Inventory Control

advertisement

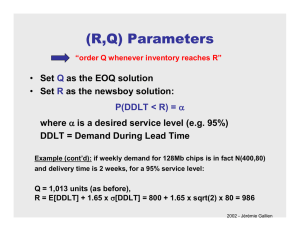

Inventory Control: Part 3 – Independent Demand Inventories 1 Types of Inventories By Function - Lot-Size (Cycle or Replenishment) - Instantaneous (Purchase) - Non-Instantaneous (Produce) - Safety (Fluctuation or Buffer) - Anticipation (Seasonal) - Transportation (Pipeline) - Hedge (Beyond Scope of Class) 2 Safety Stocks Used for Emergencies Finished Goods: Unexpected Demand (Level Related to Customer Service) Raw Materials: Orders Not Received Work-in-Process (WIP): Worker Unavailable or Machine Breakdown - Decoupling Inventory Also Known as Buffer or Fluctuation Inventory 3 Quantity Finished Goods Safety Stocks: Stored with Lot-Size Stocks Maximum probable demand during lead time Expected demand during lead time (DDLT) OP Safety stock (SS) LT Time 4 Safety Stocks From Graph: OP = DDLT + SS where OP = Order Point DD = Forecast Demand LT = Lead Time SS = Safety Stock So: SS = OP – DDLT by Algebra OP Set from Customer Service Level (SL) 5 Safety Stocks Example 1 The Frigid Corporation manufactures refrigerators. The probability distribution of demand during lead time is: Demand Probability 10 .20 20 .20 30 .30 40 .20 50 .10 Suppose the customer service level is 70%. Determine the reorder point (consider only 10, 20, 30, 40, 50). 6 Safety Stocks Example 1 Let SL = .7 (70%) Demand Probability 10 .2 20 .2 30 .3 40 .2 50 .1 CDF .2 .4 .7 .9 1.0 OP = 30 (Meets Demand 70% of Time) 7 Safety Stocks Example1 SS = OP – DDLT DDLT= Expected Value of Demand DDLT= .2(10)+.2(20)+.3(30)+.2(40)+.1(50) DDLT= 28 SS = 30 – 28 = 2 If SL is 80%, What is OP and SS? If SL is 90%, What is OP and SS? 8 Safety Stocks: Normal Demand Risk of a Stock Out Probability of No Stock Out (Service Level) Quantity Safety Stock Mean OP 9 Safety Stocks Example 2 The Inandout Production Company requires steel rods at the mean rate of 35 rods per day. This rate follows a normal distribution with a standard deviation of 3 per day. The service level has been set at 90%. If lead time for reordering is one day, what is the optimum safety stock? 10 Safety Stocks: Example 2 Given: SL = .9 (90%), DDLT = 35, DDLT = 3 Z from Normal Table (text page 314) = 1.28 ( Z is also known as safety factor) Z = (OP – DDLT) / DDLT or OP = DDLT + Z DDLT = 35 + (1.28)(3) 39 SS = OP – DDLT = 39 – 35 = 4 11 Types of Inventories Type 1. Lot-Size a. Instantaneous b. Non-Instantaneous 2. Safety 3. Anticipation 4. Transportation 5. Hedge Best Size Q*/2 IMAX*/2 OP - DDLT Guesstimate (Usage) (Time) Guesstimate 12 Implementation of Inventory Control Q* and N* Cannot Both be Fixed (E.g. Q* = 10, A= 100, N* = A/Q* = 100/10 = 10) N Varies and Q* Fixed: Order Point System (AKA Fixed Order Quantity). Requires Two-Bin System, Kanban, or Perpetual Inventory. Order say Q* when Actual Inventory ≤ OP. Q Varies and N* Fixed: Periodic Review System (AKA Fixed Order Cycle System) 13 Periodic Review System Let T = D (R + LT) + SS Where T = Target Inventory Level D = Demand per Unit of Time LT = Lead Time R = Review Period (Fixed at 1/N*) SS = Safety Stock Order Q = T – I Where I = Inventory on Hand. See Example on Page 321 of Text. 14 15