Milo and NesCafe to Chile, Venezuela, Brazil, the United States, and Mexico (Berrocal, 2007). Last year’s revenue for Nestle Panama was 17,500,000 in Panamanian Balboa, which is approximately the same in American dollars (Figure 3). Figure 3: Capital from Panama: http://www.nestle.com/assetlibrary/Documents/Library/Documents/Financial_Statements/2012-Financial-Statements-EN.pdf The parent organization is Nestle S.A. and was found in 1866. It merged with another company in 1905—Anglo-Swiss Condensed Milk Co.—and became the giant that is today. It is the “world’s largest food company with a focus on Nutrition, Health & Wellness” (Nestle, 2013). They are responsible for over 80 brands, from dog food to coffee to baby food and more. They sold over $10 billion in 2012, employee over 25,000 employees, have 25 manufacturing facilities, 35 distribution centers, and 15 sales offices in the US alone. Worldwide revenue was over $97 billion. The following business functions are the focus for this comparison: planning, design, scheduling, and material management. These business functions are critical to the comparison of Baton Rouge Coca-Cola and Nestle Panama. Planning in general is the looking to the future—long-term and short-term (Dictionary of Business, 2006). Planning includes a variety of types of planning: strategic, resources, etc. One planning software is EasiTrax is a “powerful, scalable vending management software and hardware solution” (MEI, 2012). The system is designed to streamline operations, control revenue and inventory, accelerate sales growth, and reduce cost. It is designed to support end-toend vending and control/monitor assets, cash, products, machines, trucks, and personnel (MEI, 2012). EasiTrax does the following: increase productivity, reduce delivery costs, reduce labor costs, reduce fuel costs, reduce paperwork, reduce waste/loss, reduce inventory levels, streamline operations, increase customer satisfaction, account for product and cash. Warehouse design is important for efficient and cost-effective distribution. A warehouse is a “large building where goods are stored” (Dictionary of Business, 2006). A value-added service warehouse is a facility “where key product customization activities are executed, including packaging, labeling, marking, pricing, and returns processing” (Frazelle, 2002, p. 3). In addition to warehouse design and planning, scheduling is a key-component in operations. There are several components of scheduling that are important. “The transit time is the time in days that is required to deliver goods from your premises to the customer location. It is defined for a route. The loading time is the time in days that is required for loading a delivery item. It is determined from the shipping point, the route, and the loading group of the material. The pick/pack time is the time in days that is required for allocating goods to a delivery as well as the time in days that is required for picking and packing. It is calculated using the shipping point, the route, and the weight group of the order item. Finally, the transportation lead-time is the time in days that is needed to organize the shipping of the goods. This might include booking a ship and reserving a truck from a forwarding agent. It is defined for a route” (SAP, 2013). However without this last component, production would be for naught—materials management—because if does no good to produce and house a product if you cannot distribute it. Physical distribution “is the process of supplying a market, through the dimensions of time and space. The process involved the interaction of various functional elements such as inventory and transportation, to make good available to customers in specific markets at designated times under specified conditions” (Schary, 1970, p. 6). There are several types of distribution; two of the main types are direct truck distribution and milk-run distribution. Direct truck distribution involves trucks travelling directly from supplier to destination without stopping. Milk-run truck distribution involves when trucks pick up products at one or more location(s) and delivers them to one or more destination(s). Both of these distribution methods may involve cross-dock truck delivery. Cross-dock truck delivery moves products from suppliers to a cross-dock and from the cross-dock to the destinations (Berman & Wang, 2006, p. 287). In today’s distribution