Construction Cost Estimating for the Civil Engineer

advertisement

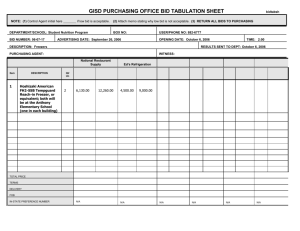

Estimating for Heavy Construction and Unit Price Bids Hal Johnston Faculty of Civil Engineering Department of Economics and Management CZECH TECHNICAL UNIVERSITY IN PRAGUE Hal Johnston ◦ Professor (20 years) Construction Management Department California State Polytechnic University (Cal Poly) San Luis Obispo, California, USA Short Bio ◦ Professional Construction Experience (17 years) Bechtel – EPC/CM Morrison Knudson – Design Build/General/CM The Austin Company – Design Build R.E. Bayley Construction – General Contractor Mason/Johnston General Contractors – General ◦ Education B.S. in Building Theory and Practice – Washington State University Masters in Building Construction – University of Florida ◦ Other 2 books, many scholarly papers, given many professional seminars Latest seminar for the ASCE – Atlanta (2 days)– Fundamentals of Construction Estimating And ASCE – Panama (Panama Canal Authority – 10 days) Const. Estimating Learning Outcomes for (Estimating for Heavy Construction and Unit Price Bids) The attendee will be able to: ◦ Discuss how heavy construction estimating is different from commercial estimating ◦ Describe a unit price bid ◦ Decide when and where the different types of estimates are used ◦ Illustrate the different parts of the unit price estimate and describe them ◦ Explain how the different types of cost play a role in heavy construction estimating Session Outline Construction organizations (review) Construction contracts (review) Contract documents Unit prices Quality control / acceptance Price adjustments ◦ Standard specifications ◦ Standard specifications for DOTs ◦ Unit bid items ◦ WSDOT Unit bid items ◦ Short in-class exercise History of Project Delivery in US Legal Separation of Design and Construction ◦ The Miller Act (1935) ◦ Public contracting laws mandating separation of design from construction & contractor selection solely on cost ◦ Professional licensing requirements Project Delivery Defined A comprehensive process including planning, design, construction and other services, necessary for organizing, executing and completing a construction project. Three fundamental owner decisions ◦ Type of project delivery system ◦ Type of procurement method ◦ Type of contract format Project Delivery Process Framework Project Feasibility Facility Owner’s Profile Critical Owner Decisions Project Performance Criteria Project Delivery System Selection Contract Format Selection Procurement Method Selection Programming & Scope Definition Team Selection Confirm Project Scope and Program Project Financing NOTE: Chart shows logic flow, not timing or sequence of steps, which vary depending on methods used. Design & Construction Operation & Maintenance Project Delivery Always 3 or 4 major parties involved in the project delivery process ◦ ◦ ◦ ◦ Owner (public or private) Designer (Engineer or Architect) Contractor Construction Management Firm (can also be one of these parties) The Method Selected will: Determines the contractual relationships among the parties. Establishes when the parties become engaged. Influences impact of changes and modifications on project cost. Project Delivery Types Design-bid-build (Lump Sum or Unit Price) Multi-prime (often under CM) Construction management-at-risk Construction Management agency Design-build (DB, EPC, etc.) Procurement Defined Procurement is the methodology used to buy design and construction services. Construction Contracts Method of pricing ◦ Fixed-price Lump sum contract Unit price contract ◦ Cost-plus Cost plus percentage of cost Cost plus fixed fee Cost plus fixed fee with a targeted