Ignition Service Service

advertisement

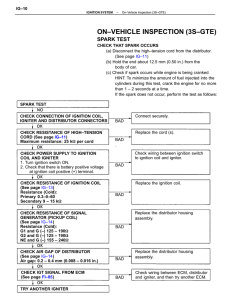

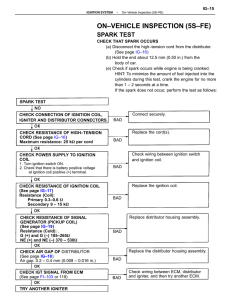

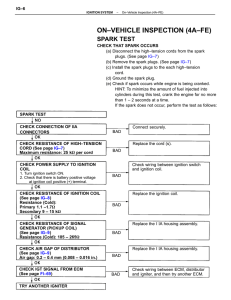

IGNITION SYSTEM SERVICE TESTING AND REPAIR Evaluate the symptoms – Narrow down possibilities Pinpoint to a specific engine system – Compression – Fuel – Ignition Perform basic tests first – Visually inspect PRELIMINARY TESTS Look for obvious problems – – – – Loose Connections Cracked components Deteriorated/Burned components Inspect other systems Do you have a “dead cylinder”? – Perform manual cylinder balance test – RPM will change if cylinder is good SPARK INTENSITY TEST Usually used with a No Start Can be used to test component integrity Install spark tester and observe spark SPARK TEST RESULTS Spark should be a good strong spark – Wide – Bright blue – Snapping electric arc Is it weak at one spark plug or all? SPARK PLUG SERVICE Bad spark plugs can cause many problems – – – – Misfiring Lack of Power Poor Fuel Economy Hard Starting SPARK PLUG PROBLEMS Can become coated with ash, oil, and fuel additives Electrodes can burn and widen gap Electrodes can deteriorate with age or cylinder efficiency SPARK PLUG REMOVAL Number wires to cylinders Grasp boot, not wire Blow debris from hole Do not mix up spark plugs Inspect “Read” spark plugs SPARK PLUG SERVICE Clean spark plugs Gap spark plug to specifications Install Spark plugs SECONDARY SERVICE Remove Spark Plug wire Test wire for high resistance – Not over 10,000 ohms per foot Secondary insulation test – Grounded Probe – Spray water – Look at wires at night Replacement of wires must be correctly done DISTRIBUTOR CAP AND ROTOR Must visually inspect cap and rotor Can cause backfiring and misfire Carbon arcing can cause problems Cracks can cause problems ELECTRONIC DISTRIBUTOR SERVICE PICK UP COIL PROBLEMS – Can cause misfire, stalling, no-start, hesitation PICK UP COIL TESTING – – – – – Use ohmmeter Must measure to specifications Wiggle and Tap test pick up coil AC analog voltmeter test Lab Scope PICK UP COIL SERVICE Follow procedures to replace Some ignition systems pick up coil air gaps are adjustable IGNITION TIMING Initial (or base) timing Must follow procedures exactly! Check Spec’s Must set during tune up or if distributor has been removed Must make sure advances not working during adjustment! IGNITION TIMING ADJUSTMENT Disable ignition advances Hook up timing light Adjusting timing causes pickup coil and electronic control unit to fire the ignition coil sooner or later. Turning distributor housing against shaft rotation advances timing Turning distributor housing with shaft rotation retards timing IGNITION TIMING PROBLEMS TIMING MUST BE EXACT! VERY IMPORTANT! Too far advanced will cause “Pinging”, engine damage Too far retarded will cause low power, poor mileage, engine damage MEASURING IGNITION TIMING Strobe type timing light Magnetic timing probe Usually connect light to number one cylinder MUST DISABLE ADVANCE – – – – Vacuum advance Mechanical (centrifugal) advance timing Computerized timing advances Align timing marks to specifications CHANGING IGNITION TIMING Loosen distributor hold down bolt Use distributor wrench if available Engine rpm low No advance operation Align marks Tighten hold down bolt Double check timing