of materials, technology plays a vital role. For instance, telemetry, which is the remote reading of measurement devices through telecommunications (BusinessDictionary.com, 2012) can be used for multiple applications like credit/debit acceptance and remote monitoring. Telemetry reports errors such as “Bill validator full; Jam in bill validator; Changer communication error; Machine not cooling; Temperature too high; Column jam; Sold out; Coin jam” (Haddon, 2008, p. 2). In Baton Rouge Coca-Cola, B.A.S.I.S is the internal system used to track accounts, payments, overages, shortages, and revenue. Technology can also be used to streamline operations. EasiTrax is a “powerful, scalable vending management software and hardware solution” (MEI, 2012). The system is designed to streamline operations, control revenue and inventory, accelerate sales growth, and reduce cost. It is designed to support end-to-end vending and control/monitor assets, cash, products, machines, trucks, and personnel (MEI, 2012). EasiTrax does the following: increase productivity, reduce delivery costs, reduce labor costs, reduce fuel costs, reduce paperwork, reduce waste/loss, reduce inventory levels, streamline operations, increase customer satisfaction, account for product and cash. 1.6 Focus The focus of this report is A Case Study: A Comparison of Logistics Practices & Facility Layout of Baton Rouge Coca-Cola Production/Distribution Center and Nestle Manufacturer/Distributor in Panama City, Panama. More specifically, this report compares the logistics and warehouses of Baton Rouge Coca-Cola and Nestle Panama, by looking at the business functions previously mentioned. 2-INFORMATION DATA/COLLECTION APPROACHES “The success or failure of today’s business may be affected by the design of the supply chain network. Warehouses are the parts of supply chain network that connect among suppliers, manufactures, distributors and customers”. The design of the warehouse has a big impact on the cost-effectiveness of the operation. Typically warehouses are designed to be rectangular in shape. There are typically three types—two blocks with stocking aisle running parallel to the warehouse with I/O point located in the middle of head or end of the aisle… Second and third are one block with stocking aisles running vertical to the warehouse with I/O point located in the middle and lower left respectively” (Sooksaksun & Kachitvichyanukul, 2010). The study by Sooksaksun & Kachitvichyanukul (2010) indicates that two-block warehouses are more efficient by providing lower distance travel. 2.1 Internet Data was collected via two methods. The first part of the research involved searching the Internet and online databases available through The University of Southern Mississippi’s library system and Louisiana State University library system. Google was the search engine of choice. Terms used were “Coca-Cola” and “Baton Rouge” and “Panama” and “Nestle.” There was an abundance of information about Coca-Cola Bottling Company United and specifically about Baton Rouge Coca-Cola available. One of the most helpful resources was an article published in Packaging World Magazine that provided details about the facility and the number of production lines, bays, etc. In addition to this article other articles were found. The company’s webpage provided a wealth of information at both the corporate level and local level. Looking online for information regarding Nestle Panama was much more difficult. There was very little information specific to Panama. Most information was either superficial or was about the parent organization Nestle or Nestle Centroamerica. 2.2 Databases Table 2 shows the databases that were consulted, and table 3 shows the keywords used for searching. These databases were selected because they are business related or as broad general databases contain business resources. Two of the databases are government resources and are open access. The keywords were selected based on the project. Database Academic Search Premiere Academic Search Complete Business Source Complete Business Searching Interface CIA World Factbook Table 2: Databases Consulted Library USM LSU USM LSU Open/Gov ht t p s : / / w w w . c i a . g o v / l i b r a r y / p u b l i c ations/the-worldfactbook/index.html EBSCO Electronic Journals Service Economia Y Negocios Fuenta Academica JSTOR MarketLine Company Profiles SAGE Journals Online Results