maximum cost Cost plus incentive fee ◦ Guaranteed Max Price GMP plus percentage of cost GMP plus fixed fee GMP plus a fixed fee plus share of savings - incentive Method of award ◦ Competitively Bid contracts With designer doing Project Supervision With CM – agency CM at Risk Design Build ◦ Negotiated contracts GMP Design Build Negotiated Lump sum CM at Risk Procurement Options Sole Source/Direct Selection Negotiated procurement Competitive ◦ QBS – Qualification Based Selection ◦ BVS - Best Value Selection ◦ Low Bid Market Penetration of Major Project Delivery Systems Design-Bid-Build Owner Contractual Relationship Sub Consultants Characteristics Designer Three linear phases: Design, bid and build Three prime players: Owner, designer, constructor Two separate contracts: Owner to designer Owner to constructor Responsibilities Owner Program, finance, management Designer Prepares plans & specs, normal services Constructor Prime and sub construction Contractor Subcontractors Design-Bid-Build Advantages ◦ ◦ ◦ ◦ Established way of doing things Suitable for competitive bidding A/E directly works for owner Extensive litigation has resulted in well established legal precedents ◦ No legal barriers in procurement and licensing ◦ Insurance and bonding are well defined Design-Bid-Build Disadvantages ◦ Two contracts for owner to manage Disagreements go through owner Owner bears design adequacy risk ◦ All parties have different agendas/objectives ◦ Initial low bid might not result in final best value ◦ Bids over budget presents most difficulties in reducing costs / creates significant delay ◦ No constructor involvement in design ◦ Slowest project delivery ◦ Most litigious delivery process Design-Bid-Build Unique attributes and challenges Utilization helps to avoid potential conflicts of interest Provides a check and balance between design and construction functions Owners less familiar with the design and construction process may benefit from DesignBid-Build because it is so well understood throughout the building industry. Primary Reasons for Choosing Design-Bid-Build Low first cost is the priority Project is simple Procurement laws restrict use of anything else Owner wants to control design No need for value engineering or innovation Influence vs. Cost Project delivery selection influences when contractor gets on board. Contractor on-board early allows best opportunity to achieve objectives RAPIDLY DECREASING INFLUENCE MAJOR INFLUENCE Large LOW INFLUENCE High COST INFLUENCE Low Planning & Design Small Construction & Operations Equipment productivity Labor productivity How material may react differently in different circumstances Locations Lower number of subcontractors on job, higher risk to the General Fuel costs Soil Conditions (acting different than expected) Risk in Heavy Construction How does Risk change the Estimate? Higher profits ◦ Commercial Profits – 1% to 5% ◦ Heavy Profits – 8% to 15% Less return on investments ◦ Large cost of equipment Contingencies for potential escalation costs Standard Specifications for DOT (Department of Transporation) Typically do not use MasterFormat 2004 Generally use 9 Divisions ◦ General Requirements ◦ Earthwork ◦ Production from Quarry and Pit Sites and Stockpiling ◦ Bases ◦ Surface Treatments and Pavements ◦ Structures ◦ Drainage Structures, Storm Sewers, Water Mains, and Conduits ◦ Miscellaneous Construction ◦ Materials Standard Specifications for most Commercial / Building Projects Typically used today is the MasterFormat 1995 edition, but a new edition has been published (2004) MASTERFORMAT 1995 EDITION Before November 2004, MasterFormat was composed of 16 primary divisions: Division Division Division Division Division Division Division Division Division Division Division Division Division Division Division Division 1 — General Requirements 2 — Site Construction 3 — Concrete 4 — Masonry 5 — Metals 6 — Wood and Plastics 7 — Thermal and Moisture Protection 8 — Doors and Windows 9 — Finishes 10 — Specialties 11 — Equipment 12 — Furnishings 13 — Special Construction 14 — Conveying Systems 15 — Mechanical 16 — Electrical Standard Specifications for most Commercial / Building Projects MASTERFORMAT 2004 EDITION After November 2004, MasterFormat was composed of 49 primary divisions: The current MasterFormat Divisions are: Division 1 - 49 Divisions MasterFormat 1995 Introductory Information Bidding Requirements Contracting Requirements 1 General Requirements MasterFormat 2004 Procurement and Contracting Requirements Group 00 Procurement and Contracting Requirements Specifications Group General Requirements Subgroup 01 General Requirements Divisions MasterFormat 1995 MasterFormat 2004 Facility Construction Subgroup 2 Site Construction 02 Existing Conditions 3 Concrete 03 Concrete 4 Masonry 04 Masonry 5 Metals 05 Metals 6 Wood and Plastics 06 Wood, Plastics, and Composites 7 Thermal and Moisture Protection 07 Thermal and Moisture Protection 8 Doors and Windows 08 Openings Divisions MasterFormat 1995 MasterFormat 2004 Facility Construction Subgroup (continued) 9 Finishes 09 Finishes 10 Specialties 10 Specialties 11 Equipment 11 Equipment 12 Furnishings 12 Furnishings 13 Special Construction 13 Special Construction 14 Conveying Systems 14 Conveying Equipment 15 – 19 Reserved Divisions MasterFormat 1995 MasterFormat 2004 Facility Services Subgroup 20 Reserved 13 Special Construction 21 Fire Suppression 15 Mechanical 22 Plumbing 15 Mechanical 23 Heating, Ventilating, and Air Conditioning 24 Reserved Divisions MasterFormat 1995 MasterFormat 2004 Facility Services Subgroup (continued) 13 Special Construction 25 Integrated Automation 16 Electrical 26 Electrical 13 Special Construction 27 Communications 13 Special Construction 28 Electronic Safety and Security 29 Reserved Divisions MasterFormat 1995 MasterFormat 2004 Site and Infrastructure Subgroup 30 Reserved 2 Site Construction 31 Earthwork 2 Site Construction 32 Exterior Improvements 2 Site Construction 33 Utilities 2 Site Construction 34 Transportation 2 Site Construction 35 Waterway and Marine 36-39 Reserved MasterFormat 2004 31 00 00 EARTHWORK 31 10 00 SITE CLEARING 31 20 00 EARTH MOVING 31 30 00 EARTHWORK METHODS 31 40 00 SHORING AND UNDERPINNING 31 50 00 EXCAVATION SUPPORT AND PROTECTION 31 60 00 SPECIAL FOUNDATIONS AND LOAD-BEARING ELEMENTS 31 70 00 TUNNELING AND MINING 31 80 00 Reserved 31 90 00 Reserved Division 31 - EARTHWORK Divisions MasterFormat 1995 MasterFormat 2004 Process Equipment Subgroup 11 Equipment 40 Process Integration 11 Equipment 41 Material Processing and Handling Equipment 11 Equipment 42 Process Heating, Cooling and Drying Equipment 11 Equipment 43 Process Gas and Liquid Handling, Purification and Storage Equipment Divisions MasterFormat 1995 MasterFormat 2004 Process Equipment Subgroup (continued) 11 Equipment 44 Pollution Control Equipment 11 Equipment 45 Industry-Specific Manufacturing Equipment 46-47 Reserved 16 Electrical / Special Construction 13 48 Electrical Power Generation 49 Reserved Unit Prices Standard Units ◦ Defined in Standard Specifications Unit Bid Items / Bid 03-0E2004 BID245 03-SIE-49-2 C O N T R A C T P R O P O S A L O F L O W B I D D E R PAGE 7 04/23/08 04/27/08 ----------------------------------------------------------------------------------------------------------------------------------ITEM ITEM UNIT OF ESTIMATED NO. CODE ITEM DESCRIPTION MEASURE QUANTITY BID AMOUNT ----------------------------------------------------------------------------------------------------------------------------------1 074016 CONSTRUCTION SITE MANAGEMENT LS 10,000.00 2 (S) 074017 WATER POLLUTION CONTROL PROGRAM LS 1,000.00 3 074032 TEMPORARY CONC WASHOUT FACILITY EA 1,500.00 4 (S) 120090 CONSTRUCTION AREA SIGNS LS 3,000.00 5 (S) 120100 TRAFFIC CONTROL SYSTEM LS 150,000.00 6 (S) 128650 PORTABLE CHANGEABLE MESSAGE SIGN LS 20,000.00 71 50662 REMOVE METAL BEAM GUARD RAILING LF 39,120.00 8 150771 REMOVE ASPHALT CONCRETE DIKE 10.00 8,400.00 9 011868 REMOVE PRECAST CONC POST SUPPORT EA 5,000.00 10 (S) 153103 COLD PLANE ASPHALT CONC PAVEMENT SQYD 16,500.00 11 160101 CLEARING AND GRUBBING LS 10,000.00 12 190101 ROADWAY EXCAVATION CY 56,250.00 13 193006 STRUCTURE BACKFILL (SLURRY CEMENT) CY 1,250.00 14 260201 CLASS 2 AGGREGATE BASE CY 5,750.00 15 390132 HOT MIX ASPHALT (TYPE A) TON 55,000.00 16 394077 PLACE HOT MIX ASPHALT DIKE (TYPE F) LF 7,050.00 17 394090 PLACE HOT MIX ASPHALT (MISC AREA) SQYD 1 10,000.00 1 1,000.00 1 1,500.00 1 3,000.00 1 150,000.00 1 20,000.00 6,520 LF 2 550 1 6.00 840 2,500.00 30.00 10,000.00 450 125.00 45 250.00 23 250.00 550 100.00 1,410 5.00 2,380 35.00 03-0E2004 BID245 03-SIE-49-2 C O N T R A C T P R O P O S A L O F L O W B I D D E R PAGE 7 04/23/08 04/27/08 ----------------------------------------------------------------------------------------------------------ITEM NO. ITEM UNIT OF CODE DESCRIPTION MEASURE ----------------------------------------------------------------------------------------------------------ESTIMATED UNIT BID QUANTITY PRICE AMOUNT ----------------------------------------------------------------------------------------------------------2 (S) 074017 WATER POLLUTION CONTROL PROGRAM LS 1 $ 1,000.00 $ 1,000.00 _______________________________________________________ _____ 4 (S) 120090 CONSTRUCTION AREA SIGNS LS 1 $ 3,000.00 $ 3,000.00 _______________________________________________________ ______ 5 (S) 120100 TRAFFIC CONTROL SYSTEM LS 1 $ 150,000.00 $ 150,000.00 ___________________________________________________ __________ 7 1 50662 REMOVE METAL BEAM GUARD RAILING UNIT OF ESTIMATED UNIT BID MEASURE QUANTITY PRICE AMOUNT -----------------------------------------------------------------------------LS 1 $ 98,000.00 $ 98,000.00 TOTAL $ 980,685.00 Heavy Estimates take on two styles: Detail Estimates for Lump Sum Contracts and Subcontracts Unit Price Estimates for DOT and other Unit Price Contracts Remember that Heavy/Civil Contractors may act as Subcontractors on many projects A Heavy Civil Detail Estimate looks much like a Detail Estimate for a Commercial Project Major Differences ◦ ◦ ◦ ◦ ◦ ◦ Larger labor component Larger equipment component Very few Subcontractors More self performed work Not as many activities or work items Work items are often quantified by the agency for Unit Price Estimates Structure of a Lump Sum Estimate and Bid Summary Sheet Headings ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦ Description Labor Material (often called Permanent Materials) Consumables / Expendables (often called Expendable Materials) Subcontractors Equipment Operating Costs or Expense Repair Costs (Labor item) Rental Costs or Company Equipment Costs Total Typical Lump Sum Bid Description Direct Costs Jobsite Indirect Costs End of Bid Items Total Bid Labor Materials Expendables Subs Equip Operating Costs Repairs Rent Total Typical Unit Price Bid 03-0E2004 BID245 03-SIE-49-2 C O N T R A C T P R O P O S A L O F L O W B I D D E R PAGE 7 04/23/08 04/27/08 ----------------------------------------------------------------------------------------------------------------------------------ITEM ITEM UNIT OF ESTIMATED