No for Panama No for Panama No for Panama No for Panama Country Information Present on Both USM No for Panama LSU LSU USM LSU LSU No for Panama Yes No for Panama No for Panama No for Panama Table 3: Keywords/Phrases Used for Search Keywords Coca-Cola + Baton Rouge Nestle + Panama United States Panama 2.3 Interviews It was anticipated that the following interviews would take place. For Baton Rouge Coca-Cola, Joe Vergeron, Distribution Manager/Special Problems. In Panama, an attempt was made to interview Ascanio Salas, Director of Operations for Nestle Panama; however, the interview took place with Gloria Reyes, Director for Demand, Supply Chain and Exporting Planning (Jefe Planificacion Demanda, Abastecimiento y Comercio Exterior). The goal of the interview was to answer the questions below especially for Nestle Panama since very little information seems to be made public. Missing information from Coca-Cola was answered via email interview. In Panama, every attempt was made to get the Nestle Panama information on the spot. Information not gathered on site was emailed to Nestle Centroamerica and the contact in Panama. The interview questions, found in table 4, were specific to the following business functions: planning, design, scheduling, and materials management. Table 4: Interview Questions Question What is the size of the facility? What is the size of the property? Does the facility hold any special certifications? What is the product production? How many SKUs can be handled on site? How many production lines are there? How many loading docks are there? How many vehicles distribute the product? What pallet system do you use? What software systems are used? How many employees are there? What are the annual sales for last year? What type of warehouse design is used? Where is product shipped? How many unique products are manufactured/distributed from the facility? Business Function Design Design Design Material management Materials management Design Design Materials management Materials management/Design Planning Scheduling Planning Design Scheduling/Materials management Materials management The interview instrument contains information that is commonly available for companies in the United States but is not readily available for Nestle Panama (Table 5). The basic information for Coca-Cola Baton Rouge was obtained through current contacts. Table 5: Interview Questions and Responses Question Baton Rouge Coca-Cola What is the size of the facility? 781,000 square feet What is the size of the property? 112 acres Does the facility hold any special LEED certifications? What is the product production? 45 million 8-ounce serving products per day How many SKUs can be handled on site? 141 SKUs created on site; 400 SKUs total How many production lines are there? 4 production lines Nestle Panama Info Not Available Info Not Available Info Not Available 33,000 TONS of product annually 300+ NATA has 3 (one How many loading docks are there? 98 loading docks How many vehicles distribute the product? 340 plus vehicles What pallet system do you use? Easy Pallet Distribution System What software systems are used? How many employees are there? What are the annual sales for last year? What type of warehouse design is used? BASIS, MEI 520 $9,096,916 Warehouse Slotting (slotpicking) Where is product shipped? Vending machines, stores, other distributor How many unique products are manufactured/distributed from the facility? Over 400 evaporated, one dry and one condensed milk lines) and Los Santos has 6 NATA = 8 (4 for local and 4 for Exporting) and Los Santos= 2 They employ 15+ 3rd Party logistic companies to distribute Push-Pull they also employ slip-sheet pallets that requires a special fork lift SAP 490 $17,500,000 Single and Double deep and/with drive in Local, Chile, US and Caribbean - to the US they only export something called “sofrito” and to the Caribbean they export condensed soups and to Chile a product called caldo cazero NATA = 95 and Los Santos = 45 ----at NATA they also repackage milk powder 20,000,000 17,500,000 15,000,000 9,096,916 10,000,000 5,000,000 Panama Nestle Baton Rouge CocaCola 0 Panama Nestle Baton Rouge Coca-Cola Figure 4: Approximate Comparison of Profits Figure 5: Baton Rouge Coca-Cola Facility Figure 4 is a comparison between the annual sales of the two companies. Figure 5 is the outside of Baton Rouge Coca-Cola. The facility opened in 2008. It is a state of the art facility. Figure 6 is a comparison of the two companies on pallets, products, and employees. Although Panama handles fewer products and pallets, they outperform Baton Rouge Coca-Cola in profits. Figures 7 and 8 are images of the production lines. A visit to the following website, provides insight on the new facility with an excellent video: http://www.packworld.com/machinery/fillingsealing/newcoke-plant-designed-future-mind. 600 500 400 Baton Rouge Coca-Cola 300 Panama Nestle 200 100 0 Pallets Products Employees Figure 6: Comparison of the two companies: Pallets, products, and Employees Figure 7: Baton Rouge Coca-Cola Plant Can Inspection Line 1 by Anne Marie Mohan, Senior Editor Figure 8: Baton Rouge Coca-Cola Plant Full Pallets on Line 1 by Anne Marie Mohan, Senior Editor Nestle Panama SA, founded in 1937, is a private company in Panama City, Panama and is categorized under Dry Condensed/Evaporated Dairy Prod Manufacturers. It is considered a manufacturer that manufactures and wholesales canned dairy products including milk, tea, coffee, infant foods, and confectionery. It employs between 100 and 250 employees—in each of its 2 facilities in addition to headquarters. Figure 9 shows two Panamanian Nestle workers and Figure 10 shows some of the executives found at Nestle Panama. Figure 9: Panamanian Nestle Workers from http://html.rincondelvago.com/industrialactea-panamena-y-globalizacion.html Figure 10: Some Panamanian Executives from http://www.dealante.com/nodo.php?nodoid=19783 The next figures—11 and 12—show the outside of the Nestle Panama administrative facility which is located in the interior of the city. Figure 11: Nestle in Panama City, Panama by Sergio Chavez Figure 12: LA PRENSA/NICOLAS PSOMAS http://mensual.prensa.com/mensual/contenido/2007/03/25/hoy/negocios/9289 99.html 3-CASE STUDY Nestle Panama SA is a private company in Panama City, Panama and is categorized under Dry Condensed/Evaporated Dairy Prod Manufacturers; in 1937, the first Nestle came to Central America with its move to Panama. It serves Panama City, the capital and largest city in the Republic of Panama. The population of the city proper is 880,691 with the metro surrounding area climbing to 1,272,672. Baton Rouge Coca-Cola Bottling Company is a division of CocaCola Bottling Company United, Inc. It was founded in 1906. Their products are distributed under exclusive franchise agreements with The Coca-Cola Company and other beverage franchise companies in the greater Baton Rouge area. The Baton Rouge facility acts as a bottler and distribution center. Baton Rouge metropolitan area has a population of 802,484. The two companies are comparable in that they are both manufacturers and distributors in metropolitan areas so it stands to reason that they face similar issues (Figure 13). Population of Service Area 802,484 39% Panama City 1,272,672, 61% Baton Rouge Figure 13: Population Comparison of Service Areas Nestle Panama manufactures and distributes confectionary food, powered milk products and beverages, including Nestle water. Baton Rouge Coca-Cola manufactures and distributes beverages. Nestle Panama is located at Urbanizacion (La Loma) Calle 69 Oeste 74D Apartado 0834-00368 (Figure 14). There are two production facilities in addition to administrative headquarters located in Panama. NATA produces Dairy products and their primary product “leche evaporada Ideal” makes up 60% of their sales in Panama. It is considered to be their flagship product. Los Santos, the other facility, produces tomato based products. Figure 14: Map of Nestle Panama Created with Google Maps Nestle Panama SA is a private company in Panama City, Panama and is categorized under Dry Condensed/Evaporated Dairy Prod Manufacturers; it was established there in 1937 and serves Panama City, the capital and largest city in the Republic of Panama. Currently, Ricardo Ramos is president of the company. Unlike Baton Rouge Coca-Cola that expanded as recently as 2008, Nestle Panama has downsized in about a decade ago by selling off the equivalent of over $700,000 in infrastructure to Cooleche—Panama’s Chiriqui Milk Producers Cooperative (Factiva, 2002). Nestle Panama employs approximately 200-280 employees per facility. In recent years, they have struggled with union negotiations (Amorin, 2012). Panama is uniquely positioned for global trade with the expansion of the Panama Canal and the Colon Free