NO. CODE ITEM DESCRIPTION MEASURE QUANTITY BID AMOUNT ----------------------------------------------------------------------------------------------------------------------------------1 074016 CONSTRUCTION SITE MANAGEMENT 2 (S) 074017 WATER POLLUTION CONTROL PROGRAM LS LS 1 1 3 4 (S) 5 (S) 6 (S) 71 8 9 10 (S) 11 12 13 14 15 16 17 18 (F) 19 20 21 (SF) 22 23 24 (S) 25 26 (S) 27 (S) 28 (S) 29 (S) 30 (S) 31 EA LS LS LS LF LF EA SQYD LS CY CY CY TON LF SQYD CY EA EA LB EA EA LF LF EA EA EA EA LF LS 1 1 1 1 6,520 840 2 550 1 450 45 23 550 1,410 2,380 4.9 24 32 916 69 4 6,690 10 10 5 5 3 350 1 074032 120090 120100 128650 50662 150771 011868 153103 160101 190101 193006 260201 390132 394077 394090 510502 011869 011870 750001 820108 820151 832002 832008 839541 839552 839581 839585 840656 999990 TEMPORARY CONC WASHOUT FACILITY CONSTRUCTION AREA SIGNS TRAFFIC CONTROL SYSTEM PORTABLE CHANGEABLE MESSAGE SIGN REMOVE METAL BEAM GUARD RAILING REMOVE ASPHALT CONCRETE DIKE REMOVE PRECAST CONC POST SUPPORT COLD PLANE ASPHALT CONC PAVEMENT CLEARING AND GRUBBING ROADWAY EXCAVATION STRUCTURE BACKFILL (SLURRY CEMENT) CLASS 2 AGGREGATE BASE HOT MIX ASPHALT (TYPE A) PLACE HOT MIX ASPHALT DIKE (TYPE F) PLACE HOT MIX ASPHALT (MISC AREA) MINOR CONCRETE (MINOR STRUCTURE) PRECAST CONC POST SUPPORT (8 FOOT) PRECAST CONC POST SUPPORT (6 FOOT) MISCELLANEOUS IRON AND STEEL DELINEATOR (CLASS 2) OBJECT MARKER (TYPE L-1) METAL BEAM GUARD RAILING (STEEL) METAL BEAM GUARD RAILING (ELEMENT) TRANSITION RAILING (TYPE WB) TERMINAL SECTION (TYPE C) END ANCHOR ASSEMBLY (TYPE SFT) ALTERNATIVE FLARED TERMINAL SYSTEM PAINT TRAFFIC STRIPE (2-COAT) MOBILIZATION 10,000.00 1,000.00 10,000.00 1,000.00 1,500.00 3,000.00 150,000.00 20,000.00 6.00 10.00 2,500.00 30.00 10,000.00 125.00 250.00 250.00 100.00 5.00 35.00 10,000.00 1,500.00 1,500.00 5.00 40.00 50.00 27.50 20.00 5,000.00 150.00 1,000.00 3,000.00 6.00 98,000.00 TOTAL 1,500.00 3,000.00 150,000.00 20,000.00 39,120.00 8,400.00 5,000.00 16,500.00 10,000.00 56,250.00 1,250.00 5,750.00 55,000.00 7,050.00 83,300.00 49,000.00 36,000.00 48,000.00 4,580.00 2,760.00 200.00 183,975.00 8,200.00 50,000.00 750.00 5,000.00 9,000.00 2,100.00 98,000.00 980,685.00 Typical Lump Sum Bid Typical Unit Price Bid In-directs are totaled Each big item is calculated as a percentage of the total direct costs Using this percentage, we multiply the total direct costs by each percentage That number is than added to the base direct cost to come up with a total. It is divided by the quantity to generate a unit price Major Difference: Distribution of Indirect Cost into Unit Prices First the In-directs and end of bid items are totaled. A total of direct costs is also established with a total A column of each bid item direct cost is made into a % of the total direct costs. This % is then multiplied by the total indirect cost This % of the indirect costs is than added to the direct costs How do we do this Distribution of Indirects? Item No. 390132 Unit TON Description HOT MIX ASPHALT (TYPE A) Quantity 550 Unit Price $ 100.00 Total $ 55,000.00 The Result is: Example of Bid Item Specification are reviewed for the Item No., what is included in each work items and how the item will be paid for. The Pay Quantity vs. Bid Quantity Bid quantity ◦ Defined as a quantity of individual units of work that represents the owner’s engineer’s estimate of the number of units of that type work included in the contract. Pay quantity ◦ Defined as the quantity that is calculated when the work is completed and will be paid for by the owner Is also defined as the quantity of projected work at time of bid Is the calculated quantity by the contractor when checking engineer’s quantity May or may not