Zone. There are many manufacturers and distributors in Panama as conditions are favorable for foreign-owned companies. Nestle Panama produced six thousand tons of evaporated milk, processed chesses, tomato based sauces in 2006. Sales abroad for Nestle Panama reached $7.5 million in 2006 and they export to Guatemala, El Salvador, Honduras, Nicaragua, Costa Rica, Haiti, Caribbean islands, Chile, Venezuela, Brazil, the United States, and Mexico (Berrocal, 2007). It is a private company that is a part of Nestle S.A., which was founded in 1866. It is the “world’s largest food company with a focus on Nutrition, Health & Wellness” (Nestle, 2013). There are between 100-250 employees at each facility. Baton Rouge Coca-Cola and Nestle Panama have some similarities in being manufacturers and distributors. They both provide the local community as well as others. Baton Rouge Coca-Cola has a world-class manufacturing facility and warehouse. Baton Rouge Coca-Cola is located at 9696 Plank Road, Baton Rouge, Louisiana U.S. (Figure 15) Figure 15: Map of Baton Rouge Coca-Cola Created with Google Maps Both companies are positioned to have access to other countries—with Panama being situated between the Caribbean Sea and Gulf of Panama/North Pacific Ocean (Figure 16) and Baton Rouge being situated on the Mississippi River and the Gulf of Mexico (Figure 17). Figure 16: CIA World Factbook Map of Panama Figure 17: CIA World Factbook Map of the U.S.A. (star added for Baton Rouge) 4-RESULTS AND RESULTS IMPACT The following business functions were the focus for this comparison: planning, design, scheduling, material management, and technology. These business functions are critical to the comparison of Baton Rouge Coca-Cola and Nestle Panama. Baton Rouge Coca-Cola is a large facility that is very technologically advanced both in warehouse design, equipment, and supporting technology applications. They employ both MEI, EasiTrax, and B.A.S.I.S. In addition to planning and scheduling through these technology applications, the production center uses state-of-the art flexible design and equipment. The CocaCola Bottling Company United in Baton Rouge, LA plant has four packaging lines and is considered to be a flexible design. The production center is 781,000 square feet and the four packaging lines produce 4.5 million 8-oz servings/day. The facility handles 400 SKUs of which 120 are produced and packaged at the plant (Mohan, 2011). There are 98 docks that surround the production area for trucks to deliver raw materials directly to the lines they are designated for. Finished cases of product are put onto pallets in the middle of the warehouse (Mohan, 2011). The can line at top speed can produce 1,800 cans per minute, the sparkling bottles line can produce up to 800 bottles per minute (Beverage World, 2011). The plant also uses the Easy Pallet Distribution System designed by Coca-Cola United. Baton Rouge Coca-Cola can be considered a value-added warehouse and production facility that participates in all of the common operations of a warehouse: receiving, prepackaging, putaway, storage, order picking, packaging and/or pricing, sortation and/or accumulation, and unitizing and shipping (Frazelle, 2002). Baton Rouge Coca Cola uses warehouse slotting which is a system that determines the most “appropriate storage location” for items in the warehouse. Each items location is determined by the “frequency of physical touches” or the number of times it is picked, moved, etc. Slotting is a method that can be used to increase efficiency. It is especially appropriate for Baton Rouge Coca Cola since the majority of the products are similar in size, the amount of access bays, and the consistency of storing specifications (Piasecki, 2012). Panama Nestle uses single and double deep rack storage with drive-in capabilities. In single deep, pallets are stored one deep and “each pallet is independently accessible” which means that any item can be stored at any location. In double deep rack, pallets are stored two deep. Although each lane is accessible, the “rear position is blocked by a pallet stored in the front position. To avoid double-handling, only 1 sku occupies each lane.” Drive in access allows for putaway and retrieval to take place on the same aisle (Shakeman, n.d.). This system is appropriate for Panama Nestle because of the variety of product type handled. Nestle Panama and Baton Rouge Coca-Cola are similar in some ways. First, both companies are production and distribution centers. Coca-Cola Baton Rouge distributes regionally but Nestle Panama distributes internationally. Nestle Panama produces and distributes milk produces (nutritional and ice cream) and prepared dishes and cooking aids. Beverages, confectionery, and pet care, along with additional milk products and prepared dishes and cooking aids, are imported to the facility for redistribution. The only Nestle product not found in Nestle Panama by production or import is pharmaceutical products (Nestle, 2012). Baton Rouge Coca-Cola produces and distributes beverages. Like Nestle, some products are produced on site and others are imported in to the site. In the case of Baton Rouge Coca-Cola, finished products are shipped to the following end points: vending machines, stores, restaurants, and other distributors in the geographic area—Louisiana and Mississippi. Panama Nestle produces and distributes finished products to stores and other distributors nationally and internationally. The variety of product type makes it necessary for them to outsource their distribution to third party trucking while Baton Rouge Coca-Cola owns over 340 vehicles and utilizes 98 bays—Panama Nestle owns 15 trucks and has 10 bays over 2 facilities. “Panama has 140 food processing companies. These include dairy processors, meat and poultry products processors, fishery products processors, fruits processors, beverages and spirits, bakery, snacks, among others” (USDA, 2012). “Panama is a multicultural and multiethnic society, and this has created a demand for frozen and refrigerated deli products, ethnic and typical foods. Many supermarkets offer a wide range of ethnic food products, including Chinese, Kosher, Spanish, Latin American and Italian, among others. Growth in the service industries, work schedules, larger female workforce and long home travel distances have also increased the number of people dining out at lunchtime; moreover, this hectic lifestyle has fueled a demand for supermarket prepared or ready to cook food in individual and family sized portions” (USDA, 2012). GDP Unemployment Rate Living in Poverty Major Industries U.S.A. $15.66 trillion 8.2%. Over 15% Petroleum, steel, motor vehicles, aerospace, telecommunications, chemicals, electronics, food processing, consumer goods, lumber, and mining Panama $56.83 billion 4.4% About 30% Services include operating the Panama Canal, logistics, banking, the Colon Free Zone, insurance, container ports, flagship registry, and tourism Main Exports Agricultural products, industrial supplies, capital goods, consumer goods Gold, bananas, shrimp, sugar, iron and steel waste, pineapples, and watermelons Export Partners Canada (19%), Mexico (13.3%), China (7%), and Japan (4.5%) Main Imports Agricultural products, industrial supplies, capital goods, consumer goods China (18.4%), Canada (14.2%), Mexico (11.7%), Japan (5.8%), and Germany (4.4%) US (13.1%), South Korea (12.5%), Honduras (10.2%), Japan (9.3%), India (7%), Canada (4.4%), and Mexico (4.2%) Fuel products, medicines, vehicles, iron and steel rods, and cellular phones Japan (23.5%), China (23%), Singapore (18.1%), US (13%), and South Korea (6%) Import Partners Table 6 shows some of the similarities and differences between the United States and Panama. Just as there are similarities and differences between the countries, there are some similarities and differences between Baton Rouge Coca-Cola. These similarities and differences in the two facilities and their logistics show that success comes more than one form and there can be overlap even the two facilities are over 3000 miles apart. 5-SUMMARY Nestle Panama SA is a private company in Panama City, Panama. It was Nestle first location in Central America. It serves Panama City, the capital and largest city in the Republic of Panama. Baton Rouge Coca-Cola Bottling Company is a division of Coca-Cola Bottling Company United, Inc., which acts as a bottler and distribution center. This paper looked at the business functions of planning, design, scheduling, and material management for these two businesses by comparing their warehousing, distribution, technology, and other logistic functions. These business functions are critical to the comparison of Baton Rouge Coca-Cola and Nestle Panama. Information was gathered using the internet, databases, email interview, and face-to-face interview. The companies and countries share many things in common and many differences, but their success—and they are both successful—is dependent on their facilities, production, technology, planning, distribution, and logistics. Although Nestle Panama’s profit is greater, when recalculate for the international distribution, the companies have a much closer profit margin.