equal the engineer’s quantity Work quantity Relationship of the work quantity to the Bid Item It is generally thought by the engineer to be equal. This is not always true as many contractors have found out – sometimes by surprise When bidding a lump sum, the quantities are not given and certified by the owner. The contractor is responsible for quantity determination. The owner will pay the lump sum bid amount plus any changes. When bidding a unit price contract, the engineer is giving the contractor the quantities and will pay the contractor the in-place quantities. Provisions are made when quantities get substantially out of balance. Indirect Cost : Lump Sum vs. Unit Price Major Differences are: ◦ Mobilization costs and items are substantially different. Plant and equipment of large heavy projects. ◦ Temporary access / roads etc. can be very different ◦ Temporary power on a commercial project is much different. ◦ Surveying requirements can be much different from commercial to heavy construction. Indirect Costs from Commercial compared to Heavy To protect out of pocket expenses because of inaccurate bid quantities To favor work performed early in the schedule to create positive cash flows on project Other strategies Is there any Strategy to Distribution of Indirect Project Costs? Unbalancing the Bid What words should we be watchful in bidding documents? ◦ “grossly unbalanced” ◦ “substantially unbalanced” First on a Balanced Bid Next on an Unbalanced Bid ◦ Most DOT specifications allow for change if quantities are grossly inaccurate. If there is no provision, the contractor could have the wrong equipment, too much equipment etc. ◦ Contractor plays the risk of being determined as non responsive and bid being rejected. ◦ Owner could be paying a premium on the work. What Happens if there are Inaccurate Bid Quantities? What Happens if there are Inaccurate Bid Quantities on a Balanced Bid? Most DOT specifications allow for change if quantities are grossly inaccurate. If there is no provision, the contractor could have the wrong equipment, too much equipment, etc. What Happens if there are Inaccurate Bid Quantities on a Unbalanced Bid? Contractor plays the risk of being determined as non responsive and bid being rejected. Owner could be paying a premium on the work. Rejection Can be the Consequences of Unbalanced Bid. Owner will use the term: Non-responsive 03-0E2004 BID245 03-SIE-49-2 S U M M A R Y O F R E M A I N I N G B I D D E R S PAGE 9 04/23/08 04/27/08 |-----------------------------|------------------------------ITEM| SIXTH | SEVENTH | BID AMOUNT | BID AMOUNT |-----------------------------|------------------------------1 | 8,000.00 8000.00 | 650.00 650.00 2 | 1,500.00 1500.00 735.00 735.00 3 | 2,000.00 2000.00 | 2,300.00 2300.00 4 | 3,200.00 3200.00 | 1,540.00 1540.00 5 | 146,000.00 146000.00 | 112,777.24 112777.24 6 | 12,500.00 12500.00 | 4,800.00 4800.00 7 | 10.00 65200.00 | 6.80 44336.00 8 | 11.00 9240.00 | 21.00 17640.00 9 | 2,000.00 4000.00 | 480.00 960.00 10 | 18.00 9900.00 | 15.70 8635.00 11 | 10,000.00 10000.00 | 15,124.00 15124.00 12 | 65.00 29250.00 | 556.80 250560.00 13 | 340.00 15300.00 | 5,346.66 240599.70 14 | 240.00 5520.00 | 401.99 9245.77 15 | 130.00 71500.00 | 127.73 70251.50 16 | 4.50 6345.00 | 2.35 3313.50 17 | 35.00 83300.00 | 30.03 71471.40 18 | 4,800.00 23520.00 | 1,885.70 9239.93 19 | 2,200.00 52800.00 | 3,450.00 82800.00 20 | 2,000.00 64000.00 | 3,400.00 108800.00 21 | 5.00 4580.00 | 8.20 7511.20 22 | 50.00 3450.00 | 42.00 2898.00 23 | 50.00 200.00 | 41.80 167.20 24 | 30.00 200700.00 | 29.24 195615.60 25 | 35.00 14350.00 | 43.50 17835.00 26 | 6,600.00 66000.00 | 3,600.00 36000.00 27 | 120.00 600.00 | 98.00 490.00 28 | 