(Figure 18). Both locations are strategically placed for water, rail, and road shipping but only Nestle Panama uses all three. Future studies on this topic could include issues that the companies face and compare whether they differ by location, how the variety of product calls for different warehousing functions and layouts, and the types of distribution used—rails, trucks, ship—for the two locations. 20,000,000 18,000,000 16,000,000 14,000,000 12,000,000 Baton Rouge Coca-Cola 10,000,000 Panama Nestle 8,000,000 6,000,000 4,000,000 2,000,000 0 Unadjusted Annual Profit Adjust Annual Profit Figure 18: Annual Profit Comparison after Removing International Sales from Nestle. References Amorin, C. (January 24, 2012). En Montevideo Rel_UITA. With Marcelino Macías Reyes. Crucial stage in Nestlé Panama negotiations. http://www6.rel-uita.org/companias/nestle/con_marcelino_reyes-eng.htm Berman, O. & Wange, Q. (2006). Inbound logistic planning: Minimizing transportation and inventory cost. Transportation Science, 40(3), 287-299. Berrocal, R. (March 25, 2007). Comercio exterior: Exportaciones de Nestlé Panamá alcanzan 7.5 millones. La Prensa. Panama. Beverage World. (January 2011). Flexibility is the future. Beverage World. http://www.nxtbook.com/nxtbooks/idealmedia/bw0111/index.php?startid=46#/46 CCBCU (2012). Coca-Cola Bottling Company United. http://cocacolaunited.com/locations/hattiesburg/ CIA. (2013). The World Factbook. Washington, DC: Central Intelligence Agency. ht t ps : / / www .ci a.gov / l i brar y/ publ i c at i ons/ t he -worl d -f act book / i ndex .ht ml Factiva. (31 January 2002). Cooleche buys plant from Nestle. (Panama). Dairy Markets. Frazelle, E. (2002). World-Class Warehousing and Material Handling. New York: McGraw Hill. Haddon, D. (2008). What operators need to know about telemetry and how it can deliver higher sales with lower costs. Vending times, 48(10), 1-3. LED (2013). Lightning in a bottle. Louisiana Economic Development. http://www.louisianaeconomicdevelopment.com/case-studies/baton-rouge-coca-cola-bottlingcompany.aspx MEI (2012). Coca-Cola Bottling Company United Successfully Deploys MEI EASITRAX® Vending Management Software With Telemetry Across 7,000 Machines. http://www.meigroup.com/usa/vending/news_events/coca-cola-bottling-compan-1/index.xml Mohan, A.M. (May 2011). New Coke plant designed with future in mind. Packaging World Magazine, p. 50. Nestle. (2012). Annual Report. http://www.nestle.com/assetlibrary/Documents/Library/Documents/Annual_Reports/2012-Annual-Report-EN.pdf Nestle. (2012). Financial Statement Report. http://www.nestle.com/assetlibrary/Documents/Library/Documents/Financial_Statements/2012-Financial-Statements-EN.pdf Piascki, D. (2012). Warehouse slotting. Inventory Operations Consulting, LLC. http://www.inventoryops.com/articles/warehouse_slotting.htm Services planning. (2006). In Dictionary of Business. Retrieved from http://www.credoreference.com.logon.lynx.lib.usm.edu/entry/acbbusiness/planning SAP (2013). SAP Group Help. http://help.sap.com/saphelp_46c/helpdata/en/dd/5607e7545a11d1a7020000e829fd11/content.ht m Schary, P. (1970). The dimensions of physical distribution. Transportation Journal, 10(1), 5-16. Segrave, K. (2002). Vending Machines: An American Social History. Jefferson, NC: McFarland & Company. Shackman. (n.d.). Pallet Storage Alternatives http://www2.isye.gatech.edu/~shackman/isye6202/PalletStorageAnalysis.pdf Sooksaksun, N and Kachitvichyanukul, V. (2010). Comparison of One-block and Two-block Layout Configuration in Warehouses design. http://www.preet.sesolution.com/iclt2010/Full%20Papers/Inventory%20and%20Warehouse%20 Management/0240-Natanaree.pdf USDA (2012). Food Processing Ingredients 2012 Report for Panama. http://gain.fas.usda.gov/Recent%20GAIN%20Publications/Food%20Processing%20Ingredients_ Panama%20City_Panama_12-11-2012.pdf warehouse. (2006). In Dictionary of Business. Retrieved from http://www.credoreference.com.logon.lynx.lib.usm.edu/entry/acbbusiness/warehouse Home Articles Glossary Links Books Equipment About Contact