1,250.00 6250.00 | 624.00 3120.00 29 | 3,000.00 9000.00 | 2,800.00 8400.00 30 | 11.00 3850.00 | 6.72 2352.00 31 | 100,000.00 100000.00 | 157,316.00 157316.00 TOT 1,032,055.00 1,487,484.04 How can an Owner tell or why would they even question the Contractor’ s Unit Prices? Other Bid # 3 Item No. 8 8 Other Bid # 5 150771 REMOVE ASPHALT CONCRETE DIKE LF 840 Unit Price Total 11.00 9240.00 Unit Price Total 21.00 17640.00 Possible Example Remember earlier we spread our indirects and end of bid items over our direct cost items. We did that based on each cost items value and gave each item a piece of the indirect costs based on that value. More costly items got more of the indirect cost. Instead of doing a percentage of each direct cost item, one could allocate any amount of the indirect costs to that bid items. We could even go so far as moving direct costs onto another direct cost in increase its total, keeping in mind that we would want to keep the total the same as a balance bid. Example of Unbalancing: Fixed Costs, In-directs, etc. Flow chart of the Heavy Bid Process Quantities are checked against the Engineers End of bid item distributed to Bid items Unit Price Estimates and The Bid Process Selection\Decision & Review Phase Select Project Review the Plans Specs. & Contract Does work fit with-in the company business plan? Does the company have the bonding capacity to handle the work? Probability of making a profit? Is it the type of work the company and its individuals can succeed at? Does my company have the right plant and equipment? Preparation for Pricing Subcontractor Determinations Begin Takeoff for Self Work Request for Material Quotes Site Visit Estimator determines the scope of work that will be subcontracted. This is a much smaller group of subcontractors. Estimator begins takeoff of quantities of work this contractor will do with their own forces. They will review the specifications for what to include in both the pay quantities and work quantities. Estimator determines the scope of materials and sends out for quotes. Heavy contractors often control their own materials. i.e. rock, asphalt, concrete Estimator schedules a site visit (Mandatory vs. Voluntary). Preparation for Pricing Continued: Request for Sub bids Job Plan & Preliminary Scheduling Historical labor & Material Cost Records Reviewed General Conditions and Indirect Job Cost Determination Much more time it spent On the job plan and scheduling Because of the plant and Equipment requirements Analysis and Pricing Budgeting for Sub trades Labor Pricing Material Pricing Plant and Equipment Pricing Indirect Job Cost Pricing Subcontract Bid Tab. Cost Extensions & Finalizing the Estimate Estimate Summary End of Bid Items (Profit & Overhead) Distribution of End of Bid Items To the Bid Items Finalizing the Estimate Adjustment to Bid or Proposal Owner’s Final Review Bid or Proposal Submission Award of Project Review & Log for Historical Can be very similar to commercial process when bidding a lump sum. But is very different when bidding a unit price type of contract Materials can play a major role in the bid process Plant and equipment are a big portion of the work Heavy Bid Process The use of digitizers is used more that in commercial because of the speed of earthwork takeoff process. Also almost all heavy estimating is done with computers because of the need to distribute the indirect costs in unit price estimates. Heavy Bid Estimating Summary Heavy Civil can be either Lump Sum or Unit Price. The Heavy Civil world also does negotiated work. More risk is associated with Heavy Construction work vs. Commercial work. ◦ Equipment productivity ◦ Labor productivity End of Today